IDX INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2064 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

ST33190000

(J25523)

Differential side bearing

drift

NT085

Installing side bearing inner cone

a: 52 mm (2.05 in) dia.

b: 45.5 mm (1.791 in) dia.

c: 34 mm (1.34 in) dia.

ST33081000

(Ð)

Side bearing puller

adapter

NT431

Installing side bearing inner cone

a: 43 mm (1.69 in) dia.

b: 33.5 mm (1.319 in) dia.

ST30611000

(J25742-1)

Drift

NT090

Installing pinion rear bearing outer race

(Use with ST30621000 or ST30613000)

ST30621000

(J25742-5)

Drift

NT073

Installing pinion rear bearing outer race

a: 79 mm (3.11 in) dia.

b: 59 mm (2.32 in) dia.

ST30613000

(J25742-3)

Drift

NT073

Installing pinion front bearing outer race

(Use with ST30611000)

a: 72 mm (2.83 in) dia.

b: 48 mm (1.89 in) dia.

KV381025S0

(Ð)

Oil seal fitting tool

1 ST30720000

(J25405)

Drift bar

2 KV38102510

(Ð)

Drift

NT525

Installing front oil seal

a: 77 mm (3.03 in) dia.

b: 55 mm (2.17 in) dia.

c: 71 mm (2.80 in) dia.

d: 65 mm (2.56 in) dia.

(J34309)

Differential shim selec-

tor

NT134

Adjusting bearing pre-load and gear height

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR FINAL DRIVEH233B

Preparation (Cont'd)

PD-39

Page 2066 of 2395

SPD738

4. Remove front oil seal.

SPD739

5. Apply multi-purpose grease to cavity at sealing lips of oil seal.

Press front oil seal into carrier.

Tool number:

KV38100500 (J25273)

6. Install companion flange and drive pinion nut.

7. Install rear propeller shaft.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR FINAL DRIVEH233B

On-vehicle Service (Cont'd)

PD-41

Page 2068 of 2395

Removal and InstallationNBPD0032REMOVALNBPD0032S01IRemove rear of propeller shaft.

Plug front end of transfer.

IRemove axle shaft.

Refer to AX-19, ªRemovalº.

IRemove rear final drive mounting bolts.

CAUTION:

Be careful not to damage spline, sleeve yoke and front oil seal

when removing propeller shaft.

SPD123

INSTALLATIONNBPD0032S02IFill final drive with recommended gear oil.

SPD767

IPay attention to the direction of gasket.

SPD149

DisassemblyNBPD0033PRE-INSPECTIONNBPD0033S01Before disassembling final drive, perform the following inspection.

ITotal preload

a) Turn drive pinion in both directions several times to seat bear-

ing rollers correctly.

b) Check total preload with Tool.

Tool number: ST3127S000 (J25765-A)

Total preload:

1.2 - 2.0 N´m (12 - 20 kg-cm, 10 - 17 in-lb)

SPD246

IRing gear to drive pinion backlash

Check backlash of ring gear with a dial indicator at several

points.

Ring gear-to-drive pinion backlash:

0.13 - 0.18 mm (0.0051 - 0.0071 in)

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR FINAL DRIVEH233B

Removal and Installation

PD-43

Page 2070 of 2395

SPD684

4. Remove side bearing adjuster with Tool.

Tool number: ST32580000 (J34312)

SPD685

5. Remove differential case assembly with a pry bar.

SPD011

Be careful to keep the side bearing outer races together with

their respective inner cones Ð do not mix them up.

SPD480A

6. Remove drive pinion nut with Tool.

Tool number: KV38108300 (J44195)

7. Remove companion flange with puller.

SPD687

8. Take out drive pinion together with pinion rear bearing inner

cone, drive pinion bearing spacer and pinion bearing adjusting

shim.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR FINAL DRIVEH233B

Disassembly (Cont'd)

PD-45

Page 2072 of 2395

SPD025

4. Drive out pinion mate shaft lock pin, with punch from ring gear

side.

Lock pin is calked at pin hole mouth on differential case.

InspectionNBPD0034RING GEAR AND DRIVE PINIONNBPD0034S01Check gear teeth for scoring, cracking or chipping.

If any damaged part is evident, replace ring gear and drive pinion

as a set (hypoid gear set).

SPD530-A

DIFFERENTIAL CASE ASSEMBLYNBPD0034S02Check mating surfaces of differential case, side gears, pinion mate

gears, pinion mate shaft, and thrust washers.

SPD715

BEARINGNBPD0034S031. Thoroughly clean bearing.

2. Check bearings for wear, scratches, pitting or flaking.

Check tapered roller bearing for smooth rotation. If damaged,

replace outer race and inner cone as a set.

SPD415

Limited Slip Differential

PREPARATION FOR DISASSEMBLYNBPD0035Checking Differential TorqueNBPD0035S01Measure differential torque with Tool.

