revolution sensor INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 357 of 2395

SAT001B

7. Install turbine revolution sensor.

8. Adjust brake band.

a. Tighten anchor end bolt to specified torque.

Anchor end bolt:

:4-6N´m(0.4 - 0.6 kg-m, 35 - 52 in-lb)

b. Back off anchor end bolt two and a half turns.

SAT002B

c. While holding anchor end bolt, tighten lock nut.

Ancher end bolt nut:

: 41 - 50 N´m (4.1 - 5.2 kg-m, 30 - 37 ft-lb)

SAT115B

9. Install terminal cord assembly.

a. Install O-ring on terminal cord assembly.

IApply petroleum jelly to O-ring.

b. Compress terminal cord assembly stopper and install terminal

cord assembly on transmission case.

SAT004BA

10. Install control valve assembly.

a. Install accumulator piston return springs B, C and D.

Free length of return springs:

Refer to SDS, AT-357.

SAT005B

b. Install manual valve on control valve.

IApply ATF to manual valve.

ASSEMBLY

Assembly (2) (Cont'd)

AT-352

Page 366 of 2395

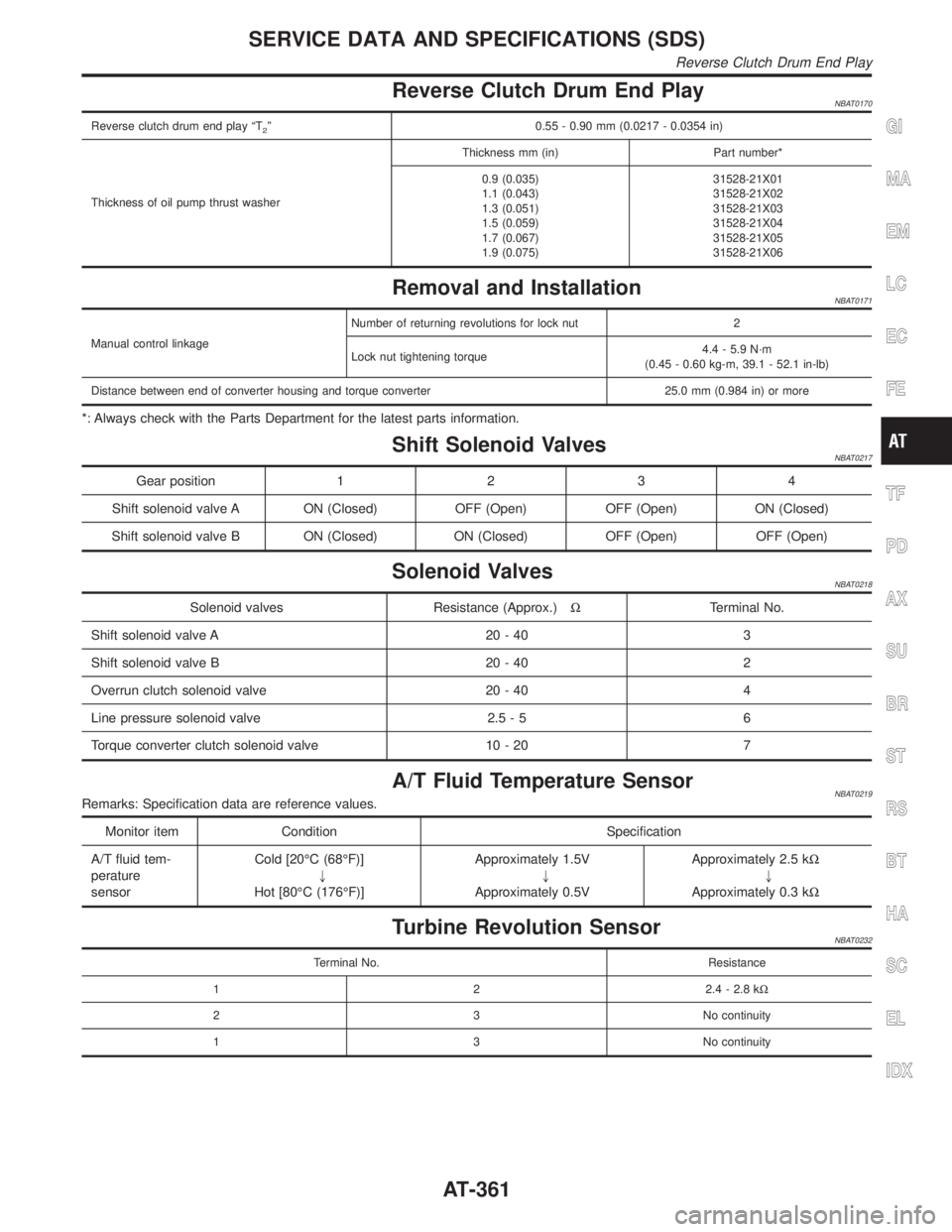

Reverse Clutch Drum End PlayNBAT0170

Reverse clutch drum end play ªT2º 0.55 - 0.90 mm (0.0217 - 0.0354 in)

Thickness of oil pump thrust washerThickness mm (in) Part number*

0.9 (0.035)

1.1 (0.043)

1.3 (0.051)

1.5 (0.059)

1.7 (0.067)

1.9 (0.075)31528-21X01

