vin INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 819 of 2395

5 CHECK HEATED OXYGEN SENSOR 2 (REAR)

With CONSULT-II

1. Start engine and drive vehicle at a speed of more than 70 km/h (43 MPH) for 2 consecutive minutes.

2. Stop vehicle with engine running.

3. Select ªFUEL INJECTIONº in ªACTIVE TESTº mode, and select ªHO2S2 (B1)/(B2)º as the monitor item with CONSULT-

II.

4. Check ªHO2S2 (B1)/(B2)º at idle speed when adjusting ªFUEL INJECTIONº to±25%.

SEF972Y

ªHO2S2 (B1)/(B2)º should be above 0.62V at least once when the ªFUEL INJECTIONº is +25%.

ªHO2S2 (B1)/(B2)º should be below 0.57V at least once when the ªFUEL INJECTIONº is þ25%.

CAUTION:

Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

OK or NG

OK©GO TO 9.

NG©GO TO 8.

6 CHECK HEATED OXYGEN SENSOR 2 (REAR)-I

Without CONSULT-II

1. Start engine and drive vehicle at a speed of more than 70 km/h (43 MPH) for 2 consecutive minutes.

2. Stop vehicle with engine running.

3. Set voltmeter probes between ECM terminal 72 (HO2S2 bank 1 right signal) or 71 (HO2S2 bank 2 left signal) and

engine ground.

4. Check the voltage when revving up to 4,000 rpm under no load at least 10 times.

(Depress and release accelerator pedal as soon as possible.)

SEF313XA

OK or NG

OK©GO TO 9.

NG©GO TO 7.

DTC P0140, P0160 HEATED OXYGEN SENSOR 2 (REAR) (BANK 1)/(BANK 2)

(HIGH VOLTAGE)

Diagnostic Procedure (Cont'd)

EC-284

Page 821 of 2395

DescriptionNBEC0162SYSTEM DESCRIPTIONNBEC0162S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS)

Engine speedHeated

oxygen

sensor 2

heater

(rear) con-

trolHeated oxygen sensor 2 heat-

ers (rear)

Crankshaft position sensor (REF)

The ECM performs ON/OFF control of the heated oxygen sensor 2 heaters (rear) corresponding to the engine

speed.

OPERATIONNBEC0162S02

Engine speed rpm Heated oxygen sensor 2 heaters (rear)

Above 3,200 OFF

Below 3,200 ON

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0163Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 HTR (B1)

HO2S2 HTR (B2)IIgnition switch: ON (Engine stopped)

IEngine is running above 3,200 rpm.OFF

IEngine is running below 3,200 rpm after driving for 2 minutes at a

speed of 70 km/h (43 MPH) or more.ON

ECM Terminals and Reference ValueNBEC0662Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

5 P/BHeated oxygen sensor

2 heater (rear) (bank

1)[Engine is running]

IEngine speed is below 3,200 rpm.

IAfter driving for 2 minutes at a speed of 70 km/h

(43 MPH) or more.0 - 1.0V

[Ignition switch ªONº]

IEngine stopped

[Engine is running]

IEngine speed is above 3,200 rpm.BATTERY VOLTAGE

(11 - 14V)

4 R/WHeated oxygen sensor

2 heater (rear) (bank

2)[Engine is running]

IEngine speed is below 3,200 rpm.

IAfter driving for 2 minutes at a speed of 70 km/h

(43 MPH) or more.0 - 1.0V

[Ignition switch ªONº]

IEngine stopped

[Engine is running]

IEngine speed is above 3,200 rpm.BATTERY VOLTAGE

(11 - 14V)

DTC P0141, P0161 HEATED OXYGEN SENSOR 2 HEATER (REAR) (BANK 1)/

(BANK 2)

Description

EC-286

Page 850 of 2395

of 2 liters per minute like pouring coolant from a kettle. Be sure

to use coolant with the proper mixture ratio. Refer to MA-12,

ªAnti-freeze Coolant Mixture Ratioº.

b) After refilling coolant, run engine to ensure that no water-flow

noise is emitted.

c) After checking or replacing coolant, go to step 3 below.

2) Ask the customer if engine coolant has been added. If it has

been added, go to ªDiagnostic Procedureº, EC-316. After

repair, go to the next step.

3) Start engine and let it idle.

4) Make sure that A/C switch is ªOFFº and air conditioner is not

operating. If NG, check air conditioner circuit. Refer to HA-30

or HA-35, ªTROUBLE DIAGNOSESº. After repair, go to the

next step.

5) Check for blocked coolant passage.

a) Warm up engine to normal operating temperature, then grasp

radiator upper hose and lower hose and make sure that cool-

ant flows.

If NG, go to ªDiagnostic Procedureº, EC-316. After repair, go

to the next step.