If it is not within the specifications, inspect components of limited

slip differential.

Differential torque:

88 - 108 N´m (9 - 11 kg-m, 65 - 80 ft-lb)

Tool number: A KV38105210 ( Ð )

Tool number: B KV38105220 ( Ð )

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR FINAL DRIVEH233B

Disassembly (Cont'd)

PD-47

Page 2074 of 2395

SPD359A

INSPECTIONNBPD0037Contact SurfacesNBPD0037S011. Clean the disassembled parts in suitable solvent and blow dry

with compressed air.

2. If following surfaces are found with burrs or scratches, smooth

with oil stone.

1Differential case B

2Differential case A

3Side gear

4Pinion mate gear

5Pinion mate shaft

6Friction plate guide

Disc and PlateNBPD0037S021. Clean the discs and plates in suitable solvent and blow dry with

compressed air.

2. Inspect discs and plates for wear, nicks and burrs.

SPD279

3. To test if friction disc or plate is not distorted, place it on a sur-

face plate and rotate it by hand with indicating finger of dial

gauge resting against disc or plate surface.

Allowable warpage:

0.08 mm (0.0031 in)

If it exceeds limits, replace with a new plate to eliminate pos-

sibility of clutch slippage or sticking.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR FINAL DRIVEH233B

Limited Slip Differential (Cont'd)

PD-49

Page 2076 of 2395

SPD418

3. Measure values of ªCº.

a. Attach a dial indicator to the base plate.

b. Place differential case B on the base plate, and install a mas-

ter gauge on case B.

Then adjust the dial indicator scale to zero with its tip on

the master gauge.

SPD419

c. Install pinion mate gears, side gears and pinion mate shaft in

differential case B.

d. Set dial indicator's tip on the side gear, and read the indication.

Example:

E = A þ D = A þ (B + C) = 0.05 to 0.15 mm

A = 49.52 mm

B = 19.45 mm

C = 29.7 mm

D=B+C

49.15 (D) = 19.45 (B) + 29.7 (C)

E =Aþ D

0.37 (E) = 49.52 (A) þ 49.15 (D)

From the above equation, end play of 0.37 mm exceeds the speci-

fied range of 0.05 to 0.15 mm.

Select suitable discs and plates to adjust correctly.

SPD421

ASSEMBLYNBPD0039Prior to assembling discs and plates, properly lubricate them by

dipping them in limited slip differential oil.

1. Alternately position specified number of friction plates and fric-

tion discs on rear of side gear.

Always position a friction plate first on rear of side gear.

SPD384A

2. Install spring plate.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR FINAL DRIVEH233B

Limited Slip Differential (Cont'd)

