IDX INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2024 of 2395

Engine Maintenance

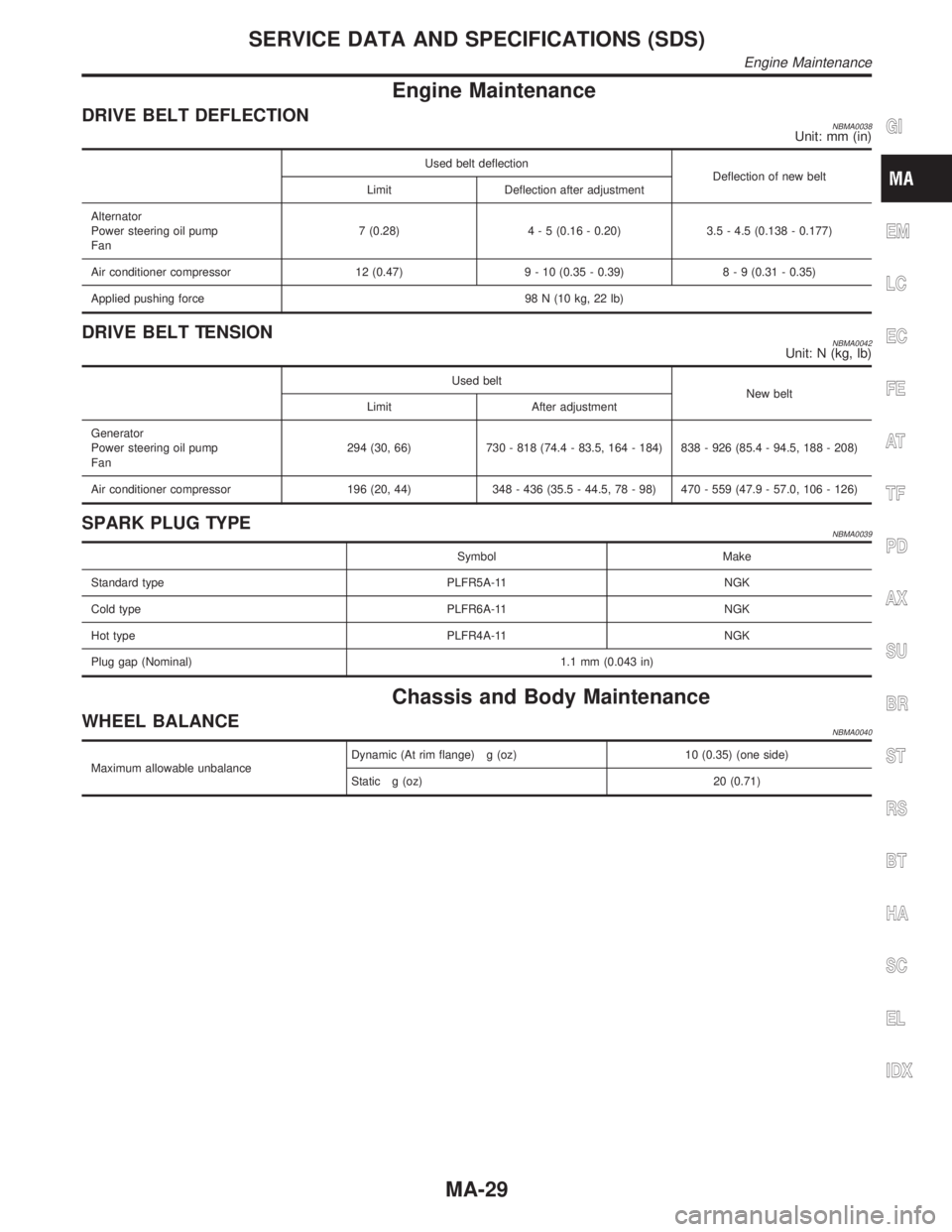

DRIVE BELT DEFLECTIONNBMA0038Unit: mm (in)

