INFINITI QX4 2001 Factory Service Manual

QX4 2001

INFINITI

INFINITI

https://www.carmanualsonline.info/img/42/57027/w960_57027-0.png

INFINITI QX4 2001 Factory Service Manual

Trending: change time, 4wd warning lamp, headlamp, coolant capacity, glove box, Bleed, rims

Page 551 of 2395

SEF289H

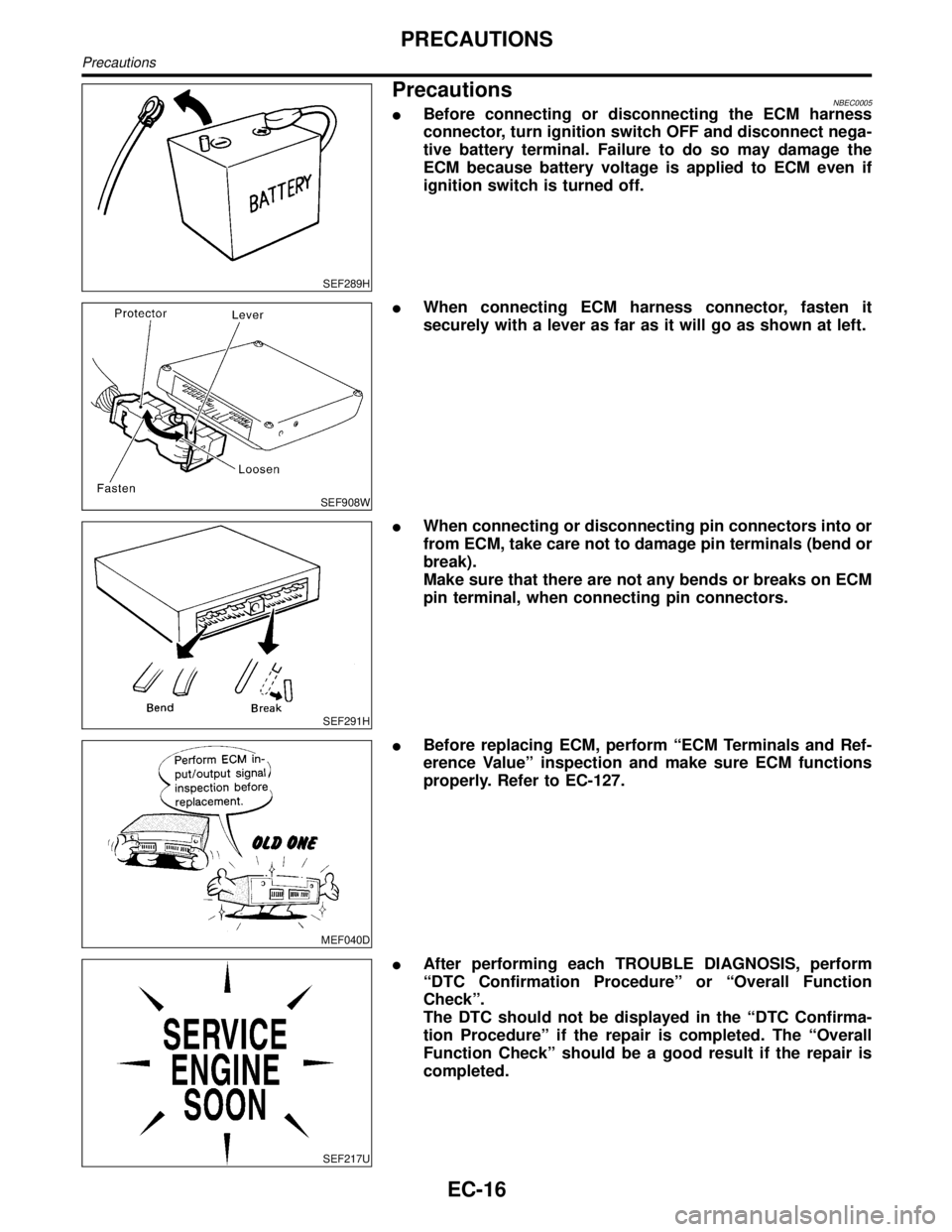

PrecautionsNBEC0005IBefore connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the

ECM because battery voltage is applied to ECM even if

ignition switch is turned off.

