vin INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 946 of 2395

SEF018S

Component Description=NBEC0622The fuel level sensor is mounted in the fuel level sensor unit. The

sensor detects a fuel level in the fuel tank and transmits a signal

to the ECM.

It consists of two parts, one is mechanical float and the other side

is variable resistor. Fuel level sensor output voltage changes

depending on the movement of the fuel mechanical float.

On Board Diagnostic LogicNBEC0623Driving long distances naturally affect fuel gauge level.

This diagnosis detects the fuel gauge malfunction of the gauge not

moving even after a long distance has been driven.

Malfunction is detected when the output signal of the fuel level

sensor does not change within the specified range even though the

vehicle has been driven a long distance.

Possible CauseNBEC0624IHarness or connectors

(The level sensor circuit is open or shorted.)

IFuel level sensor

Overall Function CheckNBEC0625Use this procedure to check the overall function of the fuel level

sensor function. During this check, a 1st trip DTC might not be

confirmed.

WARNING:

When performing following procedure, be sure to observe the

handling of the fuel. Refer to FE-5, ªFuel Tankº.

TESTING CONDITION:

Before starting overall function check, preparation of draining

fuel and refilling fuel is required.

SEF195Y

WITH CONSULT-IINBEC0625S01NOTE:

Start from step 11, if it is possible to confirm that the fuel

cannot be drained by 30(7-7/8 US gal, 6-5/8 Imp gal) in

advance.

1) Prepare a fuel container and a spare hose.

2) Release fuel pressure from fuel line, refer to ªFuel Pressure

Releaseº, EC-39.

3) Remove the fuel feed hose on the fuel level sensor unit.

4) Connect a spare fuel hose where the fuel feed hose was

removed.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0461 FUEL LEVEL SENSOR FUNCTION

