headlamp INFINITI QX4 2001 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1964 of 2395

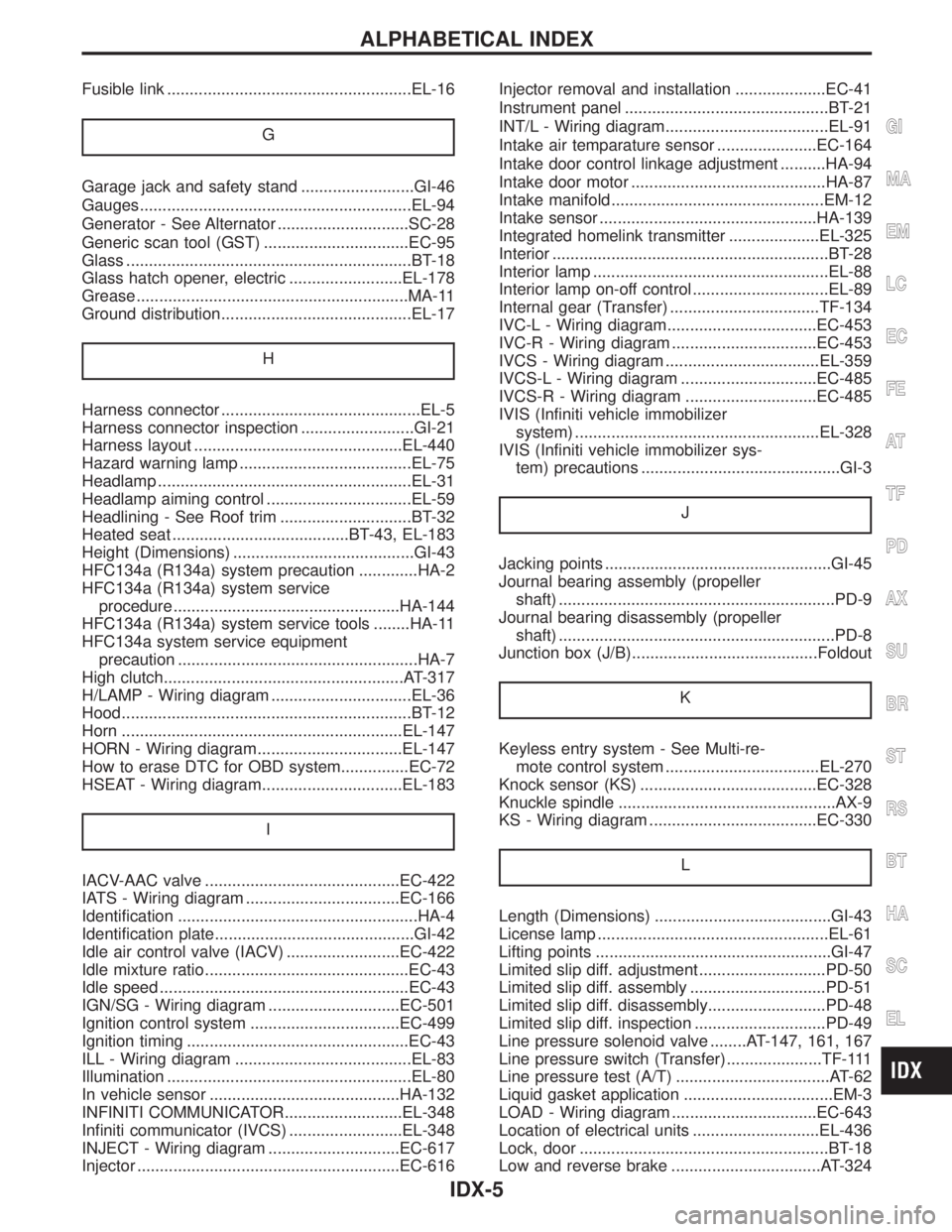

Fusible link ......................................................EL-16

G

Garage jack and safety stand .........................GI-46

Gauges............................................................EL-94

Generator - See Alternator .............................SC-28

Generic scan tool (GST) ................................EC-95

Glass ...............................................................BT-18

Glass hatch opener, electric .........................EL-178

Grease ............................................................MA-11

Ground distribution..........................................EL-17

H

Harness connector ............................................EL-5

Harness connector inspection .........................GI-21

Harness layout ..............................................EL-440

Hazard warning lamp ......................................EL-75

Headlamp ........................................................EL-31

Headlamp aiming control ................................EL-59

Headlining - See Roof trim .............................BT-32

Heated seat .......................................BT-43, EL-183

Height (Dimensions) ........................................GI-43

HFC134a (R134a) system precaution .............HA-2

HFC134a (R134a) system service

procedure ..................................................HA-144

HFC134a (R134a) system service tools ........HA-11

HFC134a system service equipment

precaution .....................................................HA-7

High clutch.....................................................AT-317

H/LAMP - Wiring diagram ...............................EL-36

Hood................................................................BT-12

Horn ..............................................................EL-147

HORN - Wiring diagram................................EL-147

How to erase DTC for OBD system...............EC-72

HSEAT - Wiring diagram...............................EL-183

I

IACV-AAC valve ...........................................EC-422

IATS - Wiring diagram ..................................EC-166

Identification .....................................................HA-4

Identification plate............................................GI-42

Idle air control valve (IACV) .........................EC-422

Idle mixture ratio.............................................EC-43

Idle speed .......................................................EC-43

IGN/SG - Wiring diagram .............................EC-501

Ignition control system .................................EC-499

Ignition timing .................................................EC-43

ILL - Wiring diagram .......................................EL-83

Illumination ......................................................EL-80

In vehicle sensor ..........................................HA-132

INFINITI COMMUNICATOR..........................EL-348

Infiniti communicator (IVCS) .........................EL-348

INJECT - Wiring diagram .............................EC-617

Injector ..........................................................EC-616Injector removal and installation ....................EC-41

