service INFINITI QX4 2001 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 279 of 2395

SAT360IA

Revolution Sensor ReplacementNBAT0210Ð 4WD MODEL ÐNBAT0210S011. Remove rear engine mounting member from side member

while supporting A/T with transfer case with jack. Tighten rear

engine mounting member to the specified torque. Refer to

EM-59, ªRear Engine Mountingº.

2. Lower A/T with transfer case as much as possible.

3. Remove revolution sensor from A/T.

4. Reinstall any part removed.

IAlways use new sealing parts.

SAT661I

Ð 2WD MODEL ÐNBAT0210S02IRemove revolution sensor from A/T.

IAlways use new sealing parts.

SAT136K

Turbine Revolution Sensor ReplacementNBAT02311. Remove A/T assembly, Refer to ªRemovalº, AT-277.

2. Remove turbine revolution sensor from A/T assembly upper

side.

3. Reinstall any part removed.

IAlways use new sealing parts.

SAT035E

Rear Oil Seal ReplacementNBAT0211Ð 4WD MODEL ÐNBAT0211S011. Remove transfer case from vehicle. Refer to TF-119, ªRemovalº.

2. Remove rear oil seal.

IDo not remove oil seal unless it is to be replaced.

3. Install rear oil seal.

IApply ATF before installing.

