timing INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1676 of 2395

SEM439G

SEM440G

17. Install RH and LH rocker covers.

Rocker cover tightening procedure:

ITighten in numerical order as shown in the figure.

a. Tighten bolts 1 to 10 in that order to 6.9 to 8.8 N´m (0.7 to 0.9

kg-m, 61 to 78 in-lb).

b. Then tighten bolts 1 to 10 as indicated in figure to 6.9 to 8.8

N´m (0.7 to 0.9 kg-m, 61 to 78 in-lb).

18. Hang engine using the right and left side engine slingers with

a suitable hoist.

19. Set a suitable transmission jack under the suspension mem-

ber.

20. Remove right and left side engine mounting nuts.

21. Remove right and left side suspension member bolts.

22. Install aluminum oil pan. Refer to EM-18, ªInstallationº.

23. Set ring gear stopper using the mounting bolt hole.

IBe careful not to damage the signal plate teeth.

SEM417G

24. Install crankshaft pulley to crankshaft.

IAlign pointer with TDC mark on crankshaft pulley.

SEM531G

25. Install crankshaft pulley bolt.

ILubricate thread and seat surface of the bolt with new

engine oil.

a. Tighten to 39 to 49 N´m (4.0 to 5.0 kg-m, 29 to 36 ft-lb).

b. Put a paint mark on the crankshaft pulley.

SEM963E

c. Again tighten by turning 60É to 66É, about the angle from one

hexagon bolt head corner to another.

26. Install camshaft position sensor (PHASE), crankshaft position

sensors (REF)/(POS) and CVTC sensors.

27. Reinstall removed parts in the reverse order of removal.

IWhen installing fuel tube and intake manifold collectors, refer

to EM-12, ªTIGHTENING PROCEDURESº.

IAfter starting engine, keep idling for three minutes. Then

rev engine up to 3,000 rpm under no load to purge air from

the high-pressure chamber of the chain tensioners. The

engine may produce a rattling noise. This indicates that

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAIN

Installation (Cont'd)

EM-33

Page 1677 of 2395

air still remains in the chamber and is not a matter of

concern.

TIMING CHAIN

Installation (Cont'd)

