IDX INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 406 of 2395

SBR231C

2. Remove piston stopper while piston is pushed into cylinder.

3. Remove piston assemblies.

If it is difficult to remove secondary piston assembly, gradu-

ally apply compressed air through fluid outlet.

4. Draw out reservoir tank.

InspectionNBBR0021Check master cylinder inner wall for pin holes or scratches.

Replace if damaged.

SBR354C

AssemblyNBBR00221. Insert secondary piston assembly. Then insert primary piston

assembly.

IPay attention to direction of piston cups in figure at left.

Also, insert pistons squarely to avoid scratches on cylin-

der bore.

IPay attention to alignment of secondary piston slit with

valve stopper mounting hole of cylinder body.

SBR940A

2. Install stopper cap.

Before installing stopper cap, ensure that claws are bent

inward.

3. Push reservoir tank seals into cylinder body.

4. Push reservoir tank into cylinder body.

SBR435B

5. Install valve stopper while piston is pushed into cylinder.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

MASTER CYLINDER

Disassembly (Cont'd)

BR-17

Page 408 of 2395

SBR002A

SBR365AA

On-vehicle ServiceNBBR0024OPERATING CHECKNBBR0024S011. Depress brake pedal several times with engine off. After

exhausting vacuum, make sure there is no change in pedal

stroke.

2. Depress brake pedal, then start engine. If pedal goes down

slightly, operation is normal.

AIRTIGHT CHECKNBBR0024S021. Start engine, and stop it after one or two minutes. Depress

brake pedal several times slowly. Booster is airtight if pedal

stroke is less each time.

2. Depress brake pedal while engine is running, and stop engine

with pedal depressed. The pedal stroke should not change

after holding pedal down for30 seconds.

SBR368DA

RemovalNBBR0025CAUTION:

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

IBe careful not to deform or bend brake pipes, during

removal of booster.

SBR208E

InspectionNBBR0026OUTPUT ROD LENGTH CHECKNBBR0026S011. Apply vacuum of þ66.7 kPa (þ500 mmHg, þ19.69 inHg) to

brake booster with a hand vacuum pump.

2. Add preload of 19.6 N (2.0 kg, 4.4 lb) to output rod.

3. Check output rod length.

Specified length:

10.275 - 10.525 mm (0.4045 - 0.4144 in)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

BRAKE BOOSTER

On-vehicle Service

BR-19

Page 410 of 2395

SBR382D

Vacuum HoseNBBR0028

SBR225B

Removal and InstallationNBBR0029CAUTION:

When installing vacuum hoses, pay attention to the following

points.

IDo not apply any oil or lubricants to vacuum hose and

check valve.

IInsert vacuum tube into vacuum hose as shown.

SBR498A

IInstall check valve, paying attention to its direction.

InspectionNBBR0030HOSES AND CONNECTORSNBBR0030S01Check vacuum lines, connections and check valve for airtightness,

improper attachment chafing and deterioration.

SBR943A

CHECK VALVENBBR0030S02Check vacuum with a vacuum pump.

Connect to booster side Vacuum should exist.

Connect to engine side Vacuum should not exist.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

