IDX INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 366 of 2395

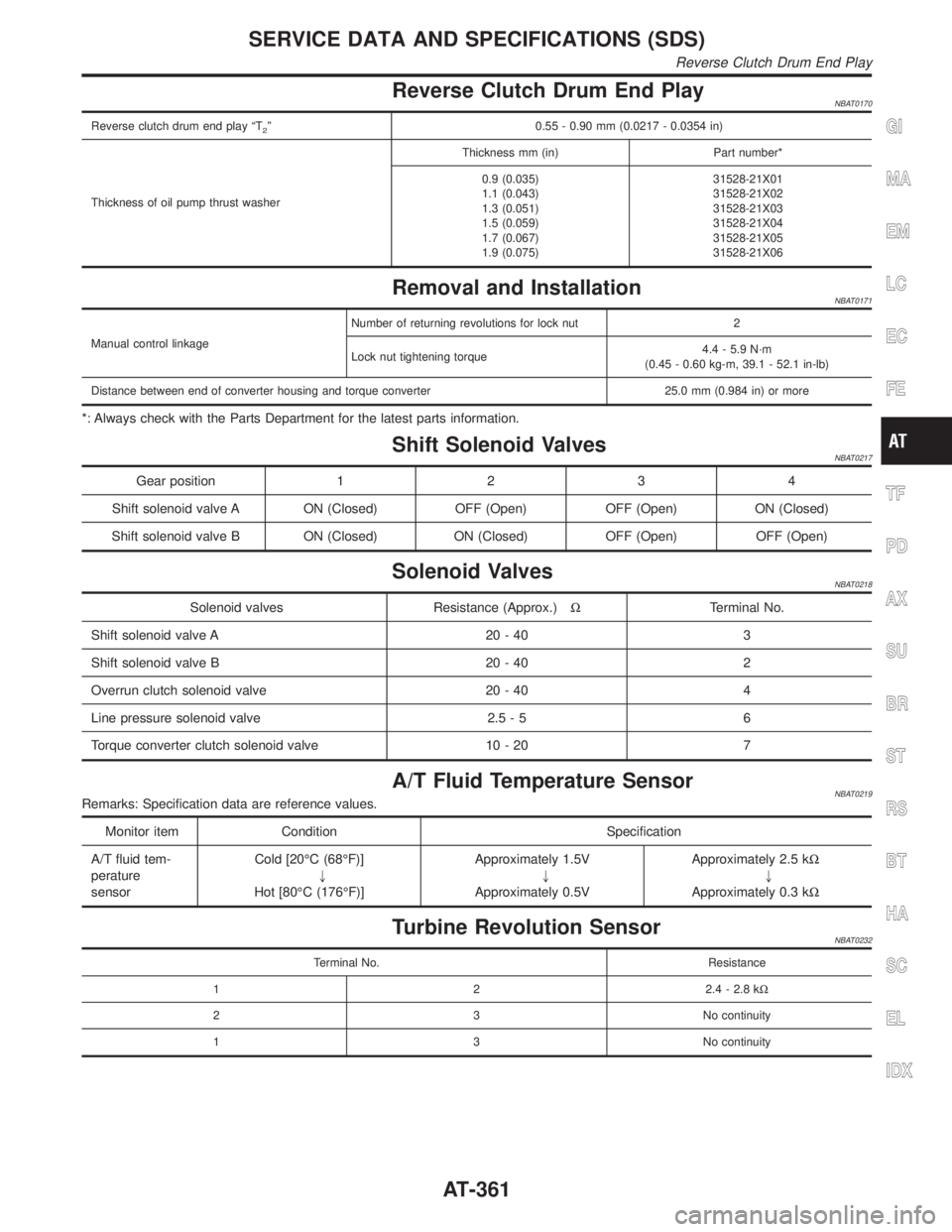

Reverse Clutch Drum End PlayNBAT0170

Reverse clutch drum end play ªT2º 0.55 - 0.90 mm (0.0217 - 0.0354 in)