31528-21X02

31528-21X03

31528-21X04

31528-21X05

31528-21X06

Removal and InstallationNBAT0171

Manual control linkageNumber of returning revolutions for lock nut 2

Lock nut tightening torque4.4 - 5.9 N´m

(0.45 - 0.60 kg-m, 39.1 - 52.1 in-lb)

Distance between end of converter housing and torque converter 25.0 mm (0.984 in) or more

*: Always check with the Parts Department for the latest parts information.

Shift Solenoid ValvesNBAT0217

Gear position1234

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

Solenoid ValvesNBAT0218

Solenoid valves Resistance (Approx.)WTerminal No.

Shift solenoid valve A 20 - 40 3

Shift solenoid valve B 20 - 40 2

Overrun clutch solenoid valve 20 - 40 4

Line pressure solenoid valve 2.5 - 5 6

Torque converter clutch solenoid valve 10 - 20 7

A/T Fluid Temperature SensorNBAT0219Remarks: Specification data are reference values.

Monitor item Condition Specification

A/T fluid tem-

perature

sensorCold [20ÉC (68ÉF)]

"

Hot [80ÉC (176ÉF)]Approximately 1.5V

"

Approximately 0.5VApproximately 2.5 kW

"

Approximately 0.3 kW

Turbine Revolution SensorNBAT0232

Terminal No. Resistance

1 2 2.4 - 2.8 kW

2 3 No continuity

1 3 No continuity

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Reverse Clutch Drum End Play

