lock INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 646 of 2395

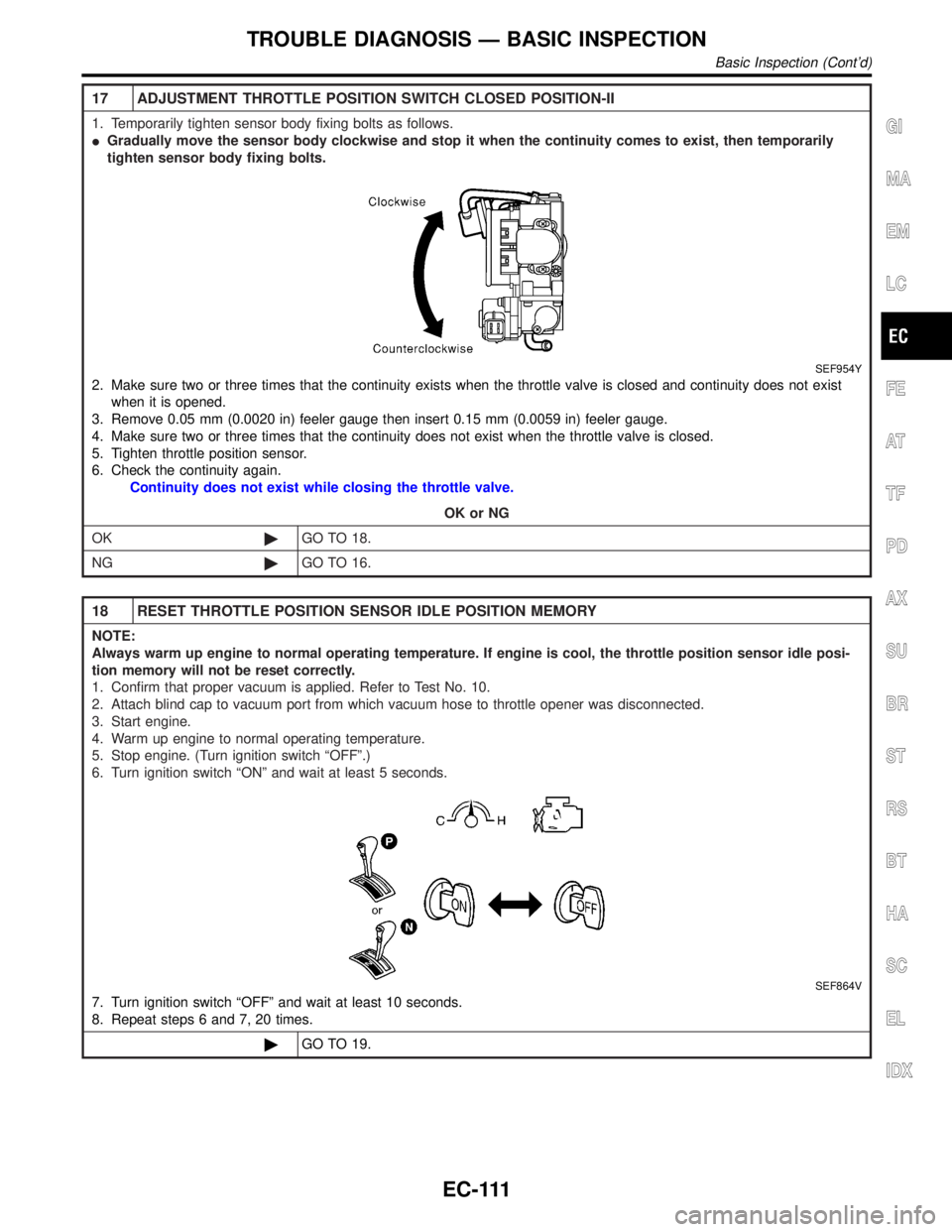

17 ADJUSTMENT THROTTLE POSITION SWITCH CLOSED POSITION-II

1. Temporarily tighten sensor body fixing bolts as follows.

IGradually move the sensor body clockwise and stop it when the continuity comes to exist, then temporarily

tighten sensor body fixing bolts.

SEF954Y

2. Make sure two or three times that the continuity exists when the throttle valve is closed and continuity does not exist

when it is opened.

3. Remove 0.05 mm (0.0020 in) feeler gauge then insert 0.15 mm (0.0059 in) feeler gauge.

4. Make sure two or three times that the continuity does not exist when the throttle valve is closed.

5. Tighten throttle position sensor.

6. Check the continuity again.

Continuity does not exist while closing the throttle valve.

OK or NG

OK©GO TO 18.