EM-34

Page 1678 of 2395

SEM948E

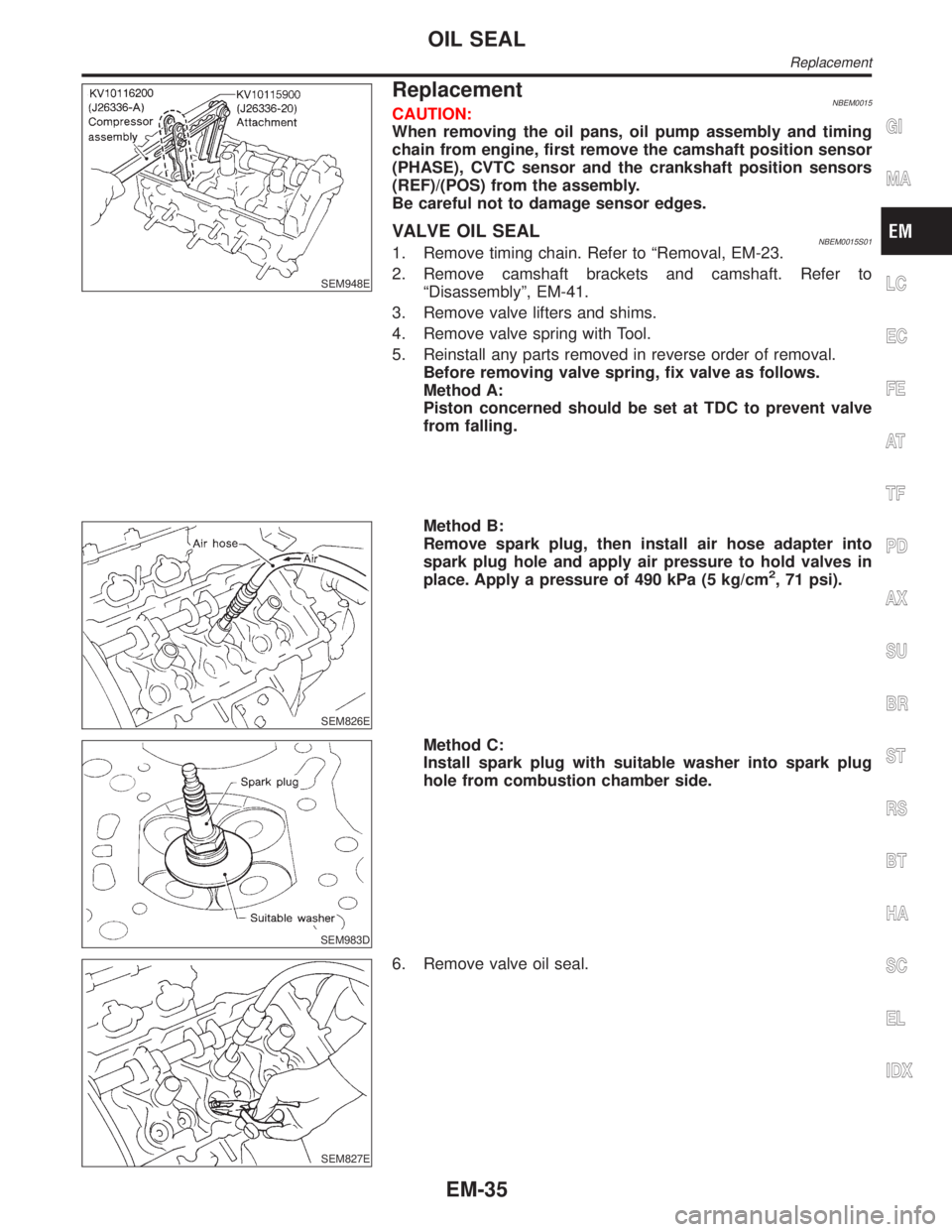

ReplacementNBEM0015CAUTION:

When removing the oil pans, oil pump assembly and timing

chain from engine, first remove the camshaft position sensor

(PHASE), CVTC sensor and the crankshaft position sensors

(REF)/(POS) from the assembly.

Be careful not to damage sensor edges.

VALVE OIL SEALNBEM0015S011. Remove timing chain. Refer to ªRemoval, EM-23.

2. Remove camshaft brackets and camshaft. Refer to

ªDisassemblyº, EM-41.

3. Remove valve lifters and shims.

4. Remove valve spring with Tool.

5. Reinstall any parts removed in reverse order of removal.

Before removing valve spring, fix valve as follows.

Method A:

Piston concerned should be set at TDC to prevent valve

from falling.

SEM826E

Method B:

Remove spark plug, then install air hose adapter into

spark plug hole and apply air pressure to hold valves in

place. Apply a pressure of 490 kPa (5 kg/cm

2, 71 psi).

SEM983D

Method C:

Install spark plug with suitable washer into spark plug

hole from combustion chamber side.

SEM827E

6. Remove valve oil seal.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OIL SEAL

Replacement

EM-35

Page 1682 of 2395

CAUTION:

IWhen installing camshafts, chain tensioners, oil seals, or

other sliding parts, lubricate contacting surfaces with new

engine oil.

IApply new engine oil to threads and seat surfaces when

installing cylinder head, camshaft sprocket, crankshaft

pulley, and camshaft bracket.

IAttach tags to valve lifters so as not to mix them up.

RemovalNBEM00171. Remove engine from vehicle. Refer to EM-57, ªRemoval and

Installationº.

2. Remove exhaust manifolds in reverse order of installation.

Refer to EM-13, ªExhaust Manifoldº.

3. Place engine on a work stand.

4. Remove aluminum oil pan. Refer to EM-15, ªRemovalº.

5. Remove timing chain. Refer to EM-23, ªRemovalº.

SEM964F

6. Remove intake manifold in reverse order of installation. Refer

to ªTIGHTENING PROCEDURESº, EM-12.

7. Remove water outlet.

SEM442G

8. Remove rear timing chain case bolts.

ILoosen in numerical order as shown in the figure.

SEM168FA

9. Remove rear timing chain case.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CYLINDER HEAD

Components (Cont'd)