Be extremely careful not to touch any moving or adjacent

parts.

6) Check for blocked radiator air passage.

a) When market fog lamps have been installed, check for dam-

aged fans and clogging in the condenser and radiator.

b) Check the front end for clogging caused by insects or debris.

c) Check for improper fitting of front-end cover, damaged radia-

tor grille or bumper, damaged vehicle front.

If NG, take appropriate action and then go to the next step.

7) Check function of ECT sensor.

Refer to step 7 of ªDiagnostic Procedureº, EC-316.

If NG, replace ECT sensor and go to the next step.

8) Check ignition timing. Refer to basic inspection, EC-101.

Make sure that ignition timing is 15ɱ5É at idle.

If NG, adjust ignition timing and then recheck.

WITH GSTNBEC0612S021) Check the coolant level and mixture ratio (using coolant tester)

in the reservoir tank and radiator.

Allow engine to cool before checking coolant level and

mixture ratio.

IIf the coolant level in the reservoir and/or radiator is below the

proper range, and go to ªDiagnostic Procedureº, EC-316.

IIf the coolant mixture ratio is out of the range of 45 to 55%,

replace the coolant in the following procedure MA-14, ªChang-

ing Engine Coolantº.

a) Fill radiator with coolant up to specified level with a filling speed

of 2 liters per minute like pouring coolant from a kettle. Be sure

to use coolant with the proper mixture ratio. Refer to MA-12,

ªAnti-freeze Coolant Mixture Ratioº.

b) After refilling coolant, run engine to ensure that no water-flow

noise is emitted.

c) After checking or replacing coolant, go to step 3 below.

2) Ask the customer if engine coolant has been added. If it has

been added, go to ªDiagnostic Procedureº, EC-316. After

repair, go to the next step.

3) Start engine and let it idle.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

Overall Function Check (Cont'd)

EC-315

Page 851 of 2395

4) Make sure that A/C switch is ªOFFº and air conditioner is not

operating. If NG, check air conditioner circuit. Refer to HA-35

or HA-30, ªTROUBLE DIAGNOSESº. After repair, go to the

next step.

5) Check for blocked coolant passage.

a) Warm up engine to normal operating temperature, then grasp

radiator upper hose and lower hose and make sure that cool-

ant flows.

If NG, go to ªDiagnostic Procedureº, EC-316. After repair, go

to the next step.

Be extremely careful not to touch any moving or adjacent

parts.

6) Check for blocked radiator air passage.

a) When market fog lamps have been installed, check for dam-

aged fans and clogging in the condenser and radiator.

b) Check the front end for clogging caused by insects or debris.

c) Check for improper fitting of front-end cover, damaged radia-

tor grille or bumper, damaged vehicle front.

If NG, take appropriate action and then go to the next step.

7) Check function of ECT sensor.

Refer to step 6 of ªDiagnostic Procedureº, EC-316.

If NG, replace ECT sensor and go to the next step.

8) Check ignition timing. Refer to basic inspection, EC-101.

Make sure that ignition timing is 15ɱ5É at idle.

If NG, adjust ignition timing and then recheck.

