Ignition harness INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 590 of 2395

31 CHECK ªCOº %

With CONSULT-II

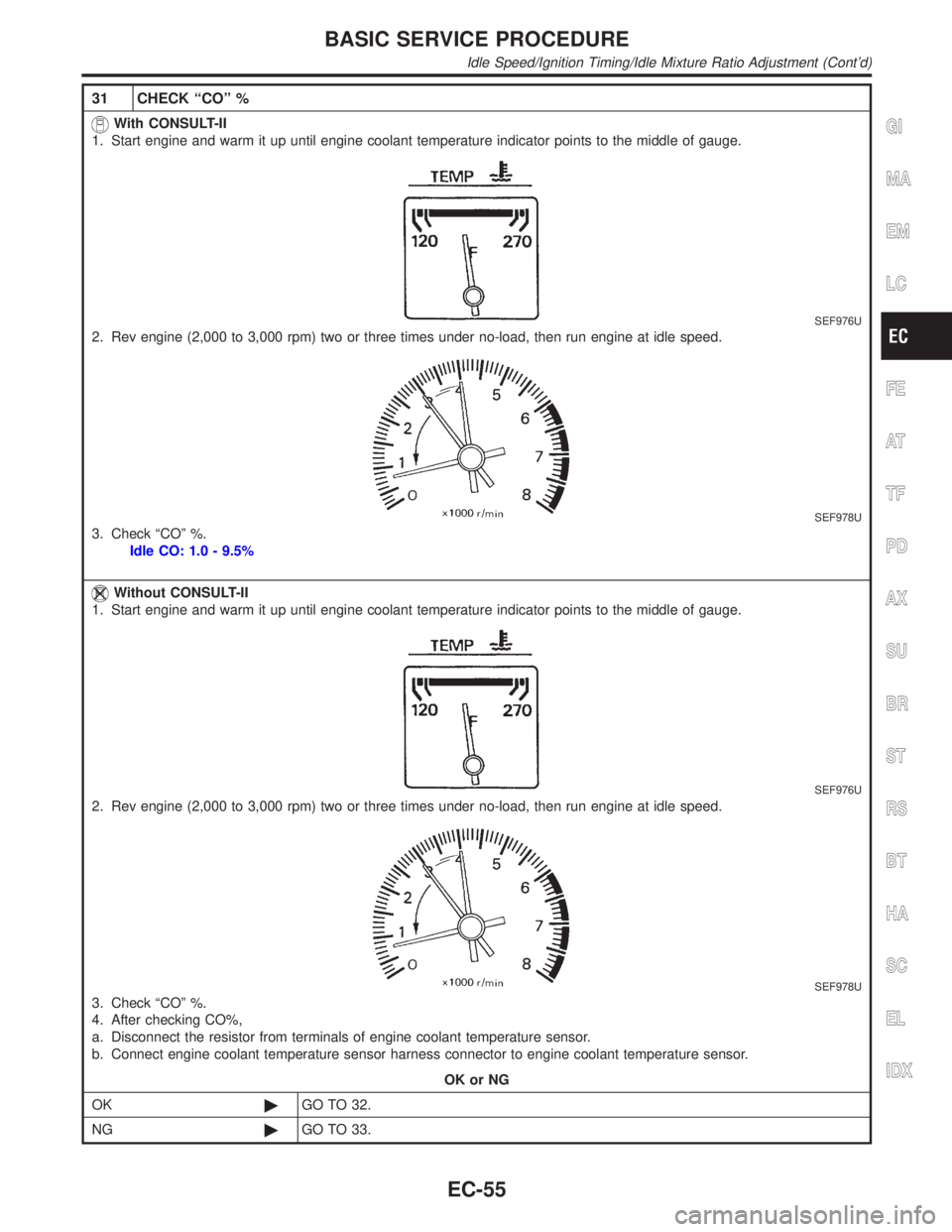

1. Start engine and warm it up until engine coolant temperature indicator points to the middle of gauge.

SEF976U

2. Rev engine (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

SEF978U

3. Check ªCOº %.

Idle CO: 1.0 - 9.5%

Without CONSULT-II

1. Start engine and warm it up until engine coolant temperature indicator points to the middle of gauge.

SEF976U

2. Rev engine (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

SEF978U

3. Check ªCOº %.

4. After checking CO%,

a. Disconnect the resistor from terminals of engine coolant temperature sensor.

b. Connect engine coolant temperature sensor harness connector to engine coolant temperature sensor.

