IDX INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 106 of 2395

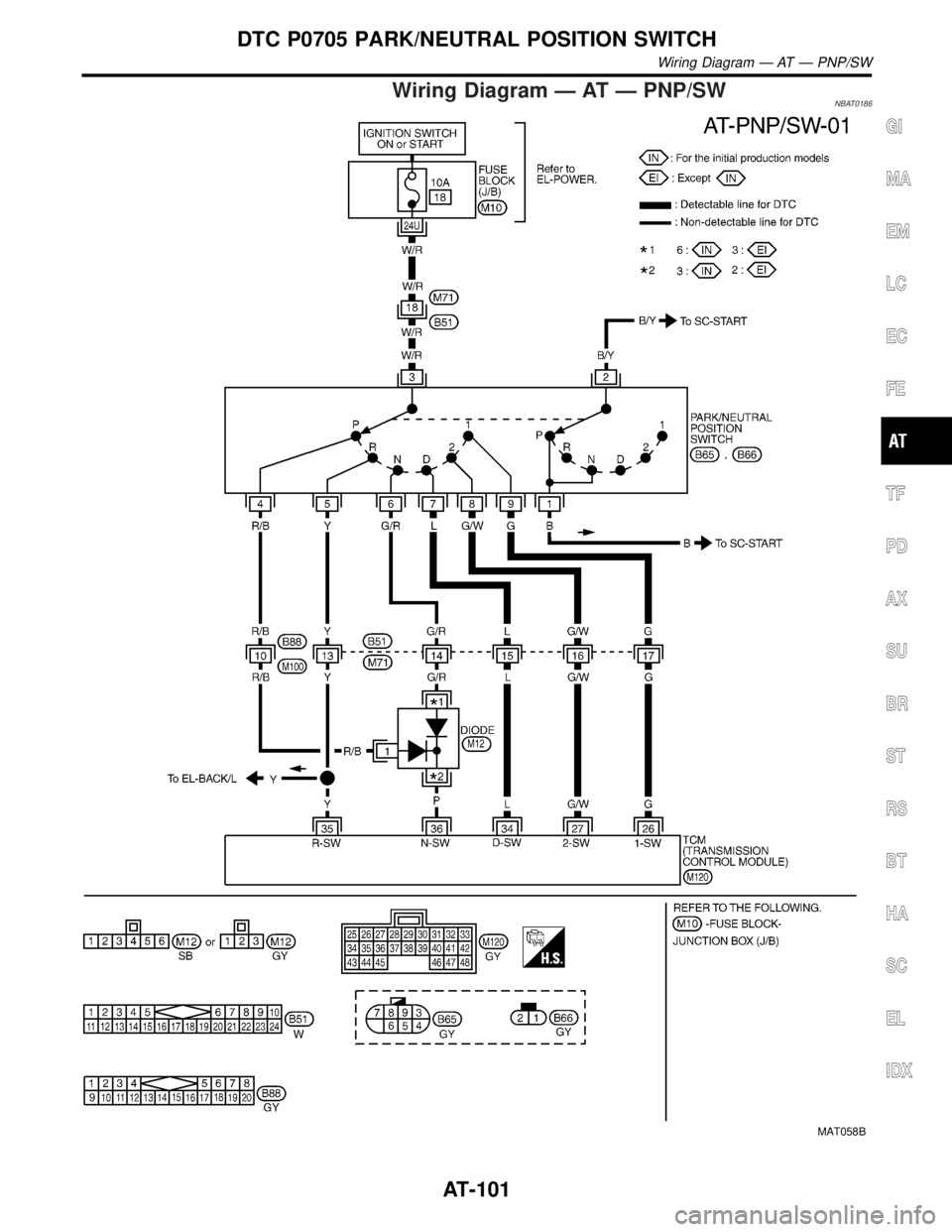

Wiring Diagram Ð AT Ð PNP/SWNBAT0186

MAT058B

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0705 PARK/NEUTRAL POSITION SWITCH

Wiring Diagram Ð AT Ð PNP/SW

AT-101

Page 108 of 2395

3 DETECT MALFUNCTIONING ITEM

Check the following items:

IPNP switch

Refer to ªComponent Inspectionº, AT-103.

IHarness for short or open between ignition switch and PNP switch (Main harness)

IHarness for short or open between PNP switch and TCM (Main harness)

IDiode (P, N position)

IIgnition switch and 10A fuse [No. 18, located in the fuse block (J/B)]

Refer to EL-9, ªSchematicº.

OK or NG

OK©GO TO 4.

NG©Repair or replace damaged parts.

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-100.

OK or NG

OK©INSPECTION END

NG©GO TO 5.

5 CHECK TCM INSPECTION

1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK©INSPECTION END

NG©Repair or replace damaged parts.

SAT517GB

SAT843BG

Component InspectionNBAT0030PARK/NEUTRAL POSITION SWITCHNBAT0030S021. Check continuity between terminals 1 and 2 and between ter-

minals 3 and 4, 5, 6, 7, 8, 9 while moving manual shaft through

each position.

Lever position Terminal No.