Thickness of oil pump thrust washerThickness mm (in) Part number*

0.9 (0.035)

1.1 (0.043)

1.3 (0.051)

1.5 (0.059)

1.7 (0.067)

1.9 (0.075)31528-21X01

31528-21X02

31528-21X03

31528-21X04

31528-21X05

31528-21X06

Removal and InstallationNBAT0171

Manual control linkageNumber of returning revolutions for lock nut 2

Lock nut tightening torque4.4 - 5.9 N´m

(0.45 - 0.60 kg-m, 39.1 - 52.1 in-lb)

Distance between end of converter housing and torque converter 25.0 mm (0.984 in) or more

*: Always check with the Parts Department for the latest parts information.

Shift Solenoid ValvesNBAT0217

Gear position1234

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

Solenoid ValvesNBAT0218

Solenoid valves Resistance (Approx.)WTerminal No.

Shift solenoid valve A 20 - 40 3

Shift solenoid valve B 20 - 40 2

Overrun clutch solenoid valve 20 - 40 4

Line pressure solenoid valve 2.5 - 5 6

Torque converter clutch solenoid valve 10 - 20 7

A/T Fluid Temperature SensorNBAT0219Remarks: Specification data are reference values.

Monitor item Condition Specification

A/T fluid tem-

perature

sensorCold [20ÉC (68ÉF)]

"

Hot [80ÉC (176ÉF)]Approximately 1.5V

"

Approximately 0.5VApproximately 2.5 kW

"

Approximately 0.3 kW

Turbine Revolution SensorNBAT0232

Terminal No. Resistance

1 2 2.4 - 2.8 kW

2 3 No continuity

1 3 No continuity

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Reverse Clutch Drum End Play

AT-361

Page 368 of 2395

FRONT & REAR AXLE

SECTION

AX

CONTENTS

FRONT AXLE..................................................................2

Precautions ..................................................................2

PRECAUTIONS.........................................................2

Preparation ..................................................................2

SPECIAL SERVICE TOOLS........................................2

COMMERCIAL SERVICE TOOLS................................2

Noise, Vibration and Harshness (NVH)

Troubleshooting ...........................................................3

NVH TROUBLESHOOTING CHART............................3

On-vehicle Service.......................................................3

FRONT AXLE PARTS................................................3

FRONT WHEEL BEARING.........................................4

DRIVE SHAFT...........................................................5

Wheel Hub and Rotor Disc..........................................6

COMPONENTS.........................................................6

REMOVAL.................................................................6

INSTALLATION..........................................................7

DISASSEMBLY..........................................................8

INSPECTION.............................................................8

ASSEMBLY...............................................................8

Knuckle Spindle ...........................................................9

REMOVAL.................................................................9

INSPECTION...........................................................10

INSTALLATION........................................................10

Drive Shaft .................................................................10

COMPONENTS.......................................................10

REMOVAL............................................................... 11

DISASSEMBLY........................................................ 11

INSPECTION...........................................................12

ASSEMBLY.............................................................13

INSTALLATION........................................................14

Service Data and Specifications (SDS).....................15

WHEEL BEARING (FRONT).....................................15

DRIVE SHAFT.........................................................16

REAR AXLE...................................................................17

Precautions ................................................................17

PRECAUTIONS.......................................................17

Preparation ................................................................17

SPECIAL SERVICE TOOLS......................................17

COMMERCIAL SERVICE TOOLS..............................18

Noise, Vibration and Harshness (NVH)

Troubleshooting .........................................................18

On-vehicle Service.....................................................18

REAR AXLE PARTS.................................................18

REAR WHEEL BEARING.........................................18

Components...............................................................19

Removal .....................................................................19

Inspection...................................................................21

AXLE SHAFT...........................................................21

BEARING CAGE......................................................21

REAR AXLE HOUSING............................................21

Installation ..................................................................21

