INFINITI QX4 2001 Factory Service Manual

QX4 2001

INFINITI

INFINITI

https://www.carmanualsonline.info/img/42/57027/w960_57027-0.png

INFINITI QX4 2001 Factory Service Manual

Page 306 of 2395

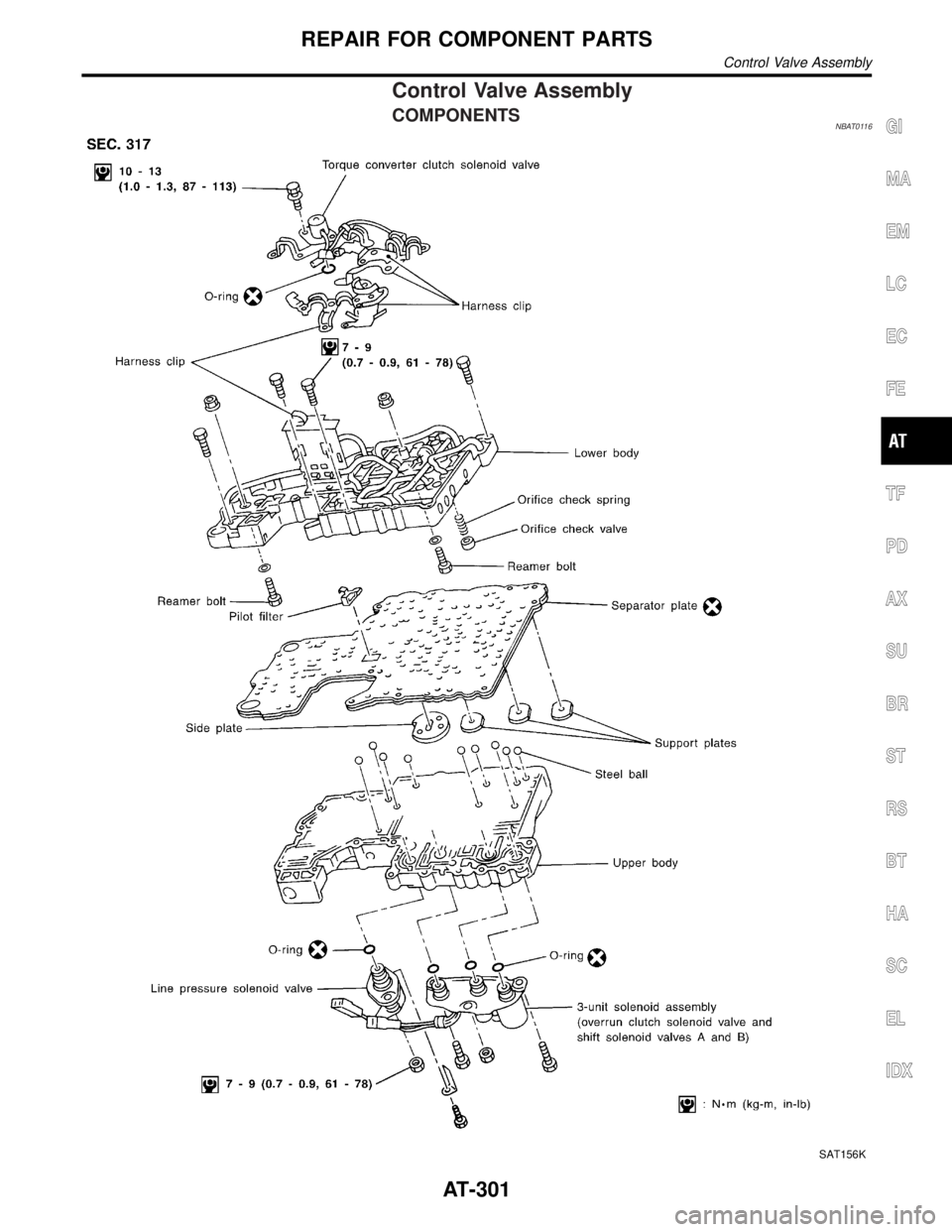

Control Valve Assembly

COMPONENTSNBAT0116

SAT156K

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Control Valve Assembly

AT-301

Page 308 of 2395

SAT671A

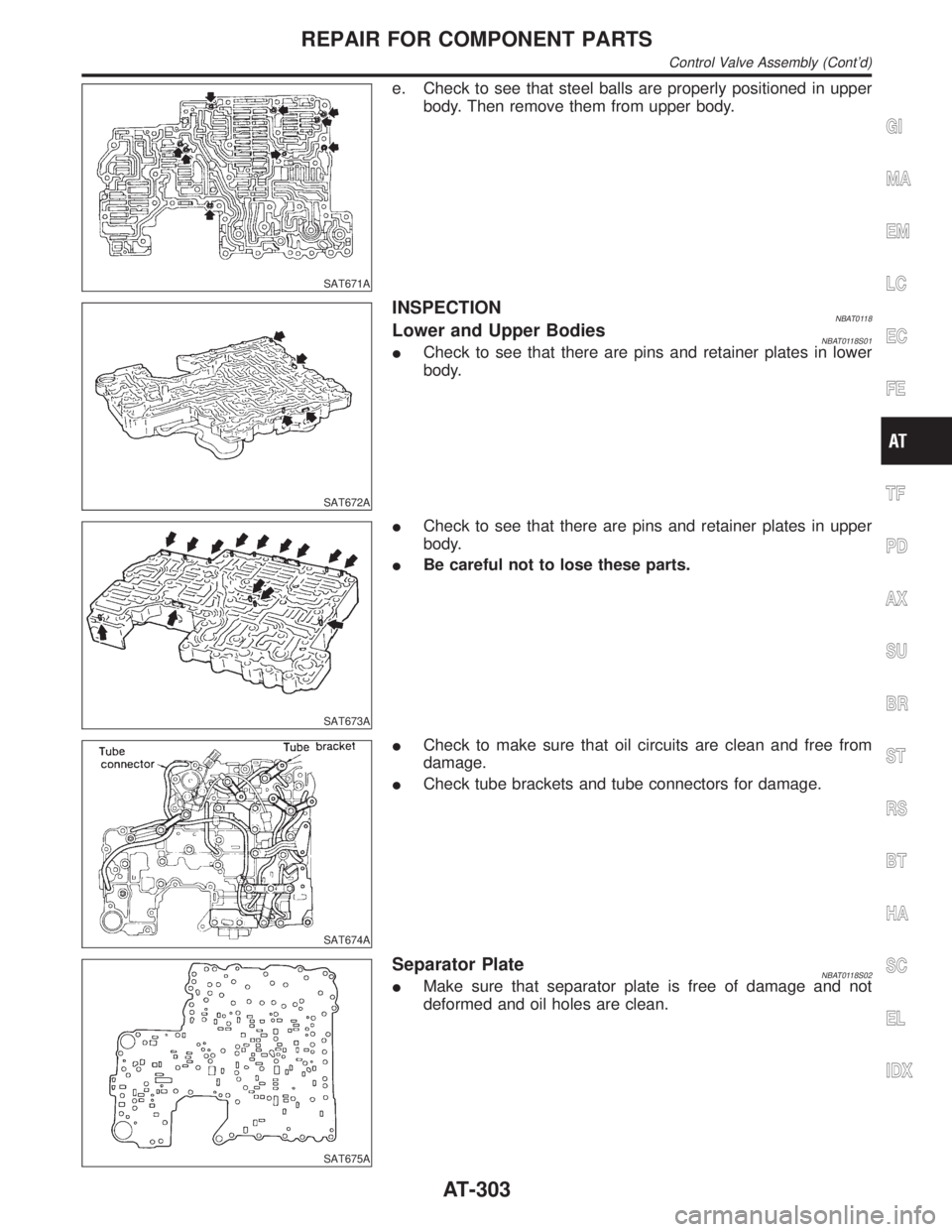

e. Check to see that steel balls are properly positioned in upper

body. Then remove them from upper body.

SAT672A

INSPECTIONNBAT0118Lower and Upper BodiesNBAT0118S01ICheck to see that there are pins and retainer plates in lower

body.

SAT673A

ICheck to see that there are pins and retainer plates in upper

body.

IBe careful not to lose these parts.

SAT674A

ICheck to make sure that oil circuits are clean and free from

damage.

ICheck tube brackets and tube connectors for damage.

SAT675A

Separator PlateNBAT0118S02IMake sure that separator plate is free of damage and not

deformed and oil holes are clean.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-303

Page 310 of 2395

SAT681A

b. Install reamer bolts from bottom of upper body.

SAT682A

c. Place oil circuit of lower body face up. Install orifice check

spring, orifice check valve and pilot filter.

SAT197B

d. Install lower separator plate on lower body.

e. Install and temporarily tighten support plates, A/T fluid tem-

perature sensor and tube brackets.

SAT198B

f. Temporarily assemble lower and upper bodies, using reamer

bolt as a guide.

IBe careful not to dislocate or drop steel balls, orifice

check spring, orifice check valve and pilot filter.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-305

Page 312 of 2395

Control Valve Upper Body

COMPONENTSNBAT0120

SAT142JA

Apply ATF to all components before their installation.

Numbers preceding valve springs correspond with those shown in SDS on page AT-357.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Control Valve Upper Body