OK or NG

OK©GO TO 32.

NG©GO TO 33.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

BASIC SERVICE PROCEDURE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-55

Page 591 of 2395

32 CHECK HEATED OXYGEN SENSOR 1 (FRONT) (BANK 1)/(BANK 2) SIGNAL

With CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front) (bank 1)/(bank 2).

3. Start engine and warm it up to normal operating temperature.

4. Run engine at approx. 2,000 rpm for approx. 2 minutes under no-load.

5. See ªHO2S1 MNTR (B1)/(B2)º in ªDATA MONITORº mode.

6. Maintaining engine at 2,000 rpm under no-load (engine is warmed up to normal operating temperature.), check that the

monitor fluctuates between ªLEANº and ªRICHº more than 5 times during 10 seconds.

1 time: RICH®LEAN®RICH

2 times: RICH®LEAN®RICH®LEAN®RICH

Without CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front) (bank 1)/(bank 2).

3. Start engine and warm it up to normal operating temperature.

4. Run engine at approx. 2,000 rpm for approx. 2 minutes under no-load.

5. Set voltmeter probe between ECM terminal 63 or 62 and ground.

6. Make sure that voltage fluctuates between 0 - 0.3V and 0.6 - 1.0V more than 5 times during 10 seconds at 2,000 rpm.

1 time: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V

2 times: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V®0.6 - 1.0V®0 - 0.3V

OK or NG

OK©GO TO 3.

NG©GO TO 33.

33 DETECT MALFUNCTIONING PART

Check the following.

IConnect heated oxygen sensor 1 (front) harness connectors to heated oxygen sensor 1 (front).

ICheck fuel pressure regulator. Refer to EC-40.

ICheck mass air flow sensor and its circuit. Refer to EC-150.

ICheck injector and its circuit. Refer to EC-616.

Clean or replace if necessary.

ICheck engine coolant temperature sensor and its circuit. Refer to EC-187.

ICheck ECM function by substituting another known-good ECM.

(ECM may be the cause of a problem, but this is rarely the case.)

©GO TO 3.