4. Reinstall any part removed.

ON-VEHICLE SERVICE

Revolution Sensor Replacement

AT-274

Page 280 of 2395

SAT544J

SAT546J

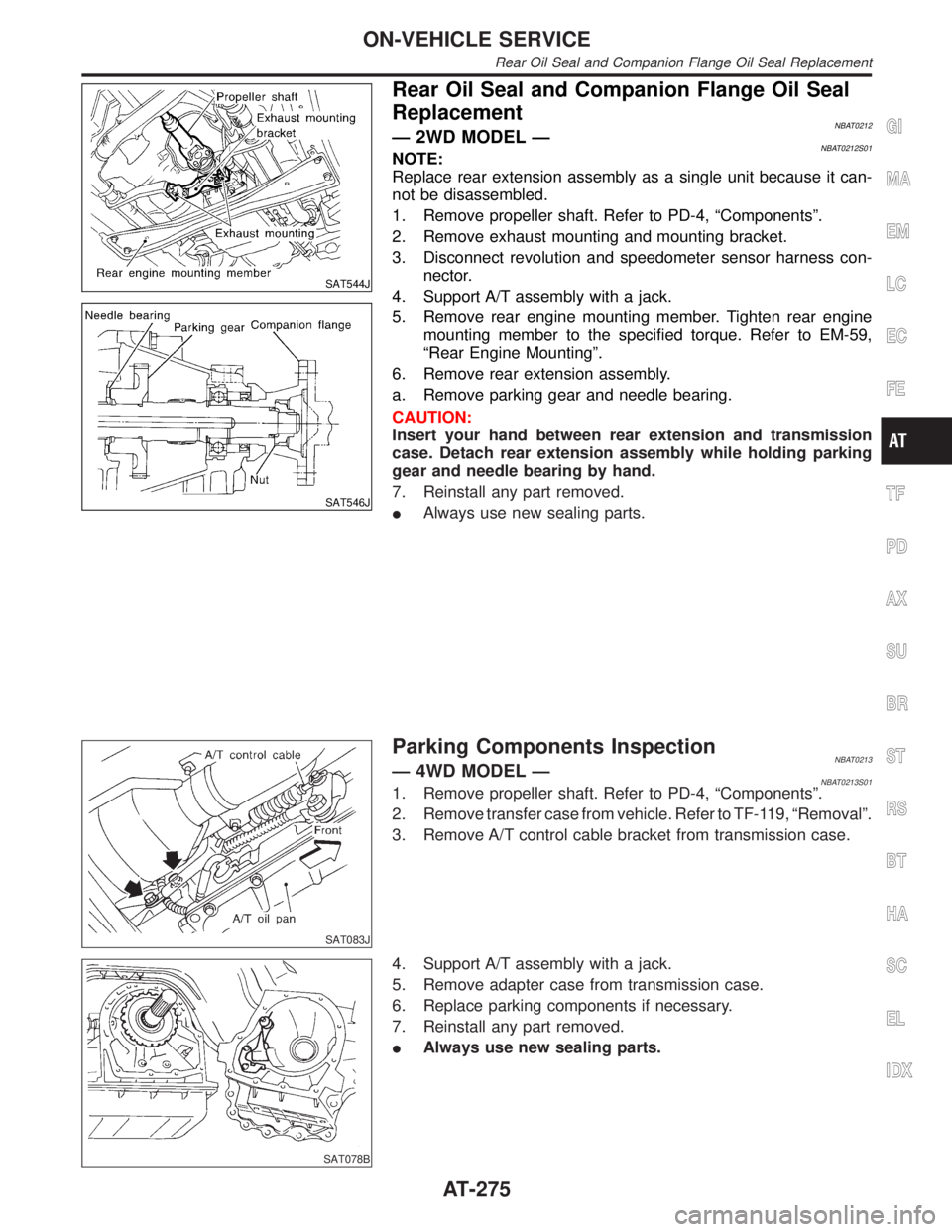

Rear Oil Seal and Companion Flange Oil Seal

Replacement

NBAT0212Ð 2WD MODEL ÐNBAT0212S01NOTE:

Replace rear extension assembly as a single unit because it can-

not be disassembled.

1. Remove propeller shaft. Refer to PD-4, ªComponentsº.

2. Remove exhaust mounting and mounting bracket.

3. Disconnect revolution and speedometer sensor harness con-

nector.

4. Support A/T assembly with a jack.

5. Remove rear engine mounting member. Tighten rear engine

mounting member to the specified torque. Refer to EM-59,

ªRear Engine Mountingº.

6. Remove rear extension assembly.

a. Remove parking gear and needle bearing.

CAUTION:

Insert your hand between rear extension and transmission

case. Detach rear extension assembly while holding parking

gear and needle bearing by hand.

7. Reinstall any part removed.

IAlways use new sealing parts.

