vin INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 373 of 2395

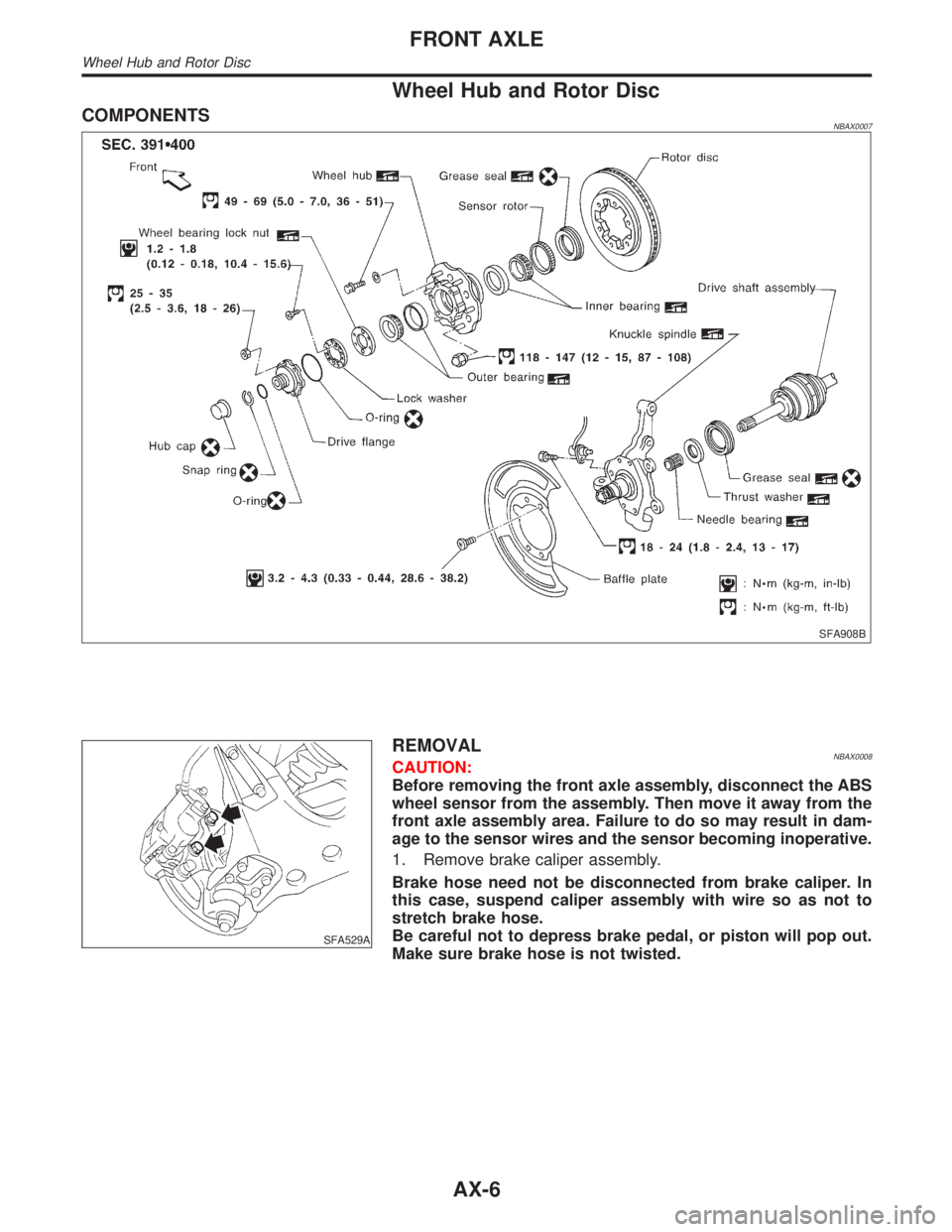

Wheel Hub and Rotor Disc

COMPONENTSNBAX0007

SFA908B

SFA529A

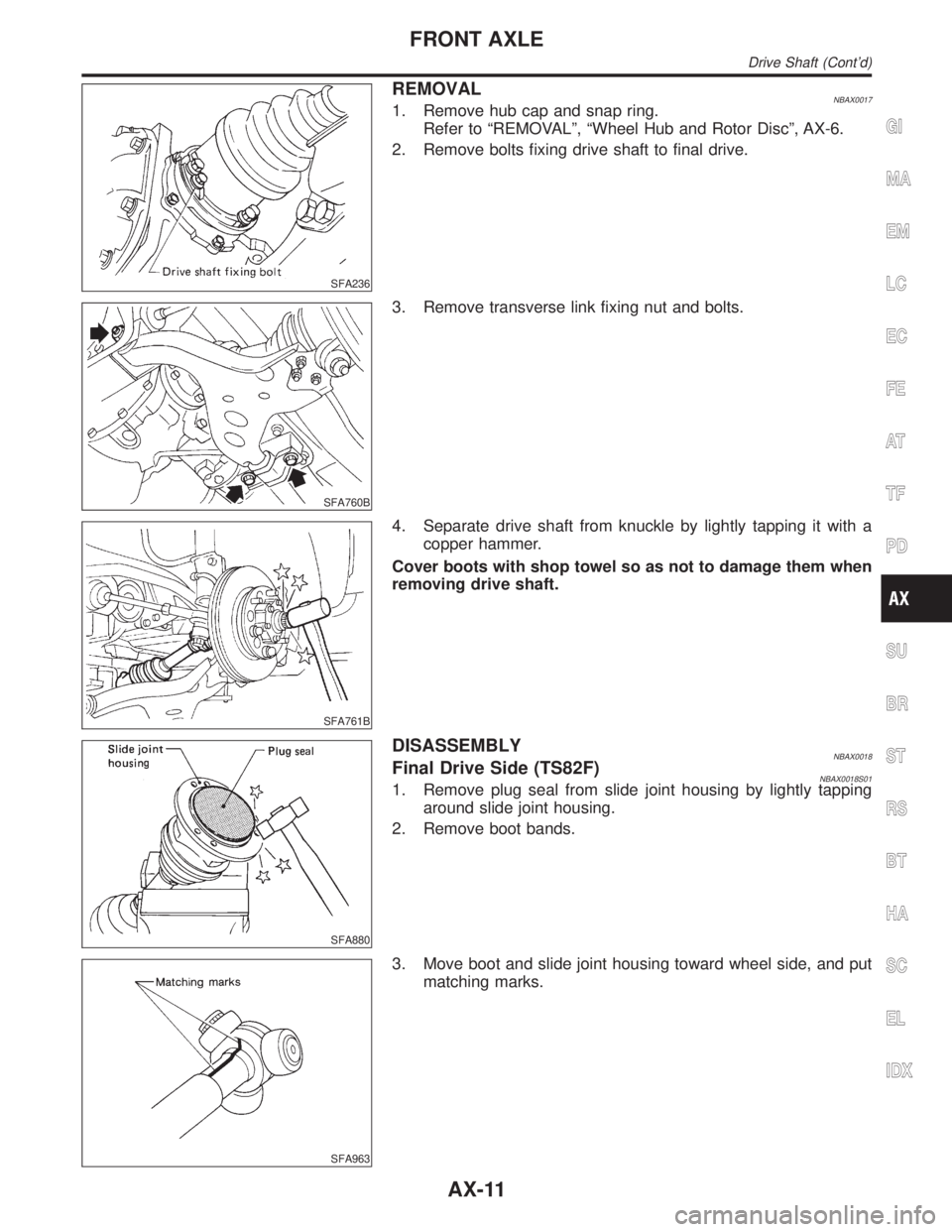

REMOVALNBAX0008CAUTION:

Before removing the front axle assembly, disconnect the ABS

wheel sensor from the assembly. Then move it away from the

front axle assembly area. Failure to do so may result in dam-

age to the sensor wires and the sensor becoming inoperative.

1. Remove brake caliper assembly.

Brake hose need not be disconnected from brake caliper. In

this case, suspend caliper assembly with wire so as not to

stretch brake hose.

Be careful not to depress brake pedal, or piston will pop out.

Make sure brake hose is not twisted.

FRONT AXLE

Wheel Hub and Rotor Disc

AX-6

Page 378 of 2395

SFA236

REMOVALNBAX00171. Remove hub cap and snap ring.

Refer to ªREMOVALº, ªWheel Hub and Rotor Discº, AX-6.

2. Remove bolts fixing drive shaft to final drive.

SFA760B

3. Remove transverse link fixing nut and bolts.

SFA761B

4. Separate drive shaft from knuckle by lightly tapping it with a

copper hammer.

Cover boots with shop towel so as not to damage them when

removing drive shaft.

SFA880

DISASSEMBLYNBAX0018Final Drive Side (TS82F)NBAX0018S011. Remove plug seal from slide joint housing by lightly tapping

around slide joint housing.

