relay INFINITI QX4 2001 Factory Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1504 of 2395

DescriptionNBEL0124The following systems are controlled by the smart entrance control unit.

IWarning chime

IRear window defogger and door mirror defogger timer

IPower door lock

IMulti-remote control system

ITheft warning system

IInterior lamp timer

IElectric sunroof and power window timer

IHeadlamp battery saver

IBattery saver

For detailed description and wiring diagrams, refer to the relevant pages for the each system.

The smart entrance control unit receives data from the switches and sensors to control their corresponding

system relays and actuators.

INPUT/OUTPUTNBEL0124S01

System Input Output

Power door lockDoor lock and unlock switch LH and RH

Key switch (Insert)

Door switches

Door key cylinder switchesDoor lock actuator

Multi-remote controlKey switch (Insert)

Ignition switch (ACC)

Door switches

Front door unlock sensor LH

Door lock and unlock switch LH

Remote controller signalHorn relay

Headlamp relay (LH and RH)

Interior lamp

Multi-remote control relay

Door lock actuator

Warning chimeKey switch (Insert)

Ignition switch (ON)

Lighting switch (1st)

Seat belt switch

Front door switch LHWarning chime (located in smart entrance

control unit)

Rear window defogger and

door mirror defogger timerIgnition switch (ON)

Rear window defogger switchRear window defogger relay

Theft warningIgnition switch (ACC, ON)

Door switches

Hood switch

Glass hatch switch

Door key cylinder switches (lock/unlock)

Door unlock sensoresHorn relay

Headlamp relay (LH and RH)

Security indicator

Interior lamp timerDoor switches

Front door unlock sensor LH

Ignition switch (ON)

Key switch (Insert)Interior lamp

Electric sunroof and power

window timerFront door switches

Ignition switch (ON)Power window relay

Headlamp battery saver timerFront door switches

Ignition switch (ON)Headlamp battery saver control unit

Battery saverIgnition switch (ON)

Door switches

Driver's door unlock sensor

Key switch (Insert)Interior lamp

Luggage room lamp

Spot lamp

Vanity mirror illumination lamp

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

SMART ENTRANCE CONTROL UNIT

Description

EL-319

Page 1509 of 2395

Smart Entrance Control Unit Inspection TableNBEL0126

Terminal

No.Wire

colorConnections Operated conditionVoltage

(Approximate

values)