AT-361

Page 367 of 2395

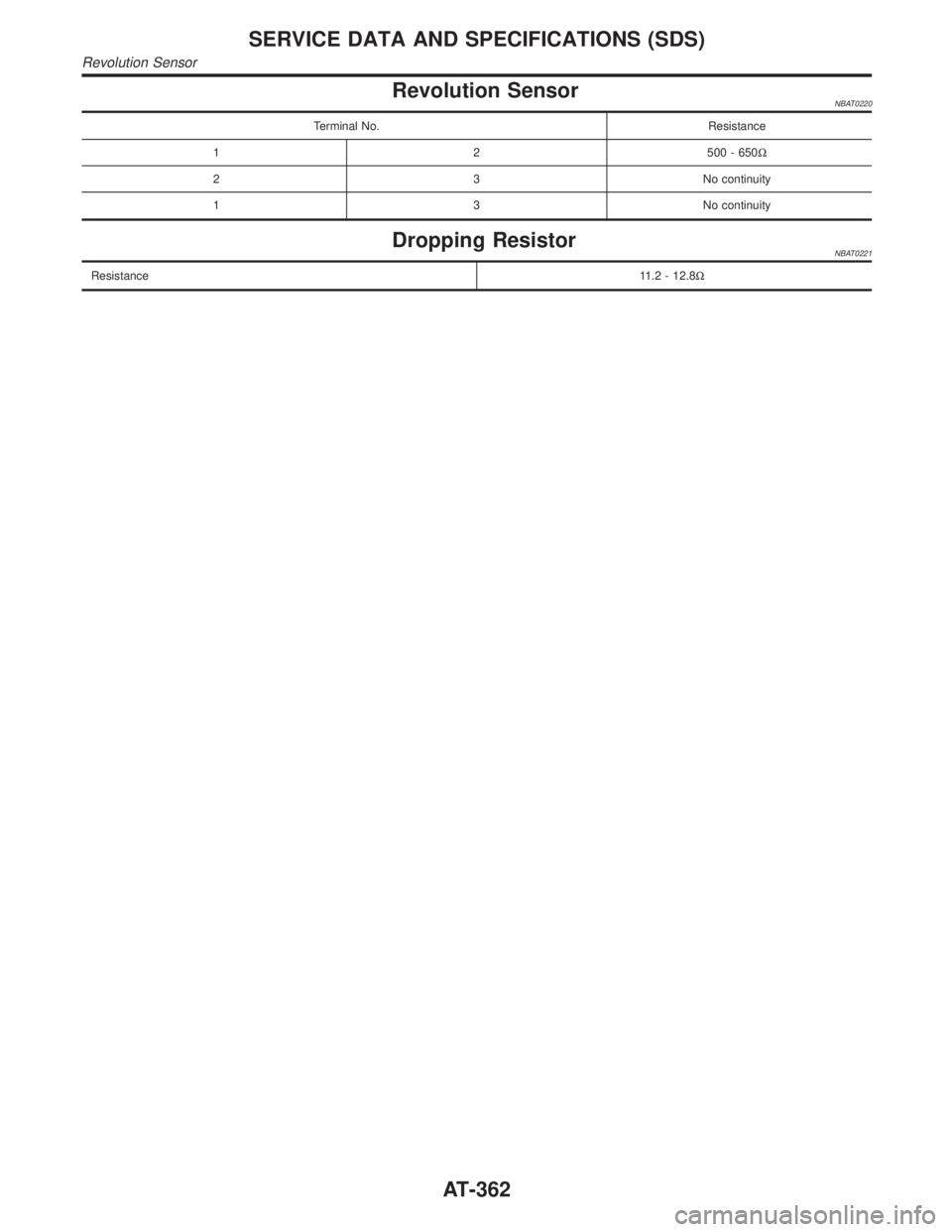

Revolution SensorNBAT0220

Terminal No. Resistance

1 2 500 - 650W

2 3 No continuity

1 3 No continuity

Dropping ResistorNBAT0221

Resistance11.2 - 12.8W

SERVICE DATA AND SPECIFICATIONS (SDS)

Revolution Sensor

AT-362

Page 545 of 2395

Items

(CONSULT-II screen terms)DTC*1 Reference page

INT/V TIM V/CIR-B1 P1111EC-451

INT/V TIM V/CIR-B2 P1136 EC-451

KNOCK SEN/CIRC-B1 P0325*2 EC-328

L/PRES SOL/CIRC P0745 AT-174

MAF SEN/CIRCUIT*3 P0100 EC-150

MULTI CYL MISFIRE P0300 EC-320

NATS MALFUNCTION P1610 - P1615*2 EL-328

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.P0000 Ð

O/R CLTCH SOL/CIRC P1760 AT-223

P-N POS SW/CIRCUIT P1706 EC-604

PNP SW/CIRC P0705 AT-111

PURG VOLUME CONT/V P0443 EC-367

PURG VOLUME CONT/V P1444 EC-541

SFT SOL A/CIRC*3 P0750 AT-180

SFT SOL B/CIRC*3 P0755 AT-189

SWIRL CONT SOL/V P1130 EC-458

SWL CON VC SW/CIRC P1165 EC-493

TCC SOLENOID/CIRC P0740 AT-165

TP SEN/CIRC A/T*3 P1705 AT-218

TRTL POS SEN/CIRC*3 P0120 EC-174

TW CATALYST SYS-B1 P0420 EC-347

TW CATALYST SYS-B2 P0430 EC-347

VC CUT/V BYPASS/V P1491 EC-591

VC/V BYPASS/V P1490 EC-585

VEH SPEED SEN/CIRC*4 P0500 EC-417

VEH SPD SEN/CIR A/T*4 P0720 AT-124

VENT CONTROL VALVE P0446 EC-374

VENT CONTROL VALVE P1446 EC-553

VENT CONTROL VALVE P1448 EC-573

*1: 1st trip DTC No. is the same as DTC No.

