INSTALLATION INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1531 of 2395

DIAGNOSTIC PROCEDURE 7=NBEL0224S11Self-diagnostic results:

ªLOCK MODEº displayed on CONSULT-II screen

1 CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm SELF-DIAGNOSTIC RESULTS ªLOCK MODEº is displayed on CONSULT-II screen.

SEL371X

Is CONSULT-II screen displayed as above?

Ye s©GO TO 2.

No©GO TO SYMPTOM MATRIX CHART 1.

2 ESCAPE FROM LOCK MODE

1. Turn ignition switch OFF.

2. Turn ignition switch ON with registered key. (Do not start engine.) Wait 5 seconds.

3. Return the key to OFF position.

4. Repeat steps 2 and 3 twice (total of three cycles).

5. Start the engine.

Does engine start?

Ye s©System is OK.

(Now system is escaped from ªLOCK MODEº.)

No©GO TO 3.

3 CHECK IMMU ILLUSTRATION

Check IMMU installation. Refer to ªHow to Replace IMMUº in EL-347.

OK or NG

OK©GO TO 4.

NG©Reinstall IMMU correctly.

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM Ð NATS)

Trouble Diagnoses (Cont'd)

EL-346

Page 1644 of 2395

ENGINE MECHANICAL

SECTION

EM

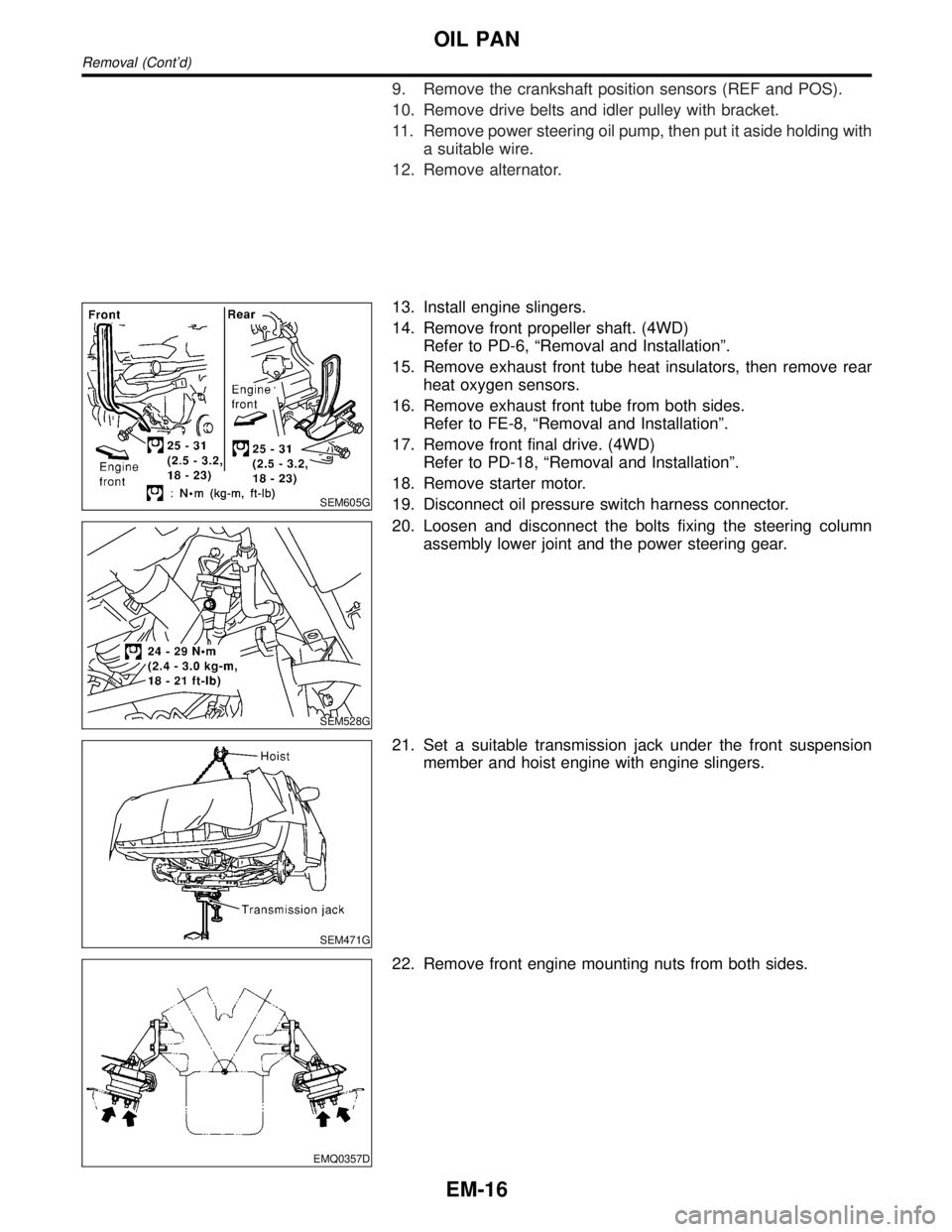

CONTENTS

PRECAUTIONS...............................................................3

Parts Requiring Angular Tightening .............................3

Liquid Gasket Application Procedure ..........................3

PREPARATION...............................................................4

Special Service Tools ..................................................4

Commercial Service Tools ...........................................6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................8

NVH Troubleshooting - Engine Noise .........................9

OUTER COMPONENT PARTS.....................................10

Removal and Installation ...........................................10

TIGHTENING PROCEDURES...................................12

MEASUREMENT OF COMPRESSION PRESSURE....14

OIL PAN.........................................................................15

Components...............................................................15

Removal .....................................................................15

Installation ..................................................................18

TIMING CHAIN..............................................................20

Components...............................................................20

POSITION FOR APPLYING LIQUID GASKET............21

Removal .....................................................................23

Inspection...................................................................29

Installation ..................................................................29

OIL SEAL.......................................................................35

Replacement ..............................................................35

VALVE OIL SEAL.....................................................35

OIL SEAL INSTALLATION DIRECTION.....................36

FRONT OIL SEAL....................................................36