BASIC SERVICE PROCEDURE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-56

Page 593 of 2395

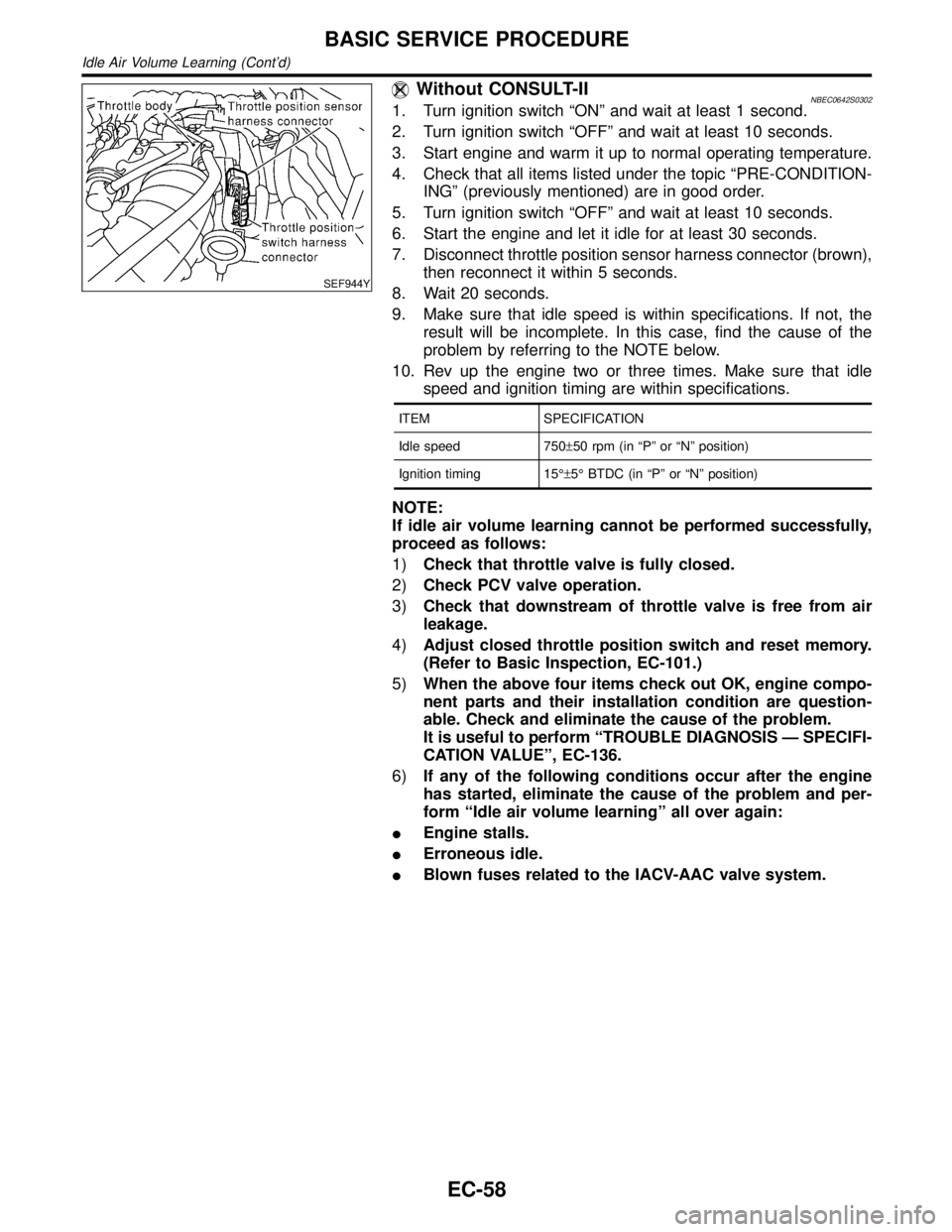

SEF944Y

Without CONSULT-IINBEC0642S03021. Turn ignition switch ªONº and wait at least 1 second.

2. Turn ignition switch ªOFFº and wait at least 10 seconds.

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic ªPRE-CONDITION-

INGº (previously mentioned) are in good order.

5. Turn ignition switch ªOFFº and wait at least 10 seconds.

6. Start the engine and let it idle for at least 30 seconds.

7. Disconnect throttle position sensor harness connector (brown),

then reconnect it within 5 seconds.

8. Wait 20 seconds.

9. Make sure that idle speed is within specifications. If not, the

result will be incomplete. In this case, find the cause of the

problem by referring to the NOTE below.

10. Rev up the engine two or three times. Make sure that idle

speed and ignition timing are within specifications.

ITEM SPECIFICATION

Idle speed 750±50 rpm (in ªPº or ªNº position)

Ignition timing 15ɱ5É BTDC (in ªPº or ªNº position)

NOTE:

If idle air volume learning cannot be performed successfully,

proceed as follows:

1)Check that throttle valve is fully closed.

2)Check PCV valve operation.

3)Check that downstream of throttle valve is free from air

leakage.

4)Adjust closed throttle position switch and reset memory.

(Refer to Basic Inspection, EC-101.)

5)When the above four items check out OK, engine compo-

nent parts and their installation condition are question-

able. Check and eliminate the cause of the problem.

