INFINITI QX4 2001 Factory Service Manual

QX4 2001

INFINITI

INFINITI

https://www.carmanualsonline.info/img/42/57027/w960_57027-0.png

INFINITI QX4 2001 Factory Service Manual

Page 286 of 2395

ComponentsNBAT0108

SAT147JA

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OVERHAUL

Components

AT-281

Page 288 of 2395

SAT155K

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OVERHAUL

Components (Cont'd)

AT-283

Page 290 of 2395

Locations of Needle Bearings, Thrust Washers

and Snap Rings

NBAT0110

SAT140JB

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OVERHAUL

Locations of Needle Bearings, Thrust Washers and Snap Rings

AT-285

Page 292 of 2395

SAT171B

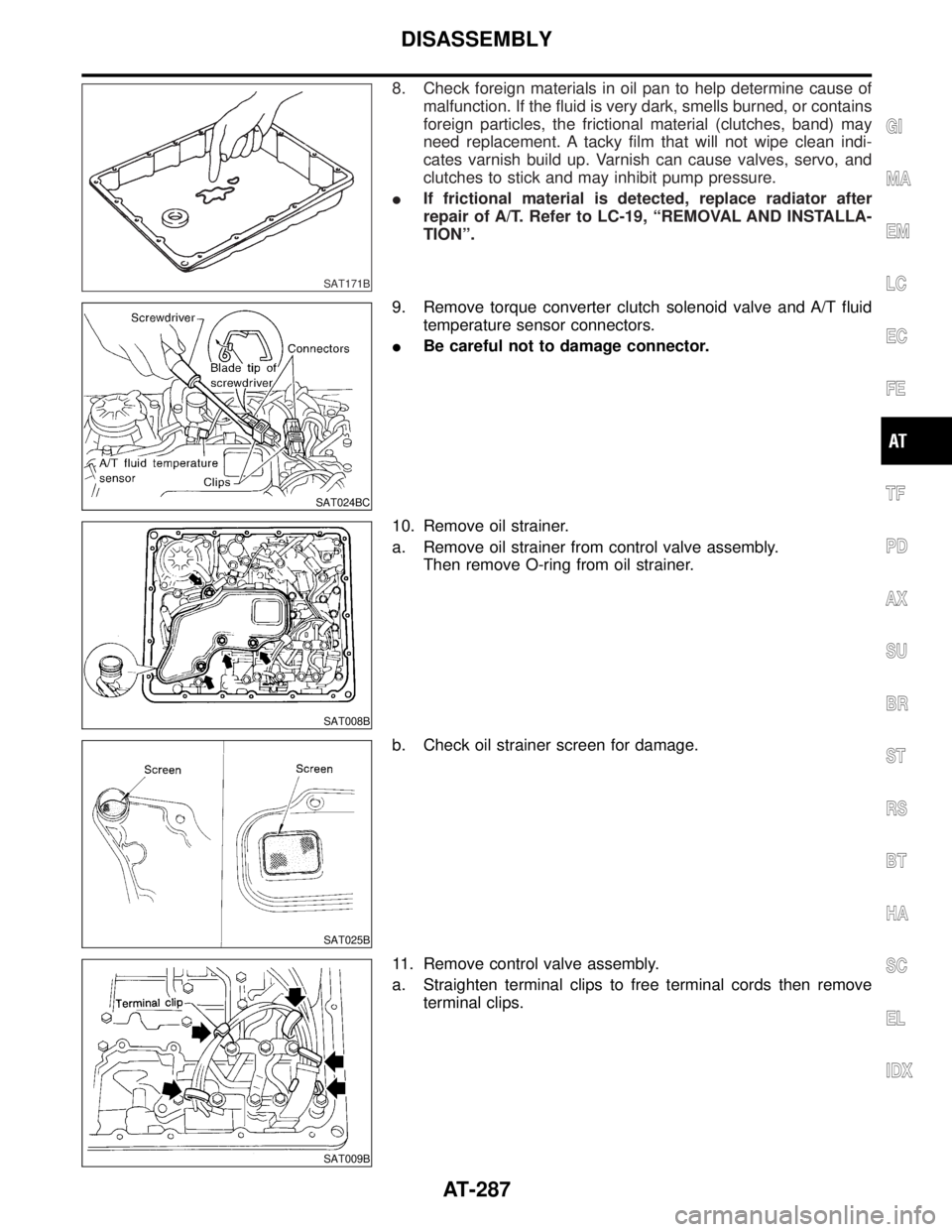

8. Check foreign materials in oil pan to help determine cause of

malfunction. If the fluid is very dark, smells burned, or contains

foreign particles, the frictional material (clutches, band) may

need replacement. A tacky film that will not wipe clean indi-

cates varnish build up. Varnish can cause valves, servo, and

clutches to stick and may inhibit pump pressure.

IIf frictional material is detected, replace radiator after

repair of A/T. Refer to LC-19, ªREMOVAL AND INSTALLA-

TIONº.

SAT024BC

9. Remove torque converter clutch solenoid valve and A/T fluid

temperature sensor connectors.

IBe careful not to damage connector.