NG©GO TO 16.

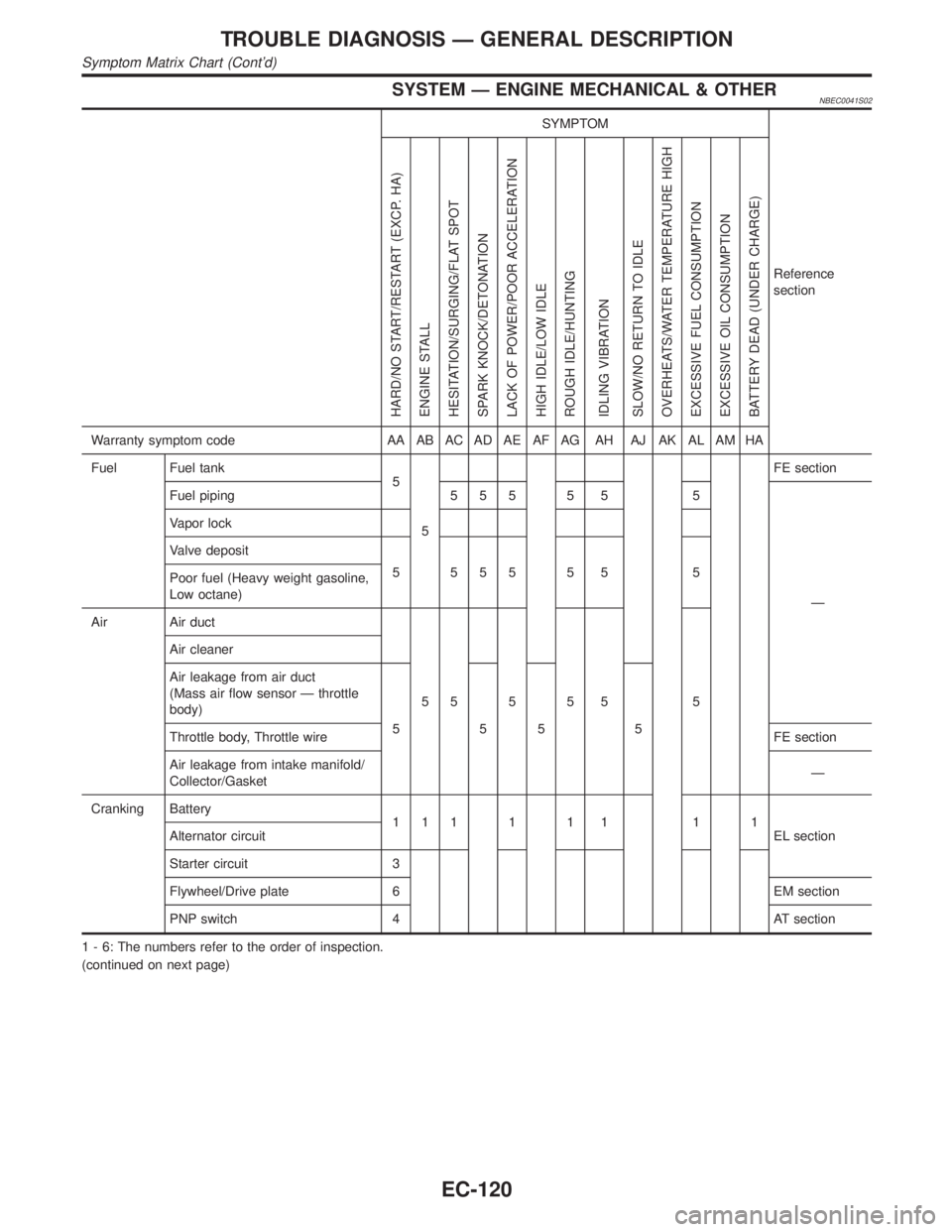

18 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

NOTE:

Always warm up engine to normal operating temperature. If engine is cool, the throttle position sensor idle posi-

tion memory will not be reset correctly.