Service Data and Specifications (SDS).....................22

WHEEL BEARING (REAR).......................................22

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 370 of 2395

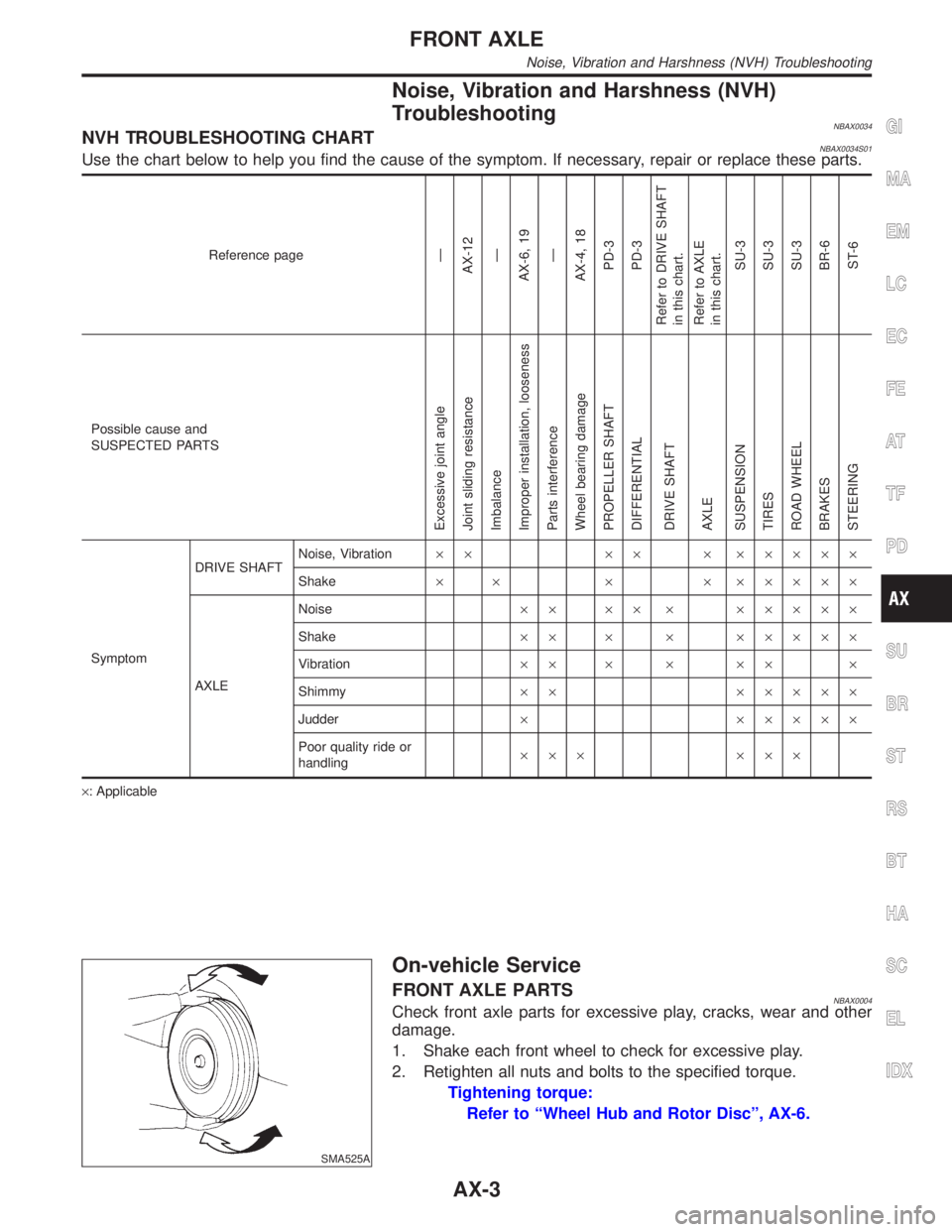

Noise, Vibration and Harshness (NVH)

Troubleshooting

NBAX0034NVH TROUBLESHOOTING CHARTNBAX0034S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageÐ

AX-12

Ð

AX-6, 19

Ð

AX-4, 18

PD-3

PD-3

Refer to DRIVE SHAFT

in this chart.