2 G/B Rear window defogger relay OFF,ON (Ignition key is in ªONº position) 0V,12V

4 PU/W Theft warning horn/lamp relay When panic alarm is operated using remote controller 12V,0V

5 R/YHeadlamp battery saver control

unitWhen headlamp battery saver timer is operated 12V

7 P Multi-remote control relay When doors are locked using remote controller 12V,0V

8 R/B Interior lampWhen interior lamp is operated using remote controller.

(Lamp switch in ªDOORº position)0V,12V

10 G/R Power source (Fuse) Ð 12V

11 W/R Power source (C/B) Ð 12V

13 W/PU Driver door lock actuator

Door lock & unlock switchFree 0V

14 Y/B Passenger door lock actuator Unlocked 12V

15 L Door lock actuators Door lock & unlock switchFree 0V

Locked 12V

16 B Ground Ð Ð

17 R/W Battery saver (Interior lamp) Battery saver is not operate,Operate 12V,0V

19 LG/B Horn relayWhen doors are locked using remote controller with horn

chirp mode.12V,0V

21 G/W Ignition switch (ACC) ªACCº position 12V

22 B/P Seat belt buckle switch Unfasten,Fasten (Ignition key is in ªONº position) 0V,12V

23 BR Door lock & unlock switches Neutral,Locks 5V,0V

26 Y/R Rear door unlock sensors All doors are locked,One or more doors are unlocked 5V,0V

27 Y/B Hood open signal ON (Open),OFF (Closed) 0V,5V

28 R/L Rear and back door switches OFF (Closed),ON (Open) 5V,0V

29 G/R Driver door switch OFF (Closed),ON (Open) 5V,0V

30 LG Door key cylinder unlock switch OFF (Neutral),ON (Unlocked) 12V,0V

31 BR/Y Theft warning indicator Goes off,Illuminates 12V,0V

32 W/R Ignition key switch (Insert) key inserted,key removed from IGN key cylinder 12V,0V

33 W/B Ignition switch (ON) Ignition key is in ªONº position 12V

35 LG/R Door lock & unlock switches Neutral,Unlocks 5V,0V

36 Y/G Driver door unlock sensor Driver door: Locked,Unlocked 5V,0V

37 Y/L Passenger door unlock sensor Passenger door: Locked,Unlocked 5V,0V

38 L/W Glass hatch switch ON (Open),OFF (Closed) 0V,12V

39 OR Rear window defogger switch OFF,ON 5V,0V

40 Y Passenger door switch OFF (Closed),ON (Open) 5V,0V

41 Y Door key cylinder lock switch OFF (Neutral),ON (Locked) 5V,0V

42 G/B Back door key unlock switch OFF (Neutral),ON (Unlock) 5V,0V

SMART ENTRANCE CONTROL UNIT

Smart Entrance Control Unit Inspection Table

EL-324

Page 1562 of 2395

TELEPHONE STEERING SWITCH CHECK=NBEL0184S14

1 CHECK POWER SUPPLY FOR STEERING SWITCH

Check power supply for steering switch.

Does horn work?

Ye s©Check the following.

I10A fuse (No. 54, located in fuse and fusible link box)

IHorn relay

IHarness for open or short

No©GO TO 2.

2 CHECK STEERING SWITCH SUB-HARNESS

1. Remove driver's air bag module. For removal procedure, refer to RS section.

2. Check steering switch sub-harness for open or short and ground screw.

For details of the harness circuit, refer to ªSTEERING SWITCHº, EL-30.

OK or NG

OK©Check harness for open or short between telephone steering switch and IVCS unit. If the

circuit is OK, replace telephone steering switch.

NG©Replace or repair the harness.

Trouble Diagnoses for Intermittent IncidentNBEL0185DESCRIPTIONNBEL0185S01An intermittent incident may be occurring if all of the following conditions exist.

IBoth ªMAYDAYº emergency and ªINFORMATIONº indicators have shown that the system is malfunction-

ing.

ICONSULT-II self-diagnosis result screen indicates a trouble code with ªTIME=1orgreaterº.

IThe INFINITI Communicator system has not been previously serviced.

To find out the cause of a malfunction, follow the procedures shown below.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

INFINITI COMMUNICATOR (IVCS)

Trouble Diagnoses (Cont'd)