1. Confirm that proper vacuum is applied. Refer to Test No. 10.

2. Attach blind cap to vacuum port from which vacuum hose to throttle opener was disconnected.

3. Start engine.

4. Warm up engine to normal operating temperature.

5. Stop engine. (Turn ignition switch ªOFFº.)

6. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V

7. Turn ignition switch ªOFFº and wait at least 10 seconds.

8. Repeat steps 6 and 7, 20 times.

©GO TO 19.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-111

Page 655 of 2395

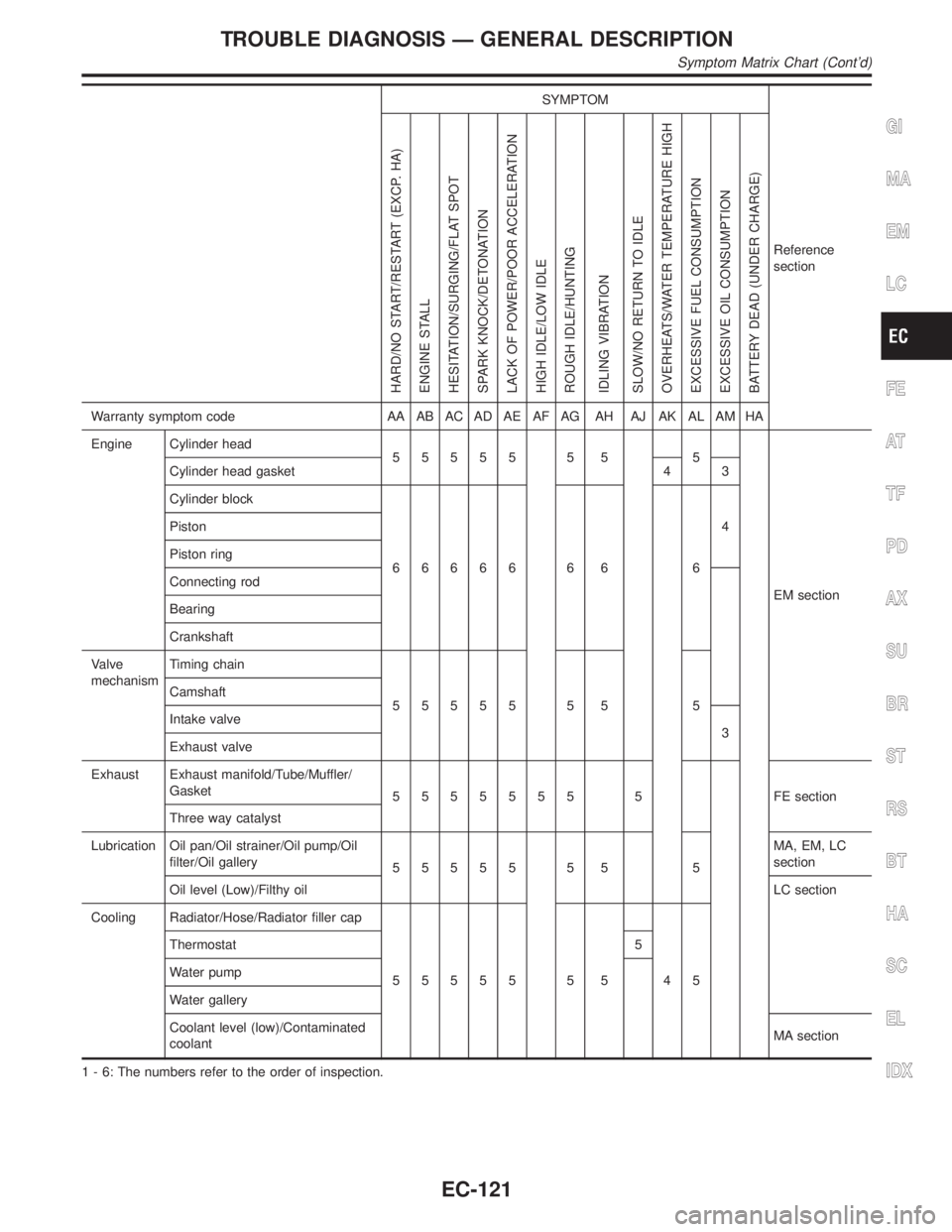

SYSTEM Ð ENGINE MECHANICAL & OTHERNBEC0041S02

SYMPTOM

Reference

section

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank

5

5FE section

Fuel piping 5 5 5 5 5 5

Ð Vapor lock

Valve deposit

5 555 5 5 5

Poor fuel (Heavy weight gasoline,

Low octane)

Air Air duct

55555 5 Air cleaner

Air leakage from air duct

(Mass air flow sensor Ð throttle

body)