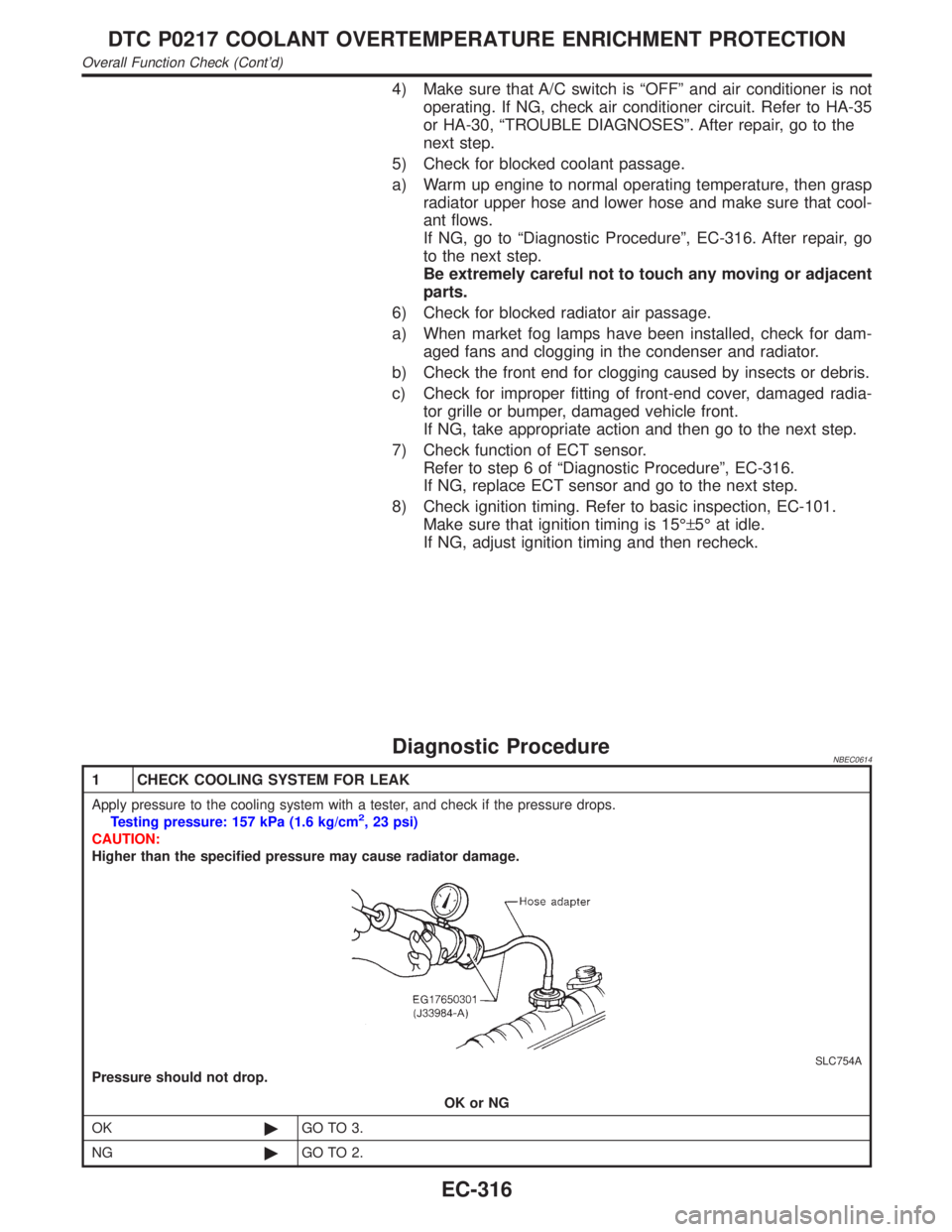

Diagnostic ProcedureNBEC0614

1 CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the pressure drops.

Testing pressure: 157 kPa (1.6 kg/cm2, 23 psi)

CAUTION:

Higher than the specified pressure may cause radiator damage.

SLC754A

Pressure should not drop.

OK or NG

OK©GO TO 3.

NG©GO TO 2.

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

Overall Function Check (Cont'd)