AT-307

Page 314 of 2395

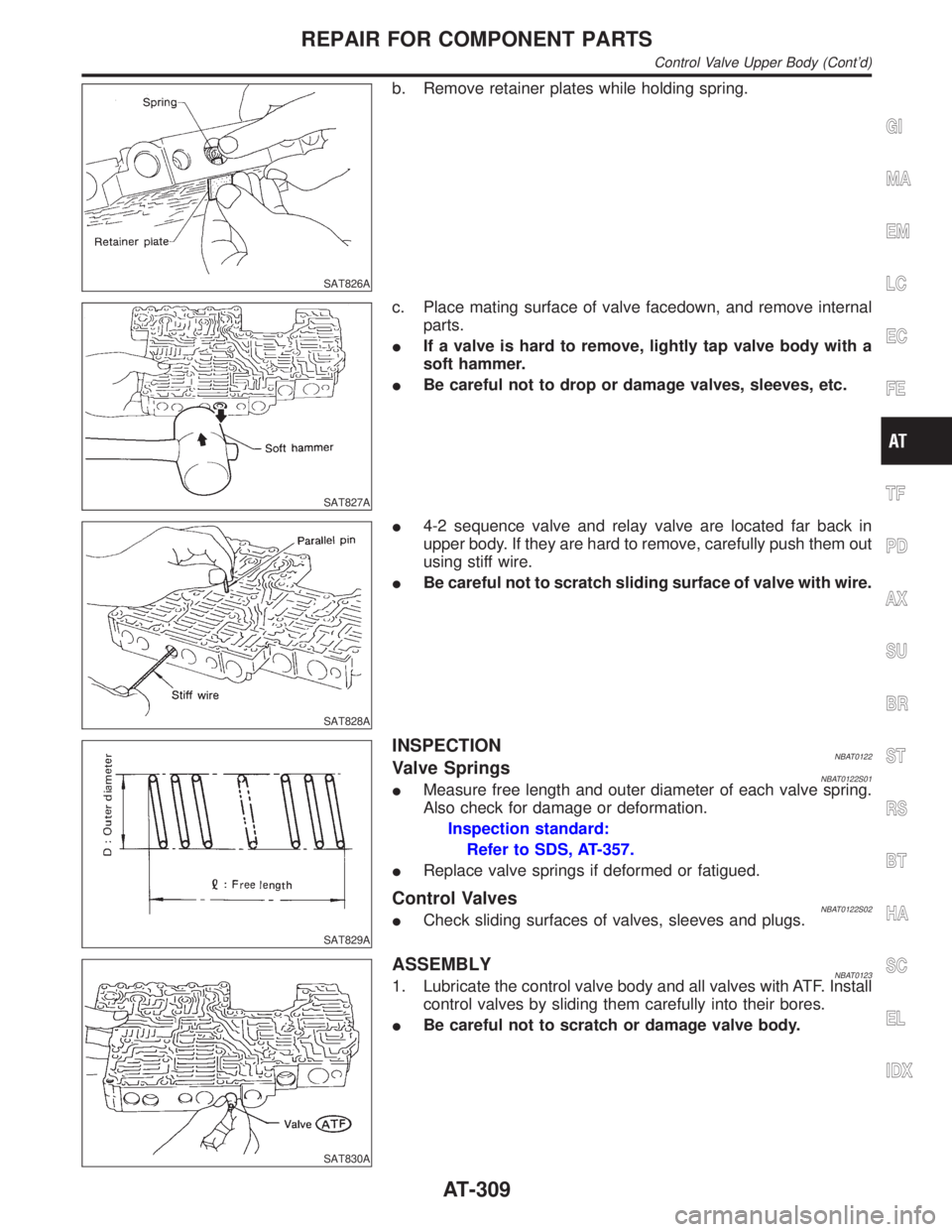

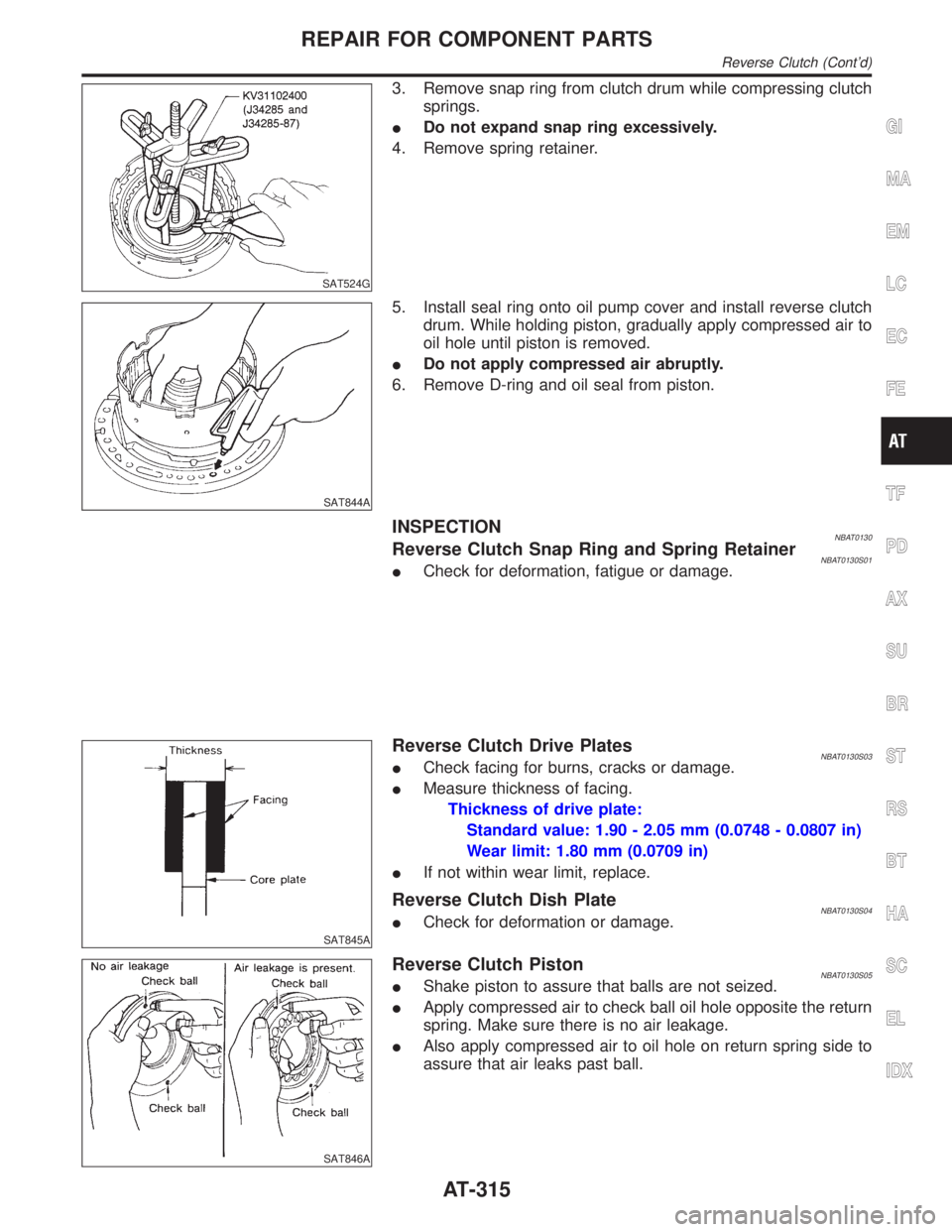

SAT826A

b. Remove retainer plates while holding spring.

SAT827A

c. Place mating surface of valve facedown, and remove internal

parts.

IIf a valve is hard to remove, lightly tap valve body with a

soft hammer.

IBe careful not to drop or damage valves, sleeves, etc.

SAT828A

I4-2 sequence valve and relay valve are located far back in

upper body. If they are hard to remove, carefully push them out

using stiff wire.

IBe careful not to scratch sliding surface of valve with wire.

SAT829A

INSPECTIONNBAT0122Valve SpringsNBAT0122S01IMeasure free length and outer diameter of each valve spring.

Also check for damage or deformation.

Inspection standard:

Refer to SDS, AT-357.

IReplace valve springs if deformed or fatigued.

Control ValvesNBAT0122S02ICheck sliding surfaces of valves, sleeves and plugs.

SAT830A

ASSEMBLYNBAT01231. Lubricate the control valve body and all valves with ATF. Install

control valves by sliding them carefully into their bores.

IBe careful not to scratch or damage valve body.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Control Valve Upper Body (Cont'd)