SAT008B

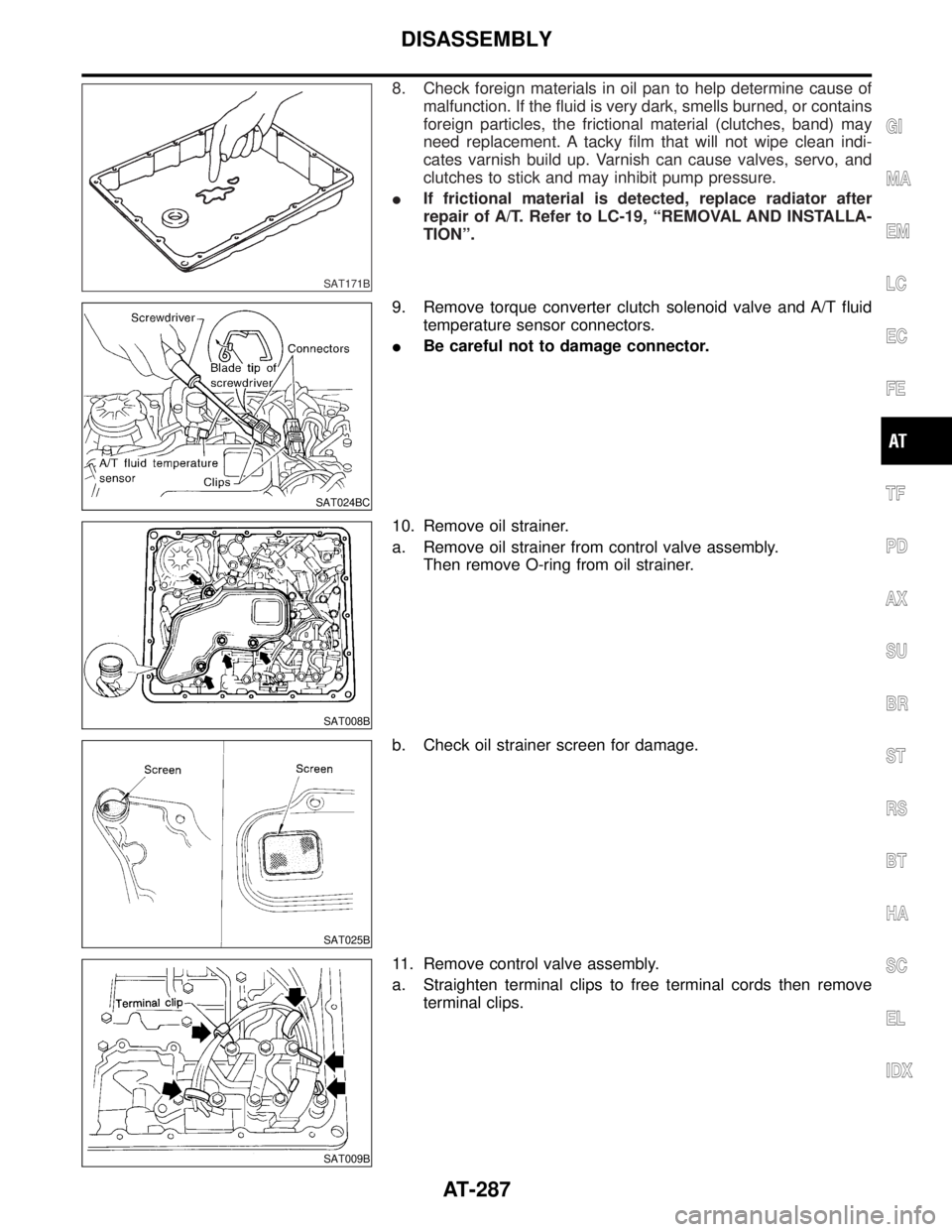

10. Remove oil strainer.

a. Remove oil strainer from control valve assembly.

Then remove O-ring from oil strainer.

SAT025B

b. Check oil strainer screen for damage.

SAT009B

11. Remove control valve assembly.

a. Straighten terminal clips to free terminal cords then remove

terminal clips.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DISASSEMBLY

AT-287

Page 294 of 2395

SAT999A

13. Remove converter housing from transmission case.

IBe careful not to scratch converter housing.

SAT995A

14. Remove O-ring from input shaft.

SAT027B

15. Remove oil pump assembly.

a. Attach Tool to oil pump assembly and extract it evenly from

transmission case.

SAT028B

b. Remove O-ring from oil pump assembly.

c. Remove traces of sealant from oil pump housing.

IBe careful not to scratch pump housing.

SAT108B

d. Remove needle bearing and thrust washer from oil pump

assembly.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DISASSEMBLY

AT-289

Page 296 of 2395

SAT113B

b. Remove front bearing race from clutch pack.

c. Remove rear bearing race from clutch pack.

SAT031B

d. Remove front planetary carrier from transmission case.

SAT968A

e. Remove front needle bearing from front planetary carrier.

f. Remove rear bearing from front planetary carrier.

SAT974A

g. Remove rear sun gear from transmission case.

SAT546J

19. Remove rear extension assembly (2WD model only).

a. Remove rear extension assembly.

b. Remove parking gear and needle bearing.

CAUTION:

Insert your hand between rear extension and transmission

case. Detach rear extension assembly while holding parking

gear and needle bearing by hand.

c. Remove rear extension gasket.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DISASSEMBLY

AT-291

Page 298 of 2395

SAT109B

d. Remove output shaft and parking gear as a unit from transmis-

sion case.

e. Remove parking gear from output shaft.

SAT033B

f. Remove needle bearing from transmission case.

SAT954A

23. Remove rear side clutch and gear components.

a. Remove front internal gear.

SAT110B

b. Remove bearing race from front internal gear.

SAT111B

c. Remove needle bearing from rear internal gear.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DISASSEMBLY

AT-293

Page 300 of 2395

SAT039B

b. Apply compressed air to oil hole until band servo piston comes

out of transmission case.

IHold piston with a rag and gradually direct air to oil hole.

c. Remove return springs.