SAT083J

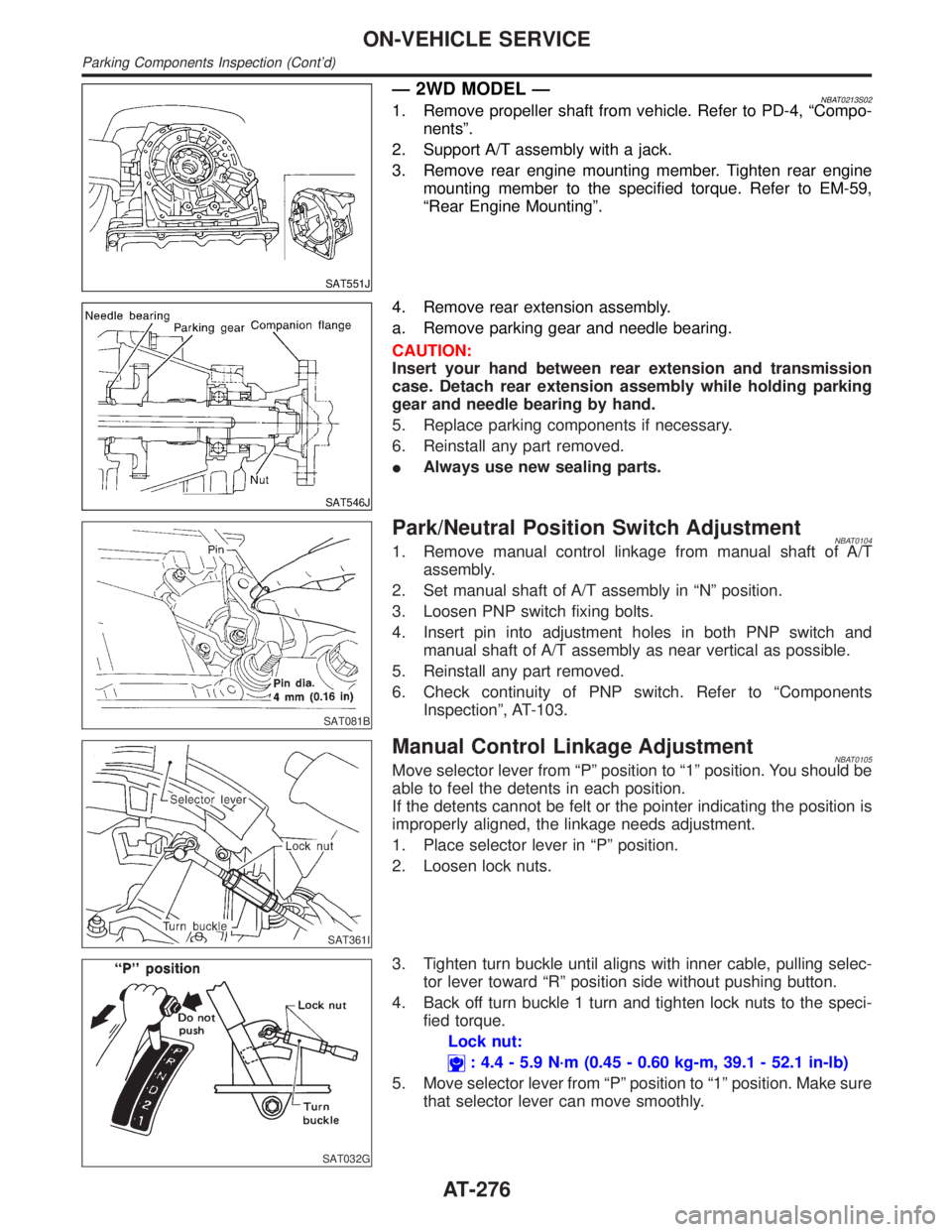

Parking Components InspectionNBAT0213Ð 4WD MODEL ÐNBAT0213S011. Remove propeller shaft. Refer to PD-4, ªComponentsº.

2. Remove transfer case from vehicle. Refer to TF-119, ªRemovalº.

3. Remove A/T control cable bracket from transmission case.

SAT078B

4. Support A/T assembly with a jack.

5. Remove adapter case from transmission case.

6. Replace parking components if necessary.

7. Reinstall any part removed.

IAlways use new sealing parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON-VEHICLE SERVICE

Rear Oil Seal and Companion Flange Oil Seal Replacement

AT-275

Page 281 of 2395

SAT551J

Ð 2WD MODEL ÐNBAT0213S021. Remove propeller shaft from vehicle. Refer to PD-4, ªCompo-

nentsº.

2. Support A/T assembly with a jack.

3. Remove rear engine mounting member. Tighten rear engine

mounting member to the specified torque. Refer to EM-59,

ªRear Engine Mountingº.

SAT546J

4. Remove rear extension assembly.

a. Remove parking gear and needle bearing.

CAUTION:

Insert your hand between rear extension and transmission

case. Detach rear extension assembly while holding parking

gear and needle bearing by hand.

5. Replace parking components if necessary.

6. Reinstall any part removed.

IAlways use new sealing parts.

SAT081B

Park/Neutral Position Switch AdjustmentNBAT01041. Remove manual control linkage from manual shaft of A/T

assembly.

2. Set manual shaft of A/T assembly in ªNº position.

3. Loosen PNP switch fixing bolts.

4. Insert pin into adjustment holes in both PNP switch and

manual shaft of A/T assembly as near vertical as possible.

5. Reinstall any part removed.

6. Check continuity of PNP switch. Refer to ªComponents

Inspectionº, AT-103.

SAT361I

Manual Control Linkage AdjustmentNBAT0105Move selector lever from ªPº position to ª1º position. You should be

able to feel the detents in each position.

If the detents cannot be felt or the pointer indicating the position is

improperly aligned, the linkage needs adjustment.

1. Place selector lever in ªPº position.

2. Loosen lock nuts.

SAT032G

3. Tighten turn buckle until aligns with inner cable, pulling selec-

tor lever toward ªRº position side without pushing button.

4. Back off turn buckle 1 turn and tighten lock nuts to the speci-

fied torque.

Lock nut:

: 4.4 - 5.9 N´m (0.45 - 0.60 kg-m, 39.1 - 52.1 in-lb)

5. Move selector lever from ªPº position to ª1º position. Make sure

that selector lever can move smoothly.