EM-39

Page 1690 of 2395

SEM867E

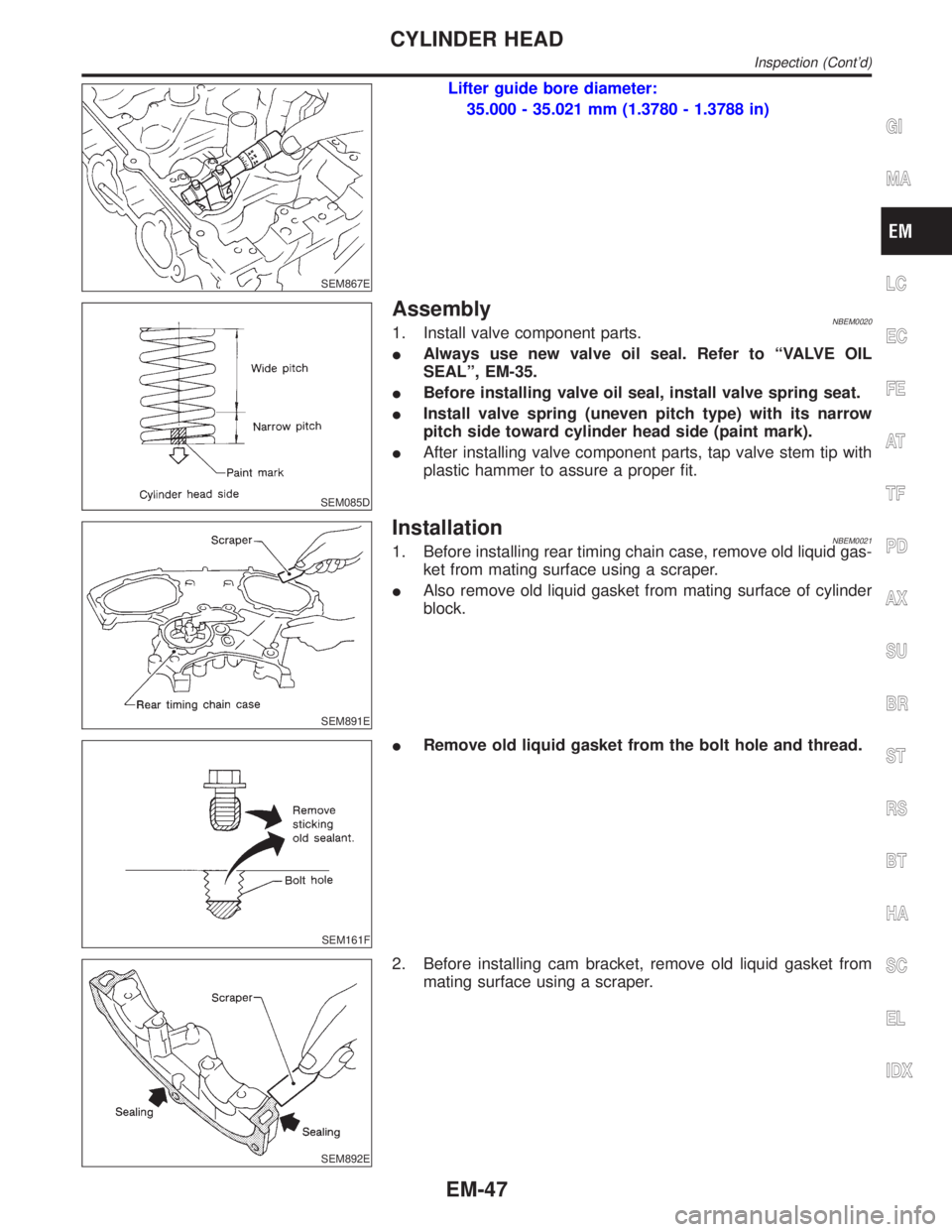

Lifter guide bore diameter:

35.000 - 35.021 mm (1.3780 - 1.3788 in)

SEM085D

AssemblyNBEM00201. Install valve component parts.

IAlways use new valve oil seal. Refer to ªVALVE OIL

SEALº, EM-35.

IBefore installing valve oil seal, install valve spring seat.

IInstall valve spring (uneven pitch type) with its narrow

pitch side toward cylinder head side (paint mark).

IAfter installing valve component parts, tap valve stem tip with

plastic hammer to assure a proper fit.

SEM891E

InstallationNBEM00211. Before installing rear timing chain case, remove old liquid gas-

ket from mating surface using a scraper.

IAlso remove old liquid gasket from mating surface of cylinder

block.

SEM161F

IRemove old liquid gasket from the bolt hole and thread.

SEM892E

2. Before installing cam bracket, remove old liquid gasket from

mating surface using a scraper.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CYLINDER HEAD

Inspection (Cont'd)