It is useful to perform ªTROUBLE DIAGNOSIS Ð SPECIFI-

CATION VALUEº, EC-136.

6)If any of the following conditions occur after the engine

has started, eliminate the cause of the problem and per-

form ªIdle air volume learningº all over again:

IEngine stalls.

IErroneous idle.

IBlown fuses related to the IACV-AAC valve system.

BASIC SERVICE PROCEDURE

Idle Air Volume Learning (Cont'd)

EC-58

Page 626 of 2395

![INFINITI QX4 2001 Factory Workshop Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running INFINITI QX4 2001 Factory Workshop Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running](/img/42/57027/w960_57027-625.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running, specifi-

cation range is indicated.

IThis data also includes the data for

the air-fuel ratio learning control. A/F ALPHA-B2 [%]q

NOTE:

IAny monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

IRegarding R50 model, ªB1º indicates bank 1 and ªB2º indicates bank 2.

ACTIVE TEST MODENBEC0034S07

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJECTIONIEngine: Return to the original

trouble condition

IChange the amount of fuel injec-

tion using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IFuel injectors

IHeated oxygen sensor

IGNITION TIMINGIEngine: Return to the original

trouble condition

ITiming light: Set

IRetard the ignition timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IAdjust initial ignition timing

IACV-AAC/V

OPENINGIEngine: After warming up, idle

the engine.

IChange the IACV-AAC valve

opening percent using CON-

SULT-II.Engine speed changes according

to the opening percent.IHarness and connector

IIACV-AAC valve

POWER BAL-

ANCEIEngine: After warming up, idle

the engine.

IA/C switch ªOFFº

IShift lever ªNº

ICut off each injector signal one

at a time using CONSULT-II.Engine runs rough or dies.IHarness and connector

ICompression

IInjectors

IPower transistor

ISpark plugs

IIgnition coils

ENG COOLANT

TEMPIEngine: Return to the original

trouble condition

IChange the engine coolant tem-

perature using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IEngine coolant temperature sen-

sor

IFuel injectors

FUEL PUMP

RELAYIIgnition switch: ON

(Engine stopped)

ITurn the fuel pump relay ªONº

and ªOFFº using CONSULT-II

and listen to operating sound.Fuel pump relay makes the operat-

ing sound.IHarness and connector

IFuel pump relay

VIAS SOL VALVEIIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with CONSULT-II and lis-

ten for operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

SWIRL CONT

S O L VA LV EIIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with CONSULT-II and lis-

ten for operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

PURG VOL

CONT/VIEngine: After warming up, run

engine at 1,500 rpm.

IChange the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-II.Engine speed changes according

to the opening percent.IHarness and connector

ISolenoid valve

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-91

Page 627 of 2395

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL/T TEMP

SENIChange the fuel tank temperature using CONSULT-II.

VENT

CONTROL/VIIgnition switch: ON

(Engine stopped)

ITurn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

VC/V BYPASS/VIIgnition switch: ON

(Engine stopped)

ITurn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

TARGET INT/V

TIMIEngine: After warming up, hold

engine speed at 1,500 to 2,000

rpm.

IChange the intake valve timing

using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IIntake valve timing control sole-

noid valve

DTC & SRT CONFIRMATION MODENBEC0034S08SRT STATUS ModeNBEC0034S0801For details, refer to ªSYSTEM READINESS TEST (SRT) CODEº,

EC-61.

SRT Work Support ModeNBEC0034S0803This mode enables a technician to drive a vehicle to set the SRT

while monitoring the SRT status.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-92

Page 679 of 2395

DIAGNOSTIC PROCEDURENBEC0049

1 INSPECTION START

Start engine.

Is engine running?

YesorNo

Ye s©GO TO 9.

No©GO TO 2.