REAR OIL SEAL......................................................36

CYLINDER HEAD..........................................................38

Components...............................................................38

Removal .....................................................................39

Disassembly...............................................................41

Inspection...................................................................42

CYLINDER HEAD DISTORTION...............................42

CAMSHAFT VISUAL CHECK....................................42

CAMSHAFT RUNOUT..............................................42

CAMSHAFT CAM HEIGHT.......................................42

CAMSHAFT JOURNAL CLEARANCE........................42

CAMSHAFT END PLAY............................................43

CAMSHAFT SPROCKET RUNOUT...........................43

VALVE GUIDE CLEARANCE....................................43

VALVE GUIDE REPLACEMENT................................44

VALVE SEATS.........................................................45

REPLACING VALVE SEAT FOR SERVICE PARTS....45

VALVE DIMENSIONS...............................................46

VALVE SPRING.......................................................46

VALVE LIFTER........................................................46

Assembly ...................................................................47

Installation ..................................................................47

Valve Clearance.........................................................52

CHECKING.............................................................52

ADJUSTING............................................................54

ENGINE ASSEMBLY.....................................................57

Removal and Installation ...........................................57

REMOVAL...............................................................58

INSTALLATION........................................................60

CYLINDER BLOCK.......................................................61

Components...............................................................61

CYLINDER BLOCK HEATER....................................62

Removal and Installation ...........................................62

Disassembly...............................................................62

PISTON, CRANKSHAFT AND OIL JET......................62

Inspection...................................................................63

PISTON AND PISTON PIN CLEARANCE..................63

PISTON RING SIDE CLEARANCE............................64

PISTON RING END GAP..........................................64

CONNECTING ROD BEND AND TORSION...............65

CYLINDER BLOCK DISTORTION AND WEAR...........65

PISTON-TO-BORE CLEARANCE..............................66

CRANKSHAFT.........................................................67

BEARING CLEARANCE...........................................67

CONNECTING ROD BUSHING CLEARANCE

(SMALL END)