555 5

Throttle body, Throttle wireFE section

Air leakage from intake manifold/

Collector/GasketÐ

Cranking Battery

111111 11

EL section Alternator circuit

Starter circuit 3

Flywheel/Drive plate 6 EM section

PNP switch 4 AT section

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-120

Page 656 of 2395

SYMPTOM

Reference

section

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Engine Cylinder head

55555 5 5 5

EM section Cylinder head gasket 4 3

Cylinder block

66666 6 6 64 Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Valve

mechanismTiming chain

55555 5 5 5 Camshaft

Intake valve

3

Exhaust valve

Exhaust Exhaust manifold/Tube/Muffler/

Gasket

5555555 5 FEsection

Three way catalyst

Lubrication Oil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery

55555 5 5 5MA, EM, LC

section

Oil level (Low)/Filthy oilLC section

Cooling Radiator/Hose/Radiator filler cap

55555 5 5 45 Thermostat 5

Water pump

Water gallery

Coolant level (low)/Contaminated

coolantMA section

1 - 6: The numbers refer to the order of inspection.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-121

Page 780 of 2395

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M32, F23

IFuse block (J/B) connector M10

I15A fuse

IHarness for open or short between heated oxygen sensor 1 (front) and fuse

©Repair harness or connectors.

3 CHECK HO2S1 (FRONT) OUTPUT CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal and HO2S1 terminal as follows.

Refer to Wiring Diagram.

MTBL0520

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK HEATED OXYGEN SENSOR 1 HEATER (FRONT)

Check resistance between HO2S1 (front) terminals as follows.

SEF969Y

CAUTION:

Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0135, P0155 HEATED OXYGEN SENSOR 1 HEATER (FRONT) (BANK

1)/(BANK 2)

Diagnostic Procedure (Cont'd)

EC-245

Page 826 of 2395

Diagnostic ProcedureNBEC0168

1 CHECK HO2S2 (REAR) POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check heated oxygen sensor harness 2 (rear) protector color.

SEF372Z

3. Disconnect corresponding heated oxygen sensor 2 (rear) harness connector.

SEF971Y

4. Turn ignition switch ªONº.

5. Check voltage between HO2S2 terminal 3 and ground.

SEF314X

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M32, F23

IFuse block (J/B) connector M10

I15A fuse

IHarness for open or short between heated oxygen sensor 2 (rear) and fuse

©Repair harness or connectors.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0141, P0161 HEATED OXYGEN SENSOR 2 HEATER (REAR) (BANK 1)/

(BANK 2)