2 CHECK ECM POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ªOFFº and then ªONº.

2. Check voltage between ECM terminal 43 and ground with CONSULT-II or tester.

SEF291X

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

I10A fuses

IHarness connectors M33, F22

IHarness for open or short between ECM and ignition switch

©Repair harness or connectors.

4 CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-I

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 48, 57, 106, 108 and engine ground.

Refer to WIRING DIAGRAM.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Main Power Supply and Ground Circuit (Cont'd)

EC-144

Page 680 of 2395

5 CHECK POWER SUPPLY-II

1. Disconnect ECM relay.

SEF681UB

2. Check voltage between ECM relay terminals 1, 5 and ground with CONSULT-II or tester.

SEF956Y

OK or NG

OK©GO TO 7.

NG©GO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

I7.5A and 10A fuses

IHarness for open or short between ECM relay and battery

©Repair open circuit or short to ground or short to power in harness or connectors.

7 CHECK OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 26 and ECM relay terminal 2.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©Go to ªDTC P1320 IGNITION SIGNALº, EC-499.

NG©GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E1, M1 and M32, F23

IHarness for open or short between ECM relay and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Main Power Supply and Ground Circuit (Cont'd)

EC-145

Page 681 of 2395

9 CHECK ECM POWER SUPPLY CIRCUIT-II

1. Stop engine.

2. Check voltage between ECM terminal 67 and ground with CONSULT-II or tester.

SEF293X

OK or NG

OK©GO TO 11.

NG©GO TO 10.

10 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E1, M1 and M32, F23

IHarness for open or short between ECM and fuse

©Repair harness or connectors.

11 CHECK ECM POWER SUPPLY CIRCUIT-III

1. Turn ignition switch ªONº and then ªOFFº.

2. Check voltage between ECM terminals 110, 112 and ground with CONSULT-II or tester.

SEF294X

OK or NG

OK©GO TO 17.

NG (Battery voltage

does not exist.)©GO TO 12.

NG (Battery voltage

exists for more than a

few seconds.)©GO TO 14.

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Main Power Supply and Ground Circuit (Cont'd)

EC-146

Page 682 of 2395

12 CHECK ECM POWER SUPPLY CIRCUIT-IV

1. Disconnect ECM relay.

SEF681UB

2. Check voltage between ECM relay terminal 7 and ground with CONSULT-II or tester.

SEF957Y

OK or NG

OK©GO TO 14.

NG©GO TO 13.

13 DETECT MALFUNCTIONING PART

Check the following.

IHarness for open or short between ECM relay and 7.5A fuse

©Repair open circuit or short to ground or short to power in harness or connectors.

14 CHECK ECM POWER SUPPLY-V

1. Turn ignition switch ªOFFº and then ªONº.

2. Check voltage between ECM terminal 12 and ground with CONSULT-II or tester.

SEF331Z

OK or NG

OK©GO TO 16.

NG©GO TO 15.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Main Power Supply and Ground Circuit (Cont'd)

EC-147

Page 683 of 2395

15 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E1, M1

IHarness connectors M94, F27

I10A fuse

©Repair harness or connectors.

16 CHECK HARNESS CONTINUITY BETWEEN ECM RELAY AND ECM FOR OPEN AND SHORT

1. Check harness continuity between ECM terminals 110, 112 and ECM relay terminal 6.

Refer to WIRING DIAGRAM.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 18.

NG©GO TO 17.

17 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E1, M1 and M32, F23

IHarness for open or short between ECM and ECM relay

©Repair open circuit or short to ground or short to power in harness or connectors.

18 CHECK ECM RELAY

1. Apply 12V direct current between ECM relay terminals 1 and 2.

2. Check continuity between relay terminals 3 and 5, 6 and 7.

SEF296X

OK or NG

OK©GO TO 19.

NG©Replace ECM relay.

19 CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-II

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 48, 57, 106, 108 and engine ground.

Refer to WIRING DIAGRAM.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 20.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Main Power Supply and Ground Circuit (Cont'd)

EC-148