Instrument panel .............................................BT-21

INT/L - Wiring diagram....................................EL-91

Intake air temparature sensor ......................EC-164

Intake door control linkage adjustment ..........HA-94

Intake door motor ...........................................HA-87

Intake manifold...............................................EM-12

Intake sensor ................................................HA-139

Integrated homelink transmitter ....................EL-325

Interior .............................................................BT-28

Interior lamp ....................................................EL-88

Interior lamp on-off control ..............................EL-89

Internal gear (Transfer) .................................TF-134

IVC-L - Wiring diagram.................................EC-453

IVC-R - Wiring diagram ................................EC-453

IVCS - Wiring diagram ..................................EL-359

IVCS-L - Wiring diagram ..............................EC-485

IVCS-R - Wiring diagram .............................EC-485

IVIS (Infiniti vehicle immobilizer

system) ......................................................EL-328

IVIS (Infiniti vehicle immobilizer sys-

tem) precautions ............................................GI-3

J

Jacking points ..................................................GI-45

Journal bearing assembly (propeller

shaft) .............................................................PD-9

Journal bearing disassembly (propeller

shaft) .............................................................PD-8

Junction box (J/B).........................................Foldout

K

Keyless entry system - See Multi-re-

mote control system ..................................EL-270

Knock sensor (KS) .......................................EC-328

Knuckle spindle ................................................AX-9

KS - Wiring diagram .....................................EC-330

L

Length (Dimensions) .......................................GI-43

License lamp ...................................................EL-61

Lifting points ....................................................GI-47

Limited slip diff. adjustment ............................PD-50

Limited slip diff. assembly ..............................PD-51

Limited slip diff. disassembly..........................PD-48

Limited slip diff. inspection .............................PD-49

Line pressure solenoid valve ........AT-147, 161, 167

Line pressure switch (Transfer) .....................TF-111

Line pressure test (A/T) ..................................AT-62

Liquid gasket application .................................EM-3

LOAD - Wiring diagram ................................EC-643

Location of electrical units ............................EL-436

Lock, door .......................................................BT-18

Low and reverse brake .................................AT-324

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

ALPHABETICAL INDEX

IDX-5

Page 1999 of 2395

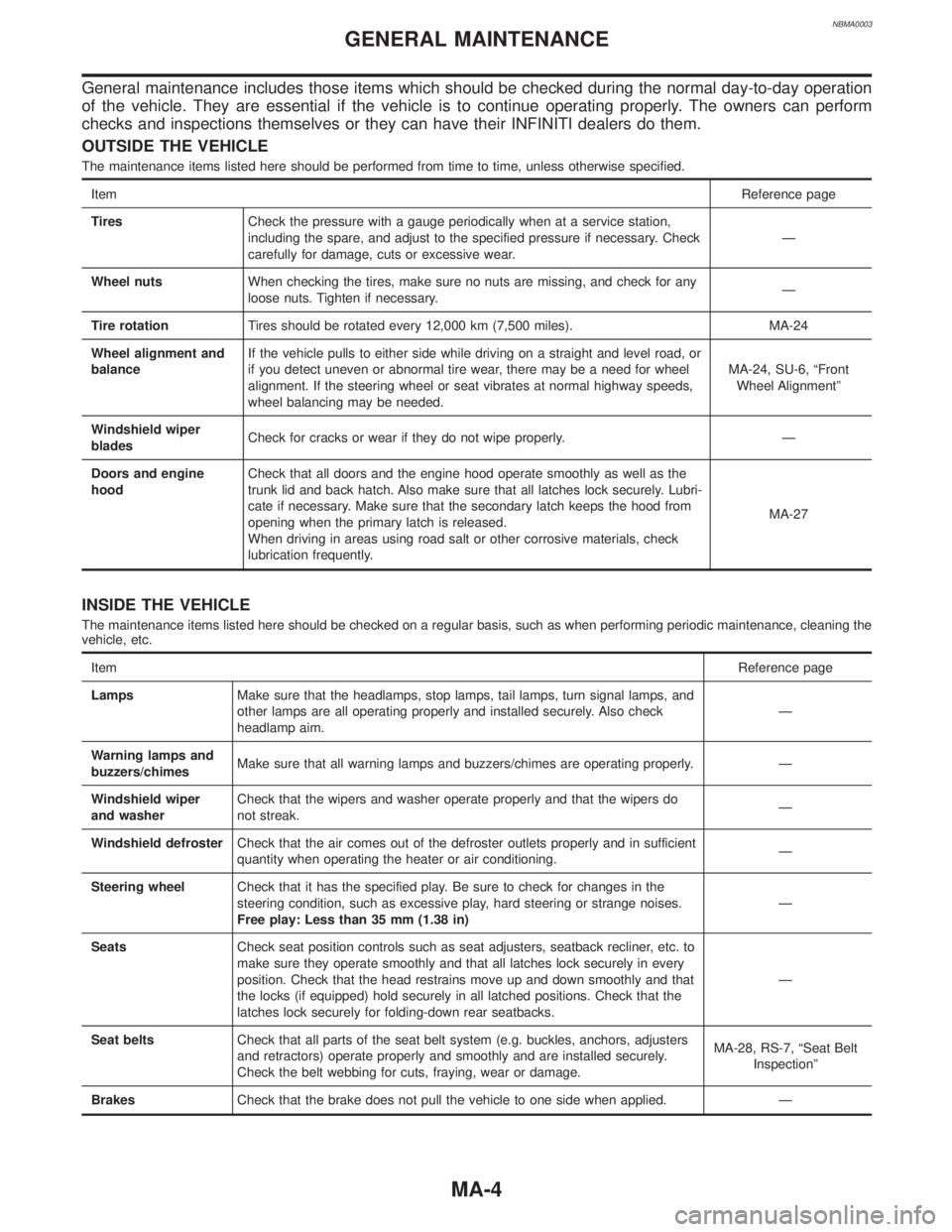

NBMA0003

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or they can have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

ItemReference page

TiresCheck the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.Ð