2. Remove boot bands.

SFA963

3. Move boot and slide joint housing toward wheel side, and put

matching marks.

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

Drive Shaft (Cont'd)

AX-11

Page 384 of 2395

SBR686C

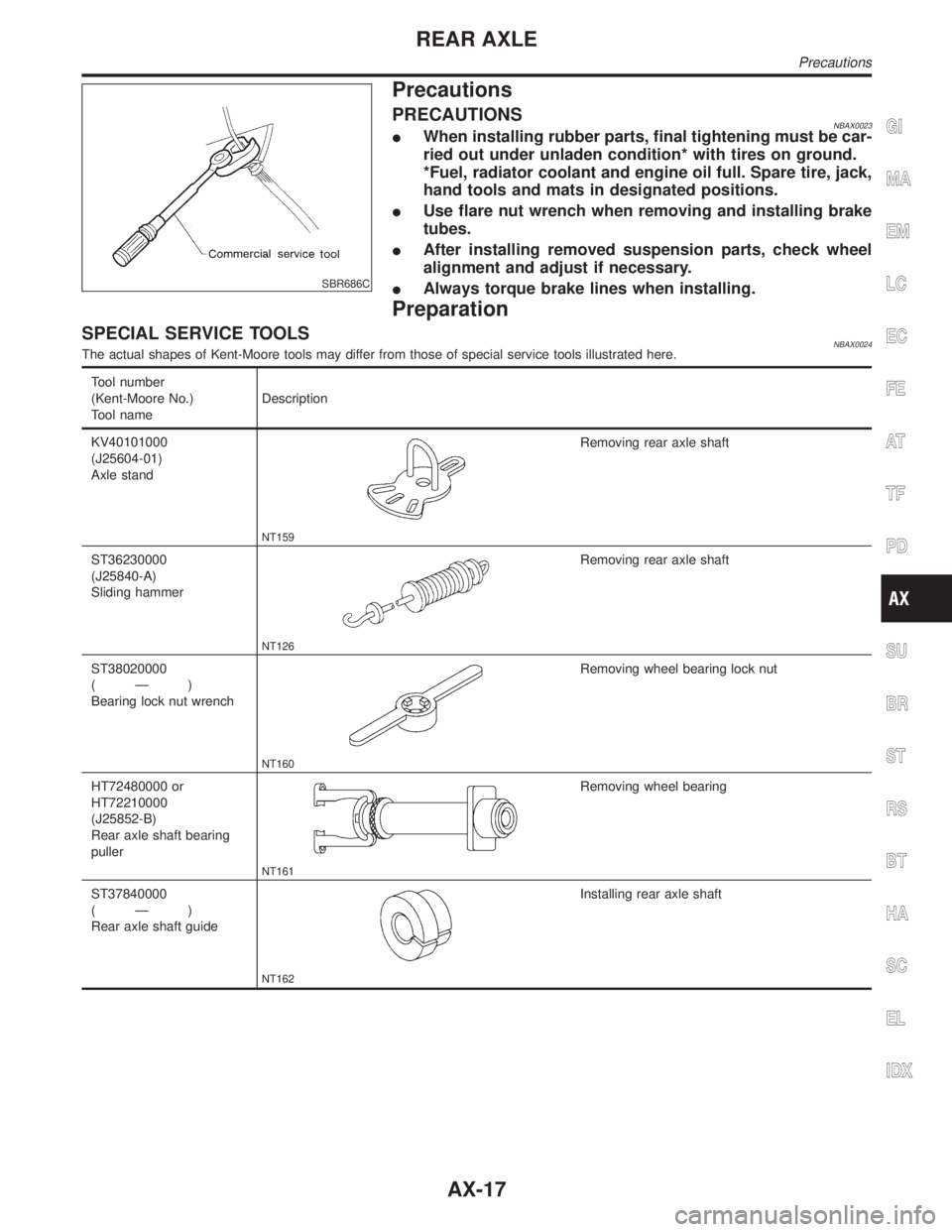

Precautions

PRECAUTIONSNBAX0023IWhen installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

IUse flare nut wrench when removing and installing brake

tubes.

IAfter installing removed suspension parts, check wheel

alignment and adjust if necessary.