*2: This DTC is displayed with CONSULT-II only.

*3: When the fail-safe operation occurs, the MIL illuminates.

*4: The MIL illuminates when both the ªRevolution sensor signalº and the ªVehicle speed sensor signalº meet the fail-safe condition at

the same time.

NOTE:

IRegarding R50 models, ª-B1º and ªBK1º indicate right bank and ª-B2º and ªBK2º indicate left bank.

IBank 1 (-B1 or BK1) includes No. 1 cylinder.

TROUBLE DIAGNOSIS Ð INDEX

Alphabetical & P No. Index for DTC (Cont'd)

EC-10

Page 548 of 2395

DTC*1Items

(CONSULT-II screen terms)Reference page

P0750 SFT SOL A/CIRC*3 AT-180

P0755 SFT SOL B/CIRC*3 AT-189

P1110 INT/V TIM CONT-B1 EC-446

P 1111INT/V TIM V/CIR-B1 EC-451

P1130 SWIRL CONT SOL/V EC-458

P1135 INT/V TIM CONT-B2 EC-446

P1136 INT/V TIM V/CIR-B2 EC-451

P1140 INTK TIM S/CIRC-B1 EC-482

P1145 INTK TIM S/CIRC-B2 EC-482

P1148 CLOSED LOOP-B1 EC-491

P1165 SWL CON VC SW/CIRC EC-493

P1168 CLOSED LOOP-B2 EC-491

P1217 ENG OVER TEMP LC-24

P1320 IGN SIGNAL-PRIMARY EC-499

P1335 CPS/CIRCUIT (REF) EC-510

P1336 CPS/CIRC (POS) COG EC-517

P1441 EVAP VERY SMALL LEAK EC-526

P1444 PURG VOLUME CONT/V EC-541

P1446 VENT CONTROL VALVE EC-553

P1447 EVAP PURG FLOW/MON EC-561

P1448 VENT CONTROL VALVE EC-573

P1464 FUEL LEVEL SEN/CIRC EC-582

P1490 VC/V BYPASS/V EC-585

P1491 VC CUT/V BYPASS/V EC-591

P1605 A/T DIAG COMM LINE EC-603

P1610 - P1615*2 NATS MALFUNCTION EL-328

P1705 TP SEN/CIRC A/T*3 AT-218

P1706 P-N POS SW/CIRCUIT EC-604

P1760 O/R CLTCH SOL/CIRC AT-223

*1: 1st trip DTC No. is the same as DTC No.

*2: This DTC is displayed with CONSULT-II only.

*3: When the fail-safe operation occurs, the MIL illuminates.

*4: The MIL illuminates when both the ªRevolution sensor signalº and the ªVehicle speed sensor signalº meet the fail-safe condition at

the same time.

NOTE:

IRegarding R50 models, ª-B1º and ªBK1º indicate right bank and ª-B2º and ªBK2º indicate left bank.

IBank 1 (-B1 or BK1) includes No. 1 cylinder.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð INDEX

Alphabetical & P No. Index for DTC (Cont'd)

EC-13

Page 622 of 2395

![INFINITI QX4 2001 Factory Workshop Manual DATA MONITOR MODE=NBEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]qqIIndicates the engine speed computed

from the REF signal (120É signal) of the

cran INFINITI QX4 2001 Factory Workshop Manual DATA MONITOR MODE=NBEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]qqIIndicates the engine speed computed

from the REF signal (120É signal) of the

cran](/img/42/57027/w960_57027-621.png)

DATA MONITOR MODE=NBEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]qqIIndicates the engine speed computed

from the REF signal (120É signal) of the

crankshaft position sensor (REF).