VACUUM PIPING

Vacuum Hose

BR-21

Page 412 of 2395

SBR383D

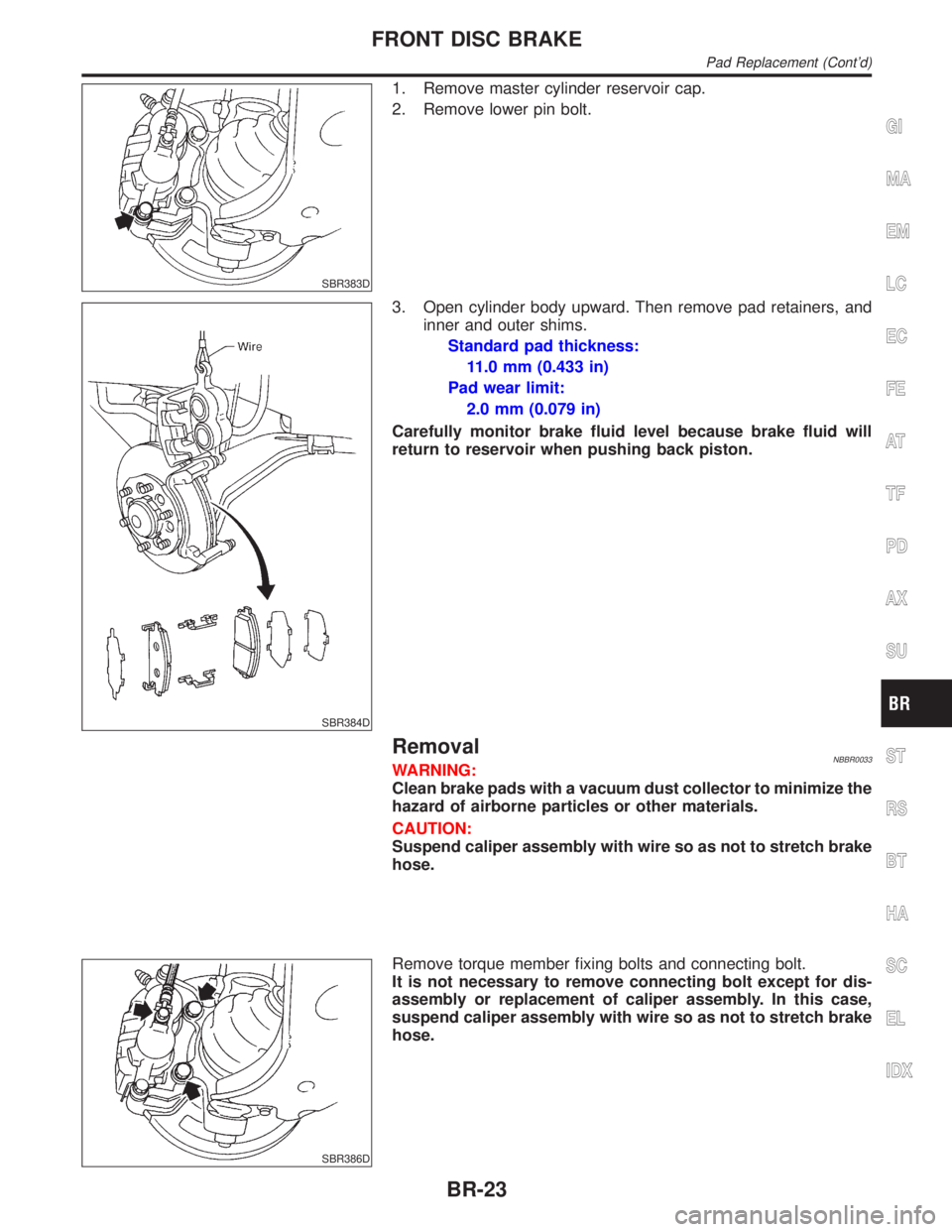

1. Remove master cylinder reservoir cap.

2. Remove lower pin bolt.

SBR384D

3. Open cylinder body upward. Then remove pad retainers, and

inner and outer shims.

Standard pad thickness:

11.0 mm (0.433 in)

Pad wear limit:

2.0 mm (0.079 in)

Carefully monitor brake fluid level because brake fluid will

return to reservoir when pushing back piston.

RemovalNBBR0033WARNING:

Clean brake pads with a vacuum dust collector to minimize the

hazard of airborne particles or other materials.

CAUTION:

Suspend caliper assembly with wire so as not to stretch brake

hose.

SBR386D

Remove torque member fixing bolts and connecting bolt.

It is not necessary to remove connecting bolt except for dis-

assembly or replacement of caliper assembly. In this case,

suspend caliper assembly with wire so as not to stretch brake

hose.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

FRONT DISC BRAKE

Pad Replacement (Cont'd)

BR-23

Page 414 of 2395

SBR020B

ThicknessNBBR0035S0202Thickness variation (At least 8 positions):

Maximum 0.015 mm (0.0006 in)

If thickness variation exceeds the specification, turn rotor with on-

car brake lathe.

Rotor repair limit:

26.0 mm (1.024 in)

SBR574

AssemblyNBBR00361. Insert piston seal into groove on cylinder body.

2. With piston boot fitted to piston, insert piston boot into groove

on cylinder body and install piston.

3. Properly secure piston boot

SBR387D

InstallationNBBR0037CAUTION:

IRefill with new brake fluid ªDOT 3º.

INever reuse drained brake fluid.

1. Install caliper assembly.

2. Install brake hose to caliper securely.

3. Install all parts and secure all bolts.

4. Bleed air. Refer to ªBleeding Brake Systemº, BR-8.

Brake Burnishing ProcedureNBBR0086When experiencing soft brake pedal feel at very low mileage, or

after replacing the rotor, burnish the brake pad contact surfaces

according to the following procedures.

CAUTION:

Only perform this procedure under safe road and traffic con-

ditions. Use extreme caution.

1. Drive the vehicle on a straight smooth road at 50 km/h (31

MPH).