EC-316

Page 854 of 2395

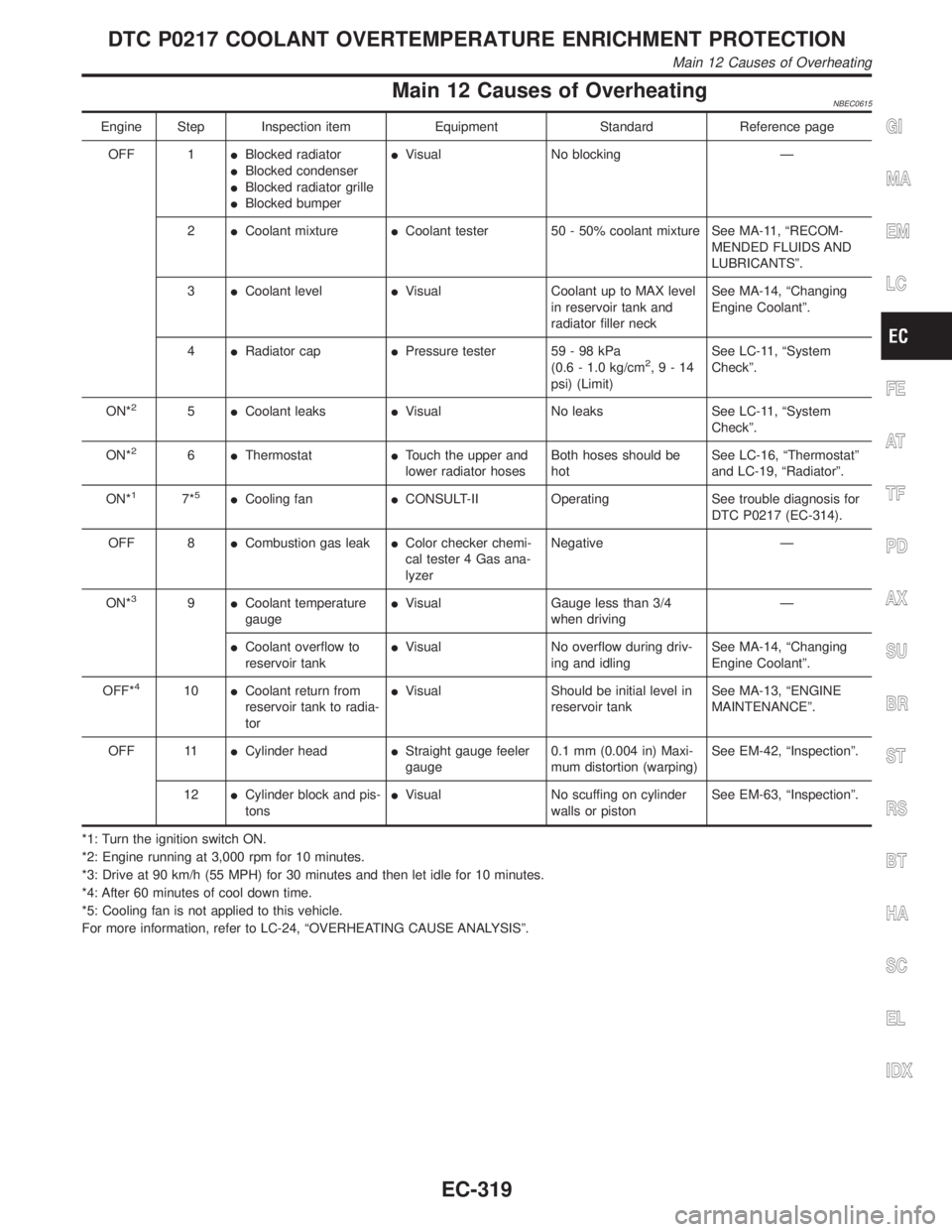

Main 12 Causes of OverheatingNBEC0615

Engine Step Inspection item Equipment Standard Reference page

OFF 1IBlocked radiator

IBlocked condenser

IBlocked radiator grille

IBlocked bumperIVisual No blocking Ð

2ICoolant mixtureICoolant tester 50 - 50% coolant mixture See MA-11, ªRECOM-

MENDED FLUIDS AND

LUBRICANTSº.

3ICoolant levelIVisual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee MA-14, ªChanging

Engine Coolantº.

4IRadiator capIPressure tester 59 - 98 kPa

(0.6 - 1.0 kg/cm

2,9-14

psi) (Limit)See LC-11, ªSystem

Checkº.

ON*

25ICoolant leaksIVisual No leaks See LC-11, ªSystem

Checkº.

ON*

26IThermostatITouch the upper and

lower radiator hosesBoth hoses should be

hotSee LC-16, ªThermostatº

and LC-19, ªRadiatorº.

ON*

17*5ICooling fanICONSULT-II Operating See trouble diagnosis for

DTC P0217 (EC-314).

OFF 8ICombustion gas leakIColor checker chemi-

cal tester 4 Gas ana-

lyzerNegative Ð

ON*

39ICoolant temperature

gaugeIVisual Gauge less than 3/4

when drivingÐ

ICoolant overflow to

reservoir tankIVisual No overflow during driv-

ing and idlingSee MA-14, ªChanging

Engine Coolantº.

OFF*

410ICoolant return from

reservoir tank to radia-

torIVisual Should be initial level in

reservoir tankSee MA-13, ªENGINE

MAINTENANCEº.

OFF 11ICylinder headIStraight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See EM-42, ªInspectionº.

12ICylinder block and pis-

tonsIVisual No scuffing on cylinder

walls or pistonSee EM-63, ªInspectionº.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

*5: Cooling fan is not applied to this vehicle.

For more information, refer to LC-24, ªOVERHEATING CAUSE ANALYSISº.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