AT-309

Page 316 of 2395

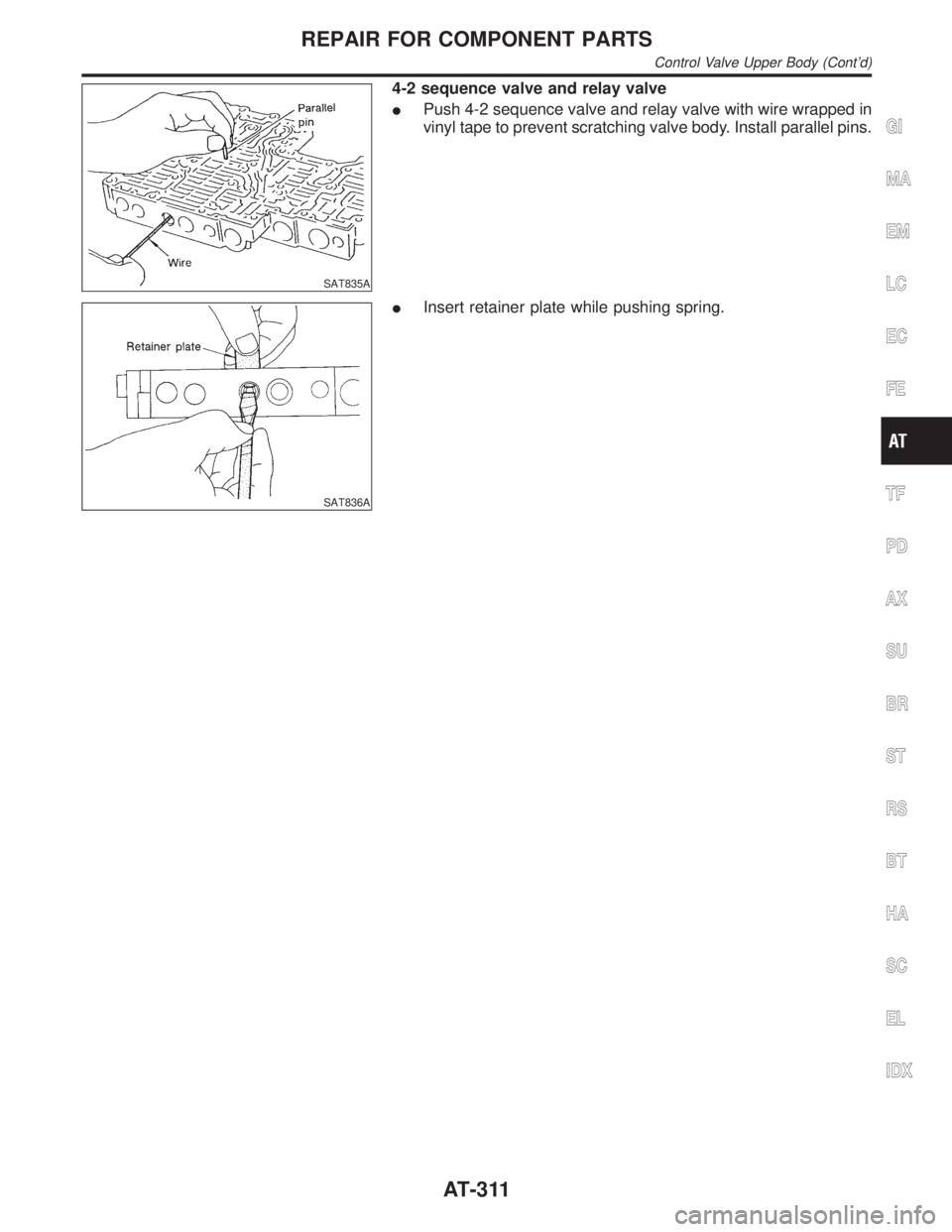

SAT835A

4-2 sequence valve and relay valve

IPush 4-2 sequence valve and relay valve with wire wrapped in

vinyl tape to prevent scratching valve body. Install parallel pins.

SAT836A

IInsert retainer plate while pushing spring.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Control Valve Upper Body (Cont'd)

AT-311

Page 318 of 2395

SAT838A

DISASSEMBLYNBAT01251. Remove valves at parallel pins.

2. Remove valves at retainer plates.

For removal procedures, refer to ªDISASSEMBLYº of Control

Valve Upper Body.

SAT829A

INSPECTIONNBAT0126Valve SpringsNBAT0126S01ICheck each valve spring for damage or deformation. Also

measure free length and outer diameter.

Inspection standard:

Refer to SDS, AT-357.

IReplace valve springs if deformed or fatigued.

Control ValvesNBAT0126S02ICheck sliding surfaces of control valves, sleeves and plugs for

damage.

SAT838A

ASSEMBLYNBAT0127IInstall control valves.

For installation procedures, refer to ªASSEMBLYº of Control

Valve Upper Body, AT-309.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Control Valve Lower Body (Cont'd)