EM-47

Page 1695 of 2395

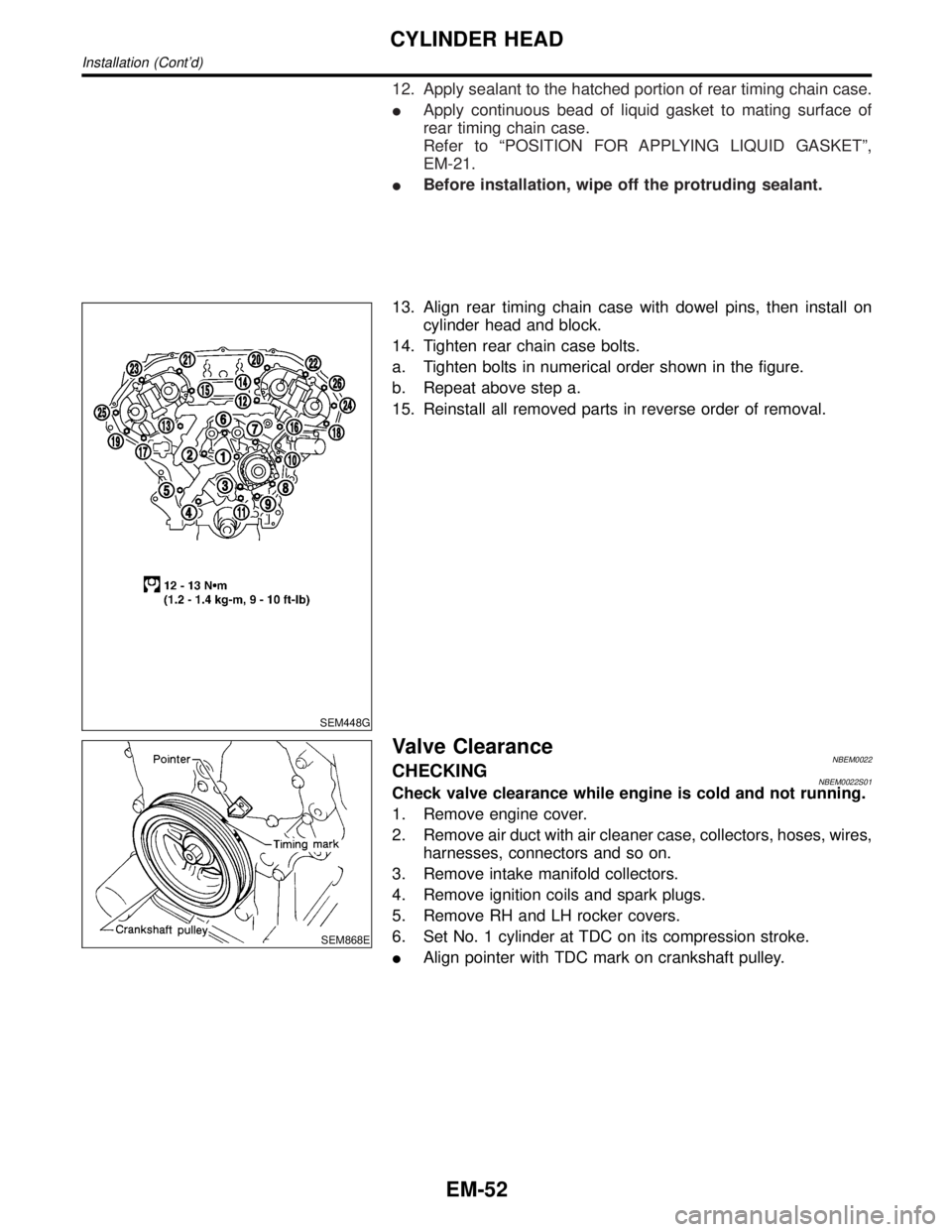

12. Apply sealant to the hatched portion of rear timing chain case.

IApply continuous bead of liquid gasket to mating surface of

rear timing chain case.

Refer to ªPOSITION FOR APPLYING LIQUID GASKETº,

EM-21.

IBefore installation, wipe off the protruding sealant.

SEM448G

13. Align rear timing chain case with dowel pins, then install on

cylinder head and block.

14. Tighten rear chain case bolts.

a. Tighten bolts in numerical order shown in the figure.

b. Repeat above step a.

15. Reinstall all removed parts in reverse order of removal.

SEM868E

Valve ClearanceNBEM0022CHECKINGNBEM0022S01Check valve clearance while engine is cold and not running.

1. Remove engine cover.

2. Remove air duct with air cleaner case, collectors, hoses, wires,

harnesses, connectors and so on.

3. Remove intake manifold collectors.

4. Remove ignition coils and spark plugs.

5. Remove RH and LH rocker covers.

6. Set No. 1 cylinder at TDC on its compression stroke.

IAlign pointer with TDC mark on crankshaft pulley.

CYLINDER HEAD

Installation (Cont'd)