Used belt deflection

Deflection of new belt

Limit Deflection after adjustment

Alternator

Power steering oil pump

Fan7 (0.28)4 - 5 (0.16 - 0.20) 3.5 - 4.5 (0.138 - 0.177)

Air conditioner compressor 12 (0.47) 9 - 10 (0.35 - 0.39)8 - 9 (0.31 - 0.35)

Applied pushing force 98 N (10 kg, 22 lb)

DRIVE BELT TENSIONNBMA0042Unit: N (kg, lb)

Used belt

New belt

Limit After adjustment

Generator

Power steering oil pump

Fan294 (30, 66) 730 - 818 (74.4 - 83.5, 164 - 184) 838 - 926 (85.4 - 94.5, 188 - 208)

Air conditioner compressor 196 (20, 44) 348 - 436 (35.5 - 44.5, 78 - 98) 470 - 559 (47.9 - 57.0, 106 - 126)

SPARK PLUG TYPENBMA0039

Symbol Make

Standard type PLFR5A-11 NGK

Cold type PLFR6A-11 NGK

Hot type PLFR4A-11 NGK

Plug gap (Nominal) 1.1 mm (0.043 in)

Chassis and Body Maintenance

WHEEL BALANCENBMA0040

Maximum allowable unbalanceDynamic (At rim flange) g (oz) 10 (0.35) (one side)

Static g (oz) 20 (0.71)

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Engine Maintenance

MA-29

Page 2026 of 2395

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

CONTENTS

PROPELLER SHAFT......................................................3

Noise, Vibration and Harshness (NVH)

Troubleshooting ...........................................................3

NVH TROUBLESHOOTING CHART............................3

Components.................................................................4

FRONT PROPELLER SHAFT.....................................4

REAR PROPELLER SHAFT.......................................5

On-vehicle Service.......................................................6

PROPELLER SHAFT VIBRATION...............................6

APPEARANCE CHECKING........................................6

Removal and Installation .............................................6

Inspection.....................................................................7

Disassembly.................................................................7

CENTER BEARING - 2WD -.......................................7

JOURNAL (71H AND 80B)..........................................8

Assembly .....................................................................9

CENTER BEARING - 2WD -.......................................9

JOURNAL (71H AND 80B)..........................................9

Service Data and Specifications (SDS)..................... 11

GENERAL SPECIFICATIONS................................... 11

SERVICE DATA....................................................... 11

SNAP RING (80B).................................................... 11

SNAP RING (71H)...................................................12

R200A

FRONT FINAL DRIVE...................................................13

Preparation ................................................................13

SPECIAL SERVICE TOOLS......................................13

Noise, Vibration and Harshness (NVH)

Troubleshooting .........................................................15

On-vehicle Service.....................................................15

FRONT OIL SEAL REPLACEMENT...........................15

REAR COVER GASKET REPLACEMENT..................16

Components...............................................................17

Removal and Installation ...........................................18

REMOVAL...............................................................18

INSTALLATION........................................................18

Disassembly...............................................................18

PRE-INSPECTION...................................................18

FINAL DRIVE HOUSING..........................................19

DIFFERENTIAL CASE..............................................21

DIFFERENTIAL SIDE SHAFT...................................22

Inspection...................................................................23

RING GEAR AND DRIVE PINION.............................23

DIFFERENTIAL CASE ASSEMBLY...........................23

BEARING................................................................23

Adjustment .................................................................24

SIDE BEARING PRELOAD.......................................24

PINION GEAR HEIGHT AND PINION BEARING

PRELOAD

...............................................................25

TOOTH CONTACT...................................................29

Assembly ...................................................................30

DIFFERENTIAL SIDE SHAFT...................................30

DIFFERENTIAL CASE..............................................31

FINAL DRIVE HOUSING..........................................32

Service Data and Specifications (SDS).....................36

R200A.....................................................................36

H233B

REAR FINAL DRIVE.....................................................38

Preparation ................................................................38

SPECIAL SERVICE TOOLS......................................38

Noise, Vibration and Harshness (NVH)