IAlways torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNBAX0024The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

KV40101000

(J25604-01)

Axle stand

NT159

Removing rear axle shaft

ST36230000

(J25840-A)

Sliding hammer

NT126

Removing rear axle shaft

ST38020000

(Ð)

Bearing lock nut wrench

NT160

Removing wheel bearing lock nut

HT72480000 or

HT72210000

(J25852-B)

Rear axle shaft bearing

puller

NT161

Removing wheel bearing

ST37840000

(Ð)

Rear axle shaft guide

NT162

Installing rear axle shaft

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR AXLE

Precautions

AX-17

Page 385 of 2395

COMMERCIAL SERVICE TOOLSNBAX0025

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Rear axle oil seal drift

NT163

Installing oil seal

a: 74 mm (2.91 in) dia.

b: 68 mm (2.68 in) dia.

c: 10 mm (0.39 in)

Noise, Vibration and Harshness (NVH)

Troubleshooting

NBAX0035Refer to ªNoise, Vibration and Harshness (NVH) Troubleshootingº,

ªFRONT AXLEº, AX-3.

SMA525A

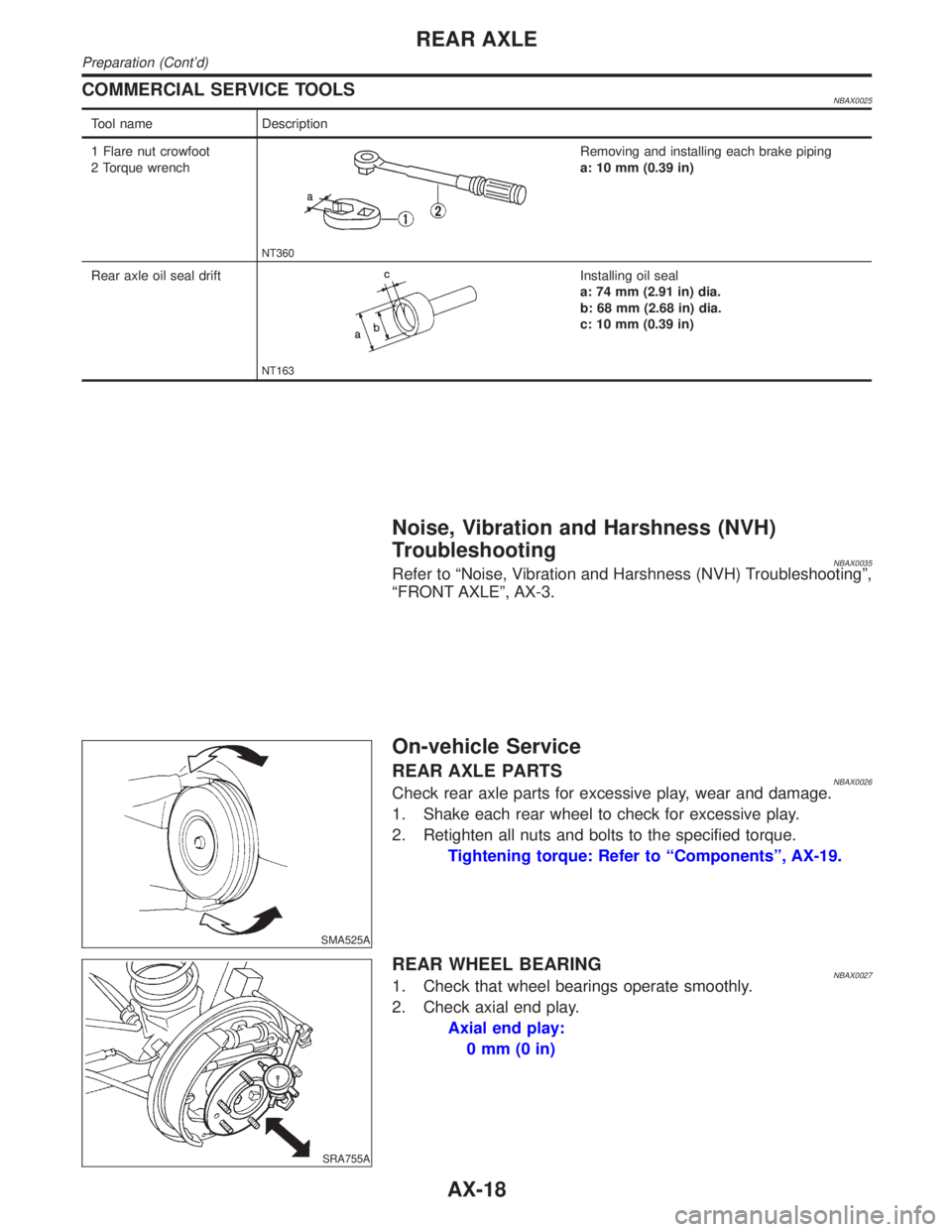

On-vehicle Service

REAR AXLE PARTSNBAX0026Check rear axle parts for excessive play, wear and damage.