SAT040BA

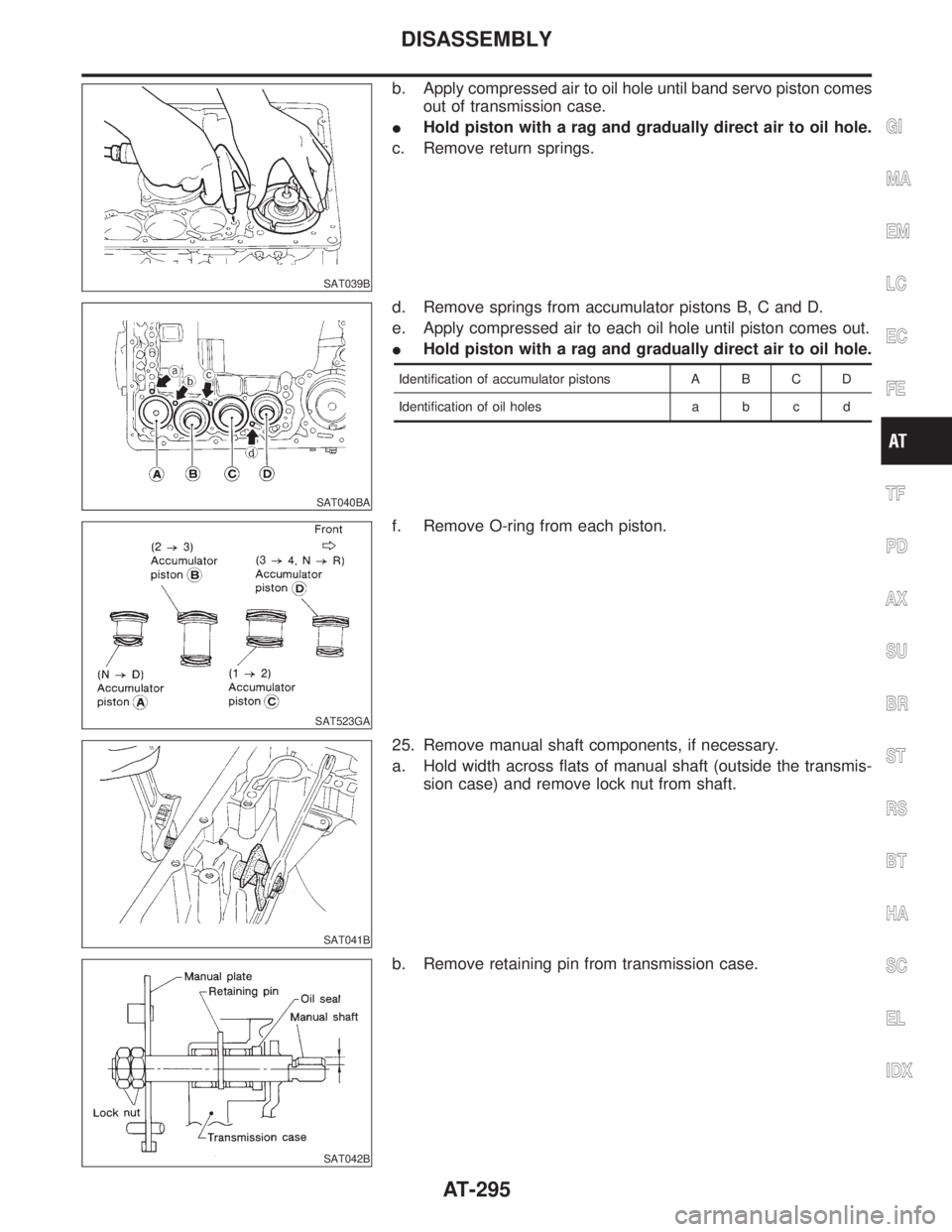

d. Remove springs from accumulator pistons B, C and D.

e. Apply compressed air to each oil hole until piston comes out.

IHold piston with a rag and gradually direct air to oil hole.

Identification of accumulator pistons A B C D

Identification of oil holes a b c d

SAT523GA

f. Remove O-ring from each piston.

SAT041B

25. Remove manual shaft components, if necessary.

a. Hold width across flats of manual shaft (outside the transmis-

sion case) and remove lock nut from shaft.

SAT042B

b. Remove retaining pin from transmission case.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DISASSEMBLY

AT-295

Page 302 of 2395

Oil Pump

COMPONENTSNBAT0112

SAT648AB

SAT649A

DISASSEMBLYNBAT01131. Loosen bolts in numerical order and remove oil pump cover.

SAT650A

2. Remove rotor, vane rings and vanes.

IInscribe a mark on back of rotor for identification of fore-

aft direction when reassembling rotor. Then remove rotor.

SAT651A

3. While pushing on cam ring remove pivot pin.

IBe careful not to scratch oil pump housing.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Oil Pump