EM-52

Page 1705 of 2395

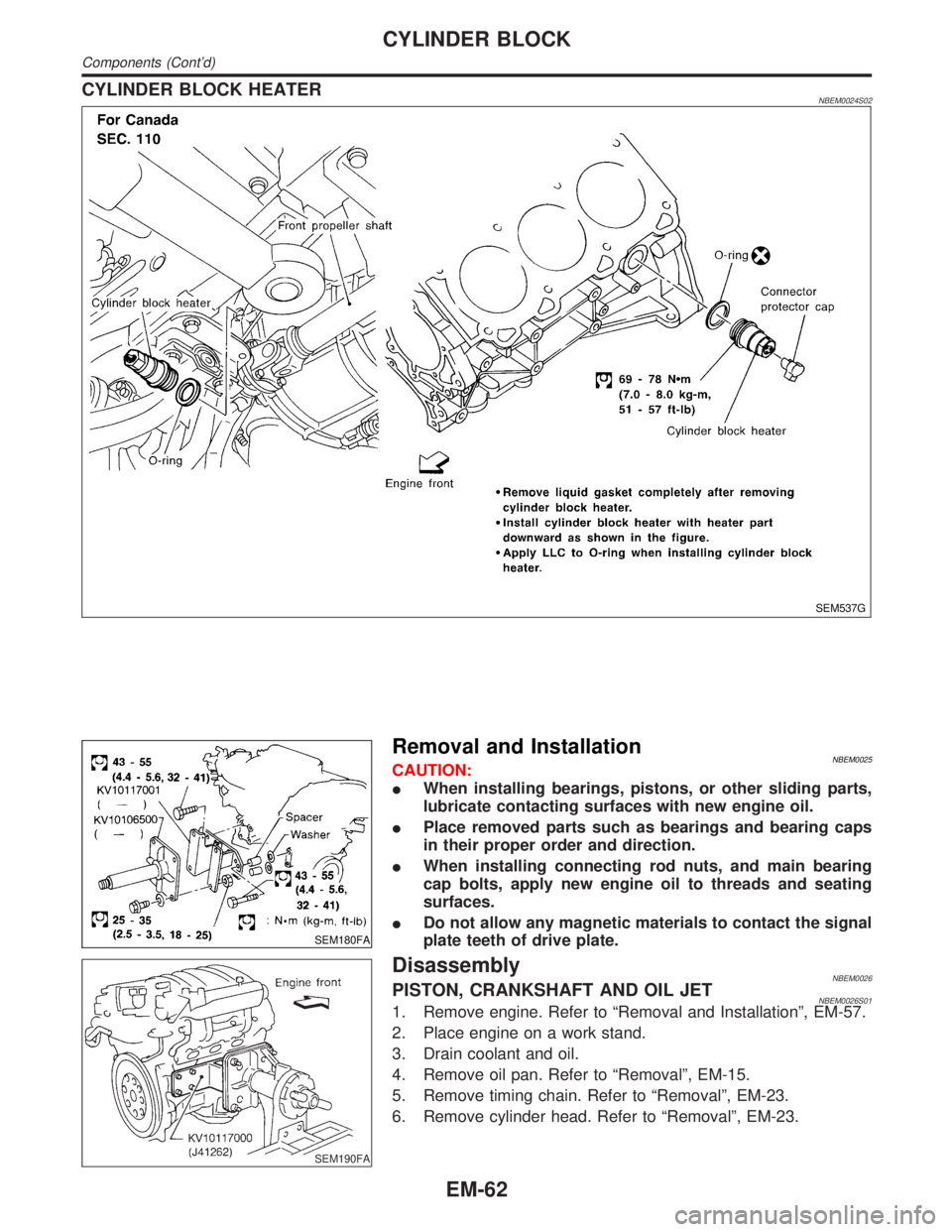

CYLINDER BLOCK HEATERNBEM0024S02

SEM537G

SEM180FA

Removal and InstallationNBEM0025CAUTION:

IWhen installing bearings, pistons, or other sliding parts,

lubricate contacting surfaces with new engine oil.

IPlace removed parts such as bearings and bearing caps

in their proper order and direction.

IWhen installing connecting rod nuts, and main bearing

cap bolts, apply new engine oil to threads and seating

surfaces.

IDo not allow any magnetic materials to contact the signal

plate teeth of drive plate.

SEM190FA

DisassemblyNBEM0026PISTON, CRANKSHAFT AND OIL JETNBEM0026S011. Remove engine. Refer to ªRemoval and Installationº, EM-57.

2. Place engine on a work stand.

3. Drain coolant and oil.

4. Remove oil pan. Refer to ªRemovalº, EM-15.

5. Remove timing chain. Refer to ªRemovalº, EM-23.

6. Remove cylinder head. Refer to ªRemovalº, EM-23.

CYLINDER BLOCK

Components (Cont'd)