ON-VEHICLE SERVICE

Parking Components Inspection (Cont'd)

AT-276

Page 323 of 2395

SAT853A

DISASSEMBLY AND ASSEMBLYNBAT0133Service procedures for high clutch are essentially the same as

those for reverse clutch, with the following exception:

SAT854A

ICheck of high clutch operation

SAT525G

IRemoval and installation of return spring

SAT829A

IInspection of high clutch return springs

Inspection standard:

Refer to SDS, AT-357.

SAT845A

IInspection of high clutch drive plate

Thickness of drive plate:

Standard

1.52 - 1.67 mm (0.0598 - 0.0657 in)

Wear limit

1.40 mm (0.0551 in)

REPAIR FOR COMPONENT PARTS

High Clutch (Cont'd)

AT-318

Page 326 of 2395

SAT860A

DISASSEMBLY AND ASSEMBLYNBAT0135Forward and overrun clutches are serviced essentially the same

way as reverse clutch is serviced. However, note the following

exceptions.

ICheck of forward clutch operation

SAT861A

ICheck of overrun clutch operation

SAT865A

IRemoval of forward clutch drum

Remove forward clutch drum from transmission case by hold-

ing snap ring.

SAT862A

IRemoval of forward clutch and overrun clutch pistons

a) While holding overrun clutch piston, gradually apply com-

pressed air to oil hole.

SAT863A

b) Remove overrun clutch from forward clutch.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Forward and Overrun Clutches (Cont'd)

AT-321

Page 361 of 2395

General SpecificationsNBAT0160

Applied modelVQ35DE engine

2WD 4WD

Automatic transmission model RE4R01A

Transmission model code number 4EX16 4EX17

Stall torque ratio2.0:1

Transmission gear ratio1st 2.785

2nd 1.545

Top 1.000

OD 0.694

Reverse 2.272

Recommended fluidNissan Matic ªDº (Continental U.S. and Alaska) or Genuine Nissan Automatic Trans-

mission Fluid (Canada)*1

Fluid capacity8.5(9 US qt, 7-1/2 Imp qt)

*1: Refer to MA-11, ªFluids and Lubricantsº.

Shift ScheduleNBAT0178VEHICLE SPEED WHEN SHIFTING GEARS THROTTLE POSITIONNBAT0178S01

Throttle positionVehicle speed km/h (MPH)

D

1,D2D2,D3D3,D4D4,D3D3,D2D2,D112,11

Full throttle55-59

(34 - 37)105 - 113

(65 - 70)174 - 184

(108 - 114)170 - 180

(106 - 112)102 - 110

(63 - 68)43-47

(27 - 29)43-47

(27 - 29)

Half throttle37-41

(23 - 25)71-79

(44 - 49)129 - 139

(80 - 86)81-91

(50 - 57)33-41

(21 - 25)12-16

(7 - 10)43-47

(27 - 29)

VEHICLE SPEED WHEN PERFORMING AND RELEASING LOCK-UPNBAT0178S02

Throttle positionOverdrive control switch [Shift posi-

tion]Vehicle speed km/h (MPH)

Lock-up ªONº Lock-up ªOFFº

Full throttleON [D

4] 174 - 184 (108 - 114) 170 - 180 (106 - 112)

OFF [D

3] 104 - 114 (65 - 71) 101 - 111 (63 - 69)

Half throttleON [D

4] 151 - 161 (94 - 100) 106 - 116 (66 - 72)

OFF [D

3] 85-95(53-59) 82-92(51-57)

Stall RevolutionNBAT0163

Stall revolution rpm2,440 - 2,640

Line PressureNBAT0164

Engine speed

rpmLine pressure kPa (kg/cm2, psi)

D, 2 and 1 positions R position

Idle 422 - 461 (4.3 - 4.7, 61 - 67) 667 - 706 (6.8 - 7.2, 97 - 102)

Stall 1,020 - 1,098 (10.4 - 11.2, 148 - 159) 1,422 - 1,500 (14.5 - 15.3, 206 - 218)

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

AT-356

Page 362 of 2395

Return SpringsNBAT0165Unit: mm (in)

PartsItem

Part No.* Free length Outer diameter

Control valveUpper body1 Torque converter relief valve spring 31742-41X23 38.0 (1.496) 9.0 (0.354)

