IDX INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 326 of 2395

SAT860A

DISASSEMBLY AND ASSEMBLYNBAT0135Forward and overrun clutches are serviced essentially the same

way as reverse clutch is serviced. However, note the following

exceptions.

ICheck of forward clutch operation

SAT861A

ICheck of overrun clutch operation

SAT865A

IRemoval of forward clutch drum

Remove forward clutch drum from transmission case by hold-

ing snap ring.

SAT862A

IRemoval of forward clutch and overrun clutch pistons

a) While holding overrun clutch piston, gradually apply com-

pressed air to oil hole.

SAT863A

b) Remove overrun clutch from forward clutch.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Forward and Overrun Clutches (Cont'd)

AT-321

Page 328 of 2395

SAT867A

IAlign notch in forward clutch piston with groove in for-

ward clutch drum.

SAT868A

b) Install overrun clutch by turning it slowly and evenly.

IApply ATF to inner surface of forward clutch piston.

SAT869A

IMeasurement of clearance between retaining plate and snap

ring of overrun clutch

Specified clearance:

Standard

1.0 - 1.4 mm (0.039 - 0.055 in)

Allowable limit

2.0 mm (0.079 in)

Retaining plate:

Refer to SDS, AT-359.

SAT870A

IMeasurement of clearance between retaining plate and snap

ring of forward clutch

Specified clearance:

Standard

0.35 - 0.75 mm (0.0138 - 0.0295 in)

Allowable limit

Model 4EX16 (2WD)

2.15 mm (0.0846 in)

Model 4EX17, 4EX23 (4WD)

2.35 mm (0.0925 in)

Retaining plate:

Refer to SDS, AT-359.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Forward and Overrun Clutches (Cont'd)

AT-323

Page 330 of 2395

SAT382I

3. Remove low one-way clutch inner race, spring retainer and

return spring from transmission case.

4. Remove seal rings from low one-way clutch inner race.

5. Remove needle bearing from low one-way clutch inner race.

SAT876A

6. Remove low and reverse brake piston using compressed air.

7. Remove oil seal and D-ring from piston.

INSPECTIONNBAT0138Low and Reverse Brake Snap Ring and Spring RetainerNBAT0138S01ICheck for deformation, or damage.

SAT829A

Low and Reverse Brake Return SpringsNBAT0138S02ICheck for deformation or damage. Also measure free length

and outside diameter.

Inspection standard:

Refer to SDS, AT-357.

SAT845A

Low and Reverse Brake Drive PlatesNBAT0138S03ICheck facing for burns, cracks or damage.

IMeasure thickness of facing.

Thickness of drive plate:

Standard value

Model 4EX16 (2WD)

1.90 - 2.05 mm (0.075 - 0.081 in)

Model 4EX17, 4EX23 (4WD)

1.52 - 1.67 mm (0.0598 - 0.0657 in)

Wear limit

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake (Cont'd)