Main 12 Causes of Overheating

EC-319

Page 856 of 2395

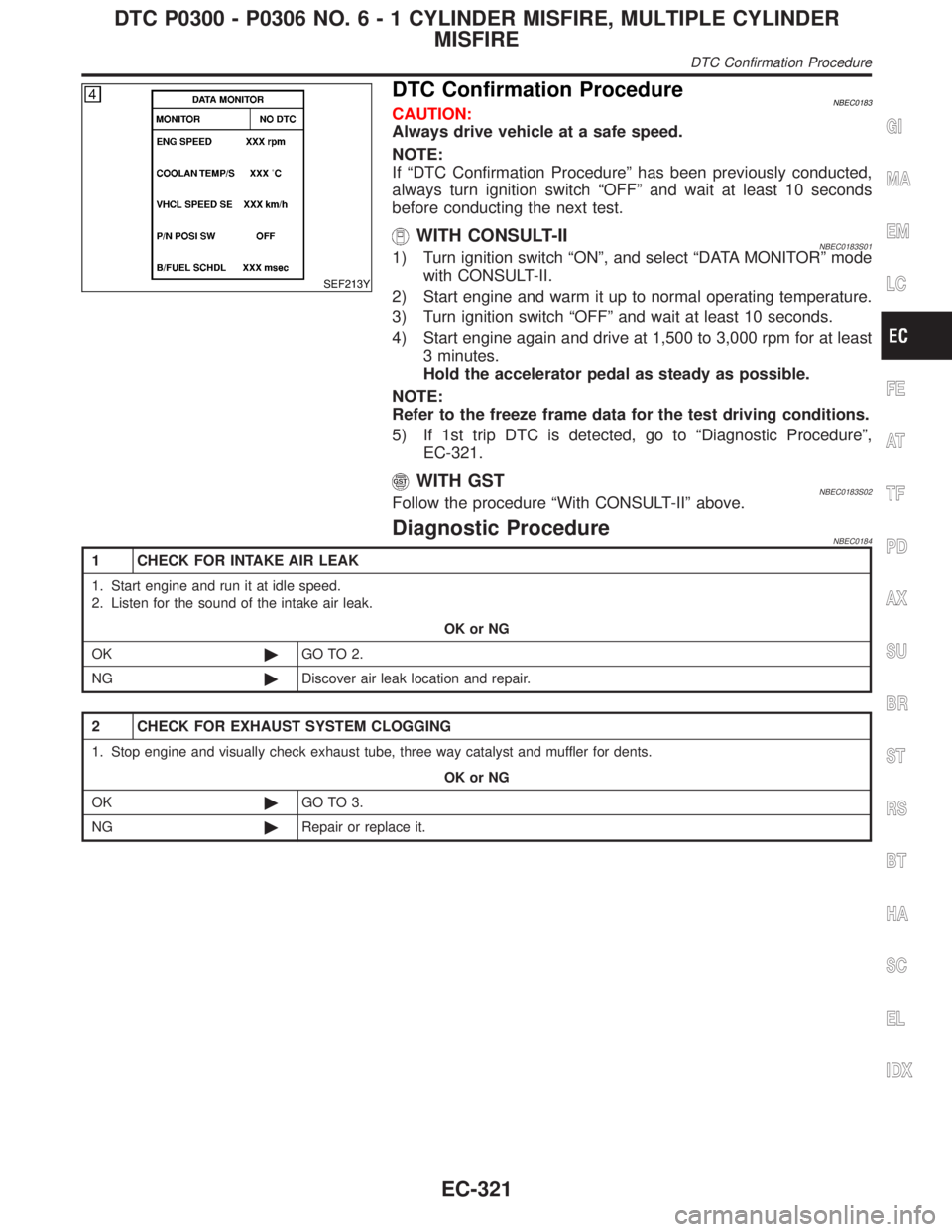

SEF213Y

DTC Confirmation ProcedureNBEC0183CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

WITH CONSULT-IINBEC0183S011) Turn ignition switch ªONº, and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and warm it up to normal operating temperature.

3) Turn ignition switch ªOFFº and wait at least 10 seconds.

4) Start engine again and drive at 1,500 to 3,000 rpm for at least

3 minutes.

Hold the accelerator pedal as steady as possible.

NOTE:

Refer to the freeze frame data for the test driving conditions.

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-321.

WITH GSTNBEC0183S02Follow the procedure ªWith CONSULT-IIº above.

Diagnostic ProcedureNBEC0184

1 CHECK FOR INTAKE AIR LEAK

1. Start engine and run it at idle speed.

2. Listen for the sound of the intake air leak.

OK or NG

OK©GO TO 2.

NG©Discover air leak location and repair.

2 CHECK FOR EXHAUST SYSTEM CLOGGING

1. Stop engine and visually check exhaust tube, three way catalyst and muffler for dents.

OK or NG

OK©GO TO 3.

NG©Repair or replace it.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0300 - P0306 NO.6-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

DTC Confirmation Procedure

EC-321

Page 889 of 2395

SEF565X

DTC Confirmation ProcedureNBEC0219

SEF566X

SEF874X

SEF567X

NOTE:

IIf DTC P0440 or P1440 is displayed with P1448, perform

trouble diagnosis for DTC P1448 first. (See EC-573.)

IIf ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

10 seconds before conducting the next test.

TESTING CONDITION:

IPerform ªDTC WORK SUPPORTº when the fuel level is

between 1/4 to 3/4 full and vehicle is placed on flat level

surface.

IOpen engine hood before conducting the following proce-

dure.

WITH CONSULT-IINBEC0219S011) Turn ignition switch ªONº.

2) Turn ignition switch ªOFFº and wait at least 10 seconds.

3) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

4) Make sure that the following conditions are met.