Troubleshooting .........................................................40

On-vehicle Service.....................................................40

FRONT OIL SEAL REPLACEMENT...........................40

Components...............................................................42

Removal and Installation ...........................................43

REMOVAL...............................................................43

INSTALLATION........................................................43

Disassembly...............................................................43

PRE-INSPECTION...................................................43

DIFFERENTIAL CARRIER........................................44

DIFFERENTIAL CASE..............................................46

Inspection...................................................................47

RING GEAR AND DRIVE PINION.............................47

DIFFERENTIAL CASE ASSEMBLY...........................47

BEARING................................................................47

Limited Slip Differential ..............................................47

PREPARATION FOR DISASSEMBLY........................47

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 2028 of 2395

Noise, Vibration and Harshness (NVH)

Troubleshooting

=NBPD0049NVH TROUBLESHOOTING CHARTNBPD0049S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageÐ

Ð

Ð

Ð

PD-6

PD-6

PD-23, 47

PD-29, 56

PD-23, 47

PD-18, 43

Ð

Ð

Ð

Ð

AX-3

AX-3

SU-3

SU-3

SU-3

BR-6

ST-6

Possible cause and

SUSPECTED PARTS

Uneven rotation torque

Excessive center bearing axial end play

Center bearing mounting (insulator) cracks, damage or deterioration

Excessive joint angle

Rotation imbalance

Excessive runout

Rough gear tooth

Improper gear contact

Tooth surfaces worn

Incorrect backlash

Companion flange excessive runout

Improper gear oil

PROPELLER SHAFT

DIFFERENTIAL

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomPROPEL-

LER

SHAFTNoise´´´´´´ ´´´´´´´´

Shake´ ´´´´´´´

Vibration´´´´´´ ´´´´ ´

DIFFER-

ENTIALNoise´´´´´´´ ´´´´´´´

´: Applicable

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PROPELLER SHAFT

Noise, Vibration and Harshness (NVH) Troubleshooting

PD-3

Page 2030 of 2395

REAR PROPELLER SHAFTNBPD0002S02

SPD522A

SPD468AA

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PROPELLER SHAFT

Components (Cont'd)

PD-5

Page 2032 of 2395

SPD359

IDraw out propeller shaft from transmission and plug up rear

end of transmission rear extension housing.

SPD106

InspectionNBPD0006IInspect propeller shaft runout. If runout exceeds specifications,

replace propeller shaft assembly.

Runout limit: 0.6 mm (0.024 in)

SPD874

IIf the play exceeds specifications, replace propeller shaft

assembly.

Journal axial play:

0.02 mm (0.0008 in) or less

SPD109

DisassemblyNBPD0007CENTER BEARING Ð 2WD ÐNBPD0007S031. Put match marks on flanges, and separate 2nd tube from 1st

tube.

SPD110

2. Put match marks on the flange and shaft.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PROPELLER SHAFT

Removal and Installation (Cont'd)