SEF908W

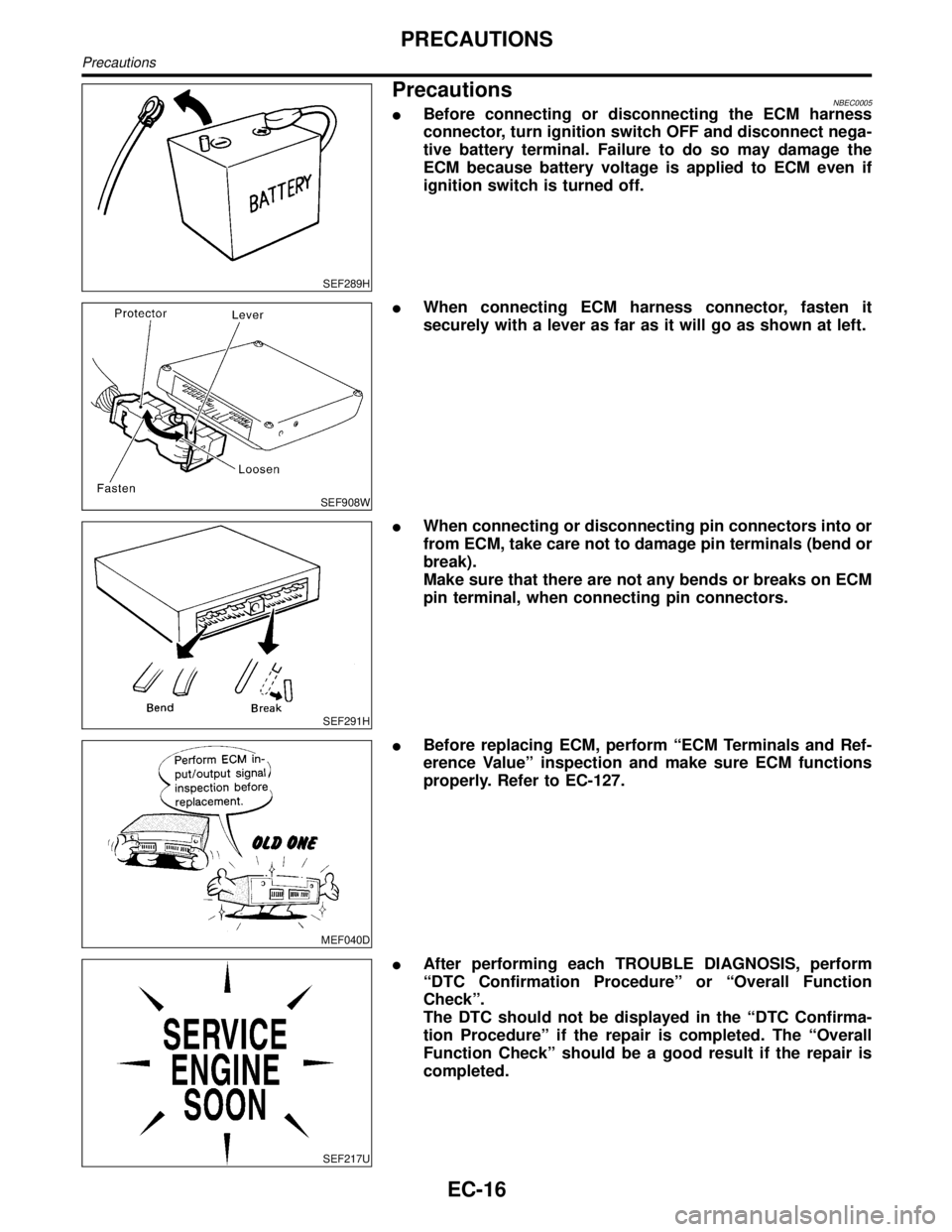

IWhen connecting ECM harness connector, fasten it

securely with a lever as far as it will go as shown at left.