COOLAN TEMP/S: 0 - 70ÉC (32 - 158ÉF)

INT/A TEMP SE: 0 - 30ÉC (32 - 86ÉF)

5) Select ªEVAP SML LEAK P0440/P1440º of ªEVAPORATIVE

SYSTEMº in ªDTC WORK SUPPORTº mode with CONSULT-

II.

Follow the instruction displayed.

NOTE:

If the engine speed cannot be maintained within the range dis-

played on the CONSULT-II screen, go to ªBasic Inspectionº,

EC-101.

6) Make sure that ªOKº is displayed.

If ªNGº is displayed, refer to ªDiagnostic Procedureº, EC-355.

NOTE:

Make sure that EVAP hoses are connected to EVAP canister

purge volume control solenoid valve properly.

WITH GSTNBEC0219S02NOTE:

Be sure to read the explanation of ªDriving Patternº on EC-66

before driving vehicle.

1) Start engine.

2) Drive vehicle according to ªDriving Patternº, EC-66.

3) Stop vehicle.

4) Select ªMODE 1º with GST.

IIf SRT of EVAP system is not set yet, go to the following step.

IIf SRT of EVAP system is set, the result will be OK.

5) Turn ignition switch ªOFFº and wait at least 10 seconds.

6) Start engine.

It is not necessary to cool engine down before driving.

7) Drive vehicle again according to the ªDriving Patternº, EC-66.

8) Stop vehicle.

9) Select ªMODE 3º with GST.

IIf P0440 or P1440 is displayed on the screen, go to ªDiagnos-

tic Procedureº, EC-355.

IIf P1447 is displayed on the screen, go to ªDiagnostic Proce-

dureº for DTC P1447, EC-564.

DTC P0440 EVAP CONTROL SYSTEM (SMALL LEAK) (NEGATIVE PRESSURE)

DTC Confirmation Procedure

EC-354

Page 896 of 2395

11 CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve attached.

The weight should be less than 1.8 kg (4.0 lb).

OK or NG

OK (With CONSULT-II)©GO TO 13.

OK (Without CONSULT-

II)©GO TO 14.

NG©GO TO 12.

12 DETECT MALFUNCTIONING PART

Check the following.

IEVAP canister for damage

IEVAP hose between EVAP canister and water separator for clogging or poor connection

©Repair hose or replace EVAP canister.

