INSTALLATION INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1701 of 2395

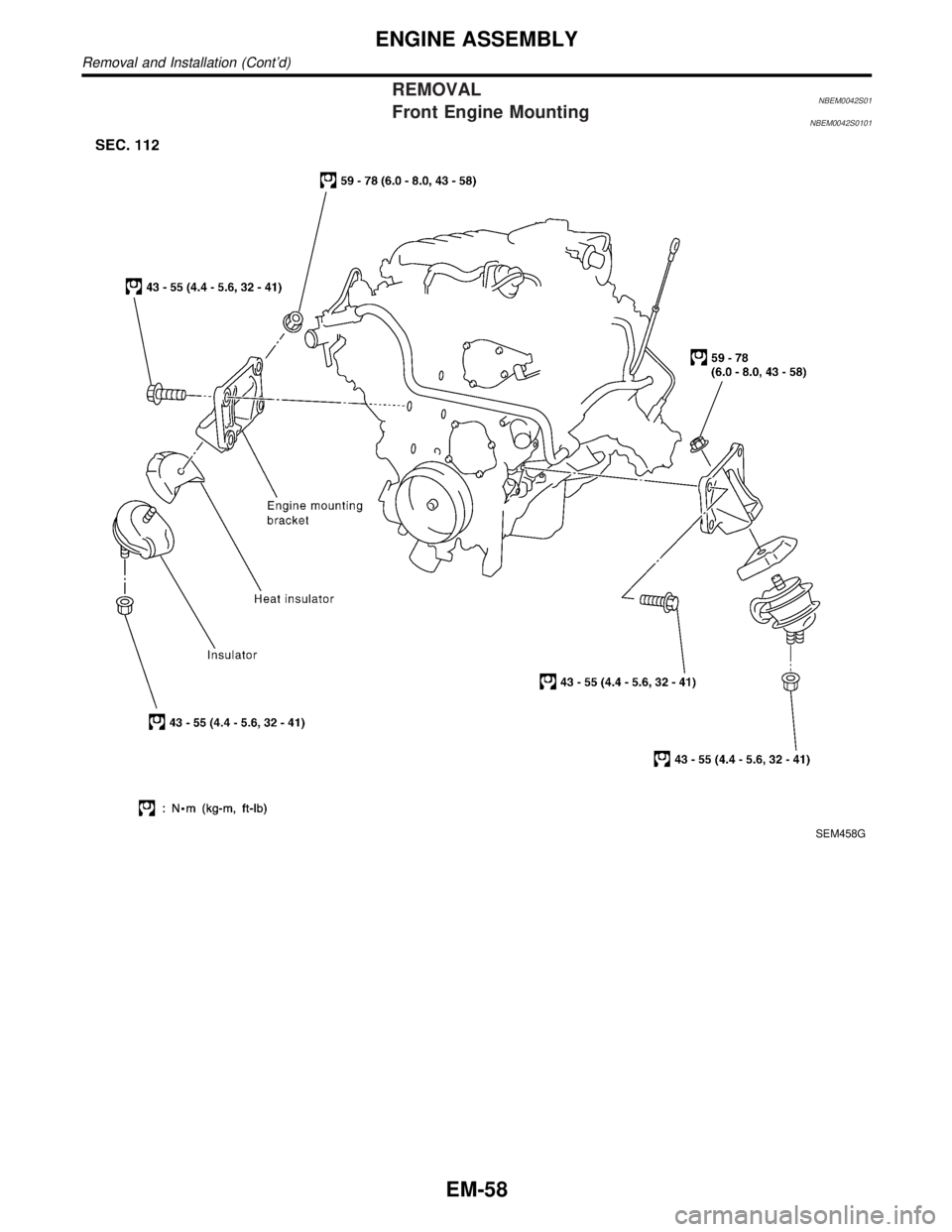

REMOVALNBEM0042S01Front Engine MountingNBEM0042S0101

SEM458G

ENGINE ASSEMBLY

Removal and Installation (Cont'd)