Wheel nutsWhen checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary.Ð

Tire rotationTires should be rotated every 12,000 km (7,500 miles). MA-24

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or

if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed.MA-24, SU-6, ªFront

Wheel Alignmentº

Windshield wiper

bladesCheck for cracks or wear if they do not wipe properly. Ð

Doors and engine

hoodCheck that all doors and the engine hood operate smoothly as well as the

trunk lid and back hatch. Also make sure that all latches lock securely. Lubri-

cate if necessary. Make sure that the secondary latch keeps the hood from

opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check

lubrication frequently.MA-27

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

ItemReference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check

headlamp aim.Ð

Warning lamps and

buzzers/chimesMake sure that all warning lamps and buzzers/chimes are operating properly. Ð

Windshield wiper

and washerCheck that the wipers and washer operate properly and that the wipers do

not streak.Ð

Windshield defrosterCheck that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioning.Ð

Steering wheelCheck that it has the specified play. Be sure to check for changes in the

steering condition, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)Ð

SeatsCheck seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every

position. Check that the head restrains move up and down smoothly and that

the locks (if equipped) hold securely in all latched positions. Check that the

latches lock securely for folding-down rear seatbacks.Ð

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.MA-28, RS-7, ªSeat Belt

Inspectionº

BrakesCheck that the brake does not pull the vehicle to one side when applied. Ð

GENERAL MAINTENANCE

MA-4

Page 2172 of 2395

Trouble Diagnoses with

Battery/Starting/Charging System Tester

NBSC0020NOTE:

To ensure a complete and thorough diagnosis, the battery, starter

and alternator test segments must be done as a set from start to

finish.

SEL417X

1. Turn off all loads on the vehicle electrical system.

2. Perform battery and starting system test with Battery/Starting/

Charging system tester.

3. Press ªENTERº to begin the charging system test.

4. Start engine.

SEL418X

5. Press ªENTERº until ªLOADS OFF REV ENGINE 5 SECº is

displayed.

6. Raise and hold the engine speed at 1,500 to 2,000 rpm for

about 5 seconds, then return to the engine to idle.

Once the increase in engine rpm is detected, press ªENTERº

to continue.

NOTE:

IIf after 30 seconds an increase in engine idle speed is not

detected, ªRPM NOT DETECTEDº will display.

ISome engines may have a higher idle initially after starting,

particularly when the engine is cold. The tester may detect this

without any other action being taken. If this occurs, continue on

with the testing process. The final results will not be affected.

SEL419X

7. The tester now checks the engine at idle and performs the

DIODE/RIPPLE check.

8. When complete, the tester will prompt you to turn on the fol-

lowing electrical loads.

IHeater fun set to highest. Do not run the A/C or windshield

defroster.

IHeadlamp high beam

IRear window defogger

NOTE:

Do not run the windshield wipers or any other cyclical loads.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester

SC-21