IDX INFINITI QX4 2001 Factory Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 166 of 2395

SAT159J

Component InspectionNBAT0056SOLENOID VALVESNBAT0056S01IFor removal, refer to AT-273.

Resistance CheckNBAT0056S0101ICheck resistance between terminals (6 or 7) and ground.

Solenoid valve Terminal No. Resistance (Approx.)

Line pressure solenoid valve 6

Ground2.5-5W

Torque converter clutch

solenoid valve7 10-20W

SAT158J

Operation CheckNBAT0056S0102ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminals (6 or 7) and ground.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0744 IMPROPER LOCK-UP OPERATION

Component Inspection

AT-161

Page 168 of 2395

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0057S01NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Depress accelerator pedal completely and wait at least 1 sec-

ond.

With GST

Follow the procedure ªWith CONSULT-IIº.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0745 LINE PRESSURE SOLENOID VALVE

Description (Cont'd)

AT-163

Page 170 of 2395

Diagnostic ProcedureNBAT0058

1 CHECK VALVE RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assembly.

3. Check resistance between terminal 6 and ground.

SAT162J

Is resistance approx. 2.5 - 5W?

Ye s©GO TO 3.

No©GO TO 2.

2 CHECK VALVE OPERATION

1. Remove control valve assembly.

Refer to AT-273.

2. Check the following items:

ILine pressure solenoid valve

Refer to ªComponent Inspectionº, AT-167.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 3.

NG©Repair or replace damaged parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0745 LINE PRESSURE SOLENOID VALVE

Diagnostic Procedure

AT-165

Page 172 of 2395

7 CHECK TCM INSPECTION

1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK©INSPECTION END

NG©Repair or replace damaged parts.

SAT657I

Component InspectionNBAT0059LINE PRESSURE SOLENOID VALVENBAT0059S01IFor removal, refer to AT-273.

Resistance CheckNBAT0059S0101ICheck resistance between terminal 6 and ground.

Solenoid valve Terminal No. Resistance (Approx.)

Line pressure solenoid valve 6 Ground 2.5 - 5W

SAT658I

Operation CheckNBAT0059S0102ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminal 6 and ground.

SAT848BD

DROPPING RESISTORNBAT0059S02ICheck resistance between two terminals.

Resistance: 11.2 - 12.8W

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0745 LINE PRESSURE SOLENOID VALVE

Diagnostic Procedure (Cont'd)

AT-167

Page 174 of 2395

Wiring Diagram Ð AT Ð SSV/ANBAT0197

MAT738A

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0750 SHIFT SOLENOID VALVE A

Wiring Diagram Ð AT Ð SSV/A

AT-169

Page 176 of 2395

5 CHECK TCM INSPECTION

1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK©INSPECTION END

NG©Repair or replace damaged parts.

SAT654I

Component InspectionNBAT0062SHIFT SOLENOID VALVE ANBAT0062S01IFor removal, refer to AT-273.

Resistance CheckNBAT0062S0101ICheck resistance between terminal 3 and ground.

Solenoid valve Terminal No. Resistance (Approx.)

Shift solenoid valve A 3 Ground 20 - 40W

SAT653I

Operation CheckNBAT0062S0102ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminal 3 and ground.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0750 SHIFT SOLENOID VALVE A

Diagnostic Procedure (Cont'd)

AT-171

Page 178 of 2395

Wiring Diagram Ð AT Ð SSV/BNBAT0198

MAT739A

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0755 SHIFT SOLENOID VALVE B

Wiring Diagram Ð AT Ð SSV/B

AT-173

Page 180 of 2395

5 CHECK TCM INSPECTION

1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK©INSPECTION END

NG©Repair or replace damaged parts.

SAT651I

Component InspectionNBAT0065SHIFT SOLENOID VALVE BNBAT0065S01IFor removal, refer to AT-273.

Resistance CheckNBAT0065S0101ICheck resistance between terminal 2 and ground.

Solenoid valve Terminal No. Resistance (Approx.)

Shift solenoid valve B 2 Ground 20 - 40W

SAT650I

Operation CheckNBAT0065S0102ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminal 2 and ground.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0755 SHIFT SOLENOID VALVE B

Diagnostic Procedure (Cont'd)