EM-58

Page 1702 of 2395

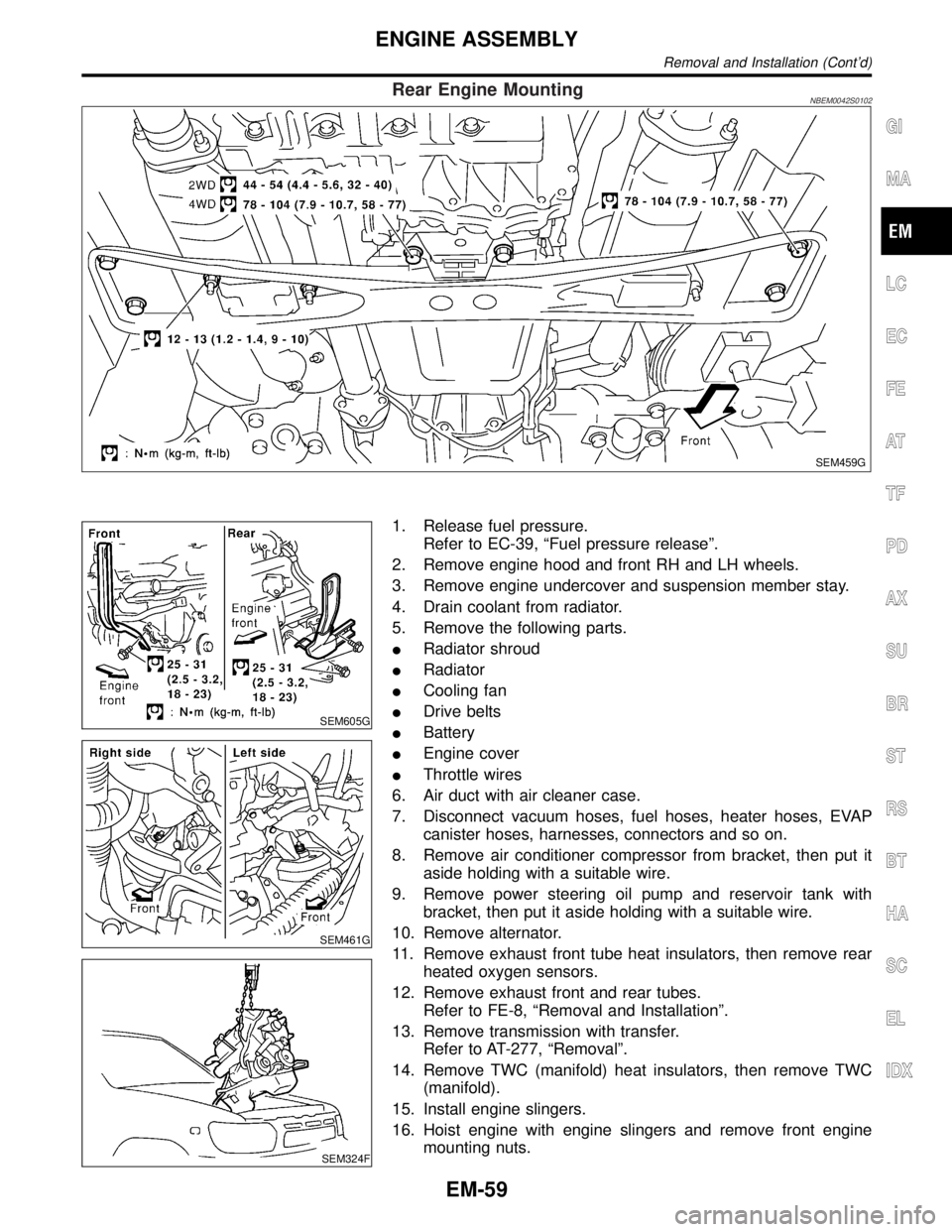

Rear Engine MountingNBEM0042S0102

SEM459G

SEM605G

SEM461G

SEM324F

1. Release fuel pressure.

Refer to EC-39, ªFuel pressure releaseº.