Component Description

EC-411

Page 953 of 2395

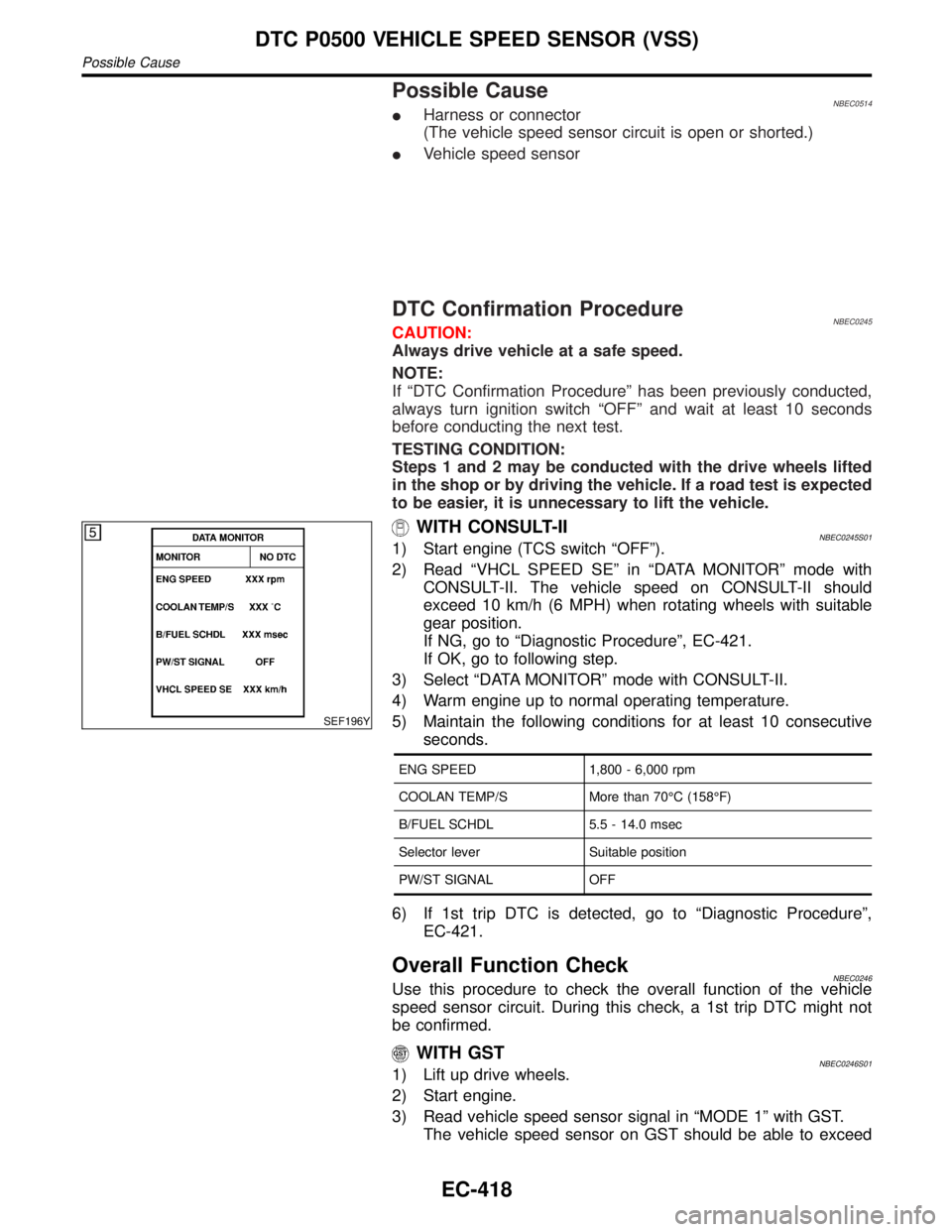

Possible CauseNBEC0514IHarness or connector

(The vehicle speed sensor circuit is open or shorted.)

IVehicle speed sensor

DTC Confirmation ProcedureNBEC0245CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Steps 1 and 2 may be conducted with the drive wheels lifted

in the shop or by driving the vehicle. If a road test is expected

to be easier, it is unnecessary to lift the vehicle.

SEF196Y

WITH CONSULT-IINBEC0245S011) Start engine (TCS switch ªOFFº).

2) Read ªVHCL SPEED SEº in ªDATA MONITORº mode with

CONSULT-II. The vehicle speed on CONSULT-II should

exceed 10 km/h (6 MPH) when rotating wheels with suitable

gear position.

If NG, go to ªDiagnostic Procedureº, EC-421.

If OK, go to following step.

3) Select ªDATA MONITORº mode with CONSULT-II.

4) Warm engine up to normal operating temperature.

5) Maintain the following conditions for at least 10 consecutive

seconds.

ENG SPEED 1,800 - 6,000 rpm

COOLAN TEMP/S More than 70ÉC (158ÉF)

B/FUEL SCHDL 5.5 - 14.0 msec

Selector lever Suitable position

PW/ST SIGNAL OFF

6) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-421.

Overall Function CheckNBEC0246Use this procedure to check the overall function of the vehicle

speed sensor circuit. During this check, a 1st trip DTC might not

be confirmed.

WITH GSTNBEC0246S011) Lift up drive wheels.

2) Start engine.

3) Read vehicle speed sensor signal in ªMODE 1º with GST.

The vehicle speed sensor on GST should be able to exceed

DTC P0500 VEHICLE SPEED SENSOR (VSS)

Possible Cause

EC-418

Page 967 of 2395

SEF197Y

SEF198Y

DTC Confirmation ProcedureNBEC0260CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

WITH CONSULT-IINBEC0260S011) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº, wait at least 10 seconds and then

start engine.

3) Select ªCLSD THL/P SWº in ªDATA MONITORº mode.

If ªCLSD THL/P SWº is not available, go to step 5.

4) Check the signal under the following conditions.

Condition Signal indication

Throttle valve: Idle position ON

Throttle valve: Slightly open OFF

If the result is NG, go to ªDiagnostic Procedureº, EC-435.

If OK, go to following step.

5) Select ªDATA MONITORº mode with CONSULT-II.

6) Drive the vehicle for at least 5 consecutive seconds under the

following condition.

THRTL POS SEN More than 2.5V

VHCL SPEED SE More than 5 km/h (3 MPH)

Selector lever Suitable position

Driving locationDriving vehicle uphill (Increased engine load)

will help maintain the driving conditions

required for this test.

7) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-435.

SEF345X

Overall Function CheckNBEC0261Use this procedure to check the overall function of the closed

throttle position switch circuit. During this check, a 1st trip DTC

might not be confirmed.

WITH GSTNBEC0261S011) Start engine and warm it up to normal operating temperature.

2) Check the voltage between ECM terminal 56 (Closed throttle

position switch signal) and ground under the following condi-

tions.

At idle: Battery voltage

DTC P0510 CLOSED THROTTLE POSITION SWITCH

DTC Confirmation Procedure

EC-432

Page 981 of 2395

DescriptionNBEC0691SYSTEM DESCRIPTIONNBEC0691S01

Sensor Input signal to ECM function ECM Actuator

Crankshaft positon sensor (POS) Engine speed (POS)

Intake valve

timing con-

trolIntake valve timing control sole-

noid valve Crankshaft position sensor (REF) Engine speed (REF)

Camshaft position sensor Engine speed

Engine coolant temperature sensor Engine coolant temperature

Vehicle speed sensor Vehicle speed

JEF349Z

This mechanism hydraulically controls cam phases continuously with the fixed operating angle of the intake

valve.