EM-62

Page 1724 of 2395

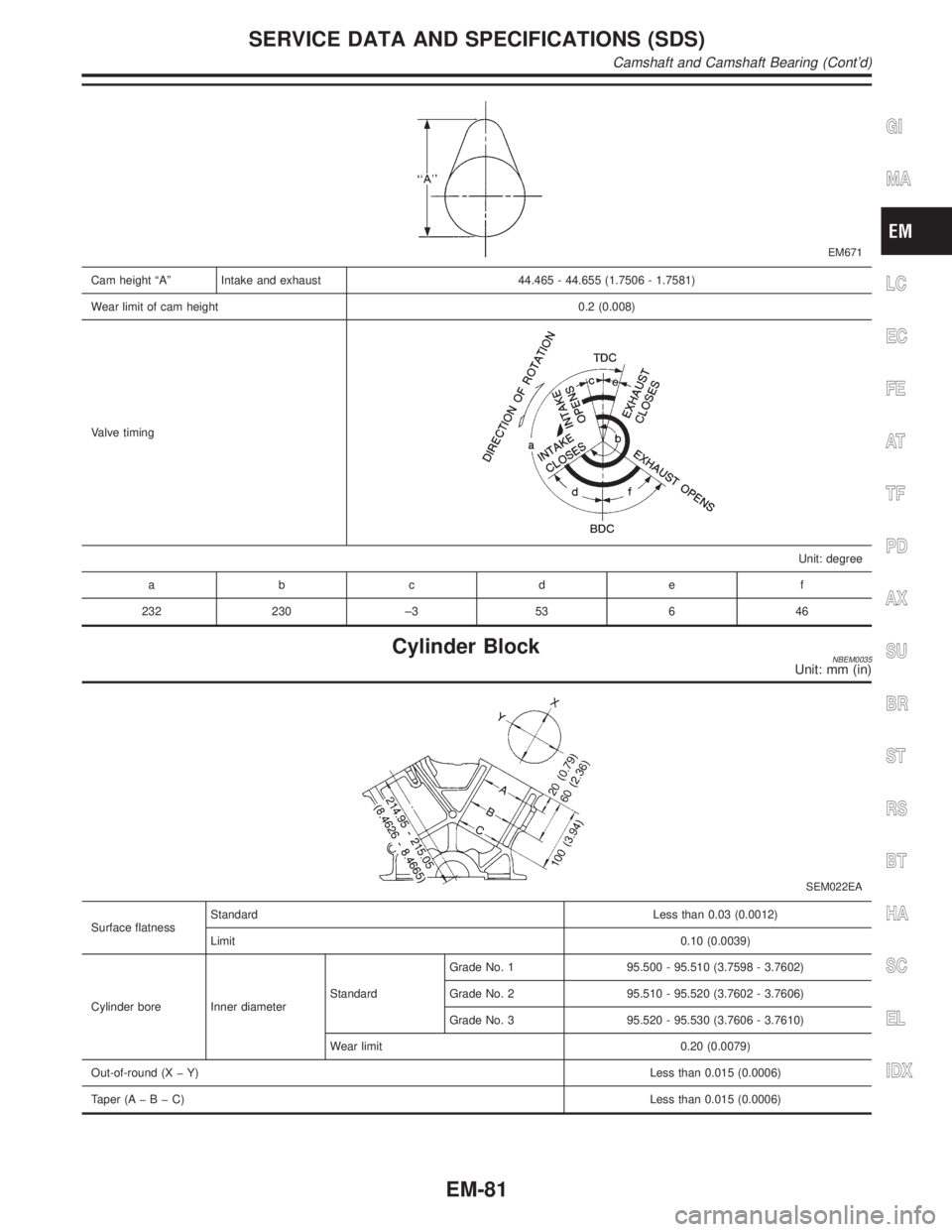

EM671

Cam height ªAº Intake and exhaust 44.465 - 44.655 (1.7506 - 1.7581)

Wear limit of cam height 0.2 (0.008)

Valve timing

Unit: degree

abcde f

232 230 ±3 53 6 46

Cylinder BlockNBEM0035Unit: mm (in)

SEM022EA

Surface flatnessStandardLess than 0.03 (0.0012)

Limit0.10 (0.0039)

Cylinder bore Inner diameterStandardGrade No. 1 95.500 - 95.510 (3.7598 - 3.7602)

Grade No. 2 95.510 - 95.520 (3.7602 - 3.7606)

Grade No. 3 95.520 - 95.530 (3.7606 - 3.7610)

Wear limit 0.20 (0.0079)

Out-of-round (X þ Y)Less than 0.015 (0.0006)

Taper (AþBþC)Less than 0.015 (0.0006)

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Camshaft and Camshaft Bearing (Cont'd)