2. Remove engine hood and front RH and LH wheels.

3. Remove engine undercover and suspension member stay.

4. Drain coolant from radiator.

5. Remove the following parts.

IRadiator shroud

IRadiator

ICooling fan

IDrive belts

IBattery

IEngine cover

IThrottle wires

6. Air duct with air cleaner case.

7. Disconnect vacuum hoses, fuel hoses, heater hoses, EVAP

canister hoses, harnesses, connectors and so on.

8. Remove air conditioner compressor from bracket, then put it

aside holding with a suitable wire.

9. Remove power steering oil pump and reservoir tank with

bracket, then put it aside holding with a suitable wire.

10. Remove alternator.

11. Remove exhaust front tube heat insulators, then remove rear

heated oxygen sensors.

12. Remove exhaust front and rear tubes.

Refer to FE-8, ªRemoval and Installationº.

13. Remove transmission with transfer.

Refer to AT-277, ªRemovalº.

14. Remove TWC (manifold) heat insulators, then remove TWC

(manifold).

15. Install engine slingers.

16. Hoist engine with engine slingers and remove front engine

mounting nuts.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE ASSEMBLY

Removal and Installation (Cont'd)

EM-59

Page 1703 of 2395

17. Remove engine from vehicle.

INSTALLATIONNBEM0042S02Installation is in the reverse order of removal.

ENGINE ASSEMBLY

Removal and Installation (Cont'd)