CKPS´RPM (POS)

[rpm]qIIndicates the engine speed computed

from the POS signal (1É signal) of the

crankshaft position sensor (POS).IAccuracy becomes poor if engine

speed drops below the idle rpm.

IIf the signal is interrupted while the

engine is running, an abnormal value

may be indicated.

POS COUNTqIIndicates the number of signal plate

(Flywheel/Drive Plate) cogs (tooth) dur-

ing one revolution of the engine.

MAS A/F SE-B1 [V]qqIThe signal voltage of the mass air flow

sensor is displayed.IWhen the engine is stopped, a certain

value is indicated.

COOLAN TEMP/S

[ÉC] or [ÉF]qqIThe engine coolant temperature (deter-

mined by the signal voltage of the

engine coolant temperature sensor) is

displayed.IWhen the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine cool-

ant temperature determined by the

ECM is displayed.

HO2S1 (B1) [V]qq

IThe signal voltage of the front heated

oxygen sensor is displayed.

HO2S1 (B2) [V]qq

HO2S2 (B1) [V]qq

IThe signal voltage of the rear heated

oxygen sensor is displayed.

HO2S2 (B2) [V]qq

HO2S1 MNTR (B1)

[RICH/LEAN]qIDisplay of front heated oxygen sensor

signal during air-fuel ratio feedback

control:

RICH ... means the mixture became

ªrichº, and control is being affected

toward a leaner mixture.

LEAN ... means the mixture became

ªleanº, and control is being affected

toward a rich mixture.IAfter turning ON the ignition switch,

ªRICHº is displayed until air-fuel mixture

ratio feedback control begins.

IWhen the air-fuel ratio feedback is

clamped, the value just before the

clamping is displayed continuously. HO2S1 MNTR (B2)

[RICH/LEAN]q

HO2S2 MNTR (B1)

[RICH/LEAN]qIDisplay of rear heated oxygen sensor

signal:

RICH ... means the amount of oxygen

after three way catalyst is relatively

small.

LEAN ... means the amount of oxygen

after three way catalyst is relatively

large.IWhen the engine is stopped, a certain

value is indicated.

HO2S2 MNTR (B2)

[RICH/LEAN]q

VHCL SPEED SE

[km/h] or [mph]qqIThe vehicle speed computed from the

vehicle speed sensor signal is dis-

played.

BATTERY VOLT [V]qqIThe power supply voltage of ECM is

displayed.

THRTL POS SEN [V]qqIThe throttle position sensor signal volt-

age is displayed.

FUEL T/TMP SE

[ÉC] or [ÉF]IThe fuel temperature judged from the

tank fuel temperature sensor signal

voltage is displayed.GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-87

Page 855 of 2395

On Board Diagnosis LogicNBEC0182When a misfire occurs, engine speed will fluctuate. If the engine

speed fluctuates enough to cause the CKP sensor signal to vary,

ECM can determine that a misfire is occurring.

Sensor Input Signal to ECM ECM function

Crankshaft position sensor (POS) Engine speed On board diagnosis of misfire

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage)

On the first trip that a misfire condition occurs that can dam-

age the three way catalyst (TWC) due to overheating, the MIL

will blink.

When a misfire condition occurs, the ECM monitors the CKP

sensor signal every 200 engine revolutions for a change.

When the misfire condition decreases to a level that will not

damage the TWC, the MIL will turn off.

If another misfire condition occurs that can damage the TWC

on a second trip, the MIL will blink.

When the misfire condition decreases to a level that will not

damage the TWC, the MIL will remain on.

If another misfire condition occurs that can damage the TWC,

the MIL will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration)

For misfire conditions that will not damage the TWC (but will

affect vehicle emissions), the MIL will only light when the mis-

fire is detected on a second trip. During this condition, the ECM

monitors the CKP sensor signal every 1,000 engine revolu-

tions.

A misfire malfunction can be detected on any one cylinder or

on multiple cylinders.