Diagnostic Procedure

EC-291

Page 849 of 2395

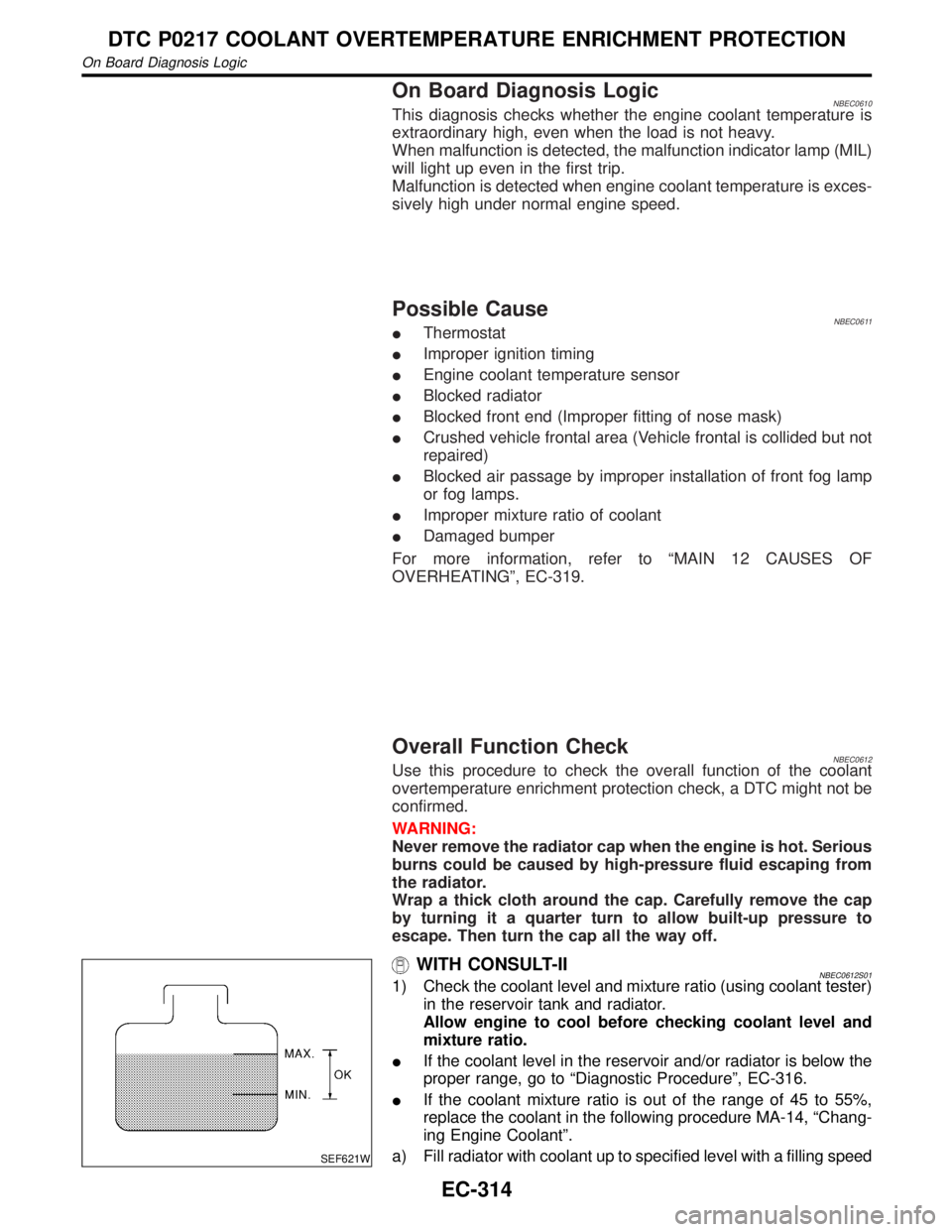

On Board Diagnosis LogicNBEC0610This diagnosis checks whether the engine coolant temperature is

extraordinary high, even when the load is not heavy.

When malfunction is detected, the malfunction indicator lamp (MIL)

will light up even in the first trip.

Malfunction is detected when engine coolant temperature is exces-

sively high under normal engine speed.

Possible CauseNBEC0611IThermostat

IImproper ignition timing

IEngine coolant temperature sensor

IBlocked radiator

IBlocked front end (Improper fitting of nose mask)

ICrushed vehicle frontal area (Vehicle frontal is collided but not

repaired)

IBlocked air passage by improper installation of front fog lamp

or fog lamps.

IImproper mixture ratio of coolant

IDamaged bumper

For more information, refer to ªMAIN 12 CAUSES OF

OVERHEATINGº, EC-319.

Overall Function CheckNBEC0612Use this procedure to check the overall function of the coolant

overtemperature enrichment protection check, a DTC might not be

confirmed.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could be caused by high-pressure fluid escaping from

the radiator.

Wrap a thick cloth around the cap. Carefully remove the cap

by turning it a quarter turn to allow built-up pressure to

escape. Then turn the cap all the way off.

SEF621W

WITH CONSULT-IINBEC0612S011) Check the coolant level and mixture ratio (using coolant tester)

in the reservoir tank and radiator.

Allow engine to cool before checking coolant level and

mixture ratio.

IIf the coolant level in the reservoir and/or radiator is below the

proper range, go to ªDiagnostic Procedureº, EC-316.

IIf the coolant mixture ratio is out of the range of 45 to 55%,

replace the coolant in the following procedure MA-14, ªChang-

ing Engine Coolantº.

a) Fill radiator with coolant up to specified level with a filling speed

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

On Board Diagnosis Logic

EC-314

Page 850 of 2395

of 2 liters per minute like pouring coolant from a kettle. Be sure

to use coolant with the proper mixture ratio. Refer to MA-12,

ªAnti-freeze Coolant Mixture Ratioº.

b) After refilling coolant, run engine to ensure that no water-flow

noise is emitted.

c) After checking or replacing coolant, go to step 3 below.

2) Ask the customer if engine coolant has been added. If it has

been added, go to ªDiagnostic Procedureº, EC-316. After

repair, go to the next step.

3) Start engine and let it idle.

4) Make sure that A/C switch is ªOFFº and air conditioner is not

operating. If NG, check air conditioner circuit. Refer to HA-30

or HA-35, ªTROUBLE DIAGNOSESº. After repair, go to the

next step.

5) Check for blocked coolant passage.

a) Warm up engine to normal operating temperature, then grasp

radiator upper hose and lower hose and make sure that cool-

ant flows.

If NG, go to ªDiagnostic Procedureº, EC-316. After repair, go

to the next step.

Be extremely careful not to touch any moving or adjacent

parts.

6) Check for blocked radiator air passage.

a) When market fog lamps have been installed, check for dam-

aged fans and clogging in the condenser and radiator.

b) Check the front end for clogging caused by insects or debris.

c) Check for improper fitting of front-end cover, damaged radia-

tor grille or bumper, damaged vehicle front.

If NG, take appropriate action and then go to the next step.