EM-60

Page 1705 of 2395

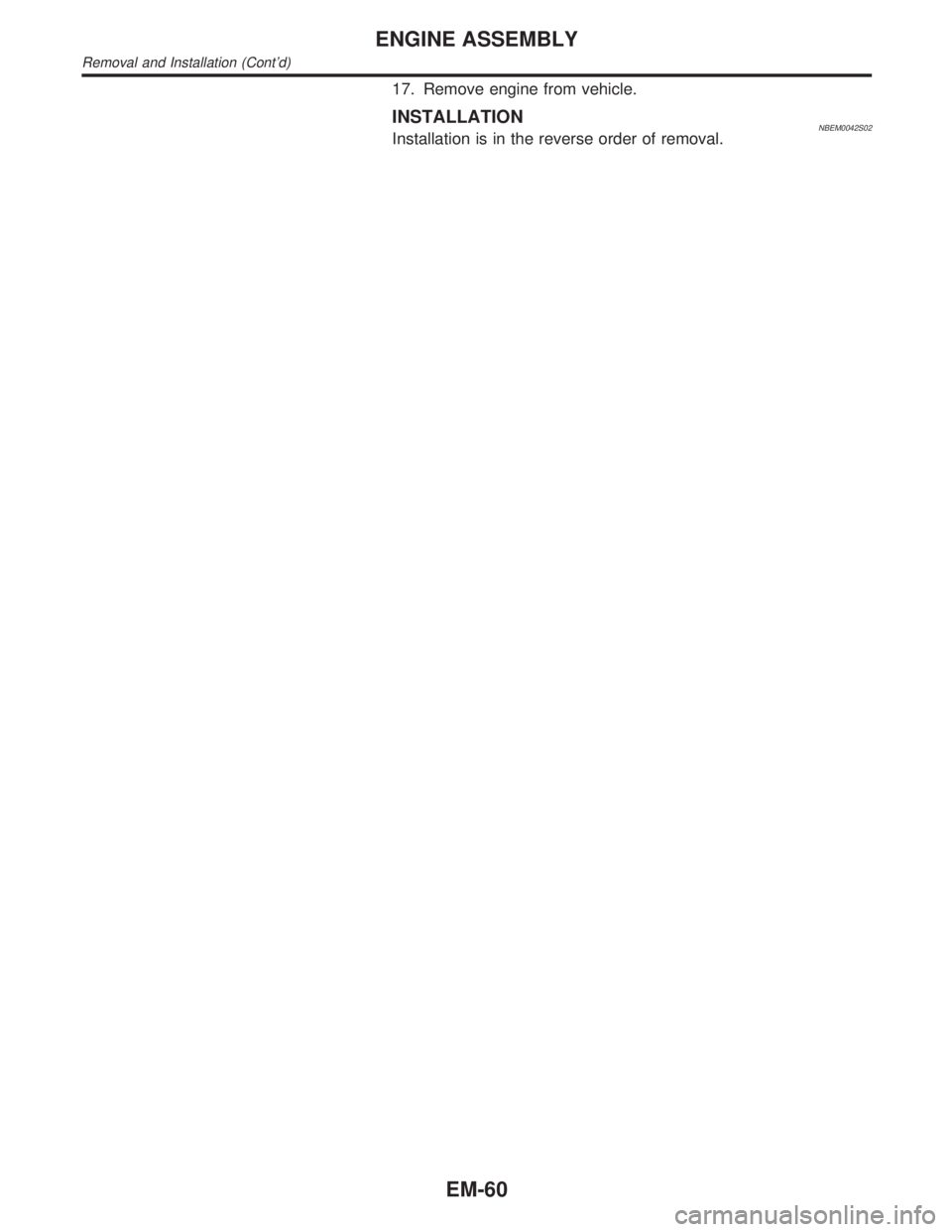

CYLINDER BLOCK HEATERNBEM0024S02

SEM537G

SEM180FA

Removal and InstallationNBEM0025CAUTION:

IWhen installing bearings, pistons, or other sliding parts,

lubricate contacting surfaces with new engine oil.

IPlace removed parts such as bearings and bearing caps

in their proper order and direction.

IWhen installing connecting rod nuts, and main bearing

cap bolts, apply new engine oil to threads and seating

surfaces.

IDo not allow any magnetic materials to contact the signal

plate teeth of drive plate.

