IDX INFINITI QX4 2001 Factory Manual PDF

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 146 of 2395

8) Make sure that ªOKº is displayed. (If ªNGº is displayed, refer

to ªDIAGNOSTIC PROCEDUREº.) Refer to ªDIAGNOSTIC

PROCEDUREº, AT-143.

Refer to shift schedule, AT-356.

With GST

Follow the procedure ªWith CONSULT-IIº.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0734 IMPROPER SHIFTING TO 4TH GEAR POSITION

Description (Cont'd)

AT-141

Page 148 of 2395

Diagnostic ProcedureNBAT0049

1 CHECK SHIFT UP (D3TO D4)

During ªCruise test þ Part 1º, AT-71.

Does A/T shift from D

3to D4at the specified speed?

SAT988H

YesorNo

Ye s©GO TO 9.

No©GO TO 2.

2 CHECK LINE PRESSURE

Perform line pressure test. Refer to AT-62.

OK or NG

OK©GO TO 3.

NG©GO TO 6.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0734 IMPROPER SHIFTING TO 4TH GEAR POSITION

Diagnostic Procedure

AT-143

Page 150 of 2395

5 CHECK SHIFT UP (D3TO D4)

Does A/T shift from D3to D4at the specified speed?

YesorNo

Ye s©GO TO 9.

No©Check control valve again. Repair or replace control valve assembly.

6 CHECK LINE PRESSURE SOLENOID VALVE

1. Remove control valve assembly. Refer to AT-273.

2. Refer to ªComponent Inspectionº, AT-147.

SAT158J

OK or NG

OK©GO TO 7.

NG©Replace solenoid valve assembly.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0734 IMPROPER SHIFTING TO 4TH GEAR POSITION

Diagnostic Procedure (Cont'd)

AT-145

Page 152 of 2395

SAT159J

Component InspectionNBAT0050SOLENOID VALVESNBAT0050S01IFor removal, refer to AT-273.

Resistance CheckNBAT0050S0101ICheck resistance between terminals (3, 2 or 6) and ground.

Solenoid valve Terminal No. Resistance (Approx.)

Shift solenoid valve A 3

Ground20-40W

Shift solenoid valve B 2

Line pressure solenoid valve 6 2.5 - 5W

SAT158J

Operation CheckNBAT0050S0102ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminals (3, 2 or 6) and ground.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0734 IMPROPER SHIFTING TO 4TH GEAR POSITION

Component Inspection

AT-147

Page 154 of 2395

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0051S01NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode for ªENGINEº with CON-

SULT-II and wait at least 1 second.

With GST

Follow the procedure ªWith CONSULT-IIº.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE

Description (Cont'd)

AT-149

Page 156 of 2395

Diagnostic ProcedureNBAT0052

1 CHECK VALVE RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assembly.

3. Check resistance between terminal 7 and ground.

SAT156J

Is resistance approx. 10 - 20W?

Ye s©GO TO 3.

No©GO TO 2.

2 CHECK VALVE OPERATION

1. Remove oil pan. Refer to AT-273.

2. Check the following items:

ITorque converter clutch solenoid valve

Refer to ªComponent Inspectionº, AT-152.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal 7 and TCM harness connector terminal 3. Refer to wiring diagram Ð AT Ð TCV.

Continuity should exist.

If OK, check harness for short to ground and short to power.

4. Reinstall any part removed.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-149.

OK or NG

OK©INSPECTION END

NG©GO TO 5.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE

Diagnostic Procedure

AT-151

Page 158 of 2395

DescriptionNBAT0054IThis is an OBD-II self-diagnostic item and not available in TCM

self-diagnosis.

IThis malfunction will not be detected while the O/D OFF indi-

cator lamp is indicating another self-diagnosis malfunction.

IThis malfunction is detected when the A/T does not shift into

fourth gear position or the torque converter clutch does not

lock up as instructed by the TCM. This is not caused by elec-

trical malfunction (circuits open or shorted) but by mechanical

malfunction such as control valve sticking, improper solenoid

valve operation, malfunctioning oil pump or torque converter

clutch, etc.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NBAT0054S02Remarks: Specification data are reference values.