The ECM receives signals such as crankshaft position, camshaft position, engine speed, and engine coolant

temperature. Then, the ECM sends ON/OFF pulse duty signals to the camshaft timing control valve depend-

ing on driving status. This makes it possible to control the shut/open timing of the intake valve to increase

engine torque in low/mid speed range and output in high-speed range.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0692Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

INT/V TIM (B1)

INT/V TIM (B2)IEngine: After warming up

IShift lever ªNº

IQuickly depressed accelerator

pedal

INo-loadIdle 0É CA

2,000 rpm Approximately 12 - 18É CA

INT/V SOL (B1)

INT/V SOL (B2)IEngine: After warming up

IShift lever ªNº

IQuickly depressed accelerator

pedal

INo-loadIdle 0%

2,000 rpm Approximately 40%

DTC P1110 (RIGHT, -B1), P1135 (LEFT, -B2) INTAKE VALVE TIMING CONTROL

Description

EC-446

Page 984 of 2395

DTC Confirmation ProcedureNBEC0696CAUTION:

Always drive at a safe speed.

NOTE:

IIf both DTC P1111(B1), P1136 (B2) or P1140 (B1), P1145

(B2) and P1110 (B1), P1135 (B2) are displayed, perform

trouble diagnosis for ªDTC P1111(B1), P1136 (B2) or

P1140 (B1), P1145 (B2)º first. (See EC-451, 482.)

IIf ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at

least 10 seconds before conducting the next test.

SEF353Z

PROCEDURE FOR MALFUNCTION ANBEC0696S01With CONSULT-IINBEC0696S01011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Maintain the following conditions for at least 10 consecutive

seconds.

ENG SPEED More than 2,000 rpm

COOLANT TEMPS More than 70ÉC (158ÉF)

Selector lever 1st position

Driving locationDriving vehicle uphill

(Increased engine load will help main-

tain the driving conditions required for

this test.)

4) Maintain the following conditions for at least 20 consecutive

seconds.

ENG SPEED Idle

COOLANT TEMPS More than 70ÉC (158ÉF)

Selector lever ªPº or ªNº position

5) If 1st trip DTC is detected, go to ªP1140, P1145 INTAKE

VALVE TIMING CONTROL POSITION SENSORº. Refer to

EC-482.

With GSTNBEC0696S0102Follow the procedure ªWith CONSULT-IIº above.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1110 (RIGHT, -B1), P1135 (LEFT, -B2) INTAKE VALVE TIMING CONTROL

DTC Confirmation Procedure

EC-449

Page 985 of 2395

SEF353Z

PROCEDURE FOR MALFUNCTION B=NBEC0696S02With CONSULT-IINBEC0696S02011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Maintain the following conditions for at least 20 consecutive

seconds.

ENG SPEED2,000 - 3,000 rpm (A constant rotation

is maintained.)

COOLANT TEMPS 70 - 90ÉC (158 - 194ÉF)

Selector lever 1st or position

Driving location uphillDriving vehicle uphill

(Increased engine load will help main-

tain the driving conditions required for

this test.)

4) If 1st trip DTC is detected, go to ªP1140, P1145 INTAKE

VALVE TIMING CONTROL POSITION SENSORº. Refer to

EC-482.

With GSTNBEC0696S0202Follow the procedure ªWith CONSULT-IIº above.

DTC P1110 (RIGHT, -B1), P1135 (LEFT, -B2) INTAKE VALVE TIMING CONTROL

DTC Confirmation Procedure (Cont'd)

EC-450

Page 993 of 2395

DescriptionNBEC0523If DTC P1130 is displayed with P1165, first perform trouble diag-

nosis for DTC P1165, EC-493.

SYSTEM DESCRIPTIONNBEC0523S01

Sensor Input Signal to ECMECM func-

tionActuator

Throttle position sensor Throttle position

Swirl control

valve con-

trolSwirl control valve control sole-

noid valve

"Vacuum signal

Swirl control valve actuator

"

Swirl control valve Ignition switch Start signal

Crankshaft position sensor (POS) Engine speed (POS signal)

Crankshaft position sensor (REF) Engine speed (REF signal)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

This system has a swirl control valve in the intake passage of each

cylinder.

While idling and during low engine speed operation, the swirl con-

trol valve closes. Thus the velocity of the air in the intake passage

increases, promoting the vaporization of the fuel and producing a

swirl in the combustion chamber.

Because of this operation, this system tends to increase the burn-

ing speed of the gas mixture, improve fuel consumption, and

increase the stability in running conditions.

Also, except when idling and during low engine speed operation,

this system opens the swirl control valve. In this condition, this

system tends to increase power by improving intake efficiency via

reduction of intake flow resistance, intake flow.