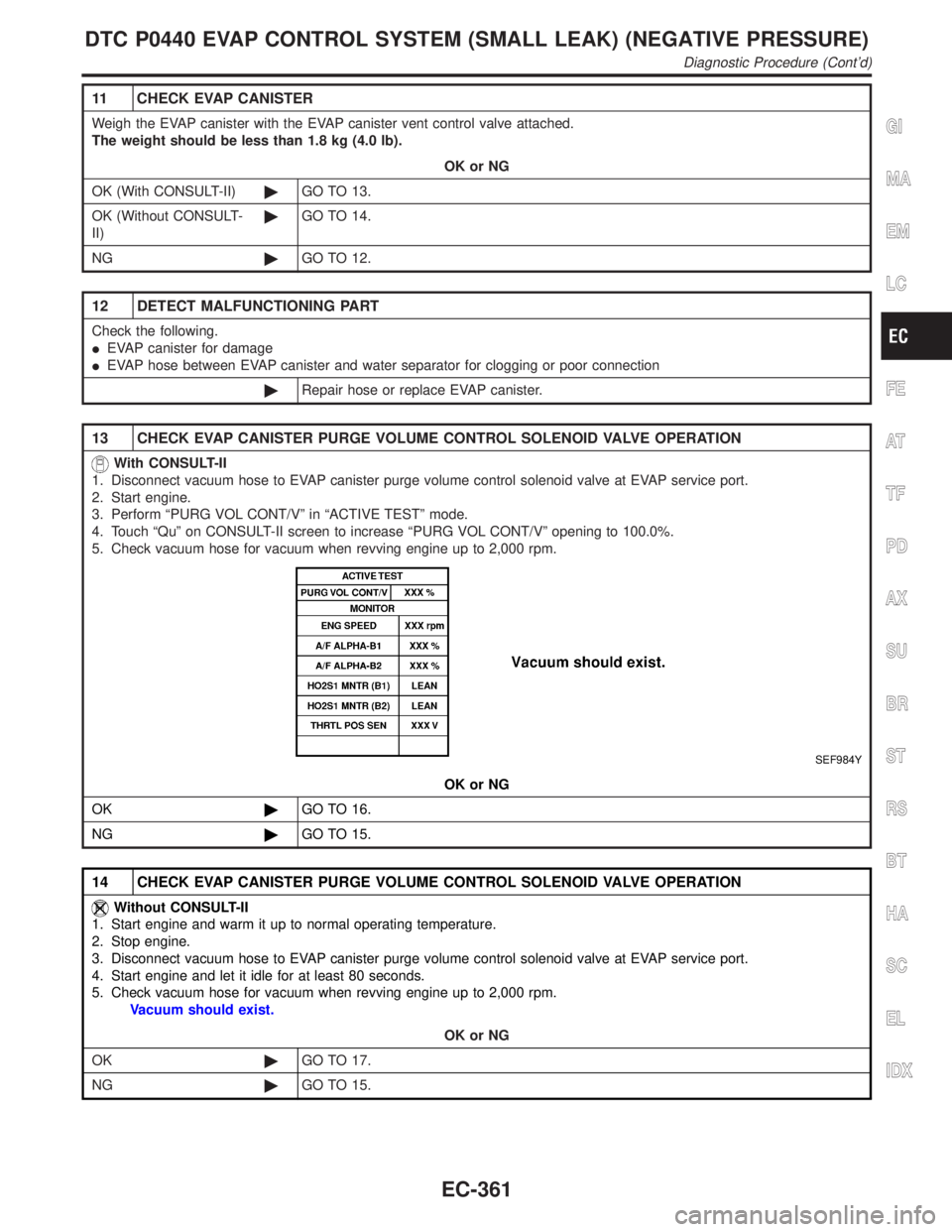

13 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With CONSULT-II

1. Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

2. Start engine.

3. Perform ªPURG VOL CONT/Vº in ªACTIVE TESTº mode.

4. Touch ªQuº on CONSULT-II screen to increase ªPURG VOL CONT/Vº opening to 100.0%.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

SEF984Y

OK or NG

OK©GO TO 16.

NG©GO TO 15.

14 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

4. Start engine and let it idle for at least 80 seconds.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

Vacuum should exist.

OK or NG

OK©GO TO 17.

NG©GO TO 15.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0440 EVAP CONTROL SYSTEM (SMALL LEAK) (NEGATIVE PRESSURE)

Diagnostic Procedure (Cont'd)

EC-361

Page 931 of 2395

SEF565X

DTC Confirmation ProcedureNBEC0646

SEF566X

SEF874X

SEF567X

CAUTION:

Never remove fuel filler cap during the DTC Confirmation Pro-

cedure.

NOTE:

IIf DTC P0455 is displayed with P1448, perform trouble

diagnosis for DTC P1448 first. (See EC-573.)

IMake sure that EVAP hoses are connected to EVAP canis-

ter purge volume control solenoid valve properly.

IIf ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

10 seconds before conducting the next test.

TESTING CONDITION:

IPerform ªDTC WORK SUPPORTº when the fuel level is

between 1/4 to 3/4 full and vehicle is placed on flat level

surface.

IOpen engine hood before conducting the following proce-

dures.

WITH CONSULT-IINBEC0646S011) Tighten fuel filler cap securely until ratcheting sound is heard.

2) Turn ignition switch ªONº.

3) Turn ignition switch ªOFFº and wait at least 10 seconds.

4) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

5) Make sure that the following conditions are met.

COOLAN TEMP/S: 0 - 70ÉC (32 - 158ÉF)

INT/A TEMP SE: 0 - 60ÉC (32 - 140ÉF)

6) Select ªEVAP SML LEAK P0440/P1440º of ªEVAPORATIVE

SYSTEMº in ªDTC WORK SUPPORTº mode with CONSULT-

II.

Follow the instruction displayed.

NOTE:

If the engine speed cannot be maintained within the range dis-

played on the CONSULT-II screen, go to ªBasic Inspectionº,

EC-101.

7) Make sure that ªOKº is displayed.

If ªNGº is displayed, select ªSELF-DIAG RESULTSº mode and

make sure that ªEVAP GROSS LEAK [P0455]º is displayed. If

it is displayed, refer to ªDiagnostic Procedureº, EC-397.

If P0440 is displayed, perform ªDiagnostic Procedureº for DTC

P0440.

WITH GSTNBEC0646S02NOTE:

Be sure to read the explanation of ªDriving Patternº on EC-66

before driving vehicle.

1) Start engine.

2) Drive vehicle according to ªDriving Patternº, EC-66.

3) Stop vehicle.

4) Select ªMODE 1º with GST.

IIf SRT of EVAP system is not set yet, go to the following step.

IIf SRT of EVAP system is set, the result will be OK.

5) Turn ignition switch ªOFFº and wait at least 10 seconds.

6) Start engine.

It is not necessary to cool engine down before driving.

7) Drive vehicle again according to the ªDriving Patternº, EC-66.