..........................................................70

DRIVE PLATE RUNOUT..........................................70

Assembly ...................................................................71

PISTON..................................................................71

OIL JET..................................................................71

CRANKSHAFT.........................................................71

REPLACEMENT OF PILOT CONVERTER.................74

DRIVE PLATE.........................................................74

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 1653 of 2395

Removal and InstallationNBEM0006

SEM483G

1. Intake manifold collector support

2. Lower intake manifold collector

3. Fuel damper and fuel feed hose

assembly

4. Injector

5. Fuel tube assembly6. Fuel pressure regulator

7. Ignition coil with power transistor

8. Upper intake manifold collector

9. Intake manifold

10. Throttle body11. IACV-AAC valve

12. EVAP canister purge volume con-

trol solenoid valve

13. Swirl control valve

14. Variable induction air control valve

control actuator

OUTER COMPONENT PARTS

Removal and Installation

EM-10

Page 1654 of 2395

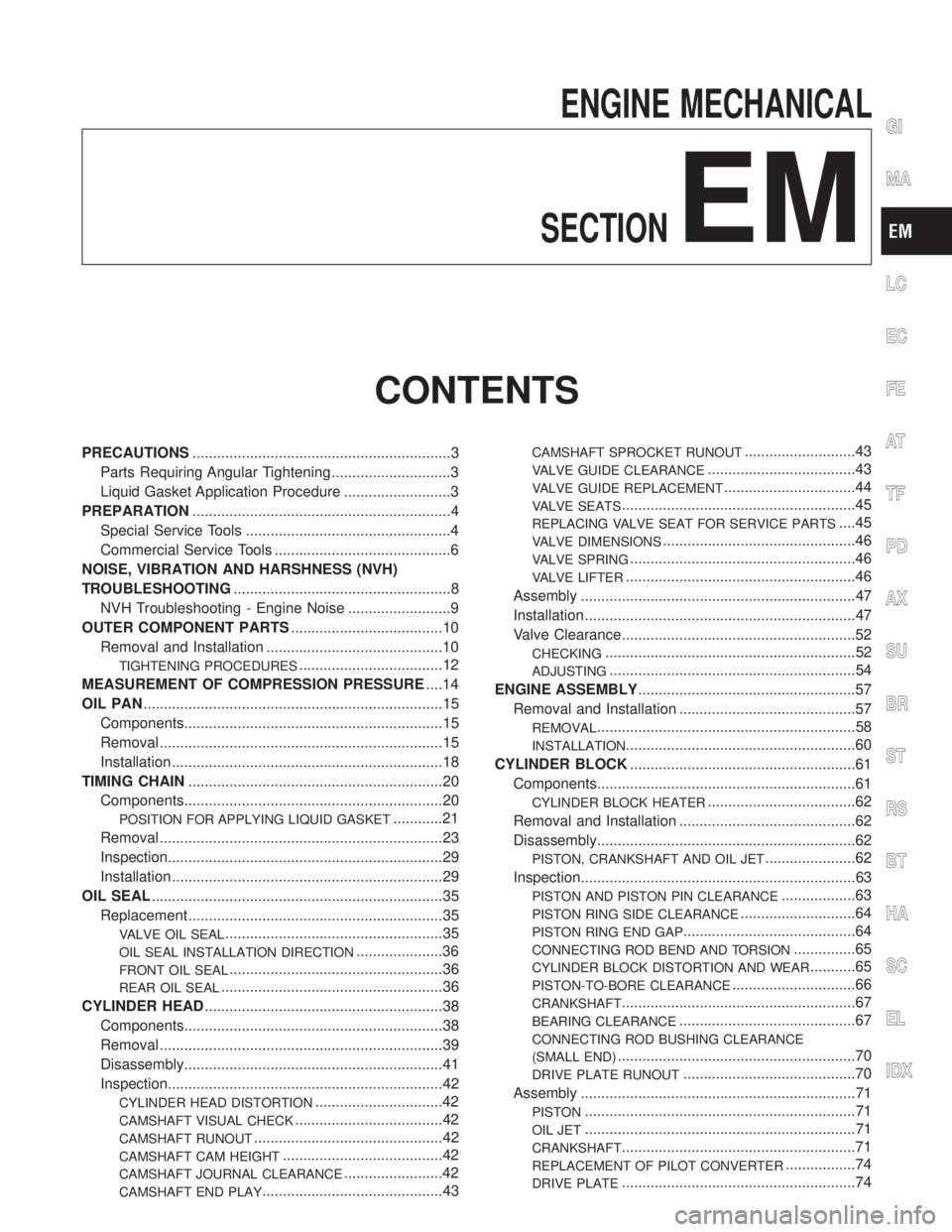

SEM484GA

1. Heated oxygen sensor 1 (front)

(bank 1)

2. Heated oxygen sensor 1 (front)

(bank 2)