PD-51

Page 2078 of 2395

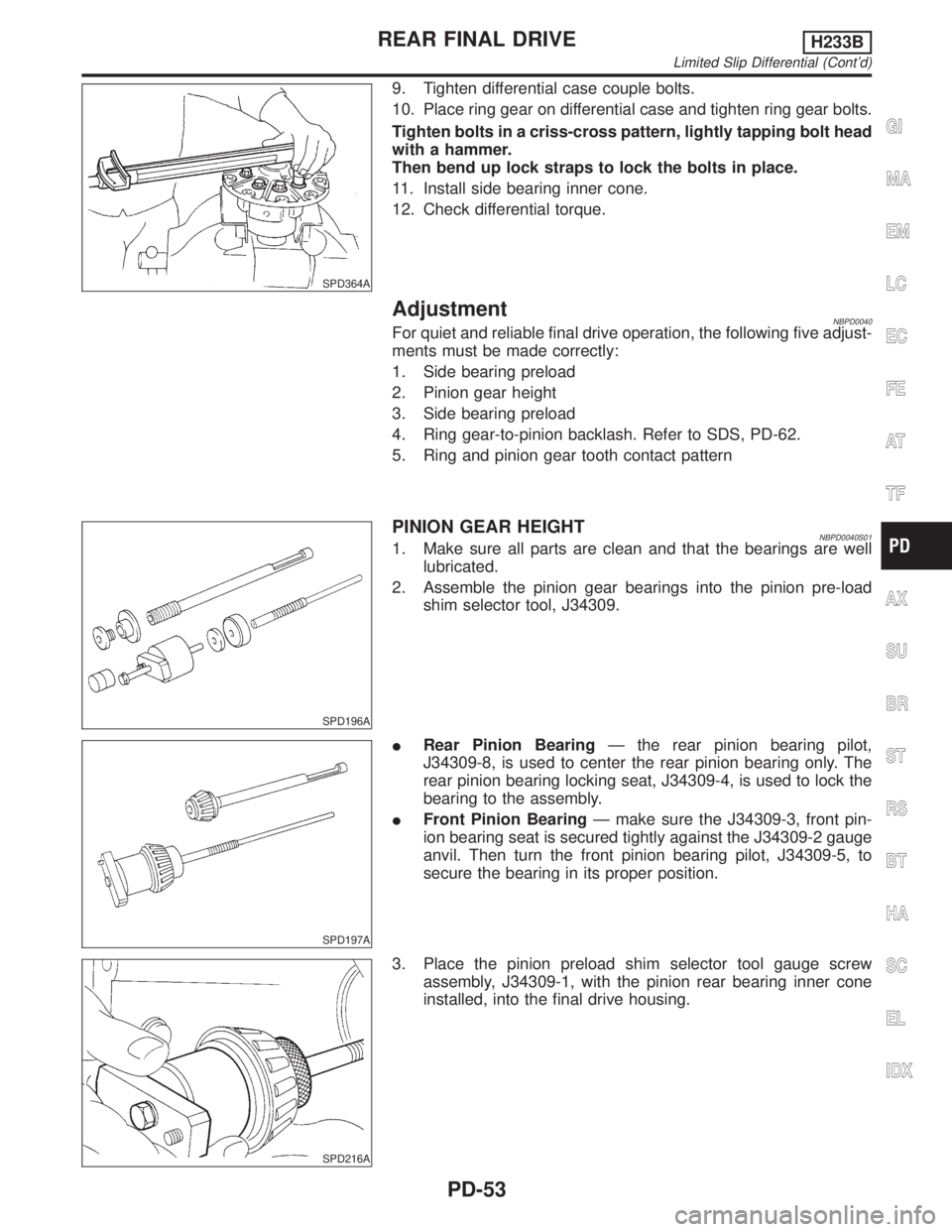

SPD364A

9. Tighten differential case couple bolts.

10. Place ring gear on differential case and tighten ring gear bolts.

Tighten bolts in a criss-cross pattern, lightly tapping bolt head

with a hammer.

Then bend up lock straps to lock the bolts in place.

11. Install side bearing inner cone.

12. Check differential torque.

AdjustmentNBPD0040For quiet and reliable final drive operation, the following five adjust-

ments must be made correctly:

1. Side bearing preload

2. Pinion gear height

3. Side bearing preload

4. Ring gear-to-pinion backlash. Refer to SDS, PD-62.

5. Ring and pinion gear tooth contact pattern

SPD196A

PINION GEAR HEIGHTNBPD0040S011. Make sure all parts are clean and that the bearings are well

lubricated.

2. Assemble the pinion gear bearings into the pinion pre-load

shim selector tool, J34309.

SPD197A

IRear Pinion BearingÐ the rear pinion bearing pilot,

J34309-8, is used to center the rear pinion bearing only. The

rear pinion bearing locking seat, J34309-4, is used to lock the

bearing to the assembly.

IFront Pinion BearingÐ make sure the J34309-3, front pin-

ion bearing seat is secured tightly against the J34309-2 gauge

anvil. Then turn the front pinion bearing pilot, J34309-5, to

secure the bearing in its proper position.

SPD216A

3. Place the pinion preload shim selector tool gauge screw

assembly, J34309-1, with the pinion rear bearing inner cone

installed, into the final drive housing.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR FINAL DRIVEH233B

Limited Slip Differential (Cont'd)

