clutch INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1643 of 2395

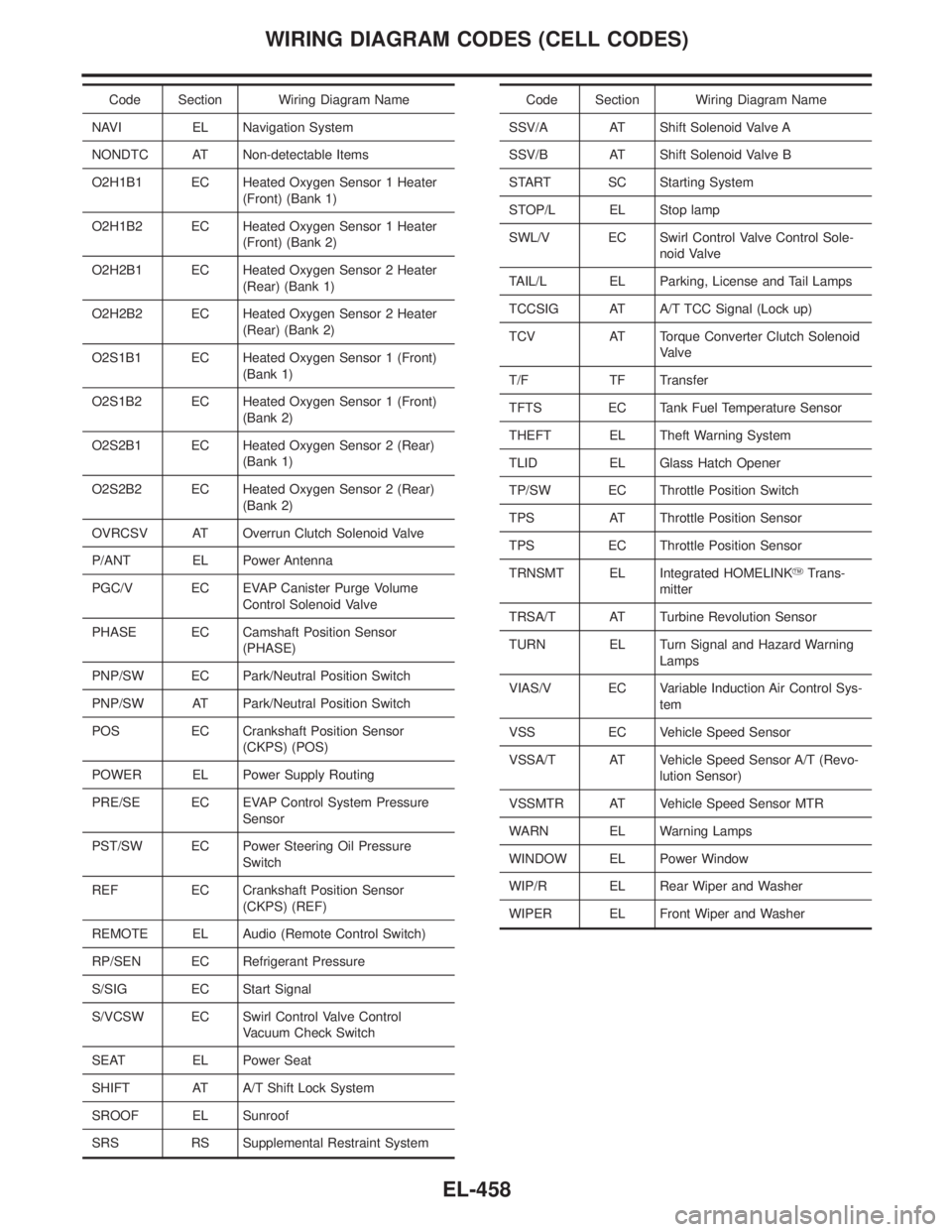

Code Section Wiring Diagram Name

NAVI EL Navigation System

NONDTC AT Non-detectable Items

O2H1B1 EC Heated Oxygen Sensor 1 Heater

(Front) (Bank 1)

O2H1B2 EC Heated Oxygen Sensor 1 Heater

(Front) (Bank 2)

O2H2B1 EC Heated Oxygen Sensor 2 Heater

(Rear) (Bank 1)