Refer to AXLE

in this chart.

SU-3

SU-3

SU-3

BR-6

ST-6

Possible cause and

SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

Wheel bearing damage

PROPELLER SHAFT

DIFFERENTIAL

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomDRIVE SHAFTNoise, Vibration´´ ´´ ´ ´´´´´

Shake´ ´ ´ ´ ´´´´´

AXLENoise´´ ´´ ´ ´´´´´

Shake´´ ´ ´ ´´´´´

Vibration´´ ´ ´ ´´ ´

Shimmy´´ ´´´´´

Judder´ ´´´´´

Poor quality ride or

handling´´´ ´´´

´: Applicable

SMA525A

On-vehicle Service

FRONT AXLE PARTSNBAX0004Check front axle parts for excessive play, cracks, wear and other

damage.

1. Shake each front wheel to check for excessive play.

2. Retighten all nuts and bolts to the specified torque.

Tightening torque:

Refer to ªWheel Hub and Rotor Discº, AX-6.

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

Noise, Vibration and Harshness (NVH) Troubleshooting

AX-3

Page 372 of 2395

SMA580A

10. Measure starting force ªAº at wheel hub bolt.

SFA830

11. Install lock washer by tightening the lock nut within 15 to 30

degrees.

12. Turn wheel hub several times in both directions to seat wheel

bearing correctly.

13. Measure starting force ªBº at wheel hub bolt. Refer to proce-

dure 10.

14. Wheel bearing preload ªCº can be calculated as shown below.

C=BþA

Wheel bearing preload ªCº:

7.06 - 20.99 N (0.72 - 2.14 kg, 1.59 - 4.72 lb)

15. If wheel bearing preload ªCº is outside specifications, remove

lock washer. Tighten or loosen lock nut within±15 degrees

(Refer to step 11 above). Install lock washer, then repeat steps

12, 13 and 14.

16. Repeat above procedures until correct axial end play and

wheel bearing preload are obtained.

17. Install drive flange and wheel hub cap.

SFA901

DRIVE SHAFTNBAX0006ICheck boot and drive shaft for cracks, wear, damage and

grease leakage.

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

On-vehicle Service (Cont'd)

AX-5

Page 374 of 2395

SFA802B

2. Remove hub cap with suitable tool.

SFA753B

3. Remove snap ring with suitable tool.

4. Remove drive flange.

SFA364BA

5. Remove lock washer.

SFA754B

6. Remove wheel bearing lock nut.

SFA832

7. Remove wheel hub and wheel bearing.

Be careful not to drop outer bearing.

INSTALLATIONNBAX00091. After installing wheel hub and wheel bearing, adjust wheel

bearing preload.

Refer to ªPreload Adjustmentº, ªFRONT WHEEL BEARINGº,

ªOn-vehicle Serviceº, AX-4.

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

Wheel Hub and Rotor Disc (Cont'd)

AX-7

Page 376 of 2395

SFA891-A

2. Pack multi-purpose grease into wheel hub.

SFA459B

3. Apply multi-purpose grease to each bearing cone.

4. Pack grease seal lip with multi-purpose grease, then install it

into wheel hub with suitable drift.

Knuckle Spindle

REMOVALNBAX00131. Remove drive shaft.

Refer to ªDrive Shaftº, AX-11.

SFA756B

2. Separate tie-rod end and lower ball joint from knuckle with

Tool.

Install stud nut conversely on stud bolt so as not to damage

stud bolt.

