service INFINITI QX4 2001 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 16 of 2395

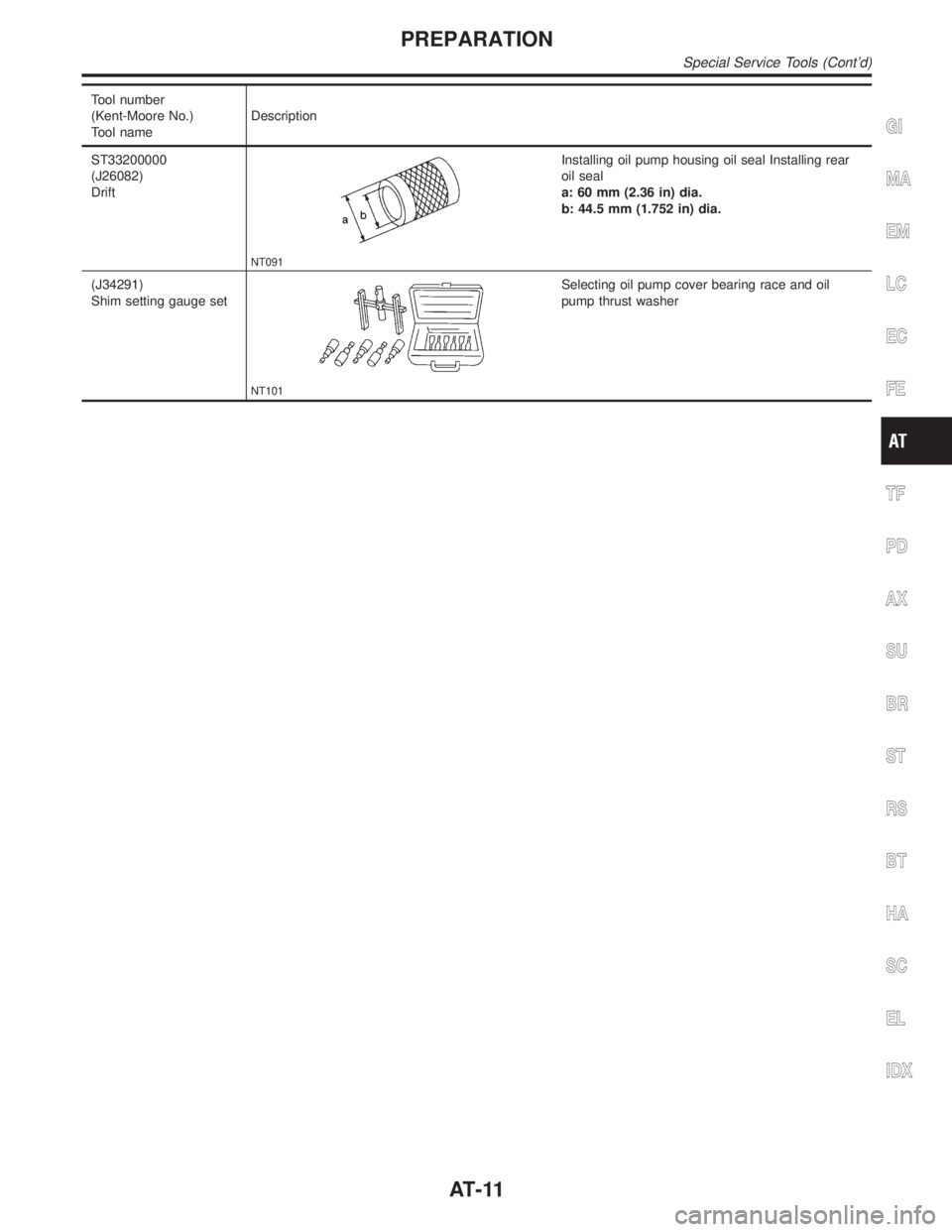

Tool number

(Kent-Moore No.)

Tool nameDescription

ST33200000

(J26082)

Drift

NT091

Installing oil pump housing oil seal Installing rear

oil seal

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

(J34291)

Shim setting gauge set

NT101

Selecting oil pump cover bearing race and oil

pump thrust washer

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PREPARATION

Special Service Tools (Cont'd)

AT-11

Page 42 of 2395

SAT964I

Malfunction Indicator Lamp (MIL)=NBAT0183The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON

without the engine running. This is a bulb check.