O2H2B2 EC Heated Oxygen Sensor 2 Heater

(Rear) (Bank 2)

O2S1B1 EC Heated Oxygen Sensor 1 (Front)

(Bank 1)

O2S1B2 EC Heated Oxygen Sensor 1 (Front)

(Bank 2)

O2S2B1 EC Heated Oxygen Sensor 2 (Rear)

(Bank 1)

O2S2B2 EC Heated Oxygen Sensor 2 (Rear)

(Bank 2)

OVRCSV AT Overrun Clutch Solenoid Valve

P/ANT EL Power Antenna

PGC/V EC EVAP Canister Purge Volume

Control Solenoid Valve

PHASE EC Camshaft Position Sensor

(PHASE)

PNP/SW EC Park/Neutral Position Switch

PNP/SW AT Park/Neutral Position Switch

POS EC Crankshaft Position Sensor

(CKPS) (POS)

POWER EL Power Supply Routing

PRE/SE EC EVAP Control System Pressure

Sensor

PST/SW EC Power Steering Oil Pressure

Switch

REF EC Crankshaft Position Sensor

(CKPS) (REF)

REMOTE EL Audio (Remote Control Switch)

RP/SEN EC Refrigerant Pressure

S/SIG EC Start Signal

S/VCSW EC Swirl Control Valve Control

Vacuum Check Switch

SEAT EL Power Seat

SHIFT AT A/T Shift Lock System

SROOF EL Sunroof

SRS RS Supplemental Restraint SystemCode Section Wiring Diagram Name

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

START SC Starting System

STOP/L EL Stop lamp

SWL/V EC Swirl Control Valve Control Sole-

noid Valve

TAIL/L EL Parking, License and Tail Lamps

TCCSIG AT A/T TCC Signal (Lock up)

TCV AT Torque Converter Clutch Solenoid

Valve

T/F TF Transfer

TFTS EC Tank Fuel Temperature Sensor

THEFT EL Theft Warning System

TLID EL Glass Hatch Opener

TP/SW EC Throttle Position Switch

TPS AT Throttle Position Sensor

TPS EC Throttle Position Sensor

TRNSMT EL Integrated HOMELINKYTrans-

mitter

TRSA/T AT Turbine Revolution Sensor

TURN EL Turn Signal and Hazard Warning

Lamps

VIAS/V EC Variable Induction Air Control Sys-

tem

VSS EC Vehicle Speed Sensor

VSSA/T AT Vehicle Speed Sensor A/T (Revo-

lution Sensor)