SFA758B

3. Separate knuckle from strut.

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

Wheel Hub and Rotor Disc (Cont'd)

AX-9

Page 378 of 2395

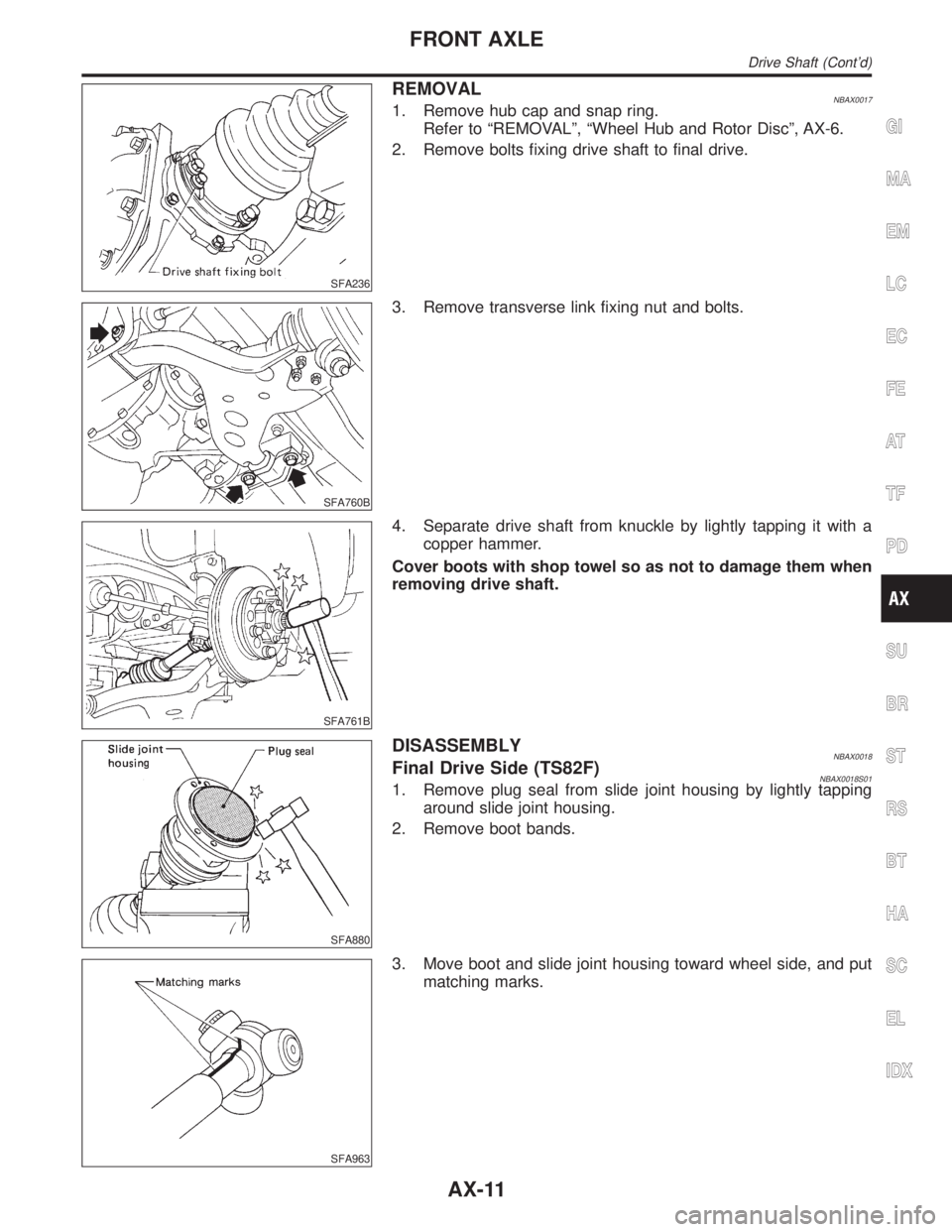

SFA236

REMOVALNBAX00171. Remove hub cap and snap ring.

Refer to ªREMOVALº, ªWheel Hub and Rotor Discº, AX-6.

2. Remove bolts fixing drive shaft to final drive.

SFA760B

3. Remove transverse link fixing nut and bolts.

SFA761B

4. Separate drive shaft from knuckle by lightly tapping it with a

copper hammer.