7) Check function of ECT sensor.

Refer to step 7 of ªDiagnostic Procedureº, EC-316.

If NG, replace ECT sensor and go to the next step.

8) Check ignition timing. Refer to basic inspection, EC-101.

Make sure that ignition timing is 15ɱ5É at idle.

If NG, adjust ignition timing and then recheck.

WITH GSTNBEC0612S021) Check the coolant level and mixture ratio (using coolant tester)

in the reservoir tank and radiator.

Allow engine to cool before checking coolant level and

mixture ratio.

IIf the coolant level in the reservoir and/or radiator is below the

proper range, and go to ªDiagnostic Procedureº, EC-316.

IIf the coolant mixture ratio is out of the range of 45 to 55%,

replace the coolant in the following procedure MA-14, ªChang-

ing Engine Coolantº.

a) Fill radiator with coolant up to specified level with a filling speed

of 2 liters per minute like pouring coolant from a kettle. Be sure

to use coolant with the proper mixture ratio. Refer to MA-12,

ªAnti-freeze Coolant Mixture Ratioº.

b) After refilling coolant, run engine to ensure that no water-flow

noise is emitted.

c) After checking or replacing coolant, go to step 3 below.

2) Ask the customer if engine coolant has been added. If it has

been added, go to ªDiagnostic Procedureº, EC-316. After

repair, go to the next step.

3) Start engine and let it idle.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

Overall Function Check (Cont'd)

EC-315

Page 851 of 2395

4) Make sure that A/C switch is ªOFFº and air conditioner is not

operating. If NG, check air conditioner circuit. Refer to HA-35

or HA-30, ªTROUBLE DIAGNOSESº. After repair, go to the

next step.

5) Check for blocked coolant passage.

a) Warm up engine to normal operating temperature, then grasp

radiator upper hose and lower hose and make sure that cool-

ant flows.

If NG, go to ªDiagnostic Procedureº, EC-316. After repair, go

to the next step.

Be extremely careful not to touch any moving or adjacent

parts.

6) Check for blocked radiator air passage.

a) When market fog lamps have been installed, check for dam-

aged fans and clogging in the condenser and radiator.

b) Check the front end for clogging caused by insects or debris.

c) Check for improper fitting of front-end cover, damaged radia-

tor grille or bumper, damaged vehicle front.

If NG, take appropriate action and then go to the next step.

7) Check function of ECT sensor.

Refer to step 6 of ªDiagnostic Procedureº, EC-316.

If NG, replace ECT sensor and go to the next step.

8) Check ignition timing. Refer to basic inspection, EC-101.

Make sure that ignition timing is 15ɱ5É at idle.

If NG, adjust ignition timing and then recheck.