1. Shake each rear wheel to check for excessive play.

2. Retighten all nuts and bolts to the specified torque.

Tightening torque: Refer to ªComponentsº, AX-19.

SRA755A

REAR WHEEL BEARINGNBAX00271. Check that wheel bearings operate smoothly.

2. Check axial end play.

Axial end play:

0mm(0in)

REAR AXLE

Preparation (Cont'd)

AX-18

Page 386 of 2395

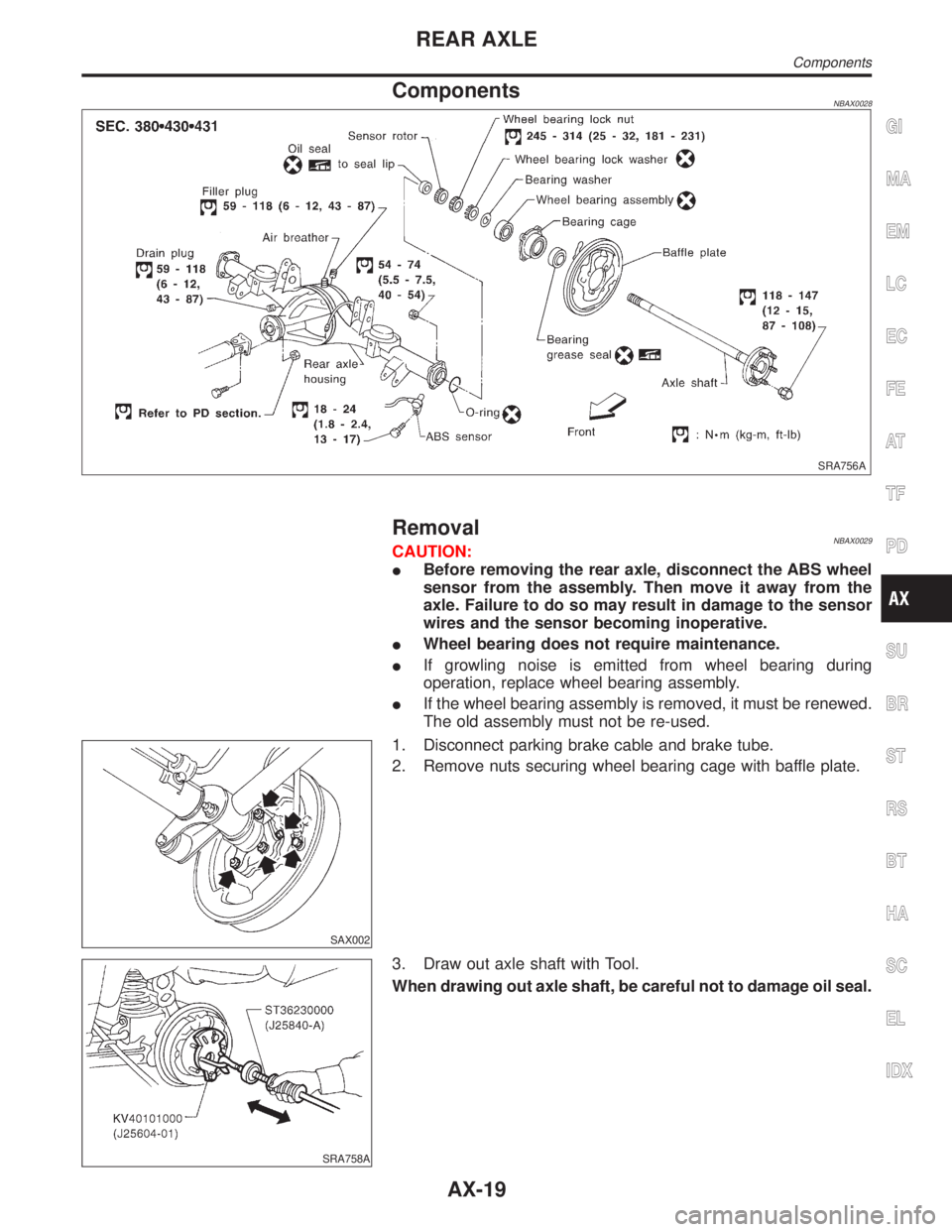

ComponentsNBAX0028

SRA756A

RemovalNBAX0029CAUTION:

IBefore removing the rear axle, disconnect the ABS wheel

sensor from the assembly. Then move it away from the

axle. Failure to do so may result in damage to the sensor

wires and the sensor becoming inoperative.