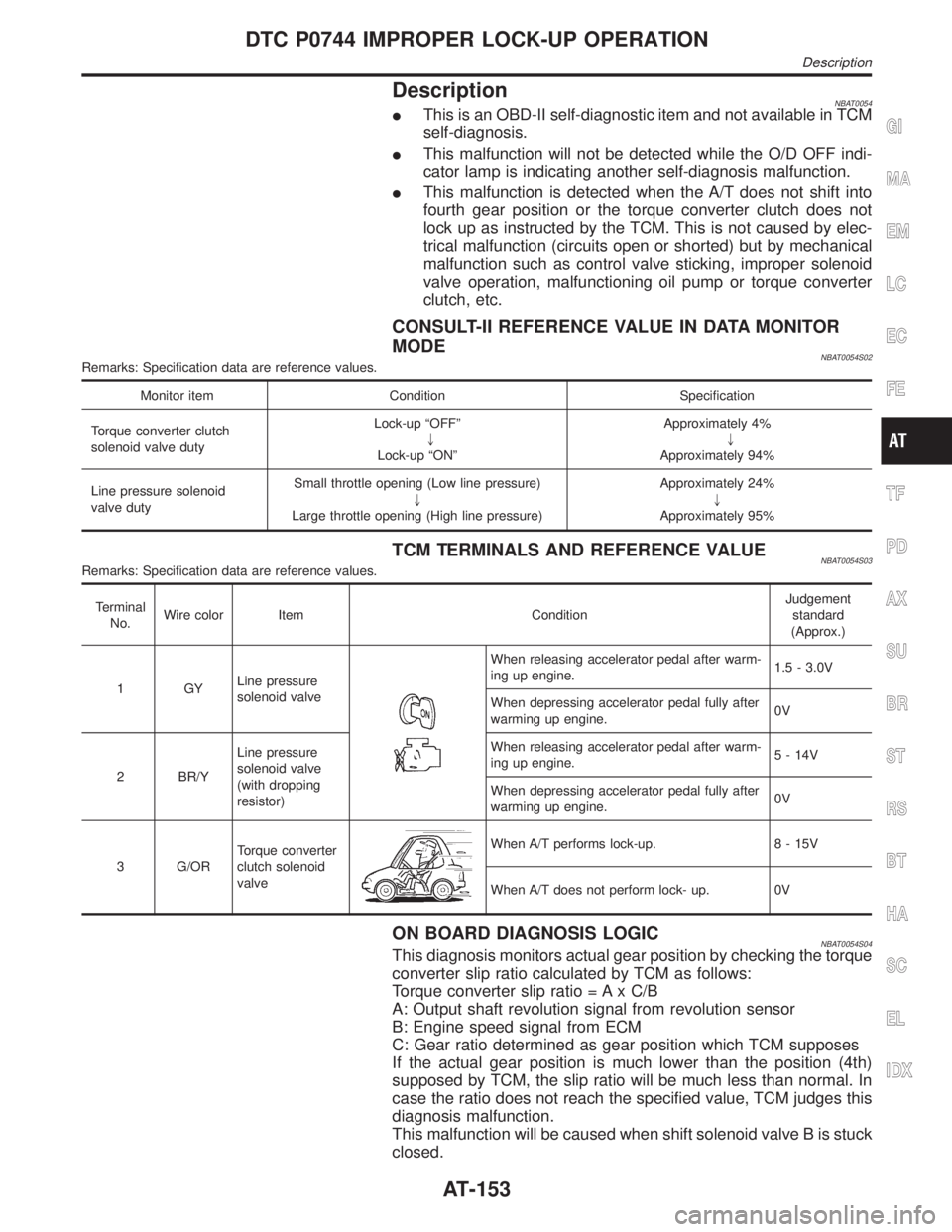

Monitor item Condition Specification

Torque converter clutch

solenoid valve dutyLock-up ªOFFº

"