Malfunction is detected when multiple cylinders misfire, No. 1 cyl-

inder misfires, No. 2 cylinder misfires, No. 3 cylinder misfires, No.

4 cylinder misfires, No. 5 cylinder misfires and No. 6 cylinder

misfires.

Possible CauseNBEC0490IImproper spark plug

IInsufficient compression

IIncorrect fuel pressure

IThe injector circuit is open or shorted

IInjectors

IIntake air leak

IThe ignition secondary circuit is open or shorted

ILack of fuel

IDrive plate or flywheel

IHeated oxygen sensor 1 (front)

DTC P0300 - P0306 NO.6-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

On Board Diagnosis Logic

EC-320

Page 1280 of 2395

![INFINITI QX4 2001 Factory Workshop Manual POWER SUPPLY AND GROUND CIRCUITNBEL0042S08Power is supplied at all times

Ithrough 7.5A fuse [No. 24, located in the fuse block (J/B)]

Ito combination meter terminal 62.

With the ignition switch in the INFINITI QX4 2001 Factory Workshop Manual POWER SUPPLY AND GROUND CIRCUITNBEL0042S08Power is supplied at all times

Ithrough 7.5A fuse [No. 24, located in the fuse block (J/B)]

Ito combination meter terminal 62.

With the ignition switch in the](/img/42/57027/w960_57027-1279.png)

POWER SUPPLY AND GROUND CIRCUITNBEL0042S08Power is supplied at all times

Ithrough 7.5A fuse [No. 24, located in the fuse block (J/B)]

Ito combination meter terminal 62.

With the ignition switch in the ON or START position, power is supplied

Ithrough 10A fuse [No. 8, located in the fuse block (J/B)]

Ito combination meter terminal 66.

Ground is supplied

Ito combination meter terminal 59

Ithrough body grounds M4, M66 and M147.

WATER TEMPERATURE GAUGENBEL0042S01The water temperature gauge indicates the engine coolant temperature. The reading on the gauge is based

on the resistance of the thermal transmitter.

As the temperature of the coolant increases, the resistance of the thermal transmitter decreases. A variable

ground is supplied to terminal 18 of the combination meter for the water temperature gauge. The needle on

the gauge moves from ªCº to ªHº.

TACHOMETERNBEL0042S02The tachometer indicates engine speed in revolutions per minute (rpm).

The tachometer is regulated by a signal

Ifrom terminal 25 of the ECM

Ito combination meter terminal 16 for the tachometer.

FUEL GAUGENBEL0042S03The fuel gauge indicates the approximate fuel level in the fuel tank.

The fuel gauge is regulated by a variable ground signal supplied

Ito combination meter terminal 17 for the fuel gauge

Ifrom terminal 3 of the fuel level sensor unit

Ithrough terminal 2 of the fuel level sensor unit and

Ithrough body grounds B11, B22 and D210.

SPEEDOMETERNBEL0042S04The vehicle speed sensor provides a voltage signal to the combination meter for the speedometer.

The voltage is supplied

Ifrom combination meter terminal 15 for the speedometer

Ito terminal 2 of the vehicle speed sensor.

The speedometer converts the voltage into the vehicle speed displayed.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

METERS AND GAUGES

System Description (Cont'd)

EL-95

Page 1287 of 2395

SYMPTOM CHARTNBEL0201S02Symptom Chart 1 (Malfunction is Indicated in

Diagnosis Mode)

NBEL0201S0201

Symptom Possible causes Repair order

Odo/trip meter indicate(s)

malfunction in Diagnosis

mode.Unified meter control unit Replace unified meter control unit.

Multiple meter/gauge indi-

cate malfunction in Diagno-

sis mode.

One of speedometer/

tachometer/fuel gauge/

water temp. gauge indi-

cates malfunction in Diag-

nosis mode.1. Meter/Gauge

2. Unified meter control unit1. Check resistance of meter/gauge indicating malfunc-

tion. If the resistance is NG, replace the meter/

gauge. Refer to ªMETER/GAUGE RESISTANCE

CHECKº, EL-108.