IWheel bearing does not require maintenance.

IIf growling noise is emitted from wheel bearing during

operation, replace wheel bearing assembly.

IIf the wheel bearing assembly is removed, it must be renewed.

The old assembly must not be re-used.

SAX002

1. Disconnect parking brake cable and brake tube.

2. Remove nuts securing wheel bearing cage with baffle plate.

SRA758A

3. Draw out axle shaft with Tool.

When drawing out axle shaft, be careful not to damage oil seal.

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR AXLE

Components

AX-19

Page 392 of 2395

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NBBR0001The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag module (located in the outer side of front seat),

satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring harness,

warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

SBR686C

Precautions for Brake SystemNBBR0002IUse brake fluid ªDOT 3º.

INever reuse drained brake fluid.

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

ITo clean master cylinder parts, disc brake caliper parts or

wheel cylinder parts, use clean brake fluid.

INever use mineral oils such as gasoline or kerosene. They

will ruin rubber parts of hydraulic system.

IUse flare nut wrench when removing and installing brake

tubes.

IAlways torque brake lines when installing.

WARNING:

IClean brakes with a vacuum dust collector to minimize

risk of health hazard from powder caused by friction.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

BR-3

Page 394 of 2395

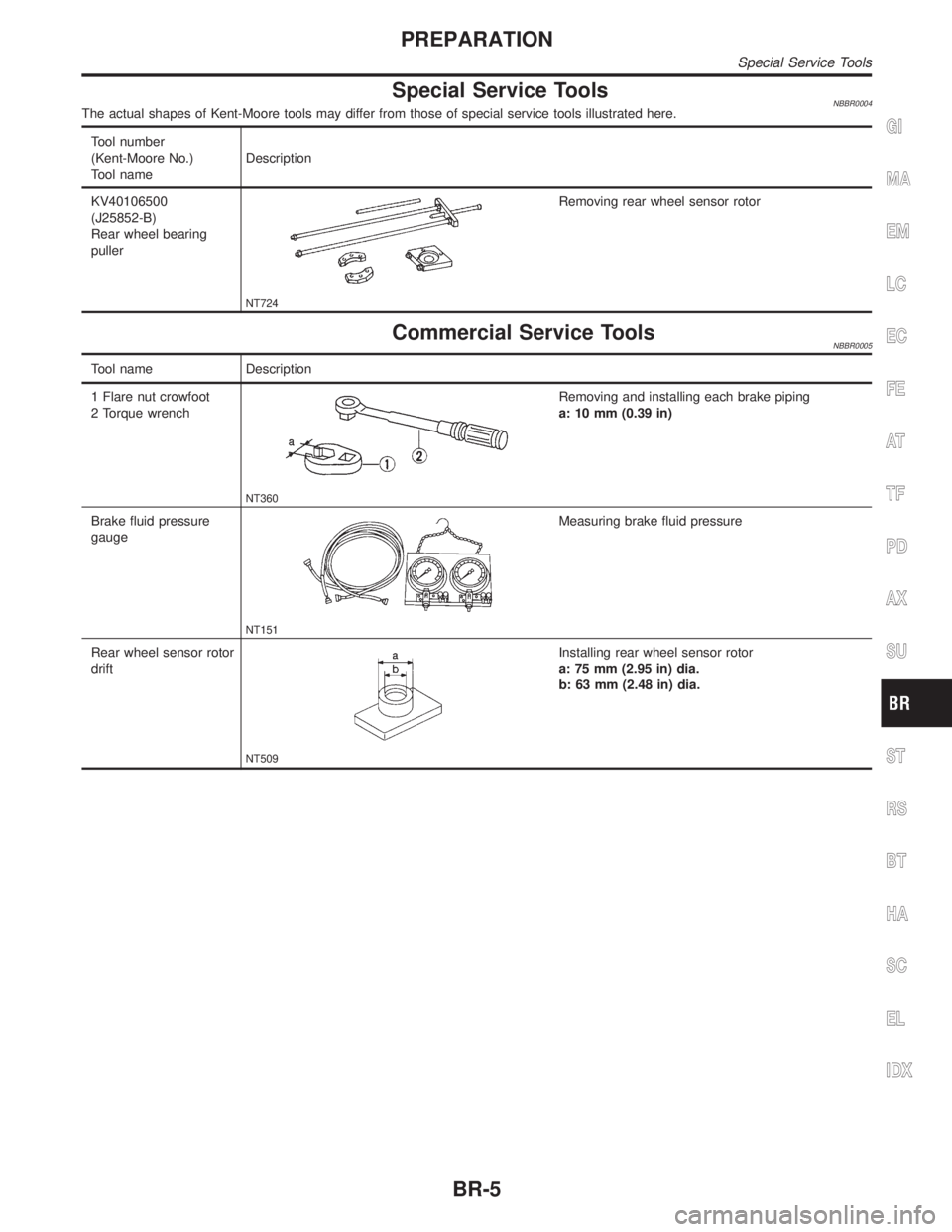

Special Service ToolsNBBR0004The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

KV40106500

(J25852-B)

Rear wheel bearing

puller

NT724

Removing rear wheel sensor rotor

Commercial Service ToolsNBBR0005

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Brake fluid pressure

gauge

NT151

Measuring brake fluid pressure

Rear wheel sensor rotor

drift

NT509

Installing rear wheel sensor rotor

a: 75 mm (2.95 in) dia.