PD-7

Page 2034 of 2395

SPD131

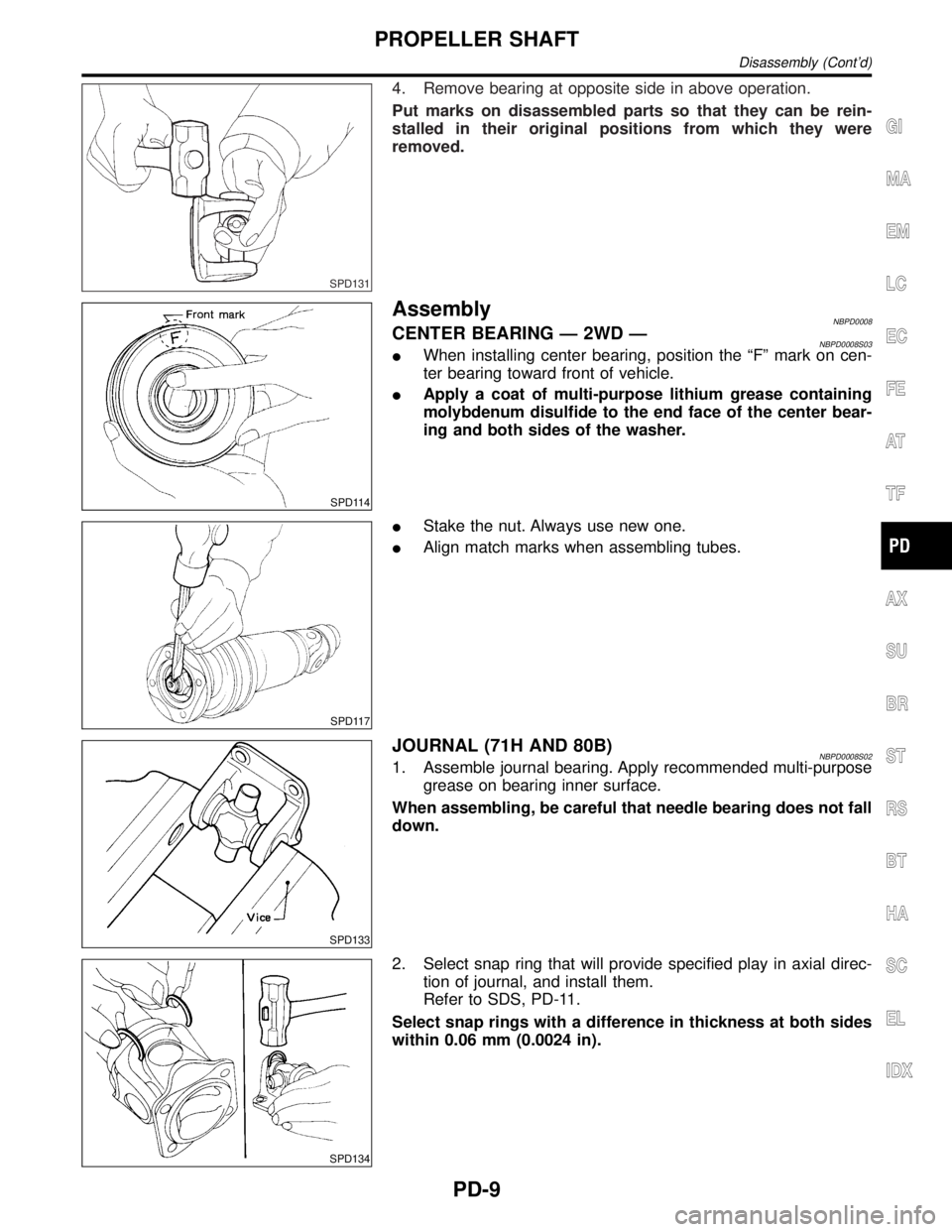

4. Remove bearing at opposite side in above operation.

Put marks on disassembled parts so that they can be rein-

stalled in their original positions from which they were

removed.

SPD114

AssemblyNBPD0008CENTER BEARING Ð 2WD ÐNBPD0008S03IWhen installing center bearing, position the ªFº mark on cen-

ter bearing toward front of vehicle.

IApply a coat of multi-purpose lithium grease containing

molybdenum disulfide to the end face of the center bear-

ing and both sides of the washer.

SPD117

IStake the nut. Always use new one.

IAlign match marks when assembling tubes.

SPD133

JOURNAL (71H AND 80B)NBPD0008S021. Assemble journal bearing. Apply recommended multi-purpose

grease on bearing inner surface.

When assembling, be careful that needle bearing does not fall

down.

SPD134

2. Select snap ring that will provide specified play in axial direc-

tion of journal, and install them.

Refer to SDS, PD-11.

Select snap rings with a difference in thickness at both sides

within 0.06 mm (0.0024 in).