The solenoid valve controls swirl control valve's shut/open condi-

tion. This solenoid valve is operated by the ECM.

Throttle position

sensor (Idle posi-

tion)Engine speedSwirl control valve

control solenoid

valveSwirl control valve

ON Below 3,200 rpm ON Closed

OFFLess than 3,200

rpmON Closed

More than 3,600

rpmOFF Open

When engine coolant temperature is below 10ÉC (50ÉF) and above 55ÉC (131ÉF),

swirl control valve is kept open regardless of above condition.

SEF446Z

DTC P1130 SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

Description

EC-458

Page 994 of 2395

SEF002Z

COMPONENT DESCRIPTIONNBEC0523S02Swirl Control Valve Control Solenoid ValveNBEC0523S0201The swirl control valve control solenoid valve responds to signals

from the ECM. When the ECM sends an ON (ground) signal, the

solenoid valve is bypassed to apply intake manifold vacuum to the

swirl control valve actuator. This operation closes the swirl control

valve. When the ECM sends an OFF signal, the vacuum signal is

cut and the swirl control valve opens.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0524Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

SWRL CONT S/VIEngine speed: IdleEngine coolant temperature is

between 15ÉC (59ÉF) to 50ÉC

(122ÉF).ON

Engine coolant temperature is

above 55ÉC (131ÉF).OFF

ECM Terminals and Reference ValueNBEC0673Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

29 GSwirl control valve con-

trol solenoid valve[Engine is running]

IIdle speed

IEngine coolant temperature is between 15 to

50ÉC (59 to 122ÉF).0 - 1.0V

[Engine is running]

IIdle speed

IEngine coolant temperature is above 55ÉC

(131ÉF).BATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis LogicNBEC0526Malfunction is detected when

(Malfunction A)An improper voltage signal is sent to ECM through

swirl control valve control solenoid valve,

(Malfunction B)The vacuum signal is not sent to swirl control

valve under specified driving conditions, even though swirl control

valve control solenoid valve is ON,

(Malfunction C)The vacuum signal is sent to swirl control valve

even though swirl control valve control solenoid valve is OFF.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1130 SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

Description (Cont'd)

EC-459

Page 1026 of 2395

On Board Diagnosis LogicNBEC0282HThe closed loop control has the one trip detection logic.

Malfunction is detected when the closed loop control function for

right bank does not operate even when vehicle is driving in the

specified condition, the closed loop control function for left bank

does not operate even when vehicle is driving in the specified

condition.

Possible CauseNBEC0531IThe front heated oxygen sensor circuit is open or shorted.

IHeated oxygen sensor 1 (front)

IHeated oxygen sensor 1 heater (front)

DTC Confirmation ProcedureNBEC0283CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

INever raise engine speed above 3,600 rpm during the

ªDTC Confirmation Procedureº. If the engine speed limit is

exceeded, retry the procedure from step 2.

IBefore performing the following procedure, confirm that

battery voltage is more than 11V at idle.

SEF063Y

WITH CONSULT-IINBEC0283S011) Start engine and warm it up to normal operating temperature.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Hold engine speed at 2,000 rpm and check one of the follow-

ing.

IªHO2S1 (B1)/(B2)º voltage should go above 0.70V at least

once.

IªHO2S1 (B1)/(B2)º voltage should go below 0.21V at least

once.

If the check result is NG, perform ªDiagnosis Procedureº,

EC-492.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1148 (RIGHT BANK, -B1), P1168 (LEFT BANK, -B2) CLOSED LOOP

CONTROL

On Board Diagnosis Logic

EC-491

Page 1070 of 2395

11 CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve attached.

The weight should be less than 1.8 kg (4.0 lb).

OK or NG

OK (With CONSULT-II)©GO TO 13.

OK (Without CONSULT-

II)©GO TO 14.

NG©GO TO 12.

12 DETECT MALFUNCTIONING PART

Check the following.

IEVAP canister for damage

IEVAP hose between EVAP canister and water separator for clogging or poor connection

©Repair hose or replace EVAP canister.

13 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With CONSULT-II

1. Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

2. Start engine.

3. Perform ªPURG VOL CONT/Vº in ªACTIVE TESTº mode.

4. Touch ªQuº on CONSULT-II screen to increase ªPURG VOL CONT/Vº opening to 100.0%.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

SEF984Y

OK or NG

OK©GO TO 16.

NG©GO TO 15.

14 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

4. Start engine and let it idle for at least 80 seconds.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

Vacuum should exist.

OK or NG

OK©GO TO 17.

NG©GO TO 15.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1441 EVAP CONTROL SYSTEM (VERY SMALL LEAK)

Diagnostic Procedure (Cont'd)

EC-535