AT-297

Page 304 of 2395

SAT657A

SAT658A

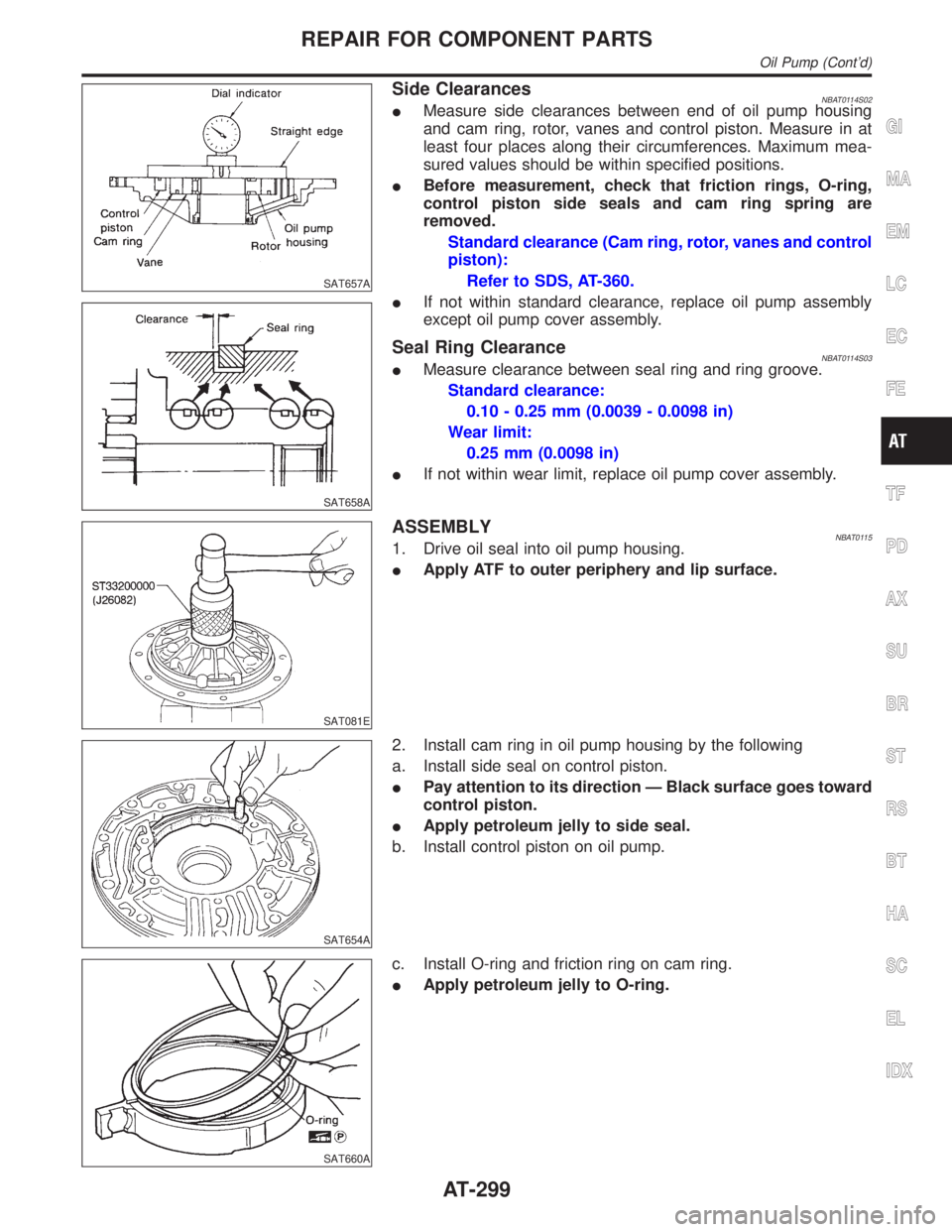

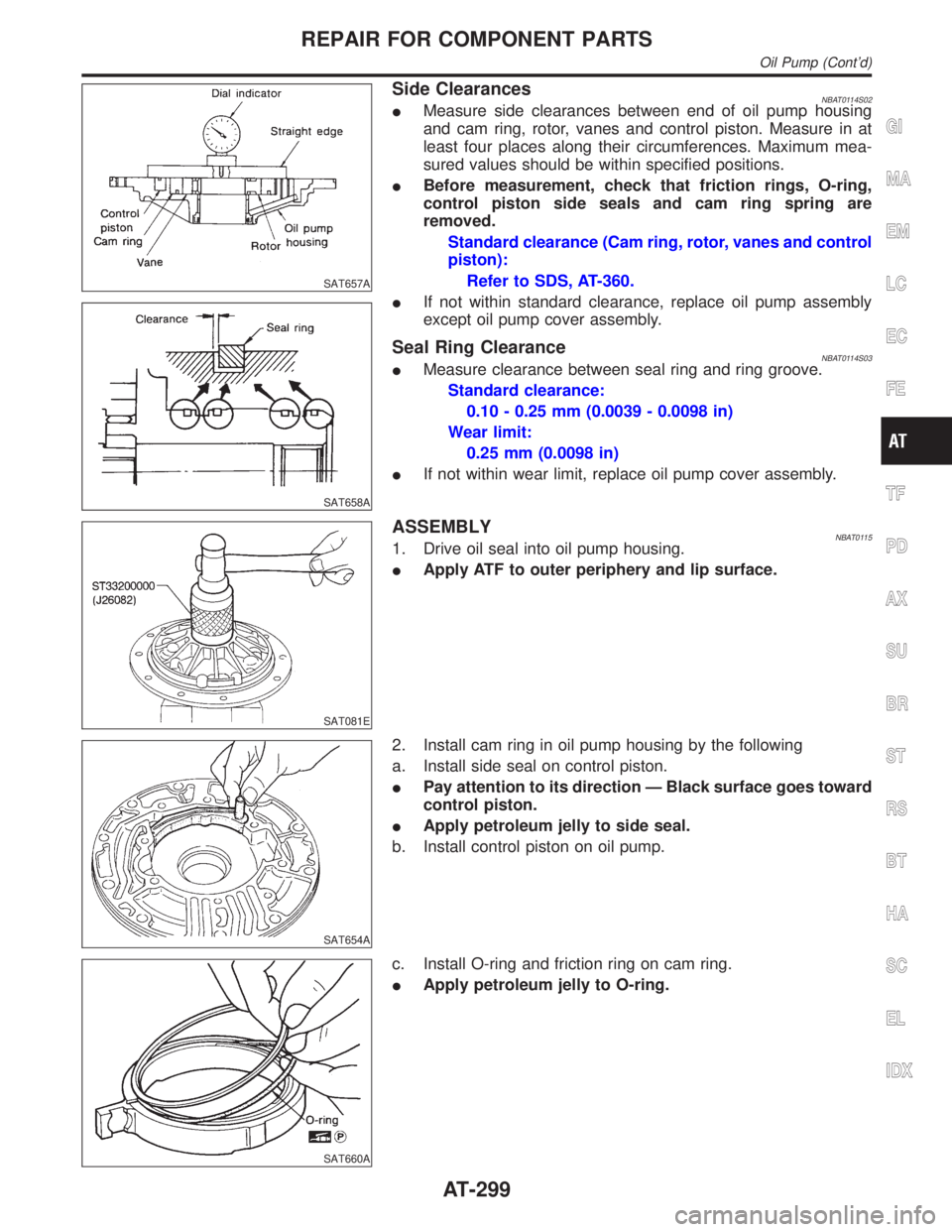

Side ClearancesNBAT0114S02IMeasure side clearances between end of oil pump housing

and cam ring, rotor, vanes and control piston. Measure in at

least four places along their circumferences. Maximum mea-

sured values should be within specified positions.

IBefore measurement, check that friction rings, O-ring,

control piston side seals and cam ring spring are

removed.

Standard clearance (Cam ring, rotor, vanes and control

piston):

Refer to SDS, AT-360.

IIf not within standard clearance, replace oil pump assembly

except oil pump cover assembly.

Seal Ring ClearanceNBAT0114S03IMeasure clearance between seal ring and ring groove.

Standard clearance:

0.10 - 0.25 mm (0.0039 - 0.0098 in)

Wear limit:

0.25 mm (0.0098 in)

IIf not within wear limit, replace oil pump cover assembly.

SAT081E

ASSEMBLYNBAT01151. Drive oil seal into oil pump housing.

IApply ATF to outer periphery and lip surface.

SAT654A

2. Install cam ring in oil pump housing by the following

a. Install side seal on control piston.

IPay attention to its direction Ð Black surface goes toward

control piston.

IApply petroleum jelly to side seal.

b. Install control piston on oil pump.

SAT660A

c. Install O-ring and friction ring on cam ring.

IApply petroleum jelly to O-ring.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Oil Pump (Cont'd)

AT-299