Cover boots with shop towel so as not to damage them when

removing drive shaft.

SFA880

DISASSEMBLYNBAX0018Final Drive Side (TS82F)NBAX0018S011. Remove plug seal from slide joint housing by lightly tapping

around slide joint housing.

2. Remove boot bands.

SFA963

3. Move boot and slide joint housing toward wheel side, and put

matching marks.

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

Drive Shaft (Cont'd)

AX-11

Page 380 of 2395

Joint Assembly (Final drive side)NBAX0019S03IReplace any parts of double offset joint which show signs of

scorching, rust, wear or excessive play.

ICheck serration for deformation. Replace if necessary.

ICheck slide joint housing for any damage. Replace if neces-

sary.

Joint Assembly (Wheel side)NBAX0019S04Replace joint assembly if it is deformed or damaged.

ASSEMBLYNBAX0020IAfter drive shaft has been assembled, ensure that it

moves smoothly over its entire range without binding.

IUse NISSAN GENUINE GREASE or equivalent after every

overhaul.

SFA800

Final Drive Side (TS82F)NBAX0020S011. Install new small boot band, boot and side joint housing to

drive shaft.

Cover drive shaft serration with tape so as not to damage boot

during installation.

SFA397

2. Install spider assembly securely, ensuring marks are properly

aligned.

IPress-fit with spider assembly serration chamfer facing

shaft.

3. Install new snap ring.

SFA460BA

4. Pack with grease.

Specified amount of grease:

95 - 105 g (3.35 - 3.70 oz)

5. Make sure that boot is properly installed on the drive shaft

groove. Set boot so that it does not swell and deform when its

length is ªL

1º.

Length ªL

1º: 95 - 97 mm (3.74 - 3.82 in)

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

Drive Shaft (Cont'd)