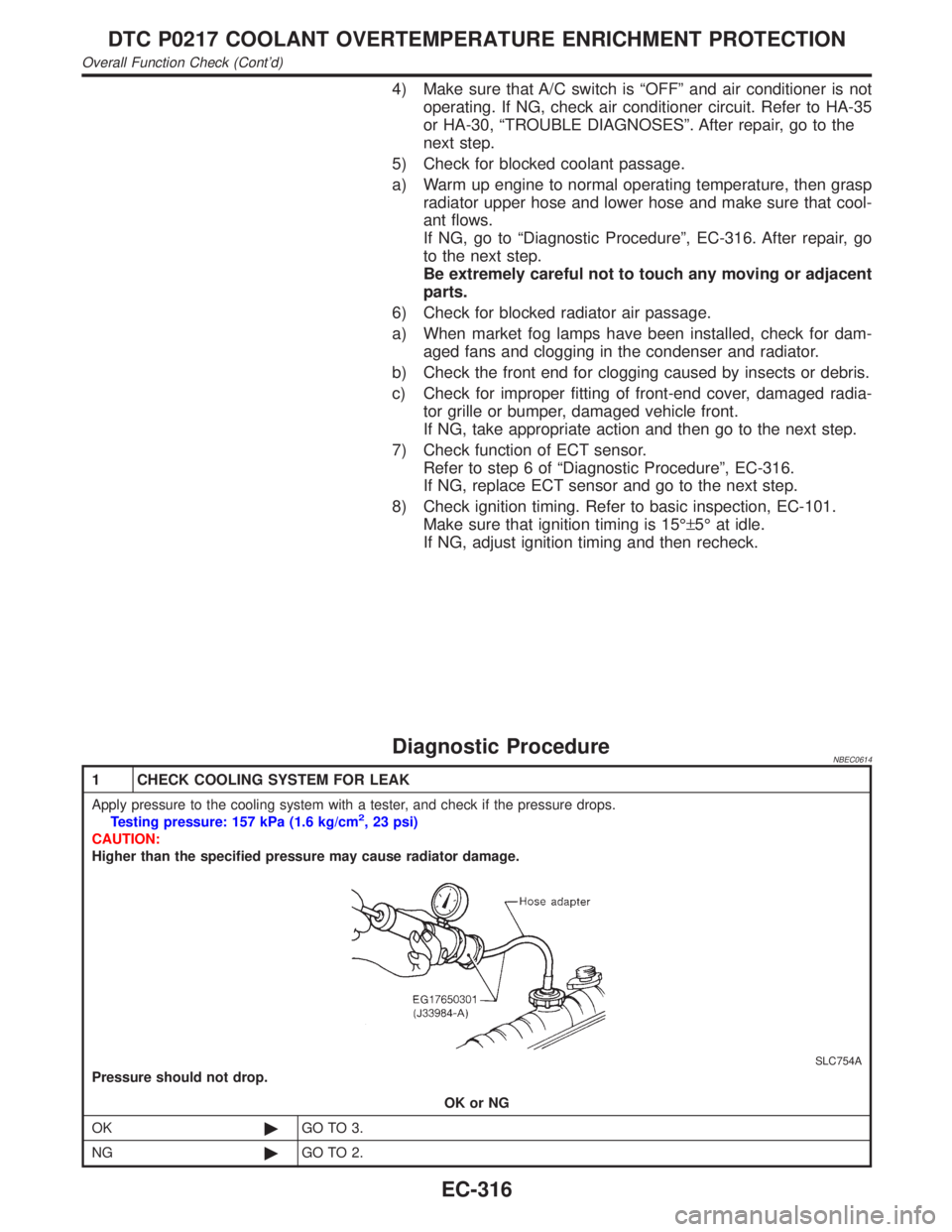

Diagnostic ProcedureNBEC0614

1 CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the pressure drops.

Testing pressure: 157 kPa (1.6 kg/cm2, 23 psi)

CAUTION:

Higher than the specified pressure may cause radiator damage.

SLC754A

Pressure should not drop.

OK or NG

OK©GO TO 3.

NG©GO TO 2.

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

Overall Function Check (Cont'd)