b: 63 mm (2.48 in) dia.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

PREPARATION

Special Service Tools

BR-5

Page 396 of 2395

SBR451D

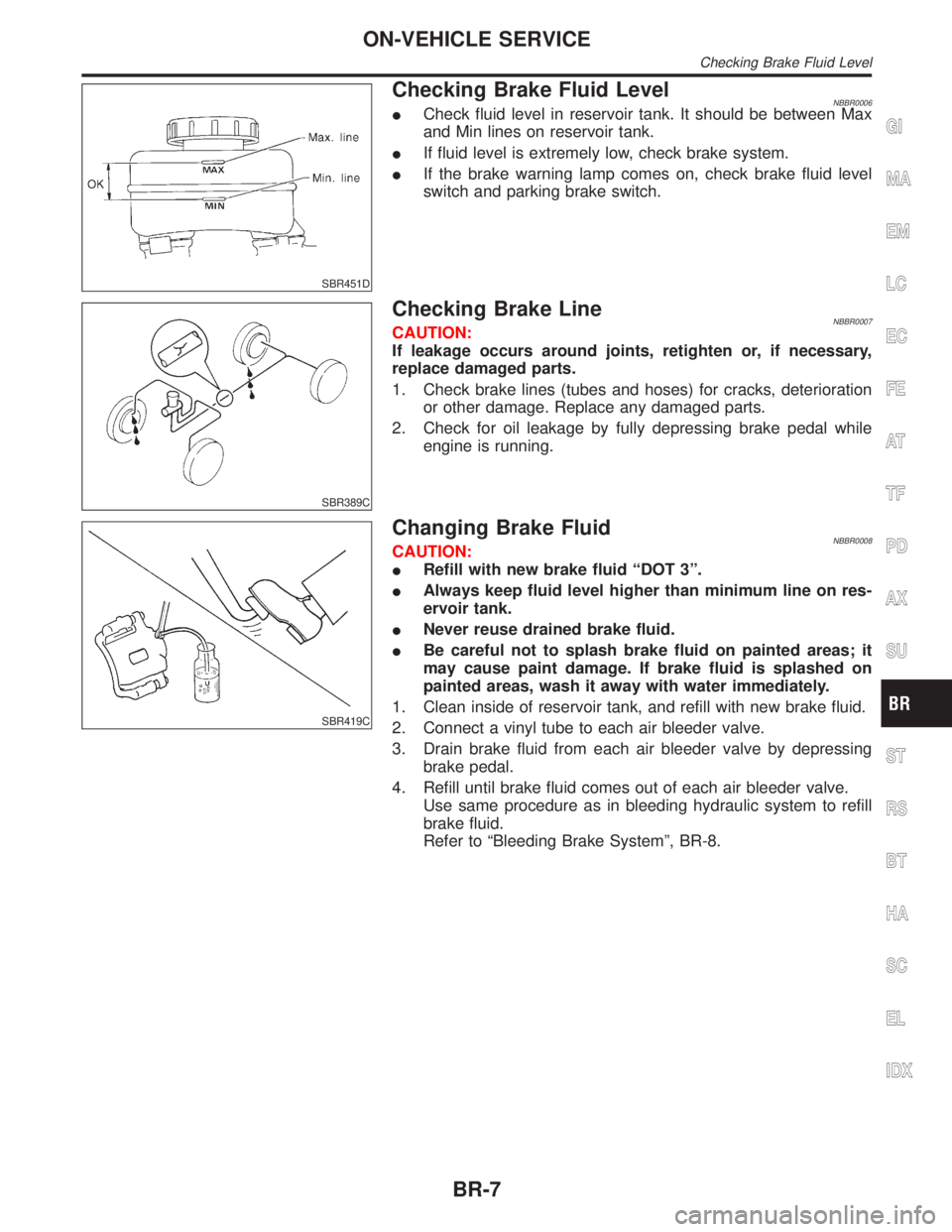

Checking Brake Fluid LevelNBBR0006ICheck fluid level in reservoir tank. It should be between Max

and Min lines on reservoir tank.

IIf fluid level is extremely low, check brake system.

IIf the brake warning lamp comes on, check brake fluid level

switch and parking brake switch.

SBR389C

Checking Brake LineNBBR0007CAUTION:

If leakage occurs around joints, retighten or, if necessary,

replace damaged parts.

1. Check brake lines (tubes and hoses) for cracks, deterioration

or other damage. Replace any damaged parts.

2. Check for oil leakage by fully depressing brake pedal while

engine is running.

SBR419C

Changing Brake FluidNBBR0008CAUTION:

IRefill with new brake fluid ªDOT 3º.

IAlways keep fluid level higher than minimum line on res-

ervoir tank.

INever reuse drained brake fluid.

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

1. Clean inside of reservoir tank, and refill with new brake fluid.

2. Connect a vinyl tube to each air bleeder valve.

3. Drain brake fluid from each air bleeder valve by depressing

brake pedal.

4. Refill until brake fluid comes out of each air bleeder valve.

Use same procedure as in bleeding hydraulic system to refill

brake fluid.

Refer to ªBleeding Brake Systemº, BR-8.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

ON-VEHICLE SERVICE

Checking Brake Fluid Level

BR-7

Page 397 of 2395

SBR995

Bleeding Brake System=NBBR0009CAUTION:

ICarefully monitor brake fluid level at master cylinder dur-

ing bleeding operation.

IIf master cylinder is suspected to have air inside, bleed air

from master cylinder first. Refer to ªInstallationº, ªMAS-

TER CYLINDERº, BR-18.

IFill reservoir with new brake fluid ªDOT 3º. Make sure it is