2. If the resistance of meter/gauge is OK, replace uni-

fied meter control unit.

Symptom Chart 2 (No Malfunction is Indicated in

Diagnosis Mode)

NBEL0201S0202

Symptom Possible causes Repair order

One of speedometer/

tachometer/fuel gauge/

water temp. gauge is mal-

functioning.1. Sensor signal

- Vehicle speed signal

- Engine revolution signal

- Fuel gauge

- Water temp. gauge

2. Unified meter control unit1. Check the sensor for malfunctioning meter/gauge.

INSPECTION/VEHICLE SPEED SENSOR (Refer to

EL-104.)

INSPECTION/ENGINE REVOLUTION SIGNAL

(Refer to EL-105.)

INSPECTION/FUEL LEVEL SENSOR UNIT (Refer to

EL-106.)

INSPECTION/THERMAL TRANSMITTER (Refer to

EL-107.)

2. Replace unified meter control unit. Multiple meter/gauge are

malfunctioning. (except

odo/trip meter)

Before starting trouble diagnoses below, perform PRELIMINARY

CHECK, EL-101.

METERS AND GAUGES

Trouble Diagnoses (Cont'd)

EL-102

Page 1643 of 2395

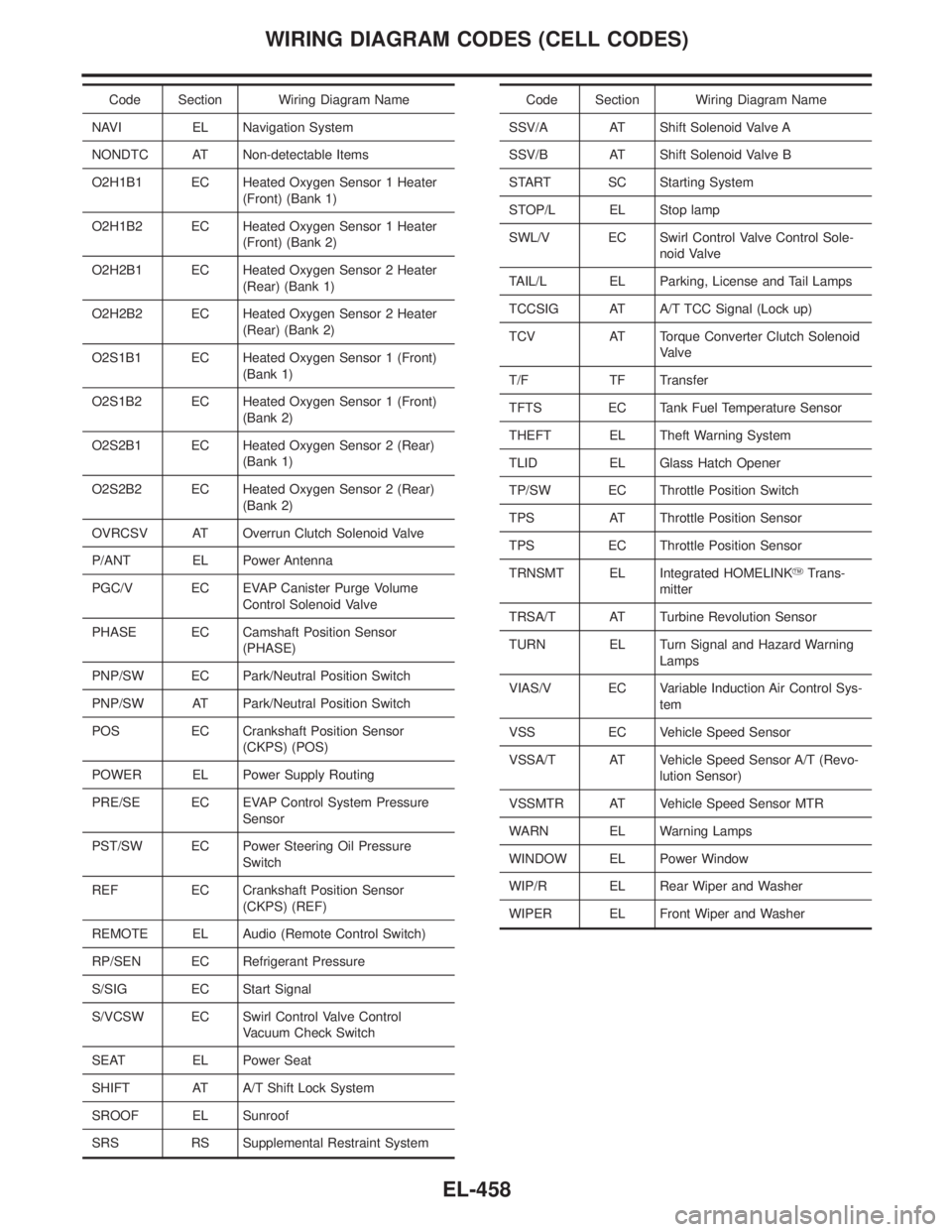

Code Section Wiring Diagram Name

NAVI EL Navigation System

NONDTC AT Non-detectable Items

O2H1B1 EC Heated Oxygen Sensor 1 Heater

(Front) (Bank 1)

O2H1B2 EC Heated Oxygen Sensor 1 Heater

(Front) (Bank 2)

O2H2B1 EC Heated Oxygen Sensor 2 Heater

(Rear) (Bank 1)

O2H2B2 EC Heated Oxygen Sensor 2 Heater

(Rear) (Bank 2)

O2S1B1 EC Heated Oxygen Sensor 1 (Front)

(Bank 1)

O2S1B2 EC Heated Oxygen Sensor 1 (Front)

(Bank 2)

O2S2B1 EC Heated Oxygen Sensor 2 (Rear)

(Bank 1)

O2S2B2 EC Heated Oxygen Sensor 2 (Rear)

(Bank 2)

OVRCSV AT Overrun Clutch Solenoid Valve

P/ANT EL Power Antenna

PGC/V EC EVAP Canister Purge Volume