EL-377

Page 1625 of 2395

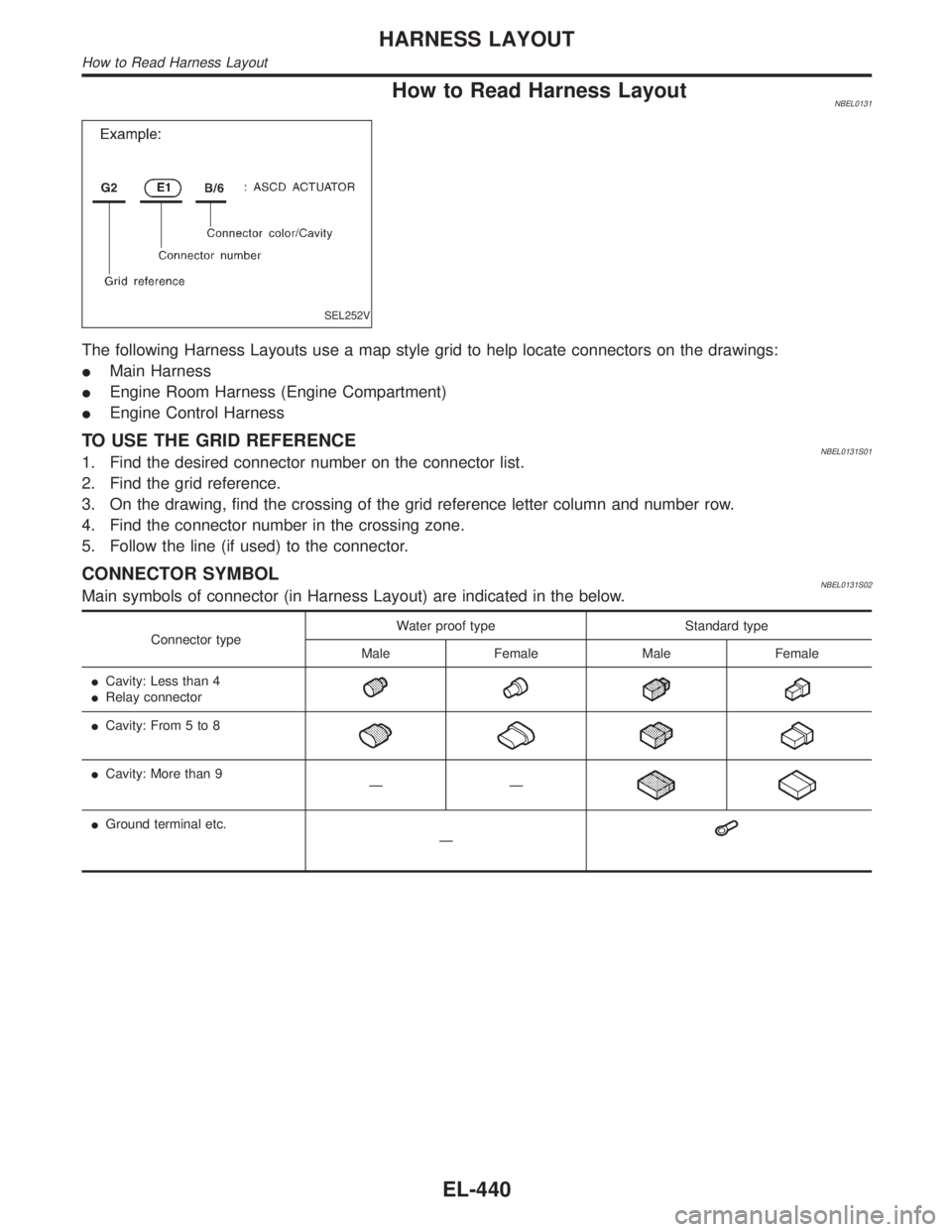

How to Read Harness LayoutNBEL0131

SEL252V

The following Harness Layouts use a map style grid to help locate connectors on the drawings:

IMain Harness

IEngine Room Harness (Engine Compartment)

IEngine Control Harness

TO USE THE GRID REFERENCENBEL0131S011. Find the desired connector number on the connector list.

2. Find the grid reference.

3. On the drawing, find the crossing of the grid reference letter column and number row.

4. Find the connector number in the crossing zone.

5. Follow the line (if used) to the connector.

CONNECTOR SYMBOLNBEL0131S02Main symbols of connector (in Harness Layout) are indicated in the below.

Connector typeWater proof type Standard type

Male Female Male Female

ICavity: Less than 4

IRelay connector

ICavity: From 5 to 8

ICavity: More than 9

ÐÐ

IGround terminal etc.

Ð

HARNESS LAYOUT

How to Read Harness Layout

EL-440

Page 1758 of 2395

Description=NBGI0003S02

Number Item Description

1 Power conditionIThis shows the condition when the system receives battery positive voltage (can be oper-

ated).

2 Fusible linkIThe double line shows that this is a fusible link.

IThe open circle shows current flow in, and the shaded circle shows current flow out.

3Fusible link/fuse loca-

tionIThis shows the location of the fusible link or fuse in the fusible link or fuse box. For

arrangement, refer to EL-10, ªPOWER SUPPLY ROUTINGº.

4 FuseIThe single line shows that this is a fuse.

IThe open circle shows current flow in, and the shaded circle shows current flow out.

5 Current ratingIThis shows the current rating of the fusible link or fuse.

6 ConnectorsIThis shows that connector E3 is female and connector M1 is male.

IThe G/R wire is located in the 1A terminal of both connectors.

ITerminal number with an alphabet (1A, 5B, etc.) indicates that the connector is SMJ con-

nector. Refer to GI-19.

7 Optional spliceIThe open circle shows that the splice is optional depending on vehicle application.

8 SpliceIThe shaded circle shows that the splice is always on the vehicle.

9 Page crossingIThis arrow shows that the circuit continues to an adjacent page.

IThe A will match with the A on the preceding or next page.

10 Common connectorIThe dotted lines between terminals show that these terminals are part of the same con-

nector.

11 Option abbreviationIThis shows that the circuit is optional depending on vehicle application.

12 RelayIThis shows an internal representation of the relay. For details, refer to EL-7, ªSTANDARD-

IZED RELAYº.