VSSMTR AT Vehicle Speed Sensor MTR

WARN EL Warning Lamps

WINDOW EL Power Window

WIP/R EL Rear Wiper and Washer

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-458

Page 1796 of 2395

NBGI0010

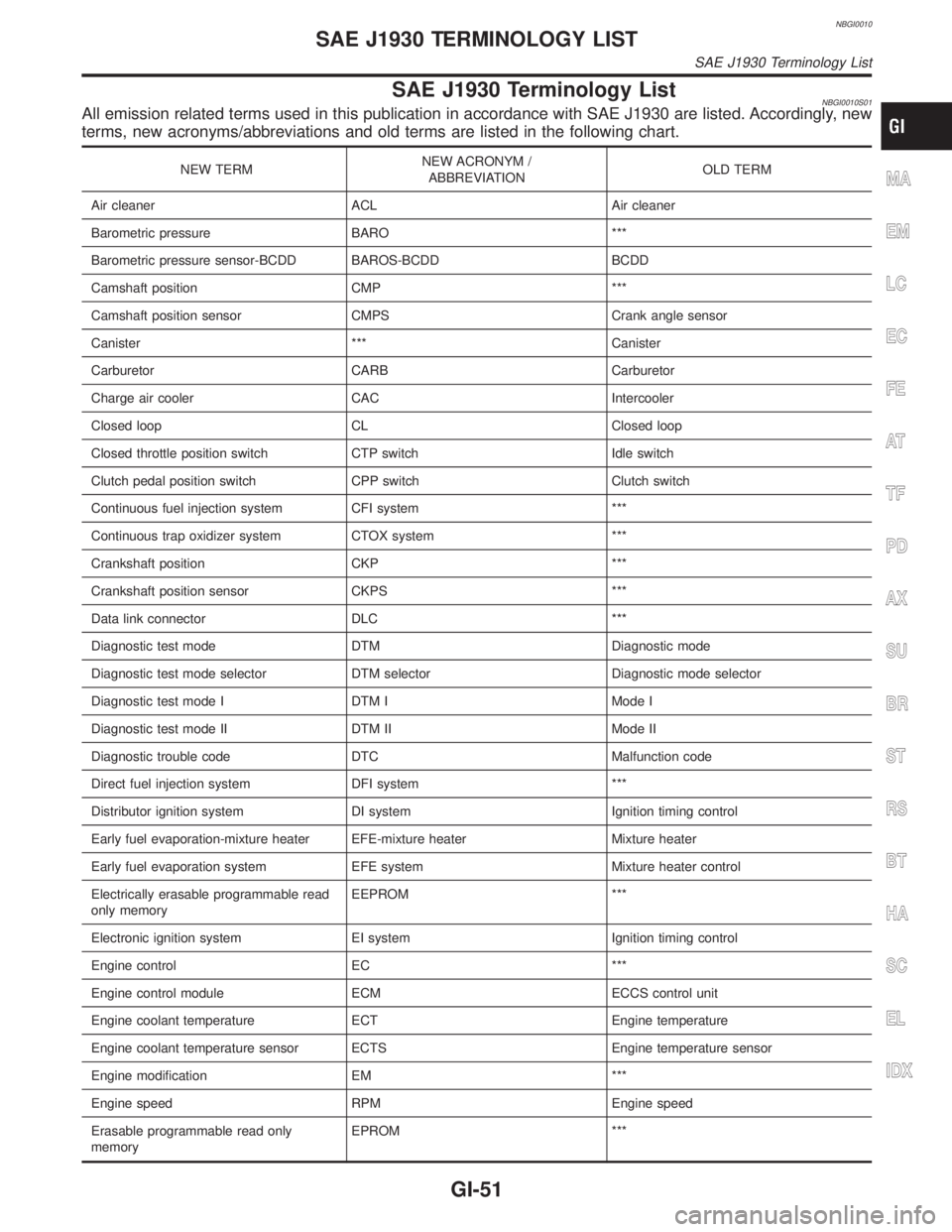

SAE J1930 Terminology ListNBGI0010S01All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memoryEEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only

memoryEPROM ***MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SAE J1930 TERMINOLOGY LIST

SAE J1930 Terminology List

GI-51

Page 1799 of 2395

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter

systemTWC + OC system ***

Throttle body TB Throttle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valve Lock-up cancel solenoid

Lock-up solenoid

Transmission control module TCM A/T control unit

Turbocharger TC Turbocharger

Vehicle speed sensor VSS Vehicle speed sensor

Volume air flow sensor VAFS Air flow meter

Warm up oxidation catalyst WU-OC Catalyst

Warm up oxidation catalytic converter sys-

temWU-OC system ***

Warm up three way catalyst WU-TWC Catalyst

Warm up three way catalytic converter

systemWU-TWC system ***

Wide open throttle position switch WOTP switch Full switch

SAE J1930 TERMINOLOGY LIST

SAE J1930 Terminology List (Cont'd)