3. TWC (manifold)4. Thermostat with water inlet

5. Exhaust manifold

6. Thermal transmitter

7. Engine coolant temperature8. Water control valve

9. Water outlet housing

10. Cylinder block water outlet

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OUTER COMPONENT PARTS

Removal and Installation (Cont'd)

EM-11

Page 1655 of 2395

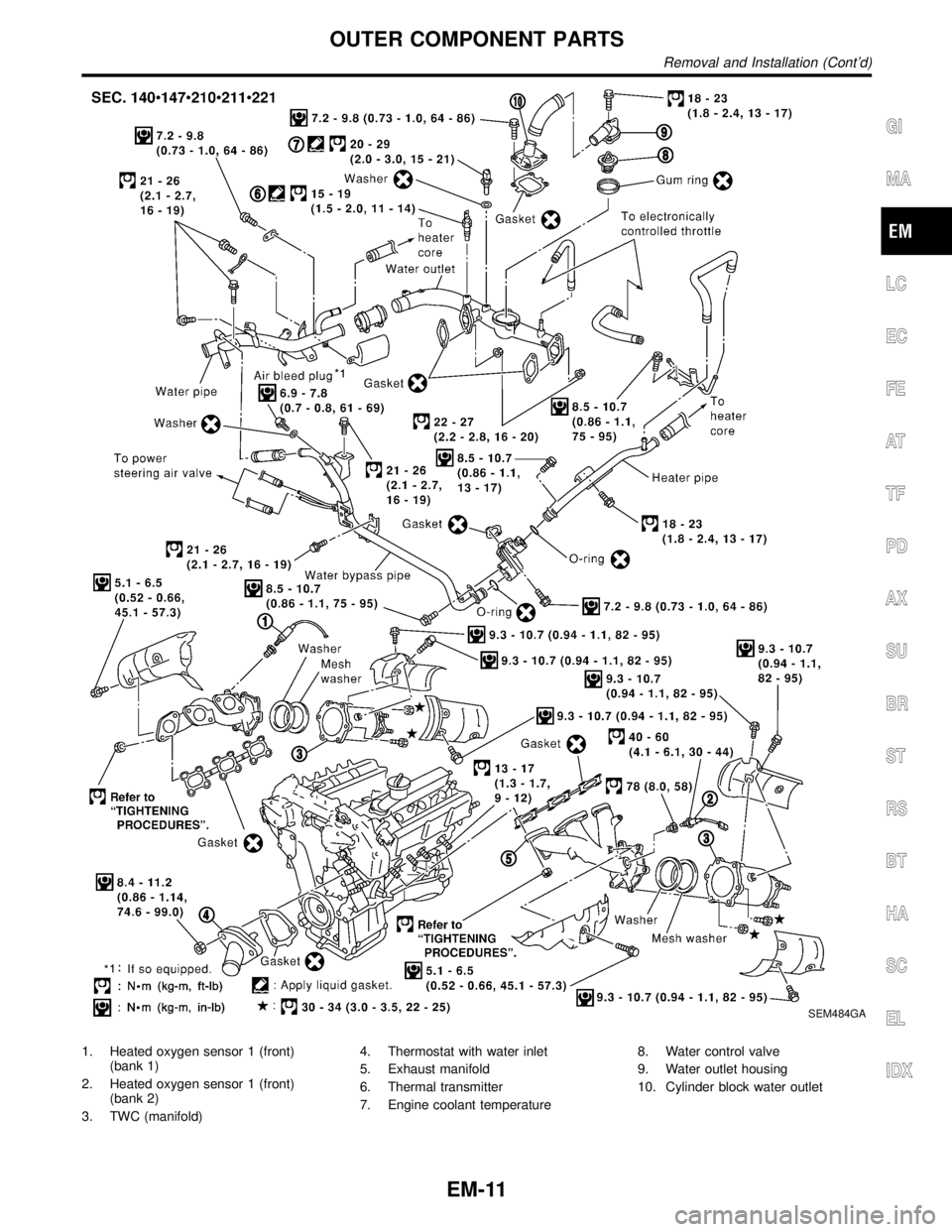

SEM950F

TIGHTENING PROCEDURESNBEM0006S01Intake ManifoldNBEM0006S0101ITighten in numerical order shown in the figure.

1. Tighten all bolts and nuts to 5 to 10 N´m (0.5 to 1.0 kg-m, 44

to 86 in-lb).