AX-13

Page 382 of 2395

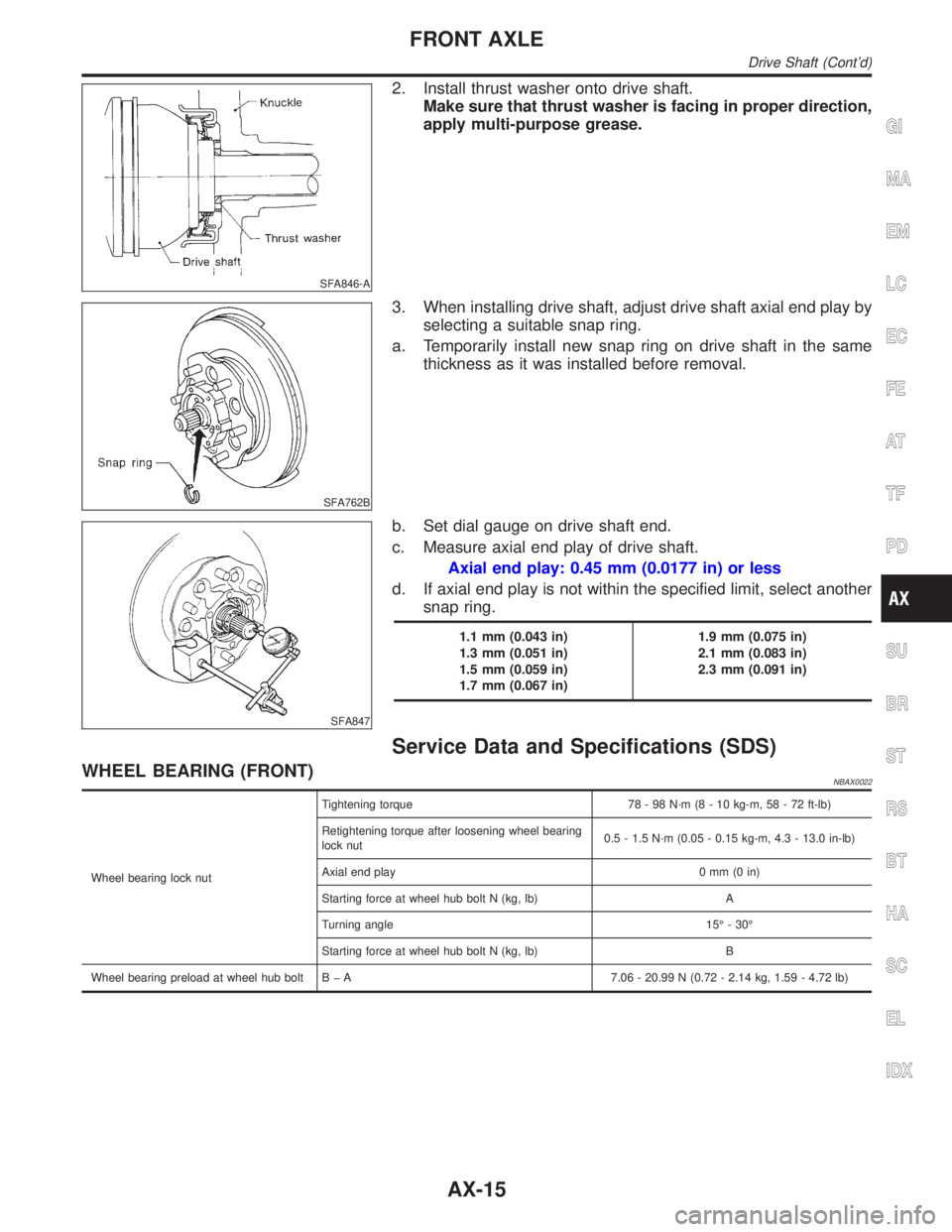

SFA846-A

2. Install thrust washer onto drive shaft.

Make sure that thrust washer is facing in proper direction,

apply multi-purpose grease.

SFA762B

3. When installing drive shaft, adjust drive shaft axial end play by

selecting a suitable snap ring.

a. Temporarily install new snap ring on drive shaft in the same

thickness as it was installed before removal.

SFA847

b. Set dial gauge on drive shaft end.

c. Measure axial end play of drive shaft.

Axial end play: 0.45 mm (0.0177 in) or less

d. If axial end play is not within the specified limit, select another

snap ring.

1.1 mm (0.043 in)

1.3 mm (0.051 in)

1.5 mm (0.059 in)

1.7 mm (0.067 in)1.9 mm (0.075 in)

2.1 mm (0.083 in)

2.3 mm (0.091 in)

Service Data and Specifications (SDS)

WHEEL BEARING (FRONT)NBAX0022

Wheel bearing lock nutTightening torque 78 - 98 N´m (8 - 10 kg-m, 58 - 72 ft-lb)

Retightening torque after loosening wheel bearing

lock nut0.5 - 1.5 N´m (0.05 - 0.15 kg-m, 4.3 - 13.0 in-lb)

Axial end play 0 mm (0 in)

Starting force at wheel hub bolt N (kg, lb) A

Turning angle 15É - 30É

Starting force at wheel hub bolt N (kg, lb) B

Wheel bearing preload at wheel hub bolt B þ A 7.06 - 20.99 N (0.72 - 2.14 kg, 1.59 - 4.72 lb)

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

Drive Shaft (Cont'd)

AX-15

Page 384 of 2395

SBR686C

Precautions

PRECAUTIONSNBAX0023IWhen installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

IUse flare nut wrench when removing and installing brake

tubes.

IAfter installing removed suspension parts, check wheel

alignment and adjust if necessary.

IAlways torque brake lines when installing.