full at all times while bleeding air out of system.

IPlace a container under master cylinder to avoid spillage

of brake fluid.

ITurn ignition switch OFF and disconnect ABS actuator

and electric unit connectors or battery ground cable.

IBleed air in the following order.

1. LSV air bleeder (4WD)

2. Left rear brake

3. Right rear brake

4. Left front brake

5. Right front brake

SBR419C

1. Connect a transparent vinyl tube to air bleeder valve.

2. Fully depress brake pedal several times.

3. With brake pedal depressed, open air bleeder valve to release

air.

4. Close air bleeder valve.

5. Release brake pedal slowly.

6. Repeat steps 2. through 5. until clear brake fluid comes out of

air bleeder valve.

7. Tighten air bleeder valve.

:7-9N´m(0.7 - 0.9 kg-m, 61 - 78 in-lb)

ON-VEHICLE SERVICE

Bleeding Brake System

BR-8

Page 399 of 2395

SBR992

RemovalNBBR0011CAUTION:

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

IAll hoses must be free from excessive bending, twisting

and pulling.

1. Connect vinyl tube to air bleeder valve.

2. Drain brake fluid from each air bleeder valve by depressing

brake pedal.

3. Remove flare nut connecting brake tube and hose, then with-

draw lock spring.

4. Cover openings to prevent entrance of dirt whenever discon-

necting brake line.

InspectionNBBR0012Check brake lines (tubes and hoses) for cracks, deterioration or

other damage. Replace any damaged parts.

SBR686C

InstallationNBBR0013CAUTION:

IRefill with new brake fluid ªDOT 3º.

INever reuse drained brake fluid.

1. Tighten all flare nuts and connecting bolts.

Flare nut:

: 15 - 17 N´m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

Connecting bolt:

: 17 - 19 N´m (1.7 - 2.0 kg-m, 12 - 14 ft-lb)

2. Refill until new brake fluid comes out of each air bleeder valve.

3. Bleed air. Refer to ªBleeding Brake Systemº, BR-8.

BRAKE HYDRAULIC LINE

Removal

BR-10