P 1-2 3-4

R 3-5

N 1-2 3-6

D 3-7

2 3-8

1 3-9

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0705 PARK/NEUTRAL POSITION SWITCH

Diagnostic Procedure (Cont'd)

AT-103

Page 110 of 2395

SAT342HA

DescriptionNBAT0031The A/T fluid temperature sensor detects the A/T fluid temperature

and sends a signal to the TCM.

SAT021J

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NBAT0031S04Remarks: Specification data are reference values.

Monitor item Condition Specification

A/T fluid tempera-

ture sensorCold [20ÉC (68ÉF)]

"

Hot [80ÉC (176ÉF)]Approximately 1.5V

"

Approximately 0.5VApproximately 2.5 kW

"

Approximately 0.3 kW

TCM TERMINALS AND REFERENCE VALUENBAT0031S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

42 BThrottle position

sensor

(Ground)

Ð0V

47 RA/T fluid tempera-

ture sensorWhen ATF temperature is 20ÉC (68ÉF). 1.5V

When ATF temperature is 80ÉC (176ÉF). 0.5V

ON BOARD DIAGNOSIS LOGICNBAT0031S03

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: ATF TEMP SEN/CIRC

TCM receives an excessively low or high

voltage from the sensor.IHarness or connectors

(The sensor circuit is open or shorted.)

IA/T fluid temperature sensor

: P0710

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT

Description

AT-105

Page 112 of 2395

Wiring Diagram Ð AT Ð FTSNBAT0187

MAT909A

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT

Wiring Diagram Ð AT Ð FTS

AT-107

Page 114 of 2395

4 CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assmebly.

3. Check resistance between terminals 8 and 9 when A/T is cold [20ÉC (68ÉF)].

SAT697I

Is resistance approx. 2.5 kW?

Ye s©GO TO 7.

No©GO TO 5.

5 DETECT MALFUNCTIONING ITEM

1. Remove oil pan.

2. Check the following items:

IA/T fluid temperature sensor

Refer to ªComponent Inspectionº, AT-110.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 7.

NG©Repair or replace damaged parts.

6 CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITHOUT CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 47 and ground while warming up A/T.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT518J

OK or NG

OK©GO TO 4.

NG©GO TO 3.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT

Diagnostic Procedure (Cont'd)

AT-109

Page 116 of 2395

SAT136K

DescriptionNBAT0034The revolution sensor detects the revolution of the out put shaft

parking pawl lock gear and emits a pulse signal. The pulse signal

is sent to the TCM which converts it into vehicle speed.

TCM TERMINALS AND REFERENCE VALUENBAT0034S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

29 WRevolution sensor

(Measure in AC

range)

When vehicle cruises at 30 km/h (19 MPH).1V or more

Voltage rises

gradually in

response to

vehicle speed.

When vehicle parks. 0V

42 BThrottle position

sensor

(Ground)

Ð0V

ON BOARD DIAGNOSIS LOGICNBAT0034S03

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: VEH SPD SEN/CIR AT

TCM does not receive the proper voltage

signal from the sensor.IHarness or connectors

(The sensor circuit is open or shorted.)

IRevolution sensor

: P0720

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0720 VEHICLE SPEED SENSOR´A/T (REVOLUTION SENSOR)

Description

AT - 111

Page 118 of 2395

Wiring Diagram Ð AT Ð VSSA/TNBAT0188

MAT910A

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0720 VEHICLE SPEED SENSOR´A/T (REVOLUTION SENSOR)

Wiring Diagram Ð AT Ð VSSA/T

AT-113

Page 120 of 2395

5 CHECK INPUT SIGNAL (WITHOUT CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 29 and ground while driving.

(Measure with AC range.)

Voltage:

At 0 km/h (0 MPH):

0V

At 30 km/h (19 MPH):

1V or more

(Voltage rises gradually in response to vehicle speed.)

SAT519J

OK or NG

OK©GO TO 3.

NG©GO TO 4.

6 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-112.

OK or NG

OK©INSPECTION END

NG©GO TO 7.

7 CHECK TCM INSPECTION

1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK©INSPECTION END

NG©Repair or replace damaged parts.

SAT210IA

Component InspectionNBAT0036REVOLUTION SENSORNBAT0036S01IFor removal, refer to AT-273.

ICheck resistance between terminals 1, 2 and 3.

Terminal No. Resistance

1 2 500 - 650W

2 3 No continuity

1 3 No continuity

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0720 VEHICLE SPEED SENSOR´A/T (REVOLUTION SENSOR)

Diagnostic Procedure (Cont'd)

AT-115

Page 122 of 2395

Wiring Diagram Ð AT Ð ENGSSNBAT0189

MAT911A

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0725 ENGINE SPEED SIGNAL

Wiring Diagram Ð AT Ð ENGSS

AT-117

Page 124 of 2395

4 CHECK INPUT SIGNAL (WITHOUT CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 39 and ground.

SAT520J

Refer toEC-127, ªECM INSPECTION TABLEº.

Ye s©GO TO 4.

No©GO TO 3.

5 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-116.

OK or NG

OK©INSPECTION END

NG©GO TO 6.

6 CHECK TCM INSPECTION

1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK©INSPECTION END

NG©Repair or replace damaged parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0725 ENGINE SPEED SIGNAL

Diagnostic Procedure (Cont'd)

AT-119