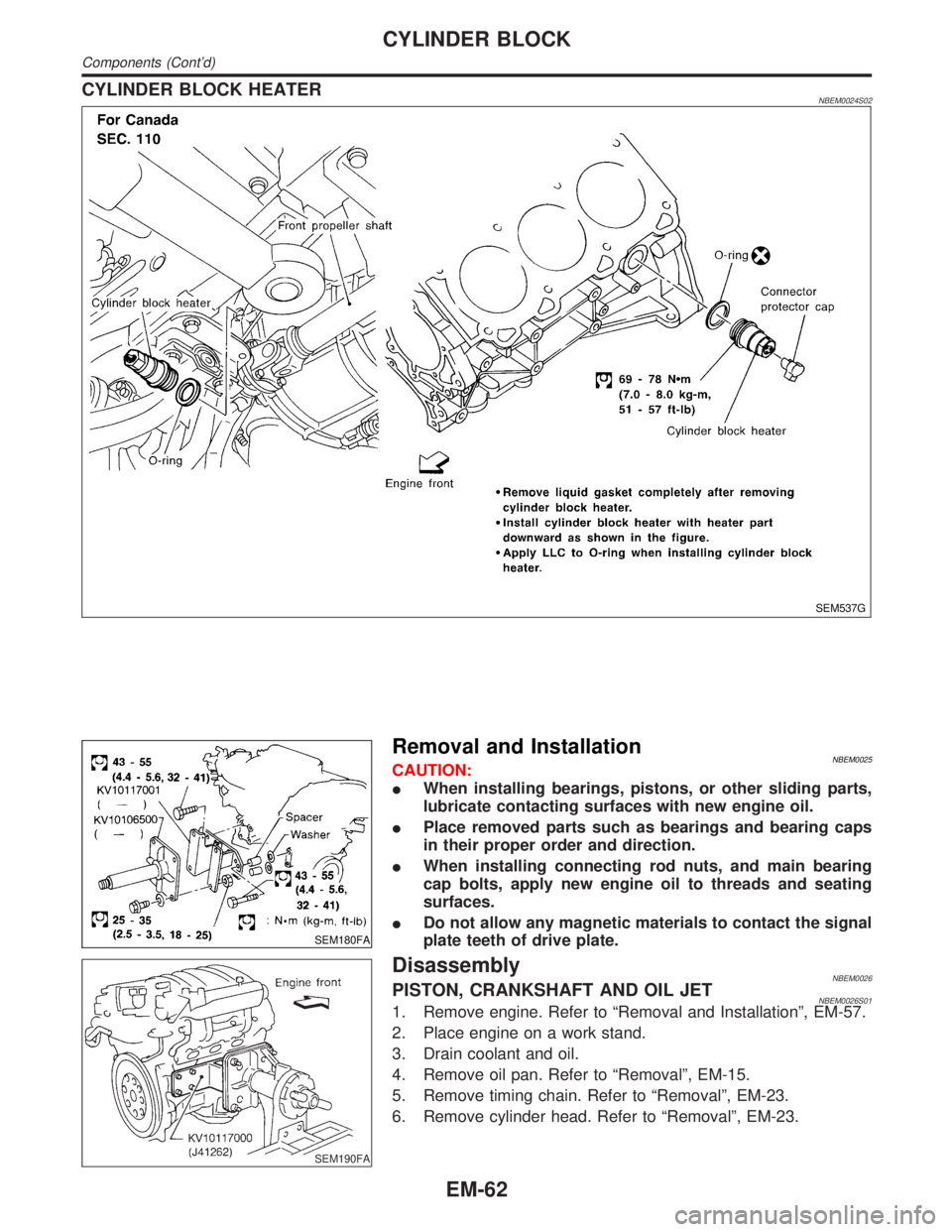

SEM190FA

DisassemblyNBEM0026PISTON, CRANKSHAFT AND OIL JETNBEM0026S011. Remove engine. Refer to ªRemoval and Installationº, EM-57.

2. Place engine on a work stand.

3. Drain coolant and oil.

4. Remove oil pan. Refer to ªRemovalº, EM-15.

5. Remove timing chain. Refer to ªRemovalº, EM-23.

6. Remove cylinder head. Refer to ªRemovalº, EM-23.

CYLINDER BLOCK

Components (Cont'd)

EM-62

Page 1717 of 2395

SEM954E

7. Measure connecting rod side clearance.

Connecting rod side clearance:

Standard

0.20 - 0.35 mm (0.0079 - 0.0138 in)

Limit

0.40 mm (0.0157 in)

If beyond the limit, replace connecting rod and/or crankshaft.

8. Install rear oil seal retainer.

SEM005G

REPLACEMENT OF PILOT CONVERTERNBEM0028S041. Remove pilot converter using tool or suitable tool.

SEM537E

2. Install pilot converter as shown.

SEM539G

DRIVE PLATENBEM0028S06Install drive plate.

IInstall the drive plate and reinforce plate in the direction shown

in the figure.

ISecure the crankshaft using a ring gear stopper.

ITighten the installation bolts crosswise over several times.

CYLINDER BLOCK

Assembly (Cont'd)

EM-74

Page 1730 of 2395

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMS

SECTION

FE

CONTENTS

PREPARATION...............................................................2

Special Service Tool ....................................................2

Commercial Service Tools ...........................................2

ACCELERATOR CONTROL SYSTEM...........................3

Removal and Installation .............................................3

Adjusting Accelerator Wire ..........................................3FUEL SYSTEM................................................................4

Removal and Installation .............................................4

FUEL TANK...............................................................5

FUEL PUMP AND GAUGE.........................................6

EXHAUST SYSTEM........................................................8

Removal and Installation .............................................8

GI

MA

EM

LC

EC

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 1732 of 2395

Removal and InstallationNBFE0002CAUTION:

IWhen removing accelerator wire, make a mark to indicate lock nut's initial position.