GI-54

Page 1800 of 2395

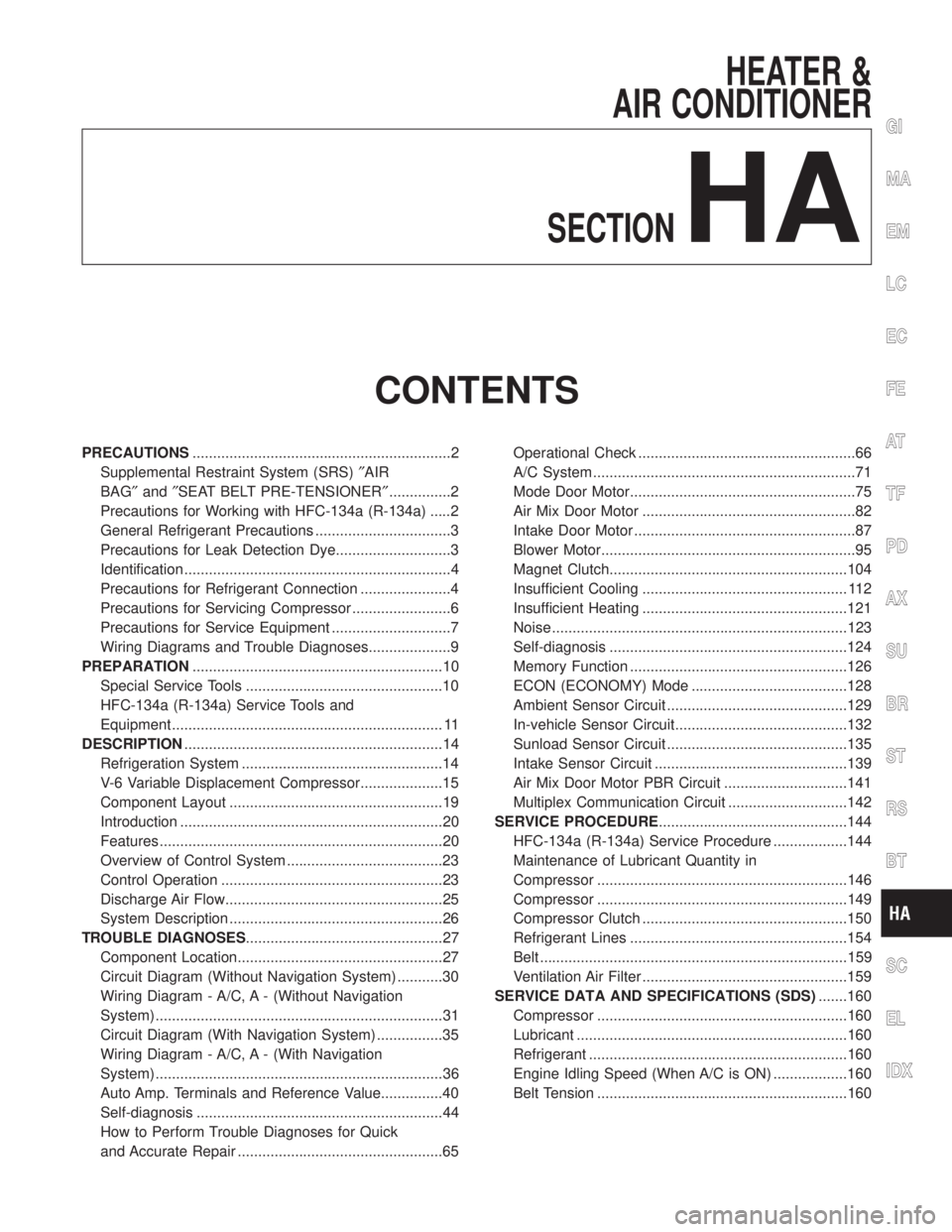

HEATER &

AIR CONDITIONER

SECTION

HA

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

Precautions for Working with HFC-134a (R-134a) .....2

General Refrigerant Precautions .................................3

Precautions for Leak Detection Dye............................3

Identification .................................................................4

Precautions for Refrigerant Connection ......................4

Precautions for Servicing Compressor ........................6

Precautions for Service Equipment .............................7

Wiring Diagrams and Trouble Diagnoses....................9

PREPARATION.............................................................10

Special Service Tools ................................................10

HFC-134a (R-134a) Service Tools and

Equipment .................................................................. 11

DESCRIPTION...............................................................14

Refrigeration System .................................................14

V-6 Variable Displacement Compressor....................15

Component Layout ....................................................19

Introduction ................................................................20

Features .....................................................................20

Overview of Control System ......................................23

Control Operation ......................................................23

Discharge Air Flow.....................................................25

System Description ....................................................26

TROUBLE DIAGNOSES................................................27

Component Location..................................................27

Circuit Diagram (Without Navigation System) ...........30

Wiring Diagram - A/C, A - (Without Navigation

System) ......................................................................31

Circuit Diagram (With Navigation System) ................35

Wiring Diagram - A/C, A - (With Navigation

System) ......................................................................36

Auto Amp. Terminals and Reference Value...............40

Self-diagnosis ............................................................44

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ..................................................65Operational Check .....................................................66

A/C System ................................................................71

Mode Door Motor.......................................................75

Air Mix Door Motor ....................................................82

Intake Door Motor ......................................................87

Blower Motor..............................................................95

Magnet Clutch..........................................