Preparation

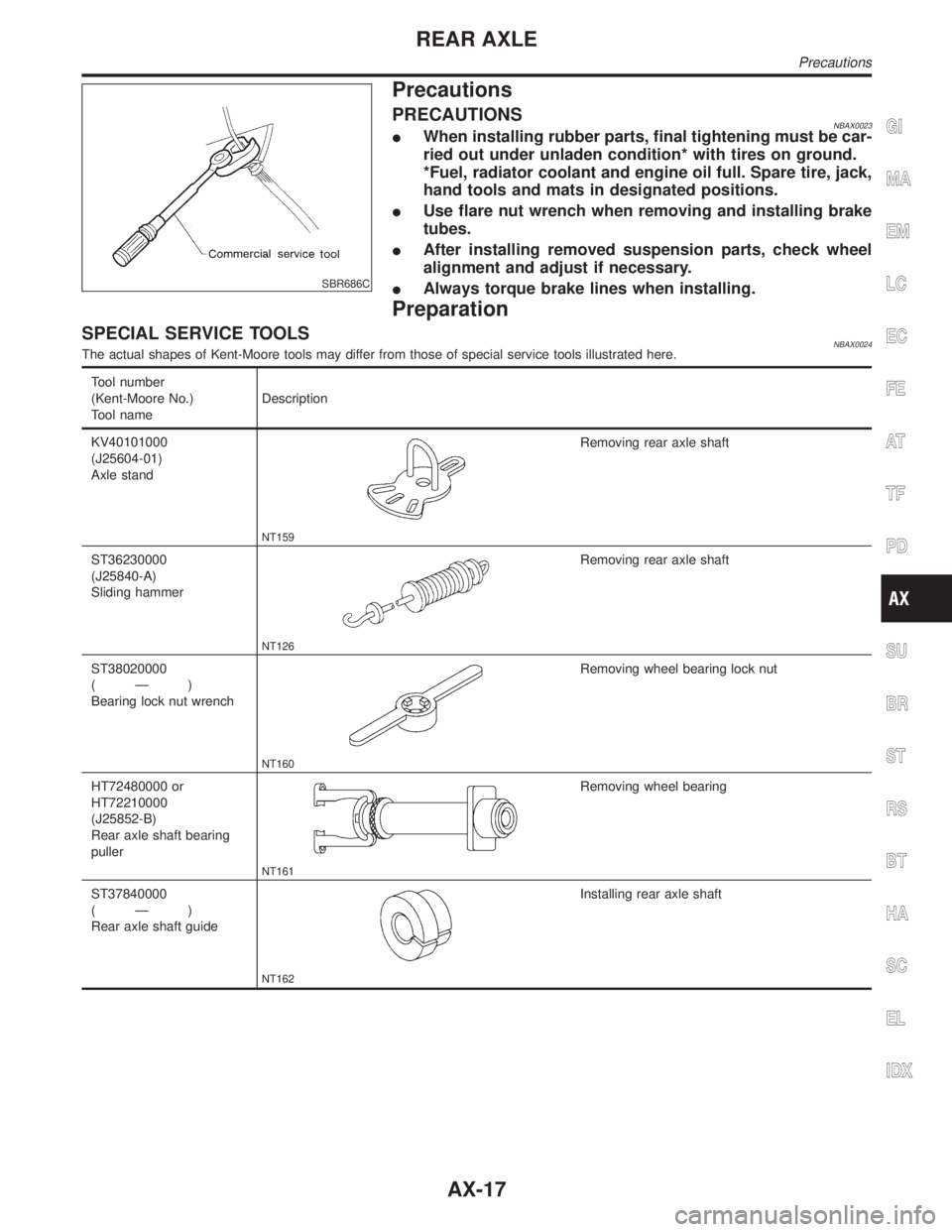

SPECIAL SERVICE TOOLSNBAX0024The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

KV40101000

(J25604-01)

Axle stand

NT159

Removing rear axle shaft

ST36230000

(J25840-A)

Sliding hammer

NT126

Removing rear axle shaft

ST38020000

(Ð)

Bearing lock nut wrench

NT160

Removing wheel bearing lock nut

HT72480000 or

HT72210000

(J25852-B)

Rear axle shaft bearing

puller

NT161

Removing wheel bearing

ST37840000

(Ð)

Rear axle shaft guide

NT162

Installing rear axle shaft

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR AXLE

Precautions

AX-17