2. Finally tighten all bolts and nuts to 26 to 31 N´m (2.7 to 3.2

kg-m, 20 to 23 ft-lb).

ITighten all bolts and nuts to the final torque, evenly dividing the

tightening into at least five steps.

SEM473G

Fuel TubeNBEM0006S0102ITighten in numerical order shown in the figure.

1. Tighten all bolts to 9.3 to 10.8 N´m (0.95 to 1.1 kg-m, 83 to 95

in-lb).

2. Then tighten all bolts to 21 to 26 N´m (2.1 to 2.7 kg-m, 15 to

20 ft-lb).

SEM474G

Fuel Pressure RegulatorNBEM0006S0103Tighten fuel pressure regulator to 2.9 to 3.8 N´m (0.3 to 0.39 kg-m,

26.0 to 33.9 in-lb).

ITighten screws evenly several times to have the fuel pres-

sure regulator tightened at the specified torque.

IAlways replace O-ring with new ones.

ILubricate O-ring with new engine oil.

SEM475G

Throttle BodyNBEM0006S0105ITighten in numerical order shown in the figure.

1. Tighten all bolts to 8.8 to 10.8 N´m (0.9 to 1.1 kg-m, 79 to 95

in-lb).

2. Then tighten all bolts to 18 to 21 N´m (1.8 to 2.2 kg-m, 13 to

15 ft-lb).

SEM476G

Upper Intake Manifold CollectorNBEM0006S0107Tighten bolts and nuts to 18 to 21 N´m (1.8 to 2.2 kg-m, 13 to 15

ft-lb) in numerical order shown in the figure.

OUTER COMPONENT PARTS

Removal and Installation (Cont'd)

EM-12

Page 1656 of 2395

SEM477G

Lower Intake Manifold CollectorNBEM0006S0108Tighten bolts and nuts to 18 to 21 N´m (1.8 to 2.2 kg-m, 13 to 15

ft-lb) in numerical order shown in the figure.

SEM478G

SEM479G

Exhaust ManifoldNBEM0006S0109Tighten nuts to 28 to 32 N´m (2.9 to 3.3 kg-m, 21 to 24 ft-lb) in

numerical order shown in the figure.

SEM607G

TWC (Manifold)NBEM0006S0110IAlign the mating mark as shown for locating exhaust flange.

SEM609G

IInstall washer and mesh washer as shown.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OUTER COMPONENT PARTS

Removal and Installation (Cont'd)