2 Pressure regulator valve spring 31742-41X24 44.02 (1.7331) 14.0 (0.551)

3 Pressure modifier valve spring 31742-41X19 31.95 (1.2579) 6.8 (0.268)

Ð Accumulator control valve spring Ð Ð Ð

4 Shuttle shift valve D spring 31762-41X01 25.0 (0.984) 7.0 (0.276)

5 4-2 sequence valve spring 31756-41X00 29.1 (1.146) 6.95 (0.2736)

6 Shift valve B spring 31762-41X01 25.0 (0.984) 7.0 (0.276)

7 4-2 relay valve spring 31756-41X00 29.1 (1.146) 6.95 (0.2736)

8 Shift valve A spring 31762-41X01 25.0 (0.984) 7.0 (0.276)

9 Overrun clutch control valve spring 31762-41X03 23.6 (0.929) 7.0 (0.276)

10 Overrun clutch reducing valve spring 31742-41X14 38.9 (1.531) 7.0 (0.276)

11 Shuttle shift valve S spring 31762-41X04 51.0 (2.008) 5.65 (0.2224)

12 Pilot valve spring 31742-41X13 25.7 (1.012) 9.0 (0.354)

13 Torque converter clutch control valve spring 31742-41X22 18.5 (0.728) 13.0 (0.512)

Lower body1 Modifier accumulator piston spring 31742-27X70 31.4 (1.236) 9.8 (0.386)

2 1st reducing valve spring 31756-60X00 20.5 (0.807) 7.0 (0.276)

3 3-2 timing valve spring 31742-41X06 23.0 (0.906) 6.7 (0.264)

4 Servo charger valve spring 31742-41X06 23.0 (0.906) 6.7 (0.264)

Reverse clutch Ð 31505-41X07 Ð Ð

High clutch10 pcs31521-41X03

(Assembly)24.2 (0.9528) 11.6 (0.457)

Forward clutch (Overrun clutch) 20 pcs31521-41X04

(Assembly)35.77 (1.4083) 9.7 (0.382)

Low & reverse brake 18 pcs31655-41X00

(Assembly)22.3 (0.878) 11.2 (0.441)

Band servoSpring A 31605-4AX03 45.6 (1.795) 34.3 (1.350)

Spring B 31605-41X01 29.7 (1.169) 27.6 (1.087)

AccumulatorAccumulator A 31605-41X02 43.0 (1.693) 18.0 (0.709)

Accumulator B 31605-41X14 47.6 (1.874) 26.5 (1.043)

Accumulator C 31605-41X09 45.0 (1.772) 29.3 (1.154)

Accumulator D 31605-41X06 58.4 (2.299) 17.3 (0.681)

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Return Springs

AT-357

Page 363 of 2395

Accumulator O-ringNBAT0166

AccumulatorDiameter mm (in)

ABC D

Small diameter end 29 (1.14) 32 (1.26) 45 (1.77) 29 (1.14)

Large diameter end 45 (1.77) 50 (1.97) 50 (1.97) 45 (1.77)

Clutches and BrakesNBAT0167REVERSE CLUTCHNBAT0167S01

Code number4EX16 4EX17

Number of drive plates2

Number of driven plates2

Thickness of drive plate mm (in)Standard 1.90 - 2.05 (0.0748 - 0.0807)

Wear limit 1.80 (0.0709)

Clearance mm (in)Standard 0.5 - 0.8 (0.020 - 0.031)

Allowable limit 1.2 (0.047)

Thickness of retaining plateThickness mm (in) Part number*

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)

5.2 (0.205)

5.4 (0.213)31537-42X20

31537-42X21

31537-42X22

31537-42X23

31537-42X24

HIGH CLUTCHNBAT0167S02

Code number4EX16 4EX17

Number of drive plates5

Number of driven plates6

Thickness of drive plate mm (in)Standard 1.52 - 1.67 (0.0598 - 0.0657)

Wear limit 1.40 (0.0551)

Clearance mm (in)Standard 1.8 - 2.2 (0.071 - 0.087)

Allowable limit 3.2 (0.126)

Thickness of retaining plateThickness mm (in) Part number*

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)31537-41X63

31537-41X64

31537-41X65

31537-41X66

31537-41X67

31537-41X68

SERVICE DATA AND SPECIFICATIONS (SDS)