PD-53

Page 2080 of 2395

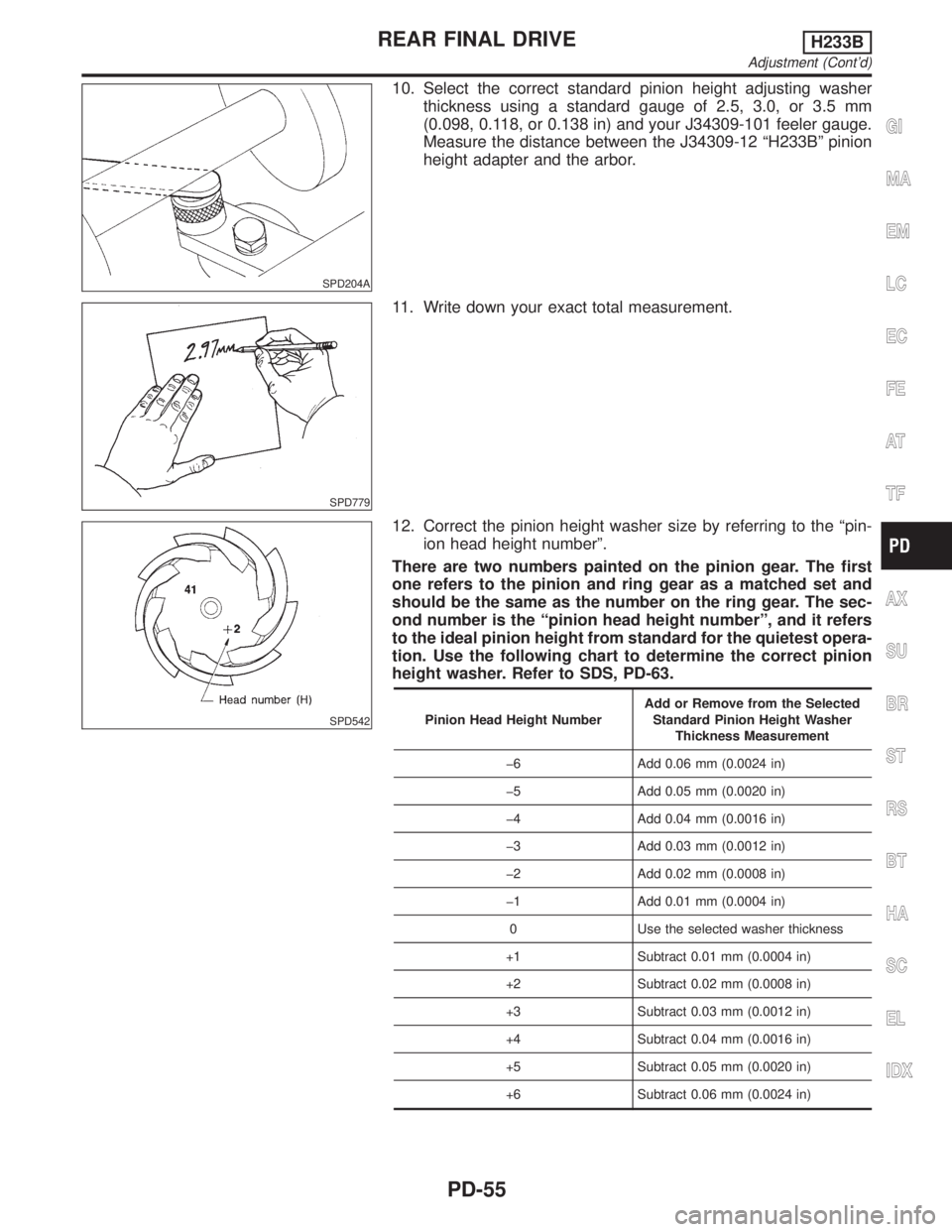

SPD204A

10. Select the correct standard pinion height adjusting washer

thickness using a standard gauge of 2.5, 3.0, or 3.5 mm

(0.098, 0.118, or 0.138 in) and your J34309-101 feeler gauge.

Measure the distance between the J34309-12 ªH233Bº pinion

height adapter and the arbor.

SPD779

11. Write down your exact total measurement.

SPD542

12. Correct the pinion height washer size by referring to the ªpin-

ion head height numberº.

There are two numbers painted on the pinion gear. The first

one refers to the pinion and ring gear as a matched set and

should be the same as the number on the ring gear. The sec-

ond number is the ªpinion head height numberº, and it refers

to the ideal pinion height from standard for the quietest opera-

tion. Use the following chart to determine the correct pinion

height washer. Refer to SDS, PD-63.

Pinion Head Height NumberAdd or Remove from the Selected

Standard Pinion Height Washer

Thickness Measurement

þ6 Add 0.06 mm (0.0024 in)

þ5 Add 0.05 mm (0.0020 in)

þ4 Add 0.04 mm (0.0016 in)

þ3 Add 0.03 mm (0.0012 in)

þ2 Add 0.02 mm (0.0008 in)

þ1 Add 0.01 mm (0.0004 in)

0 Use the selected washer thickness

+1 Subtract 0.01 mm (0.0004 in)

+2 Subtract 0.02 mm (0.0008 in)

+3 Subtract 0.03 mm (0.0012 in)

+4 Subtract 0.04 mm (0.0016 in)

+5 Subtract 0.05 mm (0.0020 in)

+6 Subtract 0.06 mm (0.0024 in)

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR FINAL DRIVEH233B

Adjustment (Cont'd)

PD-55

Page 2082 of 2395

SPD007-B

SPD552

AssemblyNBPD0041DIFFERENTIAL CASENBPD0041S011. Install side gears, pinion mate gears and thrust washers into

differential case.

SPD258

2. Fit pinion mate shaft to differential case so that it meets lock

pin holes.

3. Adjust backlash between side gear and pinion mate gear by

selecting side gear thrust washer.

Refer to SDS, PD-62.

Backlash between side gear and pinion mate gear

(Clearance between side gear thrust washer and differ-

ential case):

0.10 - 0.20 mm (0.0039 - 0.0079 in)

SPD030

4. Install pinion mate shaft lock pin with a punch.

Make sure lock pin is flush with case.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR FINAL DRIVEH233B

Adjustment (Cont'd)

PD-57