AT-175

Page 182 of 2395

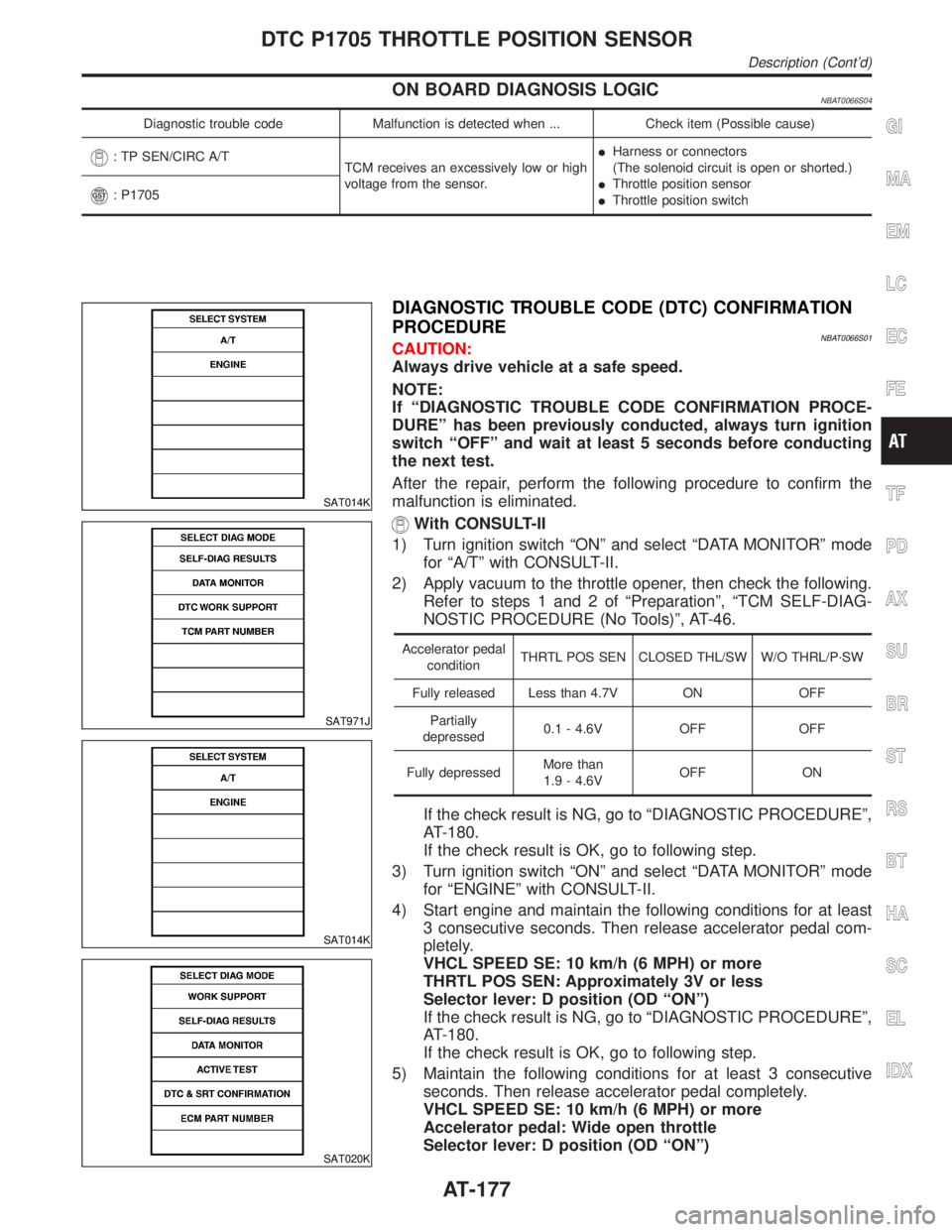

ON BOARD DIAGNOSIS LOGICNBAT0066S04

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: TP SEN/CIRC A/T

TCM receives an excessively low or high

voltage from the sensor.IHarness or connectors

(The solenoid circuit is open or shorted.)

IThrottle position sensor

IThrottle position switch

: P1705

SAT014K

SAT971J

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0066S01CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªA/Tº with CONSULT-II.

2) Apply vacuum to the throttle opener, then check the following.

Refer to steps 1 and 2 of ªPreparationº, ªTCM SELF-DIAG-

NOSTIC PROCEDURE (No Tools)º, AT-46.

Accelerator pedal

conditionTHRTL POS SEN CLOSED THL/SW W/O THRL/P´SW

Fully released Less than 4.7V ON OFF

Partially

depressed0.1 - 4.6V OFF OFF

Fully depressedMore than

1.9 - 4.6VOFF ON

If the check result is NG, go to ªDIAGNOSTIC PROCEDUREº,

AT-180.

If the check result is OK, go to following step.

3) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

4) Start engine and maintain the following conditions for at least

3 consecutive seconds. Then release accelerator pedal com-

pletely.

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: Approximately 3V or less

Selector lever: D position (OD ªONº)

If the check result is NG, go to ªDIAGNOSTIC PROCEDUREº,

AT-180.

If the check result is OK, go to following step.

5) Maintain the following conditions for at least 3 consecutive

seconds. Then release accelerator pedal completely.

VHCL SPEED SE: 10 km/h (6 MPH) or more

Accelerator pedal: Wide open throttle

Selector lever: D position (OD ªONº)

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1705 THROTTLE POSITION SENSOR

Description (Cont'd)

AT-177

Page 184 of 2395

Wiring Diagram Ð AT Ð TPSNBAT0199

MAT915A

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1705 THROTTLE POSITION SENSOR

Wiring Diagram Ð AT Ð TPS

AT-179