IIf the MIL does not light up, refer to EL-114, ªSchematicº.

(Or refer to EC-648, ªWiring Diagramº.)

2. When the engine is started, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction. For detail, refer to

EC-59, ªIntroductionº.

CONSULT-IINBAT0184After performing ªSELF-DIAGNOSTIC PROCEDURE (WITH CON-

SULT-II)º (AT-37), place check marks for results on the ªDIAGNOS-

TIC WORKSHEETº, AT-55. Reference pages are provided follow-

ing the items.

NOTICE:

1) The CONSULT-II electrically displays shift timing and lock-up

timing (that is, operation timing of each solenoid).

Check for time difference between actual shift timing and the

CONSULT-II display. If the difference is noticeable, mechani-

cal parts (except solenoids, sensors, etc.) may be malfunction-

ing. Check mechanical parts using applicable diagnostic pro-

cedures.

2) Shift schedule (which implies gear position) displayed on

CONSULT-II and that indicated in Service Manual may differ

slightly. This occurs because of the following reasons:

IActual shift schedule has more or less tolerance or allowance,

IShift schedule indicated in Service Manual refers to the point

where shifts start, and

IGear position displayed on CONSULT-II indicates the point

where shifts are completed.

3) Shift solenoid valve ªAº or ªBº is displayed on CONSULT-II at

the start of shifting. Gear position is displayed upon completion

of shifting (which is computed by TCM).

4) Additional CONSULT-II information can be found in the Opera-

tion Manual supplied with the CONSULT-II unit.

SAT014K

SELF-DIAGNOSTIC PROCEDURE (WITH CONSULT-II)NBAT0184S011. Turn on CONSULT-II and touch ªENGINEº for OBD-II detected

items or touch ªA/Tº for TCM self-diagnosis.

If A/T is not displayed, check TCM power supply and ground

circuit. Refer to AT-92. If result is NG, refer to EL-9, ªSche-

maticº.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Malfunction Indicator Lamp (MIL)

AT-37

Page 58 of 2395

SAT631IB

IntroductionNBAT0019

SAT632I

SEF234G

The TCM receives a signal from the vehicle speed sensor, throttle

position sensor or PNP switch and provides shift control or lock-up

control via A/T solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used with the OBD-related parts of the

A/T system for malfunction-diagnostic purposes. The TCM is

capable of diagnosing malfunctioning parts while the ECM can

store malfunctions in its memory.

Input and output signals must always be correct and stable in the

operation of the A/T system. The A/T system must be in good

operating condition and be free of valve seizure, solenoid valve

malfunction, etc.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the ªWork Flowº. Refer to AT-57.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example (AT-55) should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

Also check related Service bulletins.GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð INTRODUCTION

Introduction

AT-53

Page 59 of 2395

DIAGNOSTIC WORKSHEET=NBAT0019S01Information From CustomerNBAT0019S0101KEY POINTS

WHAT..... Vehicle & A/T model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

Customer name MR/MS Model & Year VIN

Trans. model Engine Mileage

Incident Date Manuf. Date In Service Date

FrequencylContinuouslIntermittent ( times a day)

SymptomslVehicle does not move. (lAny positionlParticular position)

lNo up-shift (l1st,2ndl2nd,3rdl3rd,O/D)

lNo down-shift (lO/D,3rdl3rd,2ndl2nd,1st)

lLockup malfunction

lShift point too high or too low.

lShift shock or slip (lN,DlLockuplAny drive position)

lNoise or vibration

lNo kickdown

lNo pattern select

lOthers

()

O/D OFF indicator lamp Blinks for about 8 seconds.

lContinuously litlNot lit

Malfunction indicator lamp (MIL)lContinuously litlNot lit

TROUBLE DIAGNOSIS Ð INTRODUCTION

Introduction (Cont'd)

AT-54

Page 232 of 2395

6. Vehicle Does Not Creep Backward In ªRº

Position

=NBAT0078SYMPTOM:

Vehicle does not creep backward when selecting ªRº position.

1 CHECK A/T FLUID LEVEL

Check A/T fluid level again.

SAT638A

OK or NG

OK©GO TO 2.

NG©Refill ATF.

2 CHECK STALL TEST

Check stall revolution with selector lever in ª1º and ªRº positions.

Refer to AT-356.