Accumulator O-ring

AT-358

Page 364 of 2395

FORWARD CLUTCHNBAT0167S03

Code number 4EX16 4EX17

Number of drive plates 7 8

Number of driven plates 7 8

Thickness of drive

plate mm (in)Standard 1.52 - 1.67 (0.0598 - 0.0657)

Wear limit 1.40 (0.0551)

Clearance mm (in)Standard 0.35 - 0.75 (0.0138 - 0.0295)

Allowable limit 2.15 (0.0846) 2.35 (0.0925)

Thickness of retaining plateThickness mm (in) Part number* Thickness mm (in) Part number*

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)

5.2 (0.205)

5.4 (0.213)

5.6 (0.220)31537-42X13

31537-42X14

31537-42X15

31537-4AX00

31537-4AX01

31537-4AX024.2 (0.165)

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)

5.2 (0.205)

5.4 (0.213)31537-42X11

31537-42X12

31537-42X13

31537-42X14

31537-42X15

31537-4AX00

31537-4AX01

OVERRUN CLUTCHNBAT0167S04

Code number4EX16 4EX17

Number of drive plates3

Number of driven plates5

Thickness of drive plate mm (in)Standard 1.90 - 2.05 (0.0748 - 0.0807)

Wear limit 1.80 (0.0709)

Clearance mm (in)Standard 1.0 - 1.4 (0.039 - 0.055)

Allowable limit 2.0 (0.079)

Thickness of retaining plateThickness mm (in) Part number*

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)31537-41X80

31537-41X81

31537-41X82

31537-41X83

31537-41X84

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Clutches and Brakes (Cont'd)

AT-359

Page 365 of 2395

LOW & REVERSE BRAKENBAT0167S05

Code number4EX16 4EX17

Number of drive plates8

Number of driven plates8

Thickness of drive plate mm (in)Standard 1.90 - 2.05 (0.0748 - 0.0807) 1.52 - 1.67 (0.0598 - 0.0657)

Wear limit 1.40 (0.0551)

Clearance mm (in)Standard 0.8 - 1.1 (0.031 - 0.043)

Allowable limit 2.7 (0.106)

Thickness of retaining plateThickness mm (in) Part number*

7.6 (0.299)

7.8 (0.307)

8.0 (0.315)

8.2 (0.323)

8.4 (0.331)

8.6 (0.339)

8.8 (0.346)

9.0 (0.354)

9.2 (0.362)

9.4 (0.370)

9.6 (0.378)31667-41X07

31667-41X08

31667-41X00

31667-41X01

31667-41X02

31667-41X03

31667-41X04

31667-41X05

31667-41X06

31667-41X09

31667-41X10

BRAKE BANDNBAT0167S06

Anchor end bolt nut tightening torque 40 - 51 N´m (4.1 - 5.2 kg-m, 30 - 38 ft-lb)

Anchor end bolt tightening torque4 - 6 N´m (0.4 - 0.6 kg-m, 35 - 52 in-lb)

Number of returning revolution for anchor end bolt 2.5

Oil Pump and Low One-way ClutchNBAT0168Unit: mm (in)

Oil pump clearanceCam ring Ð oil pump housing Standard 0.01 - 0.024 (0.0004 - 0.0009)

Rotor, vanes and control piston Ð oil

pump housingStandard 0.03 - 0.044 (0.0012 - 0.0017)

Seal ring clearanceStandard 0.10 - 0.25 (0.0039 - 0.0098)

Allowable limit 0.25 (0.0098)

Total End PlayNBAT0169

Total end play ªT1º 0.25 - 0.55 mm (0.0098 - 0.0217 in)

Thickness of oil pump cover bearing raceThickness mm (in) Part number*

0.8 (0.031)

1.0 (0.039)

1.2 (0.047)

1.4 (0.055)

1.6 (0.063)

1.8 (0.071)

2.0 (0.079)31435-41X01

31435-41X02

31435-41X03

31435-41X04

31435-41X05

31435-41X06

31435-41X07

SERVICE DATA AND SPECIFICATIONS (SDS)

Clutches and Brakes (Cont'd)

AT-360