EM-81

Page 1745 of 2395

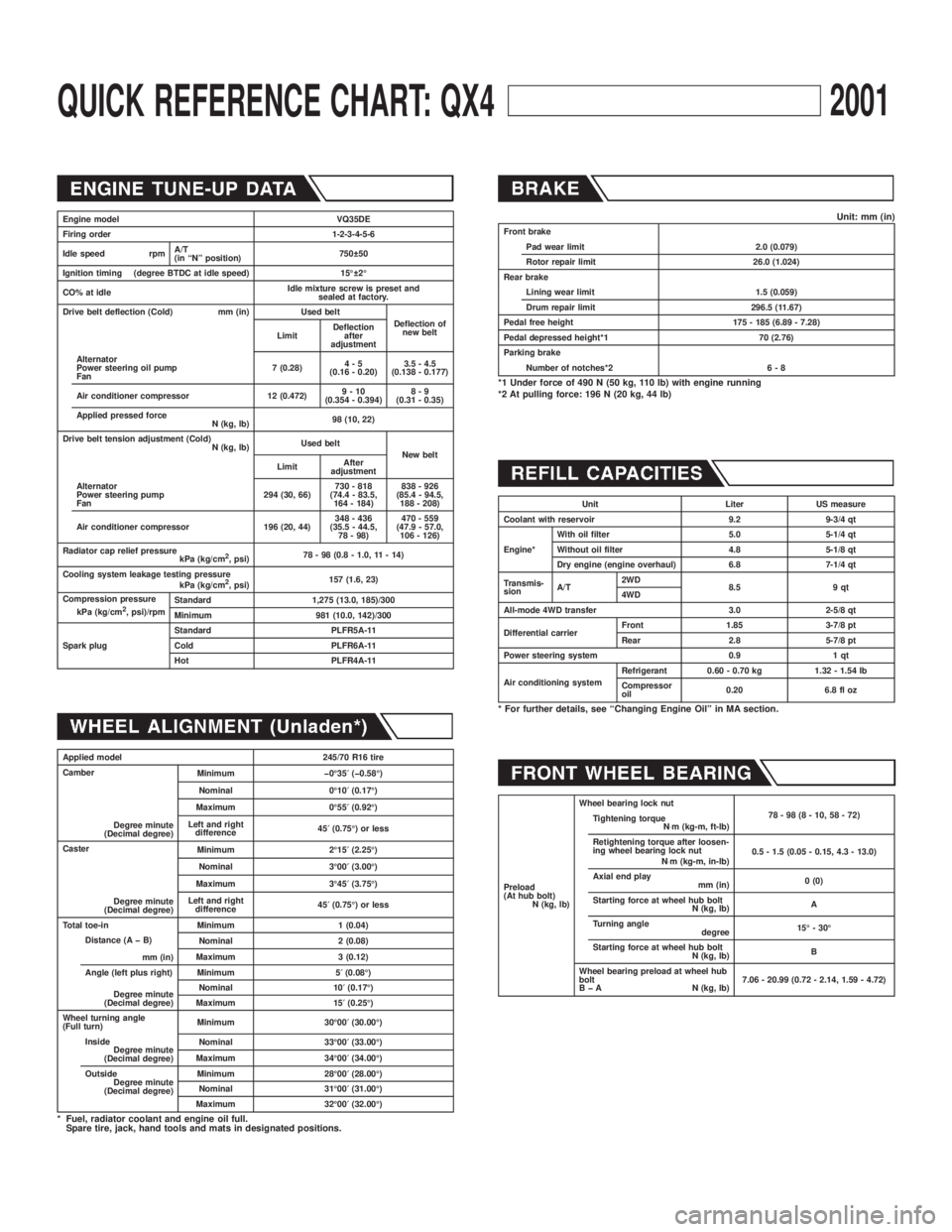

QUICK REFERENCE CHART: QX42001

Engine model VQ35DE

Firing order 1-2-3-4-5-6

Idle speed rpmA/T

(in ªNº position)750 50

Ignition timing (degree BTDC at idle speed) 15É 2É

CO% at idleIdle mixture screw is preset and

sealed at factory.

Drive belt deflection (Cold) mm (in) Used belt

Deflection of

new belt

LimitDeflection

after

adjustment

Alternator

Power steering oil pump

Fan7 (0.28)4-5

(0.16 - 0.20)3.5 - 4.5

(0.138 - 0.177)

Air conditioner compressor 12 (0.472)9-10

(0.354 - 0.394)8-9

(0.31 - 0.35)

Applied pressed force

N (kg, lb)98 (10, 22)

Drive belt tension adjustment (Cold)

N (kg, lb)Used belt

New belt

LimitAfter

adjustment

Alternator

Power steering pump

Fan294 (30, 66)730 - 818

(74.4 - 83.5,

164 - 184)838 - 926

(85.4 - 94.5,

188 - 208)

Air conditioner compressor 196 (20, 44)348 - 436

(35.5 - 44.5,

78 - 98)470 - 559

(47.9 - 57.0,

106 - 126)

Radiator cap relief pressure

kPa (kg/cm

2, psi)78 - 98 (0.8 - 1.0, 11 - 14)

Cooling system leakage testing pressure

kPa (kg/cm

2, psi)157 (1.6, 23)

Compression pressure

kPa (kg/cm

2, psi)/rpmStandard 1,275 (13.0, 185)/300

Minimum 981 (10.0, 142)/300

Spark plugStandard PLFR5A-11

Cold PLFR6A-11

Hot PLFR4A-11

Applied model 245/70 R16 tire

Camber

Degree minute

(Decimal degree)Minimum þ0É35¢(þ0.58É)

Nominal 0É10¢(0.17É)

Maximum 0É55¢(0.92É)

Left and right

difference45¢(0.75É) or less

Caster

Degree minute

(Decimal degree)Minimum 2É15¢(2.25É)

Nominal 3É00¢(3.00É)

Maximum 3É45¢(3.75É)

Left and right

difference45¢(0.75É) or less

Total toe-in Minimum 1 (0.04)

Distance (A þ B)

mm (in)Nominal 2 (0.08)

Maximum 3 (0.12)

Angle (left plus right)

Degree minute

(Decimal degree)Minimum 5¢(0.08É)

Nominal 10¢(0.17É)

Maximum 15¢(0.25É)

Wheel turning angle

(Full turn)Minimum 30É00¢(30.00É)

Inside

Degree minute

(Decimal degree)Nominal 33É00¢(33.00É)

Maximum 34É00¢(34.00É)

Outside

Degree minute

(Decimal degree)Minimum 28É00¢(28.00É)

Nominal 31É00¢(31.00É)

Maximum 32É00¢(32.00É)

* Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in designated positions.

Unit: mm (in)Front brake

Pad wear limit 2.0 (0.079)

Rotor repair limit 26.0 (1.024)

Rear brake

Lining wear limit 1.5 (0.059)

Drum repair limit 296.5 (11.67)

Pedal free height 175 - 185 (6.89 - 7.28)

Pedal depressed height*1 70 (2.76)

Parking brake

Number of notches*2 6 - 8

*1 Under force of 490 N (50 kg, 110 lb) with engine running

*2 At pulling force: 196 N (20 kg, 44 lb)

Unit Liter US measure

Coolant with reservoir 9.2 9-3/4 qt

Engine*With oil filter 5.0 5-1/4 qt

Without oil filter 4.8 5-1/8 qt

Dry engine (engine overhaul) 6.8 7-1/4 qt

Transmis-

sionA/T2WD

8.5 9 qt

4WD

All-mode 4WD transfer 3.0 2-5/8 qt

Differential carrierFront 1.85 3-7/8 pt

Rear 2.8 5-7/8 pt

Power steering system 0.9 1 qt

Air conditioning systemRefrigerant 0.60 - 0.70 kg 1.32 - 1.54 lb

Compressor

oil0.20 6.8 fl oz

* For further details, see ªChanging Engine Oilº in MA section.