Lock-up ªONºApproximately 4%

"

Approximately 94%

Line pressure solenoid

valve dutySmall throttle opening (Low line pressure)

"

Large throttle opening (High line pressure)Approximately 24%

"

Approximately 95%

TCM TERMINALS AND REFERENCE VALUENBAT0054S03Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

1GYLine pressure

solenoid valve

When releasing accelerator pedal after warm-

ing up engine.1.5 - 3.0V

When depressing accelerator pedal fully after

warming up engine.0V

2 BR/YLine pressure

solenoid valve

(with dropping

resistor)When releasing accelerator pedal after warm-

ing up engine.5 - 14V

When depressing accelerator pedal fully after

warming up engine.0V

3 G/ORTorque converter

clutch solenoid

valve

When A/T performs lock-up. 8 - 15V

When A/T does not perform lock- up. 0V

ON BOARD DIAGNOSIS LOGICNBAT0054S04This diagnosis monitors actual gear position by checking the torque

converter slip ratio calculated by TCM as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from revolution sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is much lower than the position (4th)

supposed by TCM, the slip ratio will be much less than normal. In

case the ratio does not reach the specified value, TCM judges this

diagnosis malfunction.

This malfunction will be caused when shift solenoid valve B is stuck

closed.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0744 IMPROPER LOCK-UP OPERATION

Description

AT-153

Page 160 of 2395

IIf ªTESTINGº does not appear on CONSULT-II for a long

time, select ªSELF-DIAG RESULTSº. In case a 1st trip DTC

other than P0744 is shown, refer to applicable ªTROUBLE

DIAGNOSIS FOR DTCº.

5) Make sure that ªOKº is displayed. (If ªNGº is displayed, refer

to ªDIAGNOSTIC PROCEDUREº.)

Refer to ªDIAGNOSTIC PROCEDUREº, AT-157.

Refer to shift schedule, AT-356.

With GST

Follow the procedure ªWith CONSULT-IIº.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0744 IMPROPER LOCK-UP OPERATION

Description (Cont'd)

