INSTALLATION INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1214 of 2395

MEL304D

ReplacementNBEL0010For removal and installation of spiral cable, refer to RS-18,

ªInstallation Ð Air Bag Module and Spiral Cableº.

IEach switch can be replaced without removing combination

switch base.

MEL326G

ITo remove combination switch base, remove base attaching

screw.

SEL151V

IBefore installing the steering wheel, align the steering wheel

guide pins with the screws which secure the combination

switch as shown in the left figure.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

COMBINATION SWITCH

Replacement

EL-29

Page 1293 of 2395

Electrical Components Inspection=NBEL0202METER/GAUGE RESISTANCE CHECKNBEL0202S01Check resistance between installation screws of meter/gauge.

Screws

Resistance

W

Tacho/Speedometer Fuel/Temp. gauge

A - C A - C Approx. 190 - Approx. 260

B - D B - C Approx. 230 - Approx. 310

SEL352X

YEL066K

FUEL LEVEL SENSOR UNIT CHECKNBEL0202S02IFor removal, refer to FE-4, ªFUEL SYSTEMº.

Check the resistance between terminals 3 and 2.

Ohmmeter

Float position mm (in)Resistance

valueW

(+) (þ)

32*1 Full 95 (3.74) Approx.4-6

*2 1/2 184 (7.24) 31 - 34

*3 Empty 265 (10.43) 80 - 83

*1 and *3: When float rod is in contact with stopper.

MEL424F

THERMAL TRANSMITTER CHECKNBEL0202S03Check the resistance between the terminals of thermal transmitter

and body ground.

Water temperature Resistance

60ÉC (140ÉF) Approx. 170 - 210W

100ÉC (212ÉF) Approx. 47 - 53W

METERS AND GAUGES

Electrical Components Inspection

EL-108

Page 1324 of 2395

SEL543TA

Removal and InstallationNBEL0060WIPER ARMSNBEL0060S011. Prior to wiper arm installation, turn on wiper switch to operate

wiper motor and then turn it ªOFFº (Auto Stop).

2. Lift the blade up and then set it down onto glass surface to set

the blade center to clearance ªL

1º&ªL2º immediately before

tightening nut.

3. Eject washer fluid. Turn on wiper switch to operate wiper motor

and then turn it ªOFFº.

4. Ensure that wiper blades stop within clearance ªL

1º&ªL2º.

Clearance ªL

1º: 29 - 30 mm (1.14 - 1.18 in)

Clearance ªL

2º: 32 - 42 mm (1.26 - 1.65 in)

ITighten wiper arm nuts to specified torque.

Front wiper: 21 - 26 N´m (2.1 - 2.7 kg-m, 15 - 20 ft-lb)

SEL024J

IBefore reinstalling wiper arm, clean up the pivot area as

illustrated. This will reduce possibility of wiper arm loose-

ness.

WIPER LINKAGENBEL0060S02

MEL840F

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

FRONT WIPER AND WASHER

Removal and Installation

EL-139

Page 1325 of 2395

RemovalNBEL0060S02011. Remove 4 bolts that secure wiper motor.

2. Detach wiper motor from wiper linkage at ball joint.

3. Remove wiper linkage.

Be careful not to break ball joint rubber boot.

InstallationNBEL0060S0202IGrease ball joint portion before installation.

1. Installation is the reverse order of removal.

MEL137M

Washer Nozzle AdjustmentNBEL0061IAdjust washer nozzle with suitable tool as shown in the figure

at left.

Adjustable range:±10É

MEL417N

Unit: mm (in)

*1 315 (12.40) *7 443 (17.44)

*2 227 (8.94) *8 250 (9.84)

*3 122 (4.80) *9 80 (3.15)

*4 220 (8.66) *10 430 (16.93)

*5 315 (12.40) *11 250 (9.84)

*6 145 (5.71) *12 57 (2.24)

*A: The diameters of these circles are less than 80 mm (3.15 in).

*B: The diameter of this circle is less than 120´80 mm (4.72´3.15 in).

*C: The diameter of this circle is less than 100´80 mm (3.94´3.15 in).

MEL074H

Washer Tube LayoutNBEL0062

FRONT WIPER AND WASHER

Removal and Installation (Cont'd)

EL-140

Page 1330 of 2395

Trouble DiagnosesNBEL0066REAR WIPER AMP. INSPECTION TABLENBEL0066S01(Data are reference values.)