ICheck that throttle valve opens fully when accelerator pedal is fully depressed. Also check that it

returns to idle position when pedal is released.

ICheck accelerator control parts for improper contact with any adjacent parts.

IWhen connecting accelerator wire, be careful not to twist or scratch its inner wire.

IRefer to EL-240, ªAUTOMATIC SPEED CONTROL DEVICEº for ASCD wire adjustment.

SFE635A

SEF793W

SFE249AE

Adjusting Accelerator WireNBFE00031. Remove the vacuum hose connected to the throttle opener.

2. Connect suitable vacuum hose to vacuum pump as shown left.

3. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81

inHg)] until the throttle drum becomes free from the rod of the

throttle opener.

Make sure that there is clearance between the throttle

drum and rod.

If NG, refer to EC-101, ªBasic Inspectionº.

If OK, go to following step.

4. Loosen lock nut.

5. Tighten accelerator adjusting nut until throttle drum starts to

move.

6. From that position, turn back adjusting nut 1.5 to 2 turns, and

secure lock nut.

7. Release vacuum from the throttle opener.

8. Remove vacuum pump and vacuum hose from the throttle

opener.

9. Reinstall the original vacuum hose to the throttle opener

securely.

GI

MA

EM

LC

EC

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ACCELERATOR CONTROL SYSTEM

Removal and Installation

FE-3

Page 1733 of 2395

Removal and InstallationNBFE0004WARNING:

When replacing fuel line parts, be sure to observe the follow-

ing:

IPut a ªCAUTION: INFLAMMABLEº sign in workshop.

IDo not smoke while servicing fuel system. Keep open

flames and sparks away from work area.

IBe sure to furnish the workshop with a CO

2fire extin-

guisher.

CAUTION:

IBefore removing fuel line parts, carry out the following

procedures:

a) Put drained fuel in an explosion-proof container and put

lid on securely.

b) Release fuel pressure from fuel line. Refer to MA-16,

ªChanging Fuel Filterº.

c) Disconnect battery ground cable.

IAlways replace O-ring with new ones.

IDo not kink or twist hose and tube when they are installed.

IDo not tighten hose clamps excessively to avoid damag-

ing hoses.

IWhen installing fuel check valve, be careful of its desig-

nated direction. Refer to EC-32, ªEVAPORATIVE EMIS-

SION SYSTEMº.

IAfter installation, run engine and check for fuel leaks at

connections.

FUEL SYSTEM

Removal and Installation

FE-4

Page 1734 of 2395

SFE419AA

SFE420A

FUEL TANKNBFE0004S011. Release fuel pressure from fuel line.

Refer to MA-16, ªChanging Fuel Filterº.

2. Remove inspection hole cover located behind the rear seat.

3. Disconnect harness connectors under inspection hole cover.

4. Disconnect fuel hoses.

IPut mating marks on hoses for correct installation.

SFE468A

5. Disconnect filler hose, vent hose and evaporation hose at fuel

tank side.

GI

MA

EM

LC

EC

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FUEL SYSTEM

Removal and Installation (Cont'd)

FE-5

Page 1735 of 2395

SFE422A

6. Remove parking brake wire from fuel tank protector.

7. Remove fuel tank protector.

SFE469A

8. Remove fuel tank band mounting bolts while supporting fuel

tank.

9. Remove fuel tank.

Installation procedure is the reverse order of removal.

FUEL PUMP AND GAUGENBFE0004S02

SFE541A

1. Release fuel pressure from fuel line.

Refer to MA-16, ªChanging Fuel Filterº.

2. Remove inspection hole cover located behind the rear seat.

3. Disconnect harness connectors and fuel tubes from upper

plate of fuel gauge.

IPut mating marks on tubes for correct installation.

4. Remove fuel gauge retainer and fuel gauge.

FUEL SYSTEM

Removal and Installation (Cont'd)

FE-6