13 ConnectorsIThis shows that the connector is connected to the body or a terminal with bolt or nut.

14 Wire colorIThis shows a code for the color of the wire.

B = Black

W = White

R = Red

G = Green

L = Blue

Y = Yellow

LG = Light GreenBR = Brown

OR = Orange

P = Pink

PU = Purple

GY = Gray

SB = Sky Blue

CH = Dark Brown

DG = Dark Green

When the wire color is striped, the base color is given first, followed by the stripe color as

shown below:

Example: L/W = Blue with White Stripe

15 Option descriptionIThis shows a description of the option abbreviation used on the page.

16 SwitchIThis shows that continuity exists between terminals 1 and 2 when the switch is in the A

position. Continuity exists between terminals 1 and 3 when the switch is in the B position.

17 Assembly partsIConnector terminal in component shows that it is a harness incorporated assembly.

18 Cell codeIThis identifies each page of the wiring diagram by section, system and wiring diagram

page number.

19 Current flow arrowIArrow indicates electric current flow, especially where the direction of standard flow (verti-

cally downward or horizontally from left to right) is difficult to follow.

IA double arrow ª

º shows that current can flow in either direction depending on cir-

cuit operation.

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

HOW TO READ WIRING DIAGRAMS

Description

GI-13

Page 1770 of 2395

Incident Simulation TestsNBGI0004S02INTRODUCTIONNBGI0004S0201Sometimes the symptom is not present when the vehicle is brought

in for service. If possible, re-create the conditions present at the

time of the incident. Doing so may help avoid a No Trouble Found

Diagnosis. The following section illustrates ways to simulate the

conditions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:

IVehicle vibration

IHeat sensitive

IFreezing

IWater intrusion

IElectrical load

ICold or hot start up

Get a thorough description of the incident from the customer. It is

important for simulating the conditions of the problem.

VEHICLE VIBRATIONNBGI0004S0202The problem may occur or become worse while driving on a rough

road or when engine is vibrating (idle with A/C on). In such a case,

you will want to check for a vibration related condition. Refer to the

illustration below.

Connectors & Harness

Determine which connectors and wiring harness would affect the

electrical system you are inspecting.Gentlyshake each connec-

tor and harness while monitoring the system for the incident you

are trying to duplicate. This test may indicate a loose or poor elec-

trical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin

film of corrosion on the connector terminals. A visual inspection

may not reveal this without disconnecting the connector. If the

problem occurs intermittently, perhaps the problem is caused by

corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

Sensors & Relays

Gentlyapply a slight vibration to sensors and relays in the system

you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests

GI-25

Page 1773 of 2395

NOTE:

Refer to ªHOW TO CHECK TERMINALº in GI-21 to probe or

check terminal.

TESTING FOR ªOPENSº IN THE CIRCUITNBGI0004S0303Before you begin to diagnose and test the system, you should

rough sketch a schematic of the system. This will help you to logi-

cally walk through the diagnosis process. Drawing the sketch will

also reinforce your working knowledge of the system.

SGI846

Continuity Check Method

The continuity check is used to find an open in the circuit. The

Digital Multimeter (DMM) set on the resistance function will indicate

an open circuit as over limit (no beep tone or no ohms symbol).

Make sure to always start with the DMM at the highest resistance

level.

To help in understanding the diagnosis of open circuits please refer

to the schematic above.

1) Disconnect the battery negative cable.

2) Start at one end of the circuit and work your way to the other

end. (At the fuse block in this example)

3) Connect one probe of the DMM to the fuse block terminal on

the load side.

4) Connect the other probe to the fuse block (power) side of SW1.

Little or no resistance will indicate that portion of the circuit has

good continuity. If there were an open in the circuit, the DMM

would indicate an over limit or infinite resistance condition.

(point A)

5) Connect the probes between SW1 and the relay. Little or no

resistance will indicate that portion of the circuit has good con-

tinuity. If there were an open in the circuit, the DMM would

indicate an over limit or infinite resistance condition. (point B)

6) Connect the probes between the relay and the solenoid. Little

or no resistance will indicate that portion of the circuit has good

continuity. If there were an open in the circuit, the DMM would

indicate an over limit or infinite resistance condition. (point C)

Any circuit can be diagnosed using the approach in the above

example.

Voltage Check Method

To help in understanding the diagnosis of open circuits please refer

to the previous schematic.

In any powered circuit, an open can be found by methodically

checking the system for the presence of voltage. This is done by

switching the DMM to the voltage function.