Preload

(At hub bolt)

N (kg, lb)Wheel bearing lock nut

78-98(8-10,58-72)

Tightening torque

N×m (kg-m, ft-lb)

Retightening torque after loosen-

ing wheel bearing lock nut

N×m (kg-m, in-lb)0.5 - 1.5 (0.05 - 0.15, 4.3 - 13.0)

Axial end play

mm (in)0 (0)

Starting force at wheel hub bolt

N (kg, lb)A

Turning angle

degree15É - 30É

Starting force at wheel hub bolt

N (kg, lb)B

Wheel bearing preload at wheel hub

bolt

B þ A N (kg, lb)7.06 - 20.99 (0.72 - 2.14, 1.59 - 4.72)

Page 1796 of 2395

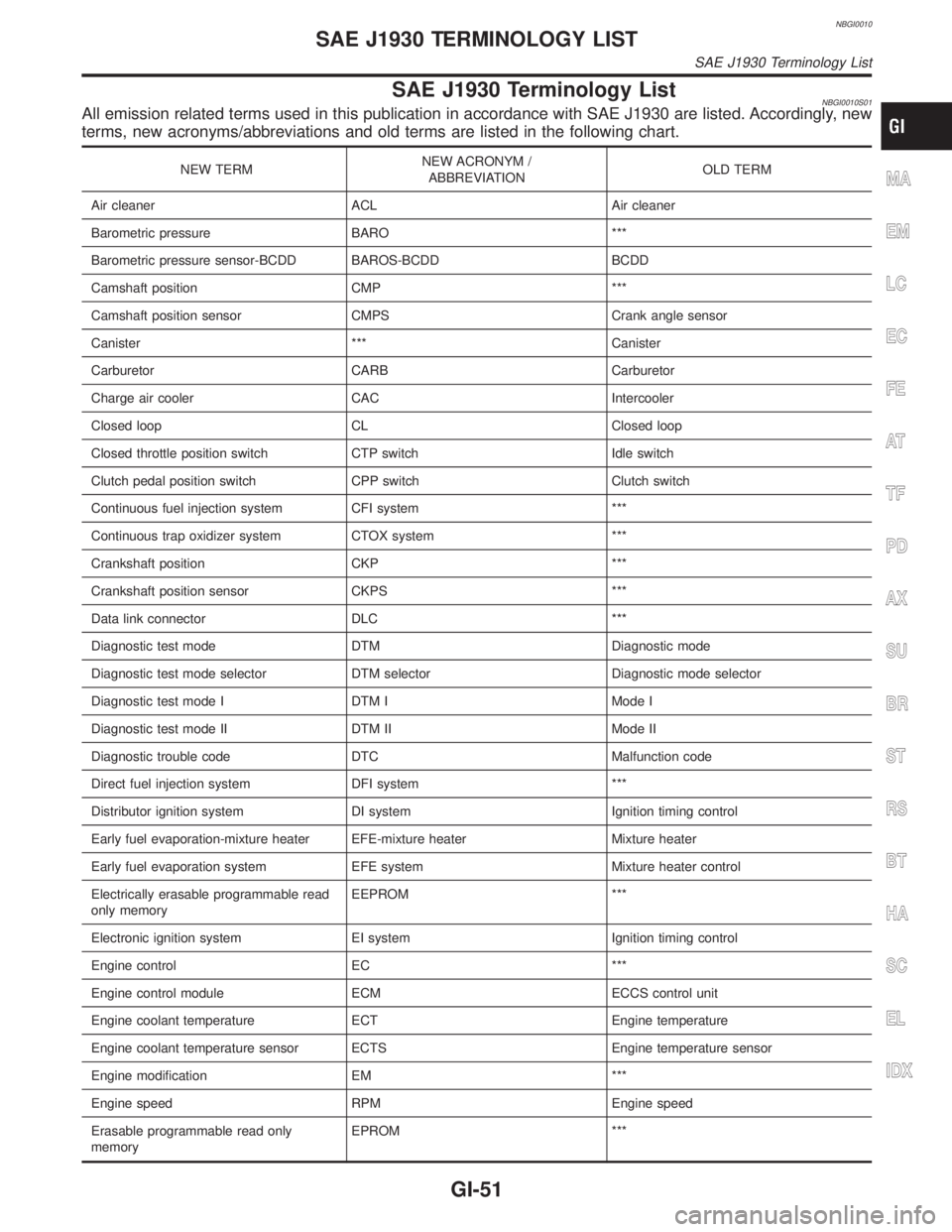

NBGI0010

SAE J1930 Terminology ListNBGI0010S01All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memoryEEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only

memoryEPROM ***MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SAE J1930 TERMINOLOGY LIST

SAE J1930 Terminology List

GI-51