Terminal No. Item Condition Voltage

(Approximate value)

1 Washer switch

Rear wiper switch WASH Less than 1V

OFF, ON or INT Battery voltage

2 Low switch

Rear wiper switch ON Less than 1V

OFF or INT Battery voltage

3 Glass hatch switch

Glass hatch Open Less than 1V

Closed Battery voltage

4 Intermittent switch

Rear wiper switch INT Less than 1V

OFF, ON or WASH Battery voltage

6 Power supply (ACC)

Ð Battery voltage

7 Washer motor

Rear washer switch WASH Battery voltage

OFF, ON or INT Less than 1V

8 Rear wiper motor

Wiper is moving (except final drive) Less than 1V

Wiper stop Less than 1V

During wiper final drive Battery voltage

9 Ground Ð Ð

10 Auto stop switch

Rear wiper switch

should be at ªINTº to

inspect the value for

wiper movement.Wiper is moving Less than 1V

Wiper stop Battery voltage

11 Rear wiper motor

Wiper is moving (except final drive) Battery voltage

Wiper stop Battery voltage

During wiper final drive Less than 1V

NOTE:

Power to the rear wiper amp. will be interrupted when the rear glass hatch is opened. In that case, conduct

the inspection of the rear wiper amp. with the rear glass hatch closed, unless otherwise indicated.

MEL066G

Removal and InstallationNBEL0067WIPER ARMSNBEL0067S011. Prior to wiper arm installation, turn on wiper switch to operate

wiper motor and then turn it ªOFFº (Auto Stop).

2. Install wiper arm to portion A as in figure below and tighten

wiper arm nut to specification.

3. Then, set wiper arm to portion B.

: 13 - 18 N´m (1.3 - 1.8 kg-m,9-13ft-lb)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

REAR WIPER AND WASHER

Trouble Diagnoses

EL-145

Page 1331 of 2395

SEL024J

IBefore reinstalling wiper arm, clean up the pivot area as

illustrated. This will reduce possibility of wiper arm loose-

ness.

SEL241P

MEL034G

Washer Nozzle AdjustmentNBEL0068IAdjust washer nozzle with suitable tool as shown in the figure

at left.

Adjustable range:±10É (In any direction)

MEL067G

Washer Tube LayoutNBEL0069

SEL411H

Check ValveNBEL0070IA check valve is provided in the washer fluid line. Be careful

not to connect check valve to washer tube in the wrong direc-

tion.

REAR WIPER AND WASHER

Removal and Installation (Cont'd)