DTC P0455 EVAP CONTROL SYSTEM (GROSS LEAK)

DTC Confirmation Procedure

EC-396

Page 937 of 2395

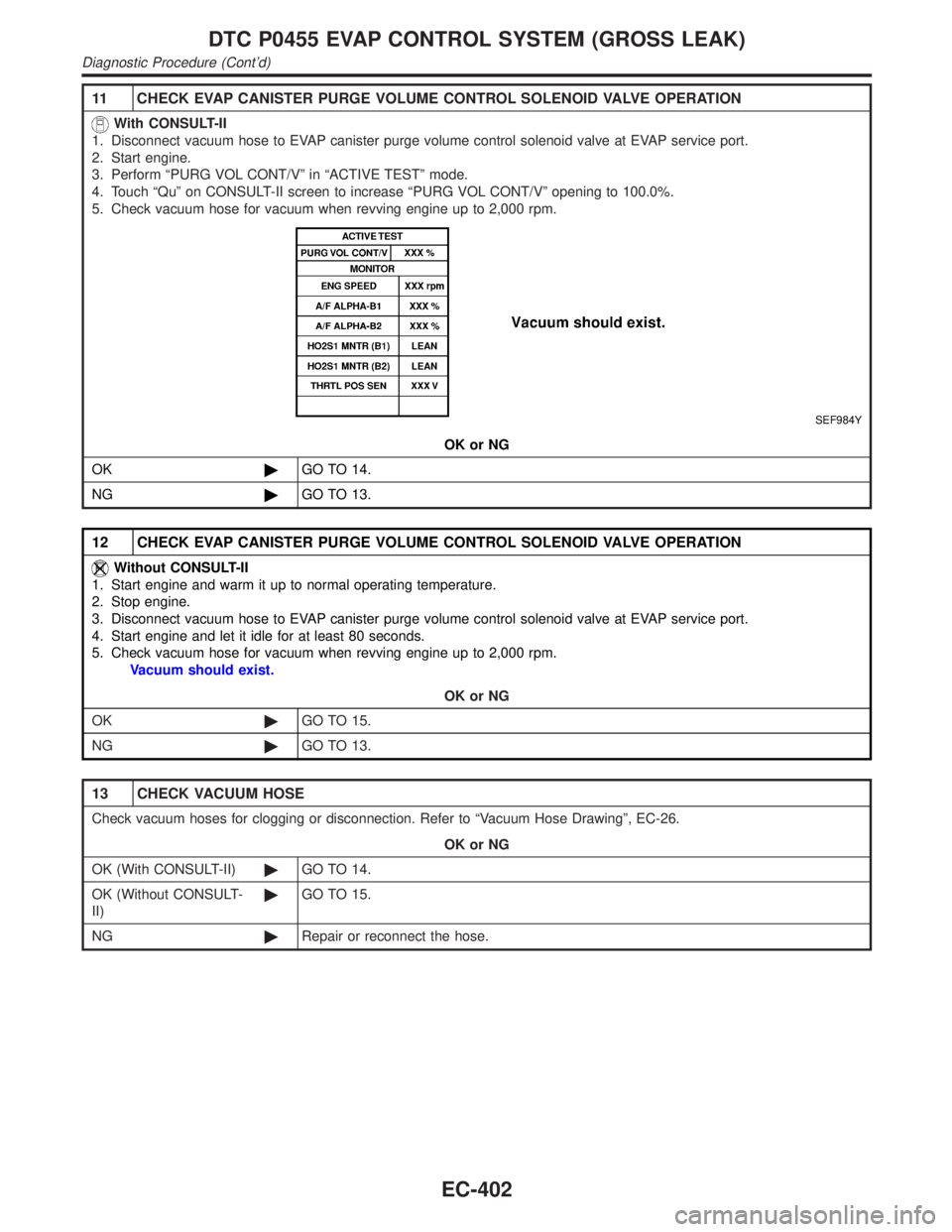

11 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With CONSULT-II

1. Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

2. Start engine.

3. Perform ªPURG VOL CONT/Vº in ªACTIVE TESTº mode.

4. Touch ªQuº on CONSULT-II screen to increase ªPURG VOL CONT/Vº opening to 100.0%.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

SEF984Y

OK or NG

OK©GO TO 14.

NG©GO TO 13.

12 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

4. Start engine and let it idle for at least 80 seconds.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

Vacuum should exist.

OK or NG

OK©GO TO 15.

NG©GO TO 13.

13 CHECK VACUUM HOSE

Check vacuum hoses for clogging or disconnection. Refer to ªVacuum Hose Drawingº, EC-26.

OK or NG

OK (With CONSULT-II)©GO TO 14.

OK (Without CONSULT-

II)©GO TO 15.

NG©Repair or reconnect the hose.

DTC P0455 EVAP CONTROL SYSTEM (GROSS LEAK)

Diagnostic Procedure (Cont'd)

EC-402