EM-13

Page 1659 of 2395

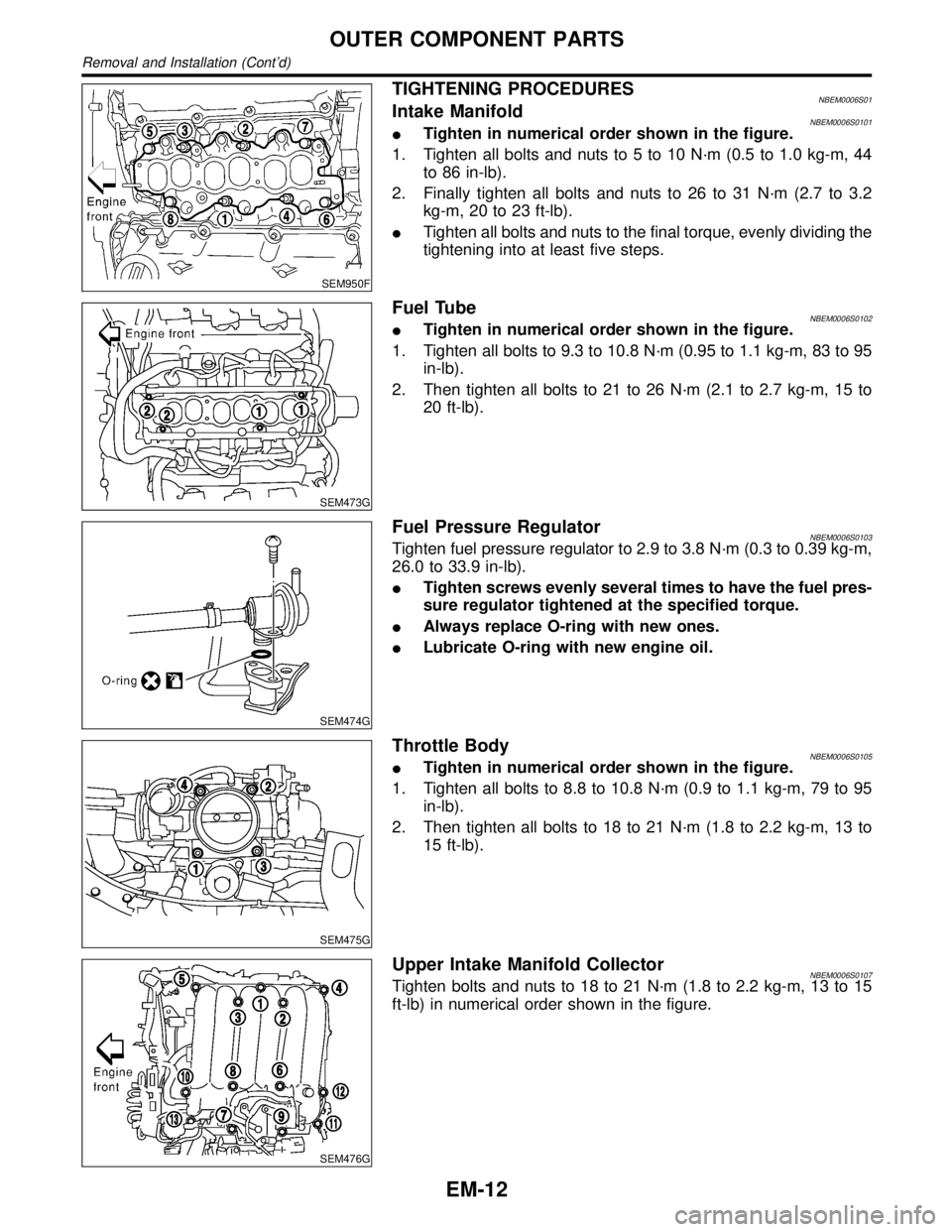

9. Remove the crankshaft position sensors (REF and POS).

10. Remove drive belts and idler pulley with bracket.

11. Remove power steering oil pump, then put it aside holding with

a suitable wire.

12. Remove alternator.

SEM605G

13. Install engine slingers.

14. Remove front propeller shaft. (4WD)

Refer to PD-6, ªRemoval and Installationº.

15. Remove exhaust front tube heat insulators, then remove rear

heat oxygen sensors.

16. Remove exhaust front tube from both sides.

Refer to FE-8, ªRemoval and Installationº.

17. Remove front final drive. (4WD)

Refer to PD-18, ªRemoval and Installationº.

18. Remove starter motor.

19. Disconnect oil pressure switch harness connector.

SEM528G

20. Loosen and disconnect the bolts fixing the steering column

assembly lower joint and the power steering gear.

SEM471G

21. Set a suitable transmission jack under the front suspension

member and hoist engine with engine slingers.

EMQ0357D

22. Remove front engine mounting nuts from both sides.

OIL PAN

Removal (Cont'd)

EM-16

Page 1661 of 2395

SEM464G

30. Remove O-rings from cylinder block and oil pump body.

SEM465G

31. Remove front cover gasket and rear oil seal retainer gasket.

SEM466G

InstallationNBEM00101. Before installing oil pan, remove old liquid gasket from mating

surface using a scraper.

IAlso remove old liquid gasket from mating surface of cyl-

inder block.

IRemove old liquid gasket from the bolt hole and thread.

SEM964E

2. Apply sealant to front cover gasket and rear oil seal retainer

gasket.

SEM465G

3. Install front cover gasket and rear oil seal retainer gasket.

OIL PAN

Removal (Cont'd)