SEF291H

IWhen connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

MEF040D

IBefore replacing ECM, perform ªECM Terminals and Ref-

erence Valueº inspection and make sure ECM functions

properly. Refer to EC-127.

SEF217U

IAfter performing each TROUBLE DIAGNOSIS, perform

ªDTC Confirmation Procedureº or ªOverall Function

Checkº.

The DTC should not be displayed in the ªDTC Confirma-

tion Procedureº if the repair is completed. The ªOverall

Function Checkº should be a good result if the repair is

completed.

PRECAUTIONS

Precautions

EC-16

Page 552 of 2395

SEF348N

IWhen measuring ECM signals with a circuit tester, never

allow the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

IDo not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the

ECM's transistor. Use a ground other than the ECM

terminals, such as the ground.

SEF099WB

IRegarding model R50, ª-B1º indicates the right bank and

ª-B2º indicates the left bank as shown in the figure.

IBank 1 includes No. 1 cylinder.

Wiring Diagrams and Trouble DiagnosisNBEC0006When you read Wiring diagrams, refer to the following:

IGI-34, ªHOW TO READ WIRING DIAGRAMSº

IEL-9, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnosis, refer to the following:

IGI-38, ªHOW TO FOLLOW TEST GROUP IN TROUBLE DIAGNOSISº

IGI-34, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Precautions (Cont'd)

EC-17

Page 553 of 2395

Special Service ToolsNBEC0007The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

KV10117100

(J36471-A)

Front heated oxygen

sensor wrench

Rear heated oxygen

sensor wrench

NT379

Loosening or tightening front and rear heated oxy-

gen sensors with 22 mm (0.87 in) hexagon nut

(J44321)

Fuel pressure adapter

and gauge kit

SEF326Z

Checking fuel pressure with pressure gauge

Commercial Service ToolsNBEC0008

Tool name

(Kent-Moore No.)Description

Leak detector

(J41416)

NT703

Locating the EVAP leak

EVAP service port

adapter

(J41413-OBD)

NT704

Applying positive pressure through EVAP service

port

Fuel filler cap adapter

NT653

Checking fuel tank vacuum relief valve opening

pressure

PREPARATION

Special Service Tools

EC-18

Page 554 of 2395

Tool name

(Kent-Moore No.)Description

Socket wrench

NT705

Removing and installing engine coolant tempera-

ture sensor

Oxygen sensor thread

cleaner

(J-43897-18)

(J-43897-12)

NT828

Reconditioning the exhaust system threads before

installing a new oxygen sensor. Use with anti-seize

lubricant shown below.

a: J-43897-18 18 mm diameter with pitch 1.5

mm, for Zirconia Oxygen Sensor

b: J-43897-12 12 mm diameter with pitch 1.25

mm, for Titania Oxygen Sensor

Anti-seize lubricant

(Permatex

TM133AR or

equivalent meeting MIL

specification MIL-A-907)

NT779

Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PREPARATION

Commercial Service Tools (Cont'd)

EC-19

Page 555 of 2395

Engine Control Component Parts LocationNBEC0009

SEF929Y

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

Engine Control Component Parts Location

EC-20

Page 556 of 2395

SEF034Z

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

Engine Control Component Parts Location (Cont'd)

EC-21

Page 557 of 2395

SEF584Z

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

Engine Control Component Parts Location (Cont'd)

EC-22

Page 558 of 2395

SEF036Z

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

Engine Control Component Parts Location (Cont'd)

EC-23

Page 559 of 2395

Circuit DiagramNBEC0010

MEC939C

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

Circuit Diagram

EC-24

Page 560 of 2395

System DiagramNBEC0011

SEF930Y

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

System Diagram

EC-25

Trending: coolant temperature, EM-29, driver seat adjustment, service reset, air filter, brake rotor, fuel consumption