2. Use medium brake pedal/foot effort to bring the vehicle to a

complete stop from 50 km/h (31 MPH). Adjust brake pedal/foot

pressure such that vehicle stopping time equals 3 to 5 sec-

onds.

3. To cool the brake system, drive the vehicle at 50 km/h (31

MPH) for 1 minute without stopping.

4. Repeat steps 1 to 3 10 times or more to complete the burnish-

ing procedure.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

FRONT DISC BRAKE

Inspection (Cont'd)

BR-25

Page 416 of 2395

SBR093A

b. Tighten the two bolts gradually.

SBR266CA

2. After removing shoe hold pin by rotating push retainer, remove

leading shoe then remove trailing shoe. Remove spring by

rotating shoes in direction arrow.

Be careful not to damage wheel cylinder piston boots.

3. Remove adjuster.

SBR267CA

4. Disconnect parking brake cable from toggle lever.

Be careful not to damage parking brake cable when separat-

ing it.

SBR093B

5. Remove retainer ring with a suitable tool. Then separate toggle

lever and brake shoe.

SBR816B

InspectionNBBR0040WHEEL CYLINDERNBBR0040S01ICheck wheel cylinder for leakage.

ICheck for wear, damage and loose conditions.

Replace if any such condition exists.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

REAR DRUM BRAKE

Removal (Cont'd)

BR-27

Page 418 of 2395

SBR217B

3. Shorten adjuster by rotating it.

IPay attention to direction of adjuster.

Wheel Screw Depression

Left Left-hand thread Yes

Right Right-hand thread No

SBR279B

4. Connect parking brake cable to toggle lever.

5. Install all parts.

Be careful not to damage wheel cylinder piston boots.

6. Check all parts are installed properly.

Pay attention to direction of adjuster assembly.

7. Install brake drum.

8. When installing new wheel cylinder or overhauling wheel

cylinder, bleed air. Refer to ªBleeding Brake Systemº, BR-8.

9. Adjust parking brake. Refer to ªAdjustmentº, ªPARKING

BRAKE CONTROLº, BR-31.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

REAR DRUM BRAKE

Installation (Cont'd)

BR-29

Page 420 of 2395

SBR042D

AdjustmentNBBR00471. Adjust clearance between shoe and drum as follows:

a. Release parking brake lever and loosen adjusting nut.

b. Depress brake pedal fully at least 10 times with engine run-

ning.

2. Pull control lever4-5notches. Then adjust control lever by

turning adjusting nut.

SBR073D

3. Pull control lever with specified amount of force. Check lever

stroke and ensure smooth operation.

Number of notches:6-8

4. Bend warning lamp switchplate to ensure:

IWarning lamp comes on when lever is lifted ªAº notches.

IWarning lamp goes out when lever is fully released.

Number of ªAº notches: 1 or less

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

PARKING BRAKE CONTROL

Adjustment

BR-31

Page 422 of 2395

System ComponentsNBBR0090

SBR447EB

SBR124B

System DescriptionNBBR0091SENSORNBBR0091S01The sensor unit consists of a gear-shaped sensor rotor and a sen-

sor element. The element contains a bar magnet around which a

coil is wound. The front sensors are installed on the front spindles

and the rear sensors are installed on the rear spindles. As the

wheel rotates, the sensor generates a sine-wave pattern. The fre-

quency and voltage increase(s) as the rotating speed increases.

SBR668E

CONTROL UNIT (BUILT-IN ABS ACTUATOR AND

ELECTRIC UNIT)

NBBR0091S02The control unit computes the wheel rotating speed by the signal

current sent from the sensor. Then it supplies a DC current to the

actuator solenoid valve. It also controls ON-OFF operation of the

valve relay and motor relay. If any electrical malfunction should be

detected in the system, the control unit causes the warning lamp

to light up. In this condition, the ABS will be deactivated by the

control unit, and the vehicle's brake system reverts to normal

operation. (For control unit layout, refer to ABS ACTUATOR AND

ELECTRIC UNIT, BR-33.)

SBR482E

ABS ACTUATOR AND ELECTRIC UNITNBBR0091S03The ABS actuator and electric unit contains:

IAn electric motor and pump

ITwo relays

ISix solenoid valves, each inlet and outlet for

Ð LH front

Ð RH front

Ð Rear

IABS control unit

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

DESCRIPTIONABS

System Components

BR-33

Page 424 of 2395

Component Parts and Harness Connector

Location

NBBR0092

SBR669E

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

DESCRIPTIONABS

Component Parts and Harness Connector Location

BR-35