Control Solenoid Valve

PHASE EC Camshaft Position Sensor

(PHASE)

PNP/SW EC Park/Neutral Position Switch

PNP/SW AT Park/Neutral Position Switch

POS EC Crankshaft Position Sensor

(CKPS) (POS)

POWER EL Power Supply Routing

PRE/SE EC EVAP Control System Pressure

Sensor

PST/SW EC Power Steering Oil Pressure

Switch

REF EC Crankshaft Position Sensor

(CKPS) (REF)

REMOTE EL Audio (Remote Control Switch)

RP/SEN EC Refrigerant Pressure

S/SIG EC Start Signal

S/VCSW EC Swirl Control Valve Control

Vacuum Check Switch

SEAT EL Power Seat

SHIFT AT A/T Shift Lock System

SROOF EL Sunroof

SRS RS Supplemental Restraint SystemCode Section Wiring Diagram Name

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

START SC Starting System

STOP/L EL Stop lamp

SWL/V EC Swirl Control Valve Control Sole-

noid Valve

TAIL/L EL Parking, License and Tail Lamps

TCCSIG AT A/T TCC Signal (Lock up)

TCV AT Torque Converter Clutch Solenoid

Valve

T/F TF Transfer

TFTS EC Tank Fuel Temperature Sensor

THEFT EL Theft Warning System

TLID EL Glass Hatch Opener

TP/SW EC Throttle Position Switch

TPS AT Throttle Position Sensor

TPS EC Throttle Position Sensor

TRNSMT EL Integrated HOMELINKYTrans-

mitter

TRSA/T AT Turbine Revolution Sensor

TURN EL Turn Signal and Hazard Warning

Lamps

VIAS/V EC Variable Induction Air Control Sys-

tem

VSS EC Vehicle Speed Sensor

VSSA/T AT Vehicle Speed Sensor A/T (Revo-

lution Sensor)

VSSMTR AT Vehicle Speed Sensor MTR

WARN EL Warning Lamps

WINDOW EL Power Window

WIP/R EL Rear Wiper and Washer

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-458