AT-155

Page 162 of 2395

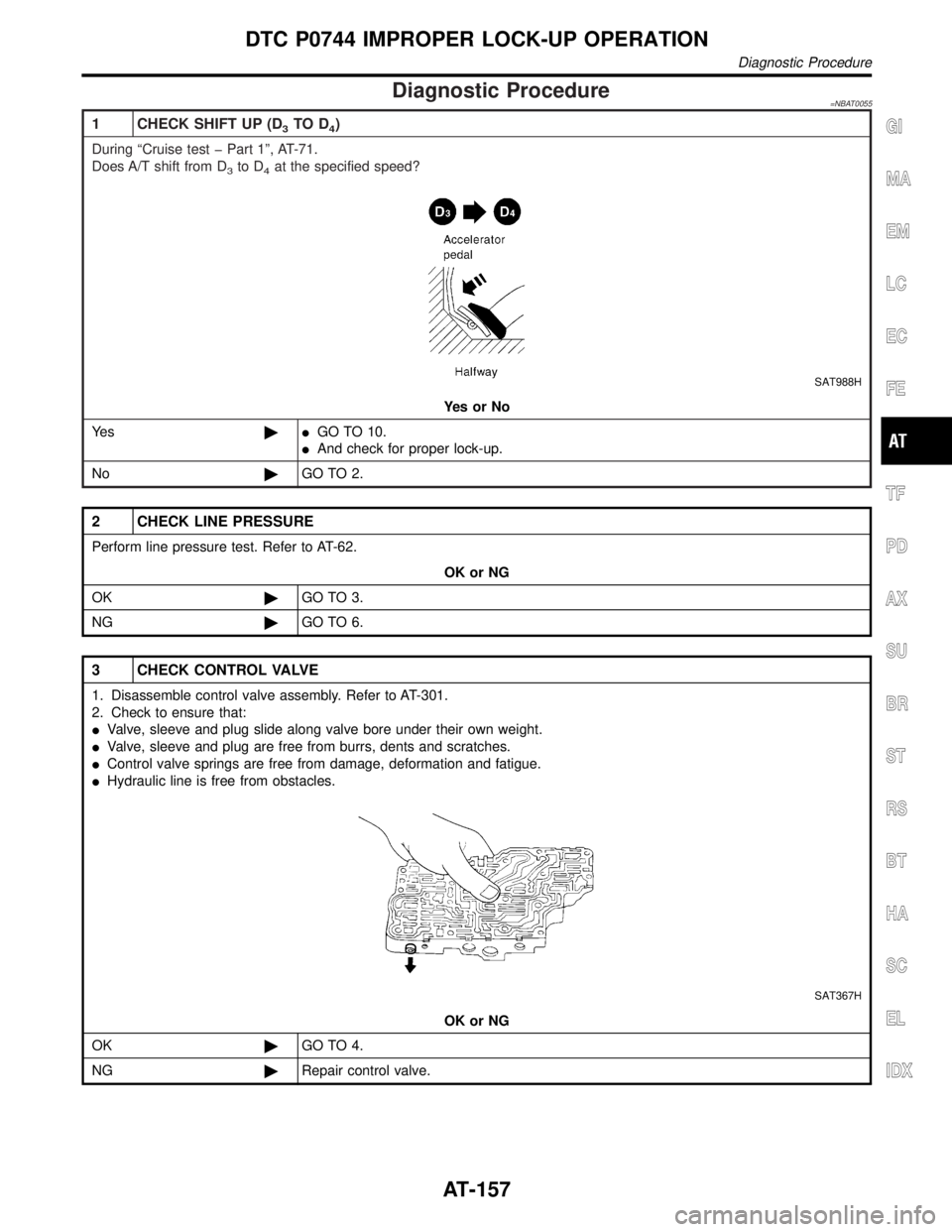

Diagnostic Procedure=NBAT0055

1 CHECK SHIFT UP (D3TO D4)

During ªCruise test þ Part 1º, AT-71.

Does A/T shift from D

3to D4at the specified speed?

SAT988H

YesorNo

Ye s©IGO TO 10.

IAnd check for proper lock-up.

No©GO TO 2.

2 CHECK LINE PRESSURE

Perform line pressure test. Refer to AT-62.

OK or NG

OK©GO TO 3.

NG©GO TO 6.

3 CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-301.

2. Check to ensure that:

IValve, sleeve and plug slide along valve bore under their own weight.

IValve, sleeve and plug are free from burrs, dents and scratches.

IControl valve springs are free from damage, deformation and fatigue.

IHydraulic line is free from obstacles.

SAT367H

OK or NG

OK©GO TO 4.

NG©Repair control valve.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0744 IMPROPER LOCK-UP OPERATION

Diagnostic Procedure

AT-157

Page 164 of 2395

7 CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-301.

2. Check line pressure circuit valves for sticking.

IPressure regulator valve

IPilot valve

IPressure modifier valve

SAT367H

OK or NG

OK©GO TO 8.

NG©Repair control valve.

8 CHECK SHIFT UP (D3TO D4)

Does A/T shift from D3to D4at the specified speed?

YesorNo

Ye s©GO TO 9.

No©Check control valve again. Repair or replace control valve assembly.

9 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-154.

OK or NG

OK©INSPECTION END

NG©IGO TO 10.

IAnd check for proper lock-up.

10 CHECK LOCK-UP CONDITION

During ªCruise test þ Part 1º, AT-71.

Does A/T perform lock-up at the specified speed?

YesorNo

Ye s©Perform ªCruise test þ Part 1º again and return to the start point of this flow chart.

No©GO TO 11.

11 CHECK TORQUE CONVERTER CLUTCH SOLENOID VALVE

1. Remove control valve assembly. Refer to AT-273.

2. Check torque converter clutch solenoid valve operation.

Refer to AT-161.

OK or NG

OK©GO TO 12.

NG©Replace solenoid valve assembly.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0744 IMPROPER LOCK-UP OPERATION

Diagnostic Procedure (Cont'd)

AT-159