1) Connect one probe of the DMM to a known good ground.

2) Begin probing at one end of the circuit and work your way to

the other end.

3) With SW1 open, probe at SW1 to check for voltage.

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-28

Page 1774 of 2395

voltage; open is further down the circuit than SW1.

no voltage; open is between fuse block and SW1 (point A).

4) Close SW1 and probe at relay.

voltage; open is further down the circuit than the relay.

no voltage; open is between SW1 and relay (point B).

5) Close the relay and probe at the solenoid.

voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the

above example.

TESTING FOR ªSHORTSº IN THE CIRCUITNBGI0004S0304To simplify the discussion of shorts in the system please refer to

the schematic below.

SGI847

Resistance Check Method

1) Disconnect the battery negative cable and remove the blown

fuse.

2) Disconnect all loads (SW1 open, relay disconnected and sole-

noid disconnected) powered through the fuse.

3) Connect one probe of the ohmmeter to the load side of the fuse

terminal. Connect the other probe to a known good ground.

4) With SW1 open, check for continuity.

continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

5) Close SW1 and disconnect the relay. Put probes at the load

side of fuse terminal and a known good ground. Then, check

for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

6) Close SW1 and jump the relay contacts with jumper wire. Put

probes at the load side of fuse terminal and a known good

ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

Voltage Check Method

1) Remove the blown fuse and disconnect all loads (i.e. SW1

open, relay disconnected and solenoid disconnected) powered

through the fuse.

2) Turn the ignition key to the ON or START position. Verify bat-

tery voltage at the B + side of the fuse terminal (one lead on

the B + terminal side of the fuse block and one lead on a known

good ground).

3) With SW1 open and the DMM leads across both fuse

terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-29

Page 1775 of 2395

4) With SW1 closed, relay and solenoid disconnected and the

DMM leads across both fuse terminals, check for voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

5) With SW1 closed, relay contacts jumped with fused jumper

wire check for voltage.

voltage; short is down the circuit of the relay or between the

relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

GROUND INSPECTIONNBGI0004S0305Ground connections are very important to the proper operation of

electrical and electronic circuits. Ground connections are often

exposed to moisture, dirt and other corrosive elements. The corro-

sion (rust) can become an unwanted resistance. This unwanted

resistance can change the way a circuit works.

Electronically controlled circuits are very sensitive to proper

grounding. A loose or corroded ground can drastically affect an

electronically controlled circuit. A poor or corroded ground can eas-

ily affect the circuit. Even when the ground connection looks clean,

there can be a thin film of rust on the surface.

When inspecting a ground connection follow these rules:

1) Remove the ground bolt or screw.

2) Inspect all mating surfaces for tarnish, dirt, rust, etc.

3) Clean as required to assure good contact.

4) Reinstall bolt or screw securely.

5) Inspect for ªadd-onº accessories which may be interfering with

the ground circuit.

6) If several wires are crimped into one ground eyelet terminal,

check for proper crimps. Make sure all of the wires are clean,

securely fastened and providing a good ground path. If multiple

wires are cased in one eyelet make sure no ground wires have

excess wire insulation.

SGI853

VOLTAGE DROP TESTSNBGI0004S0306Voltage drop tests are often used to find components or circuits

which have excessive resistance. A voltage drop in a circuit is

caused by a resistancewhen the circuit is in operation.