AT-313

Page 320 of 2395

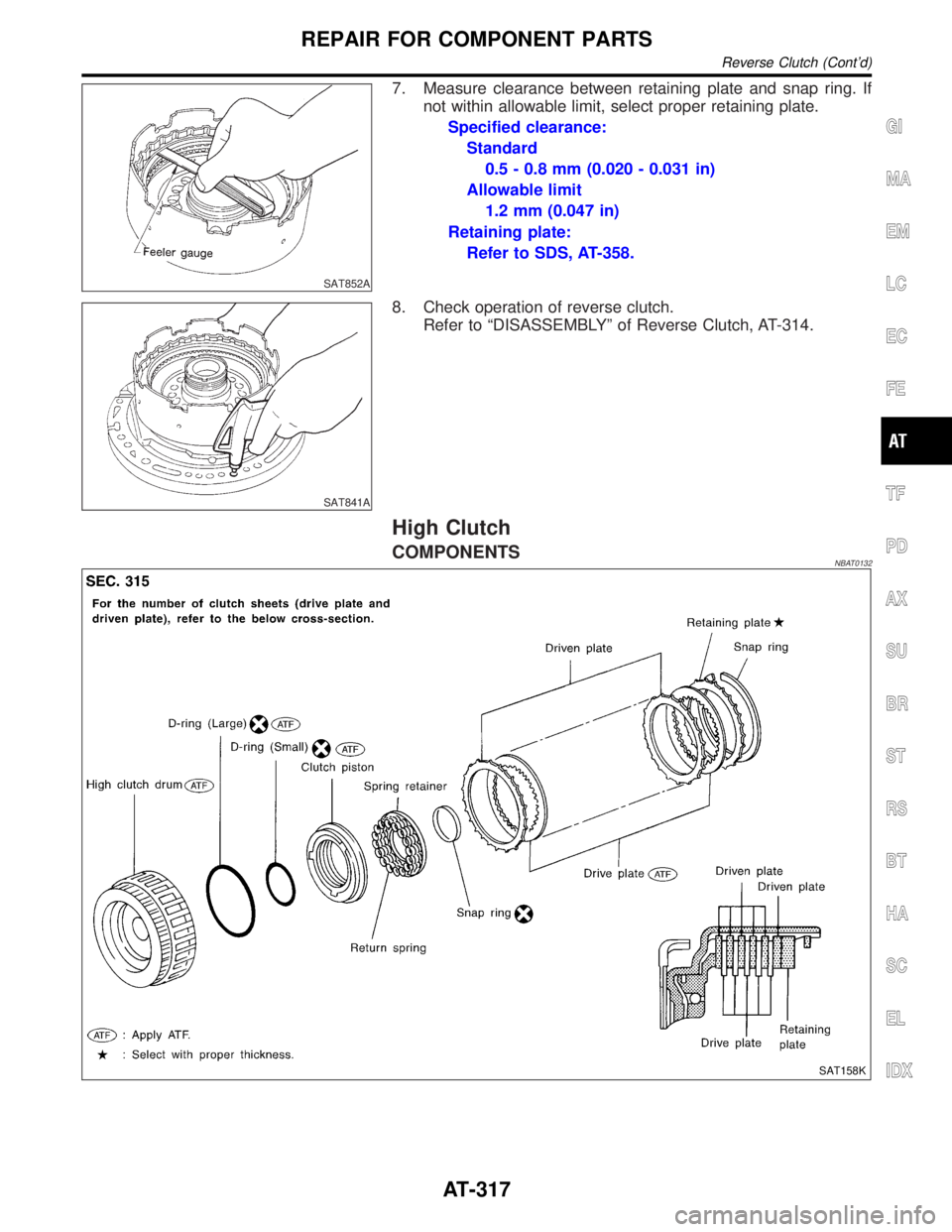

SAT524G

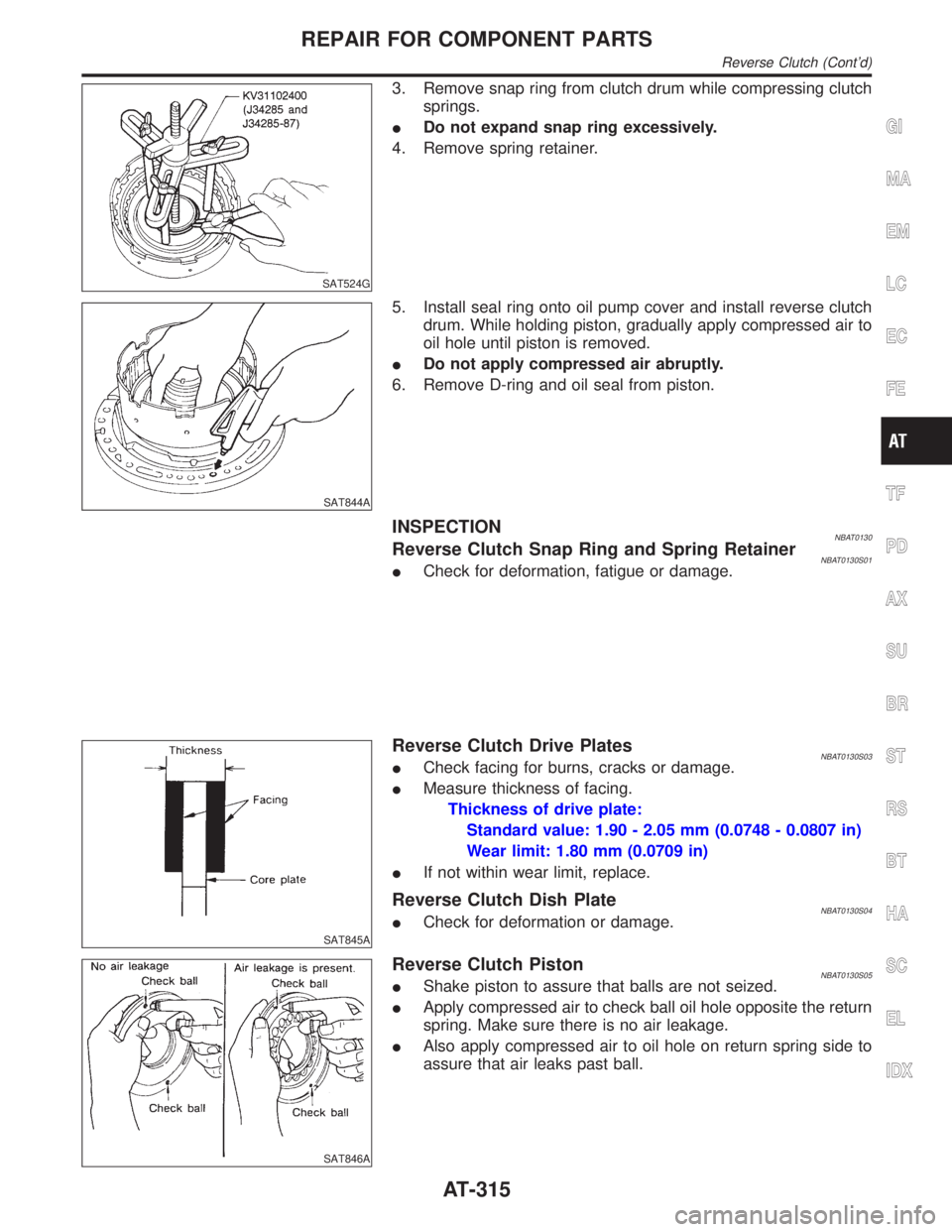

3. Remove snap ring from clutch drum while compressing clutch

springs.