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PROPELLER SHAFT

Disassembly (Cont'd)

PD-9

Page 2036 of 2395

Service Data and Specifications (SDS)

GENERAL SPECIFICATIONS=NBPD00092WD ModelNBPD0009S01

TransmissionA/T

Propeller shaft model3F80B-2BJ

Number of joints3

Coupling method with transmissionFlange type

Type of journal bearings Solid type (disassembly type Ð without birfield joint Ð)

Distance between yokes mm (in)80 (3.15)

Shaft length (Spider to spider) mm (in)1st 650 (25.59)

2nd 749 (29.49)

Shaft outer diameter mm (in)1st 75 (2.95)

2nd 65 (2.56)

4WD ModelNBPD0009S02

LocationFront Rear

Propeller shaft model 2F71H 2S80B-T

Number of joints2

Coupling method with transmission Flange type Sleeve type

Type of journal bearingsSolid type (disassembly type)

Distance between yokes mm (in) 71 (2.80) 80 (3.15)

Shaft length (Spider to spider) mm (in) 553 (21.77) 927 (36.50)

Shaft outer diameter mm (in) 50.8 (2.000) 75 and 63.5 (2.95 and 2.500)

SERVICE DATANBPD0010Unit: mm (in)

Propeller shaft runout limit0.6 (0.024)

Journal axial play0.02 (0.0008) or less

SNAP RING (80B)NBPD0011Unit: mm (in)

Thickness Color Part number*

1.99 (0.0783) White 37146-C9400

2.02 (0.0795) Yellow 37147-C9400

2.05 (0.0807) Red 37148-C9400

2.08 (0.0819) Green 37149-C9400

2.11 (0.0831) Blue 37150-C9400

2.14 (0.0843) Light brown 37151-C9400

2.17 (0.0854) Black 37152-C9400

2.20 (0.0866) No paint 37153-C9400

*: Always check with the Parts Department for the latest parts information.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PROPELLER SHAFT

Service Data and Specifications (SDS)

PD-11

Page 2038 of 2395

Preparation

SPECIAL SERVICE TOOLSNBPD0013The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

ST3127S000

(See J25765-A)

Preload gauge

1 GG91030000

(J25765)

Torque wrench

2 HT62940000

(Ð)

Socket adapter

3 HT62900000

(Ð)

Socket adapter

NT124

Measuring pinion bearing preload and total preload

KV38100800

(J34310, J25604-01)

Differential attachment

NT119

Mounting final drive

(To use, make a new hole.)

a: 152 mm (5.98 in)

KV38108300

(J44195)

Companion flange

wrench

NT771

Removing and installing propeller shaft lock nut,

and drive pinion lock nut

ST3090S000

(Ð)

Drive pinion rear inner

race puller set

1 ST30031000

(J22912-01)

Puller

2 ST30901000

(J26010-01)

Base

NT527

Removing and installing drive pinion rear inner

cone

a: 79 mm (3.11 in) dia.

b: 45 mm (1.77 in) dia.

c: 35 mm (1.38 in) dia.

ST3306S001

Differential side bearing

puller set

1 ST33051001

(J22888-20)

Body

2 ST33061000

(J8107-2)

Adapter

NT072

Removing and installing differential side bearing

inner cone

a: 28.5 mm (1.122 in) dia.

b: 38 mm (1.50 in) dia.

KV38100300

(J25523)

Differential side bearing

drift

NT085

Installing side bearing inner cone

a: 54 mm (2.13 in) dia.

b: 46 mm (1.81 in) dia.

c: 32 mm (1.26 in) dia.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT FINAL DRIVER200A

Preparation

PD-13

Page 2040 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

(J8129)

Spring gauge

NT127

Measuring carrier turning torque

Noise, Vibration and Harshness (NVH)

Troubleshooting

NBPD0050Refer to ªNVH TROUBLESHOOTING CHARTº, PD-3.

SPD476A

On-vehicle Service

FRONT OIL SEAL REPLACEMENTNBPD00141. Remove front propeller shaft.

2. Loosen drive pinion nut.

Tool number: KV38108300 (J44195)

SPD734

3. Remove companion flange.

SPD735

4. Remove front oil seal.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT FINAL DRIVER200A

Preparation (Cont'd)

PD-15

Page 2042 of 2395

ComponentsNBPD0016

SPD357AD

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT FINAL DRIVER200A

Components

PD-17