EM-18

Page 1662 of 2395

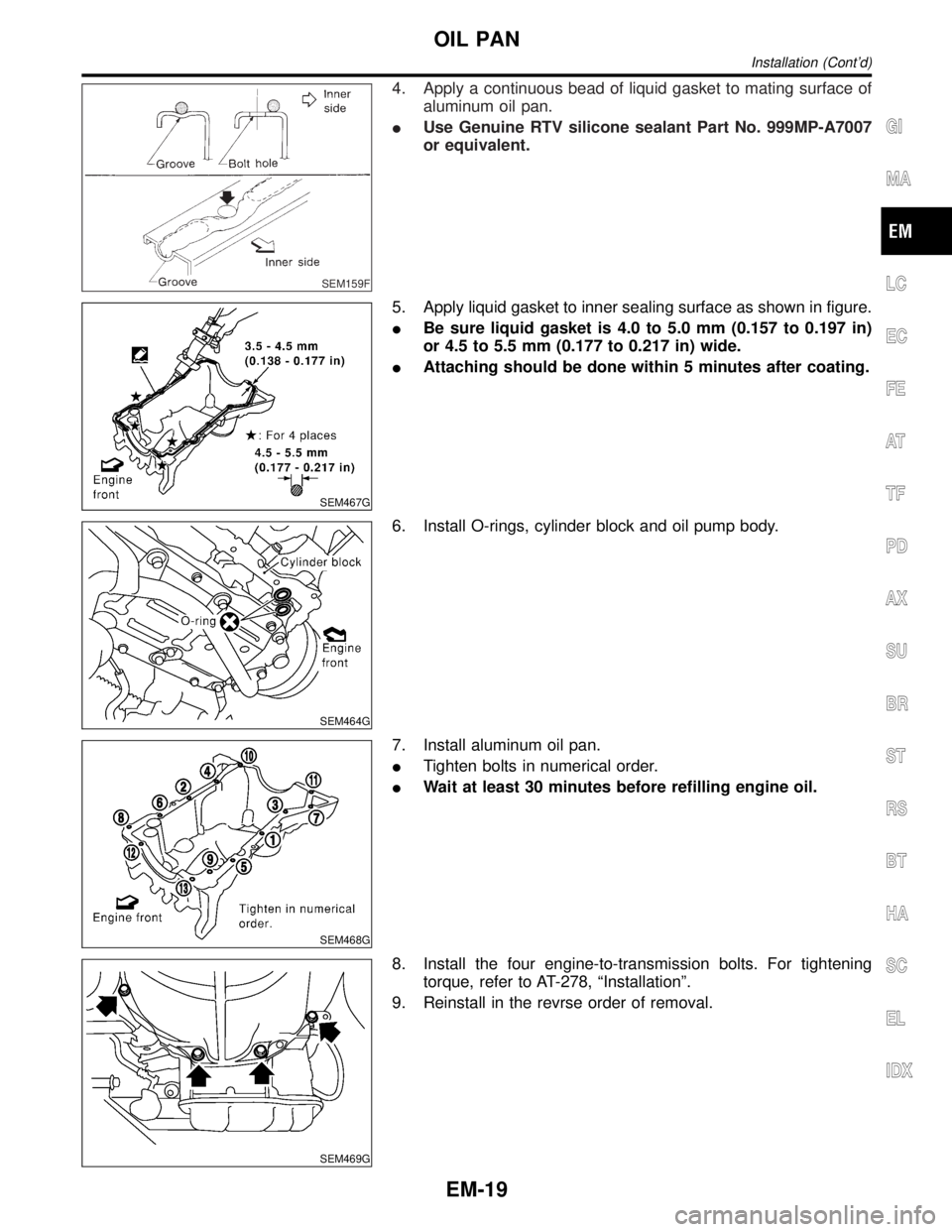

SEM159F

4. Apply a continuous bead of liquid gasket to mating surface of

aluminum oil pan.

IUse Genuine RTV silicone sealant Part No. 999MP-A7007

or equivalent.

SEM467G

5. Apply liquid gasket to inner sealing surface as shown in figure.

IBe sure liquid gasket is 4.0 to 5.0 mm (0.157 to 0.197 in)

or 4.5 to 5.5 mm (0.177 to 0.217 in) wide.

IAttaching should be done within 5 minutes after coating.

SEM464G

6. Install O-rings, cylinder block and oil pump body.

SEM468G

7. Install aluminum oil pan.

ITighten bolts in numerical order.

IWait at least 30 minutes before refilling engine oil.

SEM469G

8. Install the four engine-to-transmission bolts. For tightening

torque, refer to AT-278, ªInstallationº.

9. Reinstall in the revrse order of removal.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OIL PAN

Installation (Cont'd)

EM-19

Page 1664 of 2395

POSITION FOR APPLYING LIQUID GASKET=NBEM0011S01Refer to ªInstallationº in ªOIL PANº, EM-18.

IBefore installation, wipe off the protruding sealant.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAIN

Components (Cont'd)

EM-21