IDo not expand snap ring excessively.

4. Remove spring retainer.

SAT844A

5. Install seal ring onto oil pump cover and install reverse clutch

drum. While holding piston, gradually apply compressed air to

oil hole until piston is removed.

IDo not apply compressed air abruptly.

6. Remove D-ring and oil seal from piston.

INSPECTIONNBAT0130Reverse Clutch Snap Ring and Spring RetainerNBAT0130S01ICheck for deformation, fatigue or damage.

SAT845A

Reverse Clutch Drive PlatesNBAT0130S03ICheck facing for burns, cracks or damage.

IMeasure thickness of facing.

Thickness of drive plate:

Standard value: 1.90 - 2.05 mm (0.0748 - 0.0807 in)

Wear limit: 1.80 mm (0.0709 in)

IIf not within wear limit, replace.

Reverse Clutch Dish PlateNBAT0130S04ICheck for deformation or damage.

SAT846A

Reverse Clutch PistonNBAT0130S05IShake piston to assure that balls are not seized.

IApply compressed air to check ball oil hole opposite the return

spring. Make sure there is no air leakage.

IAlso apply compressed air to oil hole on return spring side to

assure that air leaks past ball.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Reverse Clutch (Cont'd)

AT-315

Page 322 of 2395

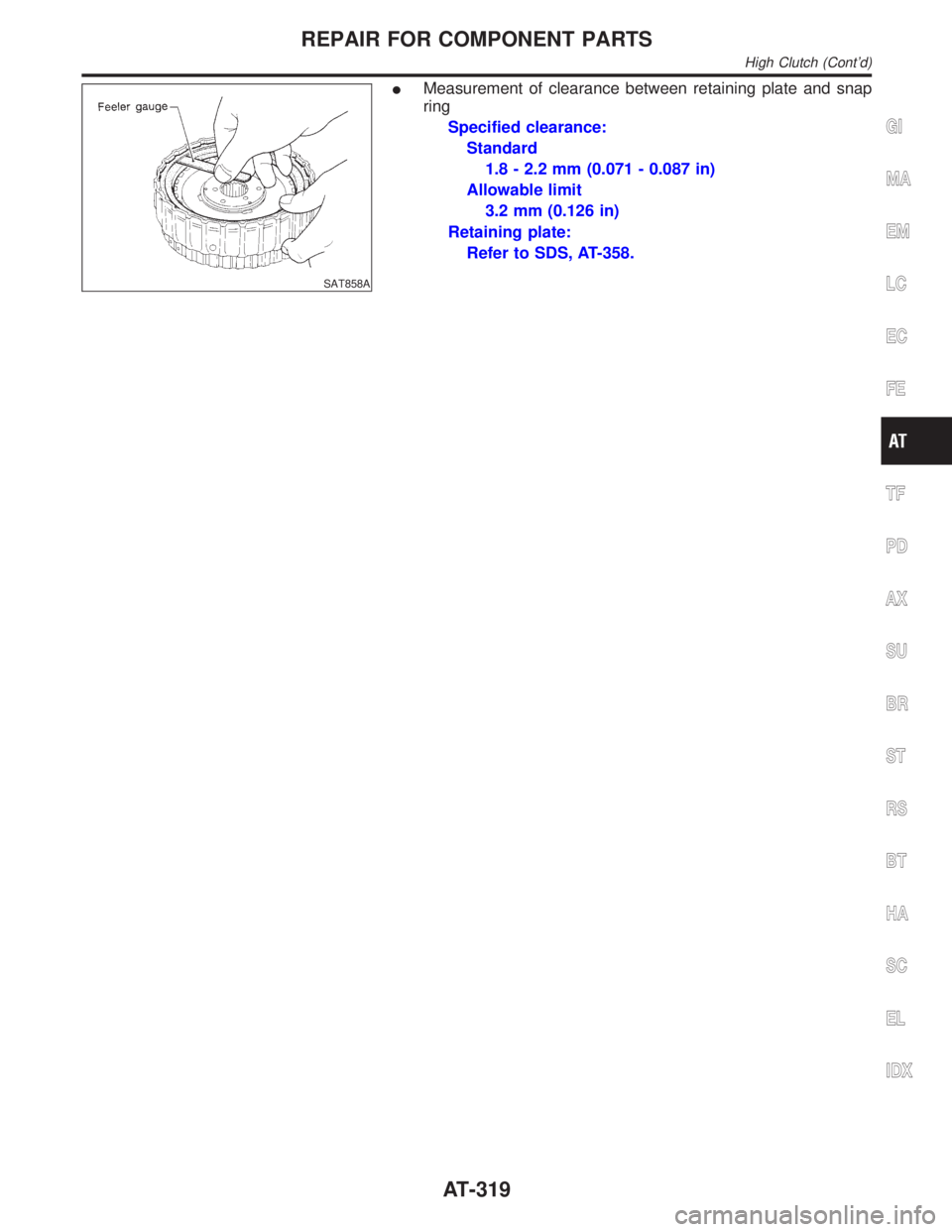

SAT852A

7. Measure clearance between retaining plate and snap ring. If

not within allowable limit, select proper retaining plate.