EC-316

Page 854 of 2395

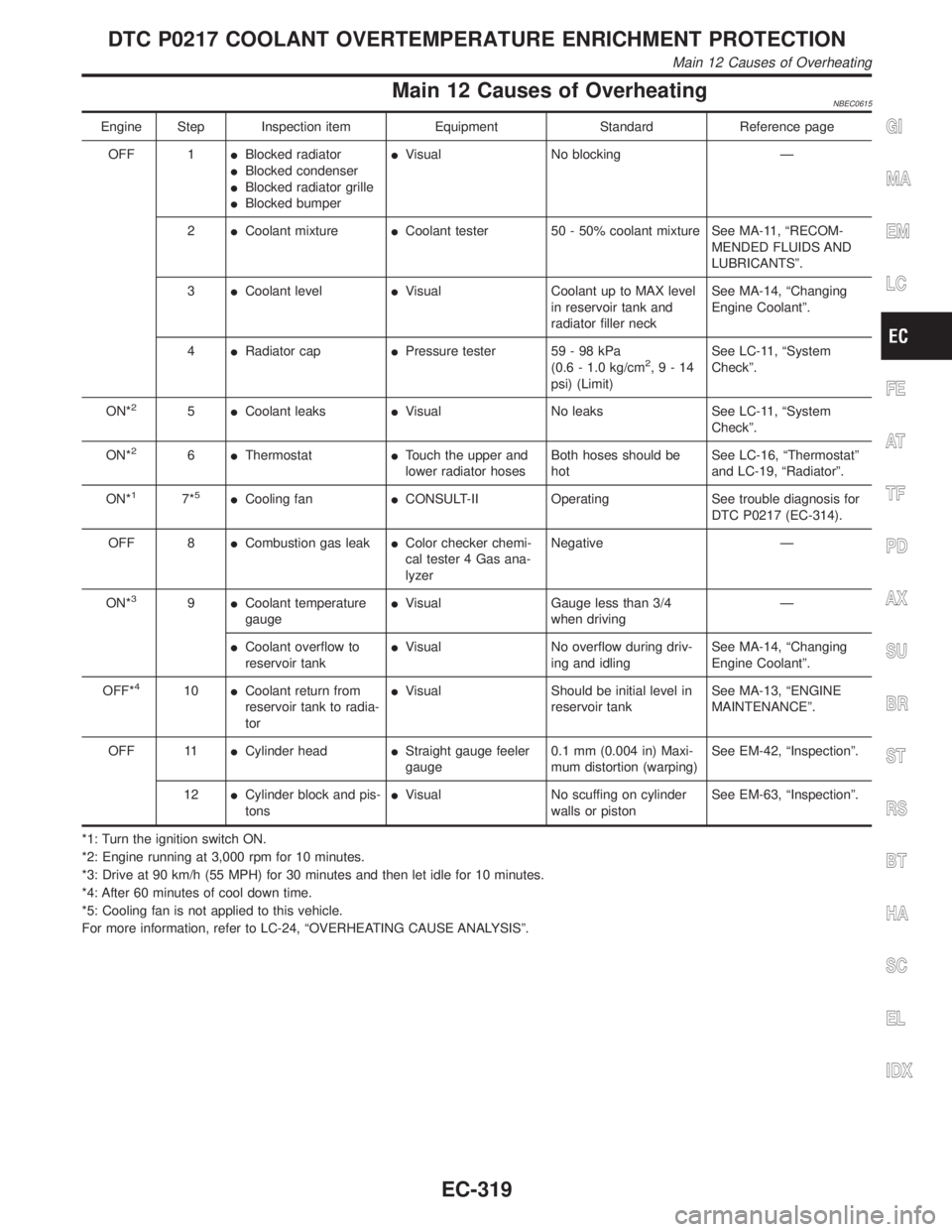

Main 12 Causes of OverheatingNBEC0615

Engine Step Inspection item Equipment Standard Reference page

OFF 1IBlocked radiator

IBlocked condenser

IBlocked radiator grille

IBlocked bumperIVisual No blocking Ð

2ICoolant mixtureICoolant tester 50 - 50% coolant mixture See MA-11, ªRECOM-

MENDED FLUIDS AND

LUBRICANTSº.

3ICoolant levelIVisual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee MA-14, ªChanging

Engine Coolantº.

4IRadiator capIPressure tester 59 - 98 kPa

(0.6 - 1.0 kg/cm

2,9-14

psi) (Limit)See LC-11, ªSystem

Checkº.

ON*

25ICoolant leaksIVisual No leaks See LC-11, ªSystem

Checkº.

ON*

26IThermostatITouch the upper and

lower radiator hosesBoth hoses should be

hotSee LC-16, ªThermostatº

and LC-19, ªRadiatorº.

ON*

17*5ICooling fanICONSULT-II Operating See trouble diagnosis for

DTC P0217 (EC-314).

OFF 8ICombustion gas leakIColor checker chemi-

cal tester 4 Gas ana-

lyzerNegative Ð

ON*

39ICoolant temperature

gaugeIVisual Gauge less than 3/4

when drivingÐ

ICoolant overflow to

reservoir tankIVisual No overflow during driv-

ing and idlingSee MA-14, ªChanging

Engine Coolantº.

OFF*

410ICoolant return from

reservoir tank to radia-

torIVisual Should be initial level in

reservoir tankSee MA-13, ªENGINE

MAINTENANCEº.

OFF 11ICylinder headIStraight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See EM-42, ªInspectionº.

12ICylinder block and pis-

tonsIVisual No scuffing on cylinder

walls or pistonSee EM-63, ªInspectionº.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

*5: Cooling fan is not applied to this vehicle.

For more information, refer to LC-24, ªOVERHEATING CAUSE ANALYSISº.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

Main 12 Causes of Overheating

EC-319

Page 863 of 2395

SEF332I

Component DescriptionNBEC0185The knock sensor is attached to the cylinder block. It senses

engine knocking using a piezoelectric element. A knocking vibration

from the cylinder block is sensed as vibrational pressure. This

pressure is converted into a voltage signal and sent to the ECM.

Freeze frame data will not be stored in the ECM for the knock

sensor. The MIL will not light for knock sensor malfunction.

The knock sensor has one trip detection logic.

ECM Terminals and Reference ValueNBEC0663Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

93 W Knock sensor[Engine is running]

IIdle speedApproximately 2.5V

On Board Diagnosis LogicNBEC0187Malfunction is detected when an excessively low or high voltage

from the knock sensor is sent to ECM.

Possible CauseNBEC0491IHarness or connectors

(The knock sensor circuit is open or shorted.)

IKnock sensor

SEF058Y

DTC Confirmation ProcedureNBEC0188NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10V at idle.

DTC P0325 KNOCK SENSOR (KS)

Component Description

EC-328