AT-325

Page 332 of 2395

SAT880A

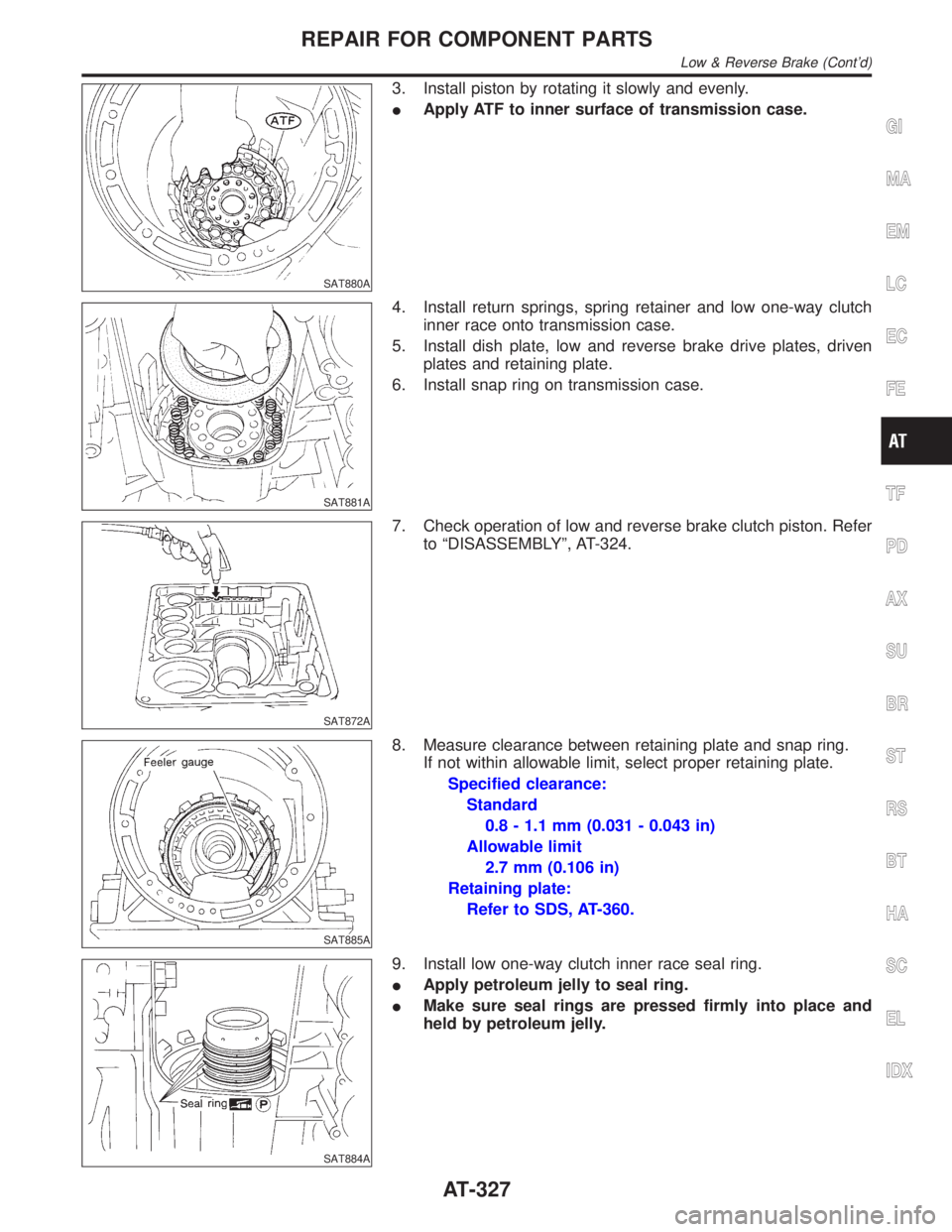

3. Install piston by rotating it slowly and evenly.

IApply ATF to inner surface of transmission case.

SAT881A

4. Install return springs, spring retainer and low one-way clutch

inner race onto transmission case.

5. Install dish plate, low and reverse brake drive plates, driven

plates and retaining plate.

6. Install snap ring on transmission case.

SAT872A

7. Check operation of low and reverse brake clutch piston. Refer

to ªDISASSEMBLYº, AT-324.

SAT885A

8. Measure clearance between retaining plate and snap ring.

If not within allowable limit, select proper retaining plate.

Specified clearance:

Standard

0.8 - 1.1 mm (0.031 - 0.043 in)

Allowable limit

2.7 mm (0.106 in)

Retaining plate:

Refer to SDS, AT-360.

SAT884A

9. Install low one-way clutch inner race seal ring.

IApply petroleum jelly to seal ring.

IMake sure seal rings are pressed firmly into place and

held by petroleum jelly.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake (Cont'd)

AT-327

Page 334 of 2395

SAT892A

INSPECTIONNBAT0142Forward Clutch DrumNBAT0142S01ICheck spline portion for wear or damage.

ICheck frictional surfaces of low one-way clutch and needle

bearing for wear or damage.

SAT893A

Needle Bearing and Low One-way ClutchNBAT0142S02ICheck frictional surface for wear or damage.

SAT214G

ASSEMBLYNBAT01431. Install needle bearing in forward clutch drum.

2. Install snap ring onto forward clutch drum.

SAT894A

3. Install low one-way clutch onto forward clutch drum by push-

ing the roller in evenly.

SAT895A

IInstall low one-way clutch with flange facing rearward.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Forward Clutch Drum Assembly (Cont'd)

AT-329

Page 336 of 2395

SAT899A

3. Remove snap ring from forward clutch hub.

SAT900A

4. Remove end bearing.

SAT955A

5. Remove forward one-way clutch and end bearing as a unit

from forward clutch hub.

SAT901A

6. Remove snap ring from forward clutch hub.

SAT902A

INSPECTIONNBAT0146Rear Internal Gear and Forward Clutch HubNBAT0146S01ICheck gear for excessive wear, chips or cracks.

ICheck frictional surfaces of forward one-way clutch and thrust

washer for wear or damage.

ICheck spline for wear or damage.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Rear Internal Gear and Forward Clutch Hub (Cont'd)

AT-331

Page 338 of 2395

SAT905A

8. After installing, check to assure that forward clutch hub rotates

clockwise.

Band Servo Piston Assembly

COMPONENTSNBAT0148

SAT161K

SAT909A

DISASSEMBLYNBAT01491. Block one oil hole in OD servo piston retainer and the center

hole in OD band servo piston.

2. Apply compressed air to the other oil hole in piston retainer to

remove OD band servo piston from retainer.

3. Remove D-ring from OD band servo piston.

SAT910A

4. Remove band servo piston assembly from servo piston

retainer by pushing it forward.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Rear Internal Gear and Forward Clutch Hub (Cont'd)

AT-333

Page 340 of 2395

SAT162K

Return SpringsNBAT0150S02ICheck for deformation or damage. Measure free length and

outer diameter.

Inspection standard:

Refer to SDS, AT-357.

SAT917A

ASSEMBLYNBAT01511. Install O-rings onto servo piston retainer.

IApply ATF to O-rings.

IPay attention to position of each O-ring.

SAT918A

2. Install servo cushion spring retainer onto band servo piston.

SAT919A

3. Install E-ring onto servo cushion spring retainer.

SAT920A

4. Install D-rings onto band servo piston.

IApply ATF to D-rings.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Band Servo Piston Assembly (Cont'd)

AT-335

Page 342 of 2395

Parking Pawl Components

COMPONENTSNBAT0152

SAT558J

SAT226H

DISASSEMBLYNBAT01531. Slide return spring to the front of adapter case flange.

2. Remove return spring, parking pawl spacer and parking pawl

from adapter case.

3. Remove parking pawl shaft from adapter case.

SAT228H

4. Remove parking actuator support from adapter case.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Parking Pawl Components

AT-337

Page 344 of 2395

SAT931A

Assembly (1)NBAT01551. Install manual shaft components.

a. Install oil seal onto manual shaft.

IApply ATF to oil seal.

IWrap threads of manual shaft with masking tape.

b. Insert manual shaft and oil seal as a unit into transmission

case.

c. Remove masking tape.

SAT932A

d. Push oil seal evenly and install it onto transmission case.

SAT933A

e. Align groove in shaft with retaining pin hole, then retaining pin

into position as shown in figure at left.

SAT901E

f. Install detent spring and spacer.

g. While pushing detent spring down, install manual plate onto

manual shaft.

SAT936A

h. Install lock nuts onto manual shaft.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ASSEMBLY

Assembly (1)

AT-339