Check the wire in the illustration. When measuring resistance with

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-30

Page 1813 of 2395

Refrigeration System

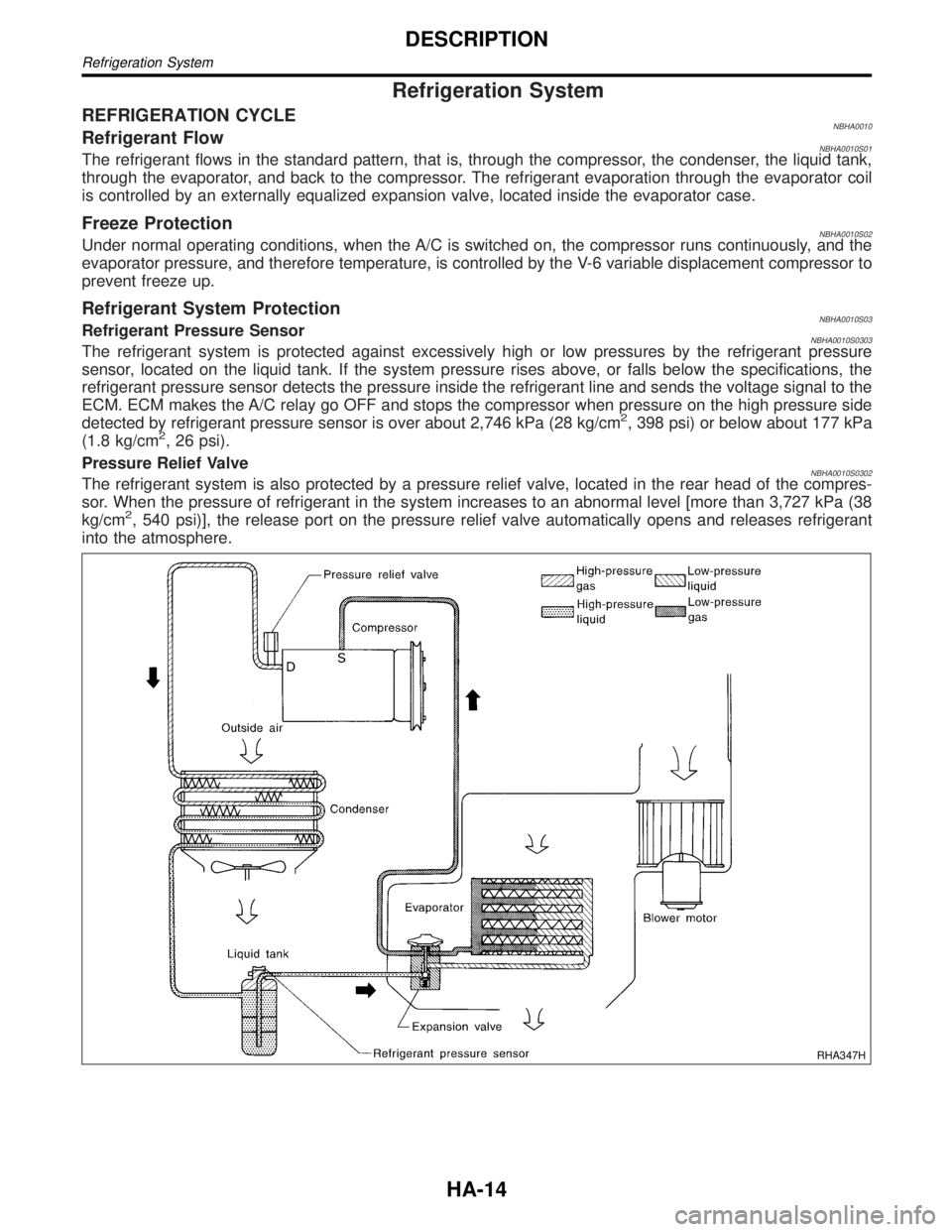

REFRIGERATION CYCLENBHA0010Refrigerant FlowNBHA0010S01The refrigerant flows in the standard pattern, that is, through the compressor, the condenser, the liquid tank,

through the evaporator, and back to the compressor. The refrigerant evaporation through the evaporator coil

is controlled by an externally equalized expansion valve, located inside the evaporator case.

Freeze ProtectionNBHA0010S02Under normal operating conditions, when the A/C is switched on, the compressor runs continuously, and the

evaporator pressure, and therefore temperature, is controlled by the V-6 variable displacement compressor to

prevent freeze up.

Refrigerant System ProtectionNBHA0010S03Refrigerant Pressure SensorNBHA0010S0303The refrigerant system is protected against excessively high or low pressures by the refrigerant pressure

sensor, located on the liquid tank. If the system pressure rises above, or falls below the specifications, the

refrigerant pressure sensor detects the pressure inside the refrigerant line and sends the voltage signal to the

ECM. ECM makes the A/C relay go OFF and stops the compressor when pressure on the high pressure side

detected by refrigerant pressure sensor is over about 2,746 kPa (28 kg/cm

2, 398 psi) or below about 177 kPa

(1.8 kg/cm2, 26 psi).

Pressure Relief Valve

NBHA0010S0302The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compres-

sor. When the pressure of refrigerant in the system increases to an abnormal level [more than 3,727 kPa (38

kg/cm

2, 540 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant

into the atmosphere.

RHA347H

DESCRIPTION

Refrigeration System

HA-14