SAT493G

OK or NG

OK©GO TO 3.

OK in ª1º position, NG in

ªRº position©1. Remove control valve assembly. Refer to ªON-VEHICLE SERVICEº, AT-273.

2. Check the following items:

IValves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot

valve and pilot filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following items:

IOil pump assembly

ITorque converter

IReverse clutch assembly

IHigh clutch assembly

NG in both ª1º and ªRº

positions©GO TO 6.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMS

6. Vehicle Does Not Creep Backward In ªRº Position

AT-227

Page 233 of 2395

3 CHECK LINE PRESSURE

Check line pressure at idle with selector lever in ªRº position. Refer to ªLINE PRESSURE TESTº, AT-62.

SAT494G

OK or NG

OK©GO TO 4.

NG©1. Remove control valve assembly. Refer to ªON-VEHICLE SERVICEº, AT-273.

2. Check the following items:

IValves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot

valve and pilot filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following items:

IOil pump assembly

4 CHECK A/T FLUID CONDITION

1. Remove oil pan.

2. Check A/T fluid condition.

SAT171B

OK or NG

OK©GO TO 5.

NG©GO TO 6.

5 CHECK SYMPTOM

Check again.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

TROUBLE DIAGNOSES FOR SYMPTOMS

6. Vehicle Does Not Creep Backward In ªRº Position (Cont'd)

AT-228

Page 234 of 2395

6 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to ªON-VEHICLE SERVICEº, AT-273.

2. Check the following items:

IValves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following items:

IOil pump assembly

ITorque converter

IReverse clutch assembly

IHigh clutch assembly

ILow & reverse brake assembly

ILow one-way clutch

©Repair or replace damaged parts.GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMS

6. Vehicle Does Not Creep Backward In ªRº Position (Cont'd)

AT-229

Page 237 of 2395

6 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to ªON-VEHICLE SERVICEº, AT-273.

2. Check the following items:

IValves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following items:

IOil pump assembly

IForward clutch assembly

IForward one-way clutch

ILow one-way clutch

ILow & reverse brake assembly

ITorque converter

©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

7. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Position (Cont'd)

AT-232

Page 272 of 2395

Diagnostic ProcedureNBAT0095SYMPTOM 1:

ISelector lever cannot be moved from ªPº position with key

in ªONº position and brake pedal applied.

ISelector lever can be moved from ªPº position with key in

ªONº position and brake pedal released.

ISelector lever can be moved from ªPº position when key

is removed from key cylinder.

SYMPTOM 2:

Ignition key cannot be removed when selector lever is set to

ªPº position. It can be removed when selector lever is set to

any position except ªPº.

1 CHECK KEY INTERLOCK CABLE

Check key interlock cable for damage.

OK or NG

OK©GO TO 2.

NG©Repair key interlock cable. Refer to ªKey Interlock Cableº, AT-271.

2 CHECK SELECTOR LEVER POSITION

Check selector lever position for damage.

OK or NG

OK©GO TO 3.

NG©Check selector lever. Refer to ªON-VEHICLE SERVICE Ð PNP Switch and Manual Con-

trol Linkage Adjustmentº, AT-276 and AT-276.

3 CHECK POWER SOURCE

1. Turn ignition switch to ON position. (Do not start engine.)

2. Check voltage between A/T device harness terminal 5 and ground.

SAT758JA

OK or NG

OK©GO TO 5.

NG©GO TO 4.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

AT-267

Page 278 of 2395

SAT359I

Control Valve Assembly and AccumulatorsNBAT0100REMOVALNBAT0100S011. Remove exhaust front tube.

2. Remove oil pan and gasket and drain ATF.

SAT073BA

3. Remove A/T fluid temperature sensor if necessary.

4. Remove oil strainer.

SAT353B

5. Remove control valve assembly by removing fixing bolts and

disconnecting harness connector.

Bolt length and location

Bolt symbolmm (in)

A 33 (1.30)

B 45 (1.77)

6. Remove solenoids and valves from valve body if necessary.

7. Remove terminal cord assembly if necessary.

SAT074BA

8. Remove accumulatorA, B, CandDby applying compressed

air if necessary.

IHold each piston with rag.

9. Reinstall any part removed.

IAlways use new sealing parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON-VEHICLE SERVICE

Control Valve Assembly and Accumulators

AT-273