Specified clearance:

Standard

0.5 - 0.8 mm (0.020 - 0.031 in)

Allowable limit

1.2 mm (0.047 in)

Retaining plate:

Refer to SDS, AT-358.

SAT841A

8. Check operation of reverse clutch.

Refer to ªDISASSEMBLYº of Reverse Clutch, AT-314.

High Clutch

COMPONENTSNBAT0132

SAT158K

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Reverse Clutch (Cont'd)

AT-317

Page 324 of 2395

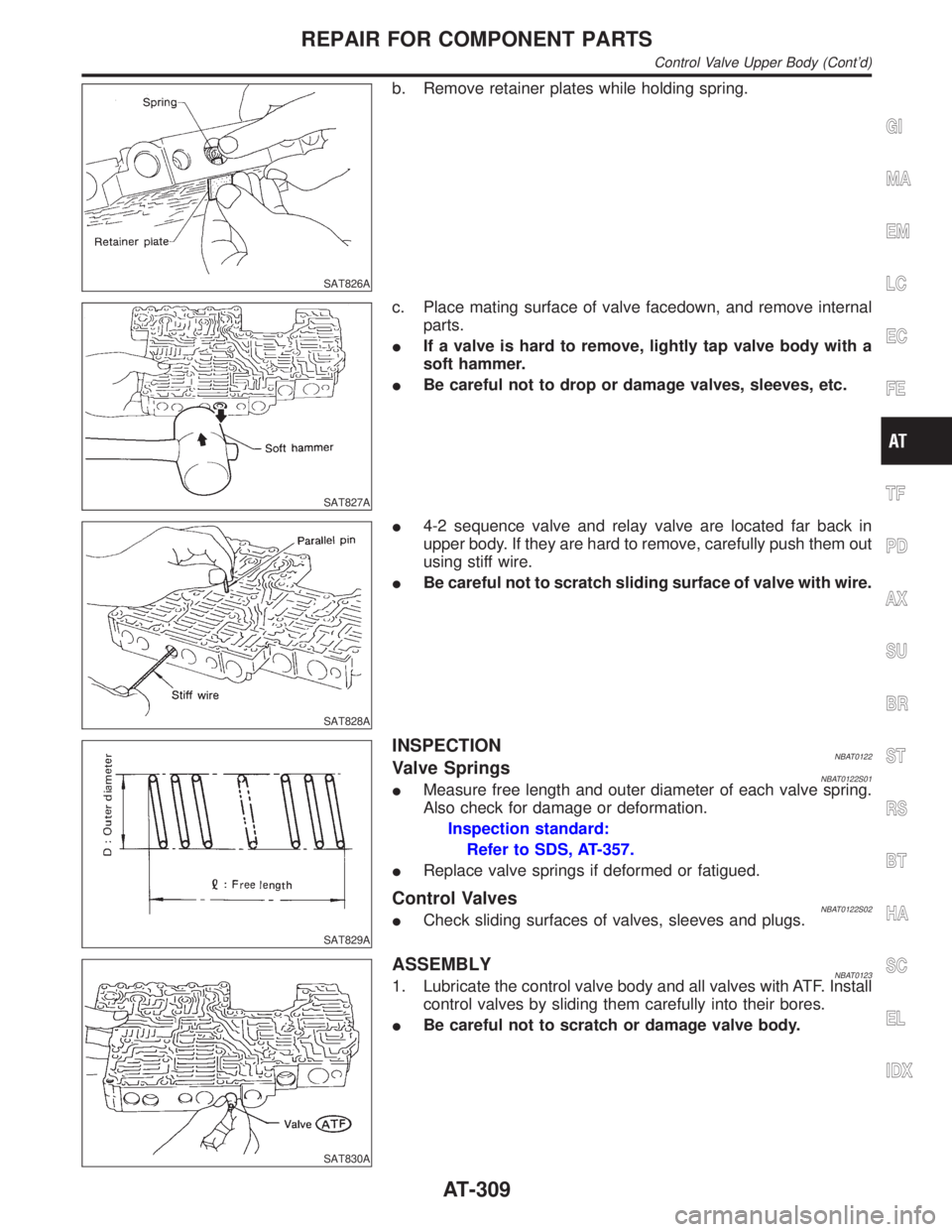

SAT858A

IMeasurement of clearance between retaining plate and snap

ring

Specified clearance:

Standard

1.8 - 2.2 mm (0.071 - 0.087 in)

Allowable limit

3.2 mm (0.126 in)

Retaining plate:

Refer to SDS, AT-358.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

High Clutch (Cont'd)

AT-319