EL-146

Page 1357 of 2395

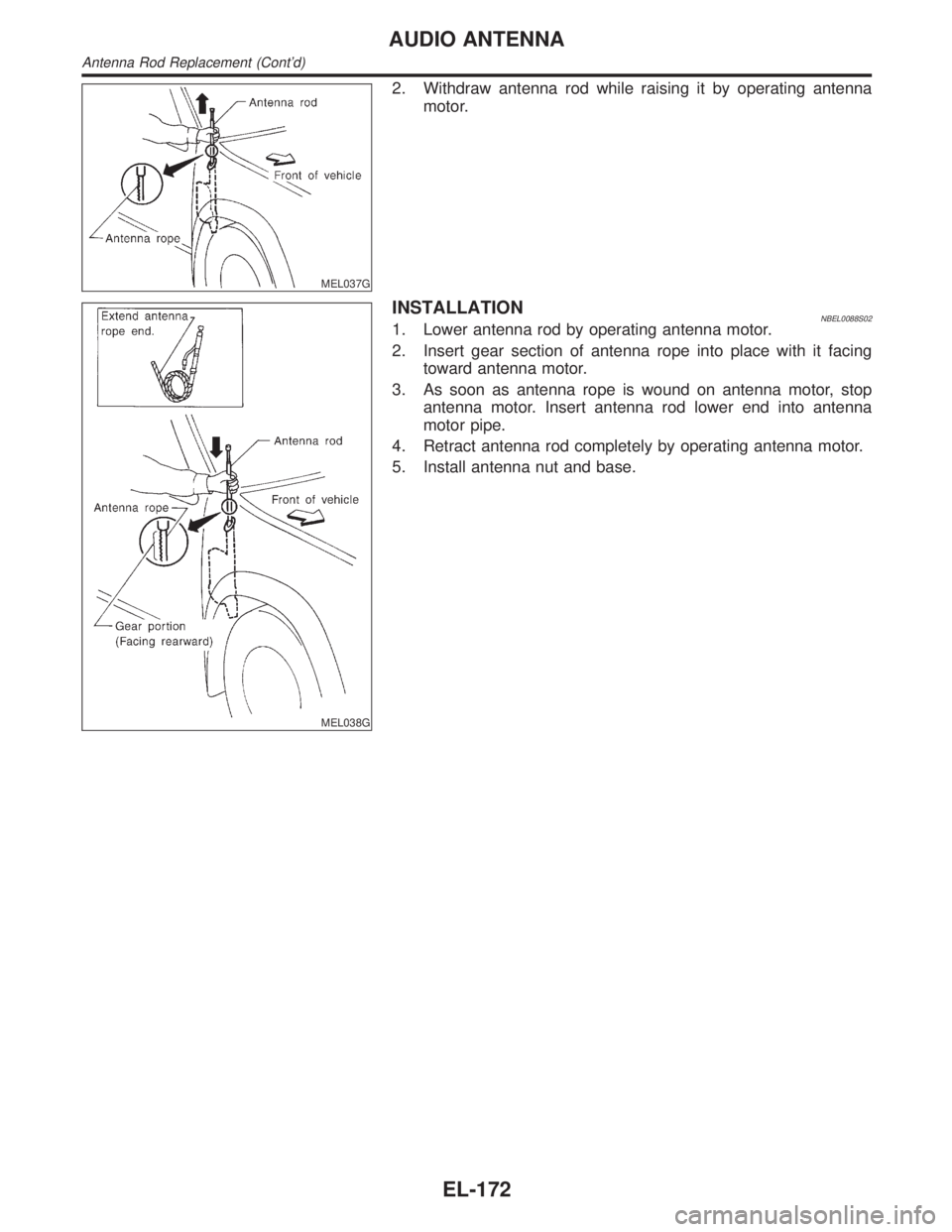

MEL037G

2. Withdraw antenna rod while raising it by operating antenna

motor.

MEL038G

INSTALLATIONNBEL0088S021. Lower antenna rod by operating antenna motor.

2. Insert gear section of antenna rope into place with it facing

toward antenna motor.

3. As soon as antenna rope is wound on antenna motor, stop

antenna motor. Insert antenna rod lower end into antenna

motor pipe.

4. Retract antenna rod completely by operating antenna motor.

5. Install antenna nut and base.

AUDIO ANTENNA

Antenna Rod Replacement (Cont'd)

EL-172

Page 1422 of 2395

ASCD ACTUATOR/PUMP CHECK=NBEL0218S08

1 CHECK VACUUM HOSE

Check vacuum hose (between ASCD actuator and ASCD pump) for breakage, cracks or fracture.

MEL402G

OK or NG

OK©GO TO 2.

NG©Repair or replace hose.

2 CHECK ASCD WIRE

Check wire for improper installation, rust formation or breaks.

OK or NG

OK©GO TO 3.

NG©Repair or replace wire. Refer to ªASCD Wire Adjustmentº (EL-240).

3 CHECK ASCD ACTUATOR

1. Disconnect vacuum hose from ASCD actuator.

2. Connect the hose of hand vacuum pump to ASCD actuator.

SEL264W

OK or NG

OK©GO TO 4.

NG©Replace ASCD actuator.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

Trouble Diagnoses (Cont'd)

EL-237

Page 1495 of 2395

Hood Switch Check=NBEL0123S0402

1 CHECK HOOD SWITCH FITTING CONDITION

OK or NG

OK©GO TO 2.

NG©Adjust installation of hood switch or hood.

2 CHECK HOOD SWITCH INPUT SIGNAL

Check voltage between smart entrance control unit terminal 27 and ground.

SEL337X

Refer to wiring diagram in EL-300.

OK or NG

OK©Hood switch is OK, and go to glass hatch switch check.

NG©GO TO 3.

3 CHECK HOOD SWITCH

1. Disconnect hood switch connector.

2. Check continuity between hood switch terminals 1 and 2.

SEL338X

OK or NG

OK©Check the following.

IHood switch ground circuit

IHarness for open or short between smart entrance control unit and hood switch

NG©Replace hood switch.

THEFT WARNING SYSTEM

Trouble Diagnoses (Cont'd)

EL-310

Page 1527 of 2395

DIAGNOSTIC PROCEDURE 4=NBEL0224S08Self-diagnostic results:

ªCHAIN OF IMMU-KEYº displayed on CONSULT-II screen

1 CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm SELF-DIAGNOSTIC RESULTS ªCHAIN OF IMMU-KEYº displayed on CONSULT-II screen.

SEL368X

Is CONSULT-II screen displayed as above?

Ye s©GO TO 2.

No©GO TO SYMPTOM MATRIX CHART 1.

2 CHECK IVIS (NATS) IGNITION KEY ID CHIP

Start engine with another registered IVIS (NATS) ignition key.

Does the engine start?

Ye s©Ignition key ID chip is malfunctioning.

Replace the ignition key.

Ref. part No. E

Perform initialization with CONSULT-II.

For initialization, refer to ªCONSULT-II Operation Manual IVIS/NVISº.

No©GO TO 3.

3 CHECK IMMU INSTALLATION

Check IMMU installation.

Refer to ªHow to Replace IMMUº in EL-347.

OK or NG

OK©IMMU is malfunctioning.

Replace IMMU.Ref. part No. A

Perform initialization with CONSULT-II.

For initialization, refer to ªCONSULT-II Operation Manual IVIS/NVISº.

NG©Reinstall IMMU correctly.

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM Ð NATS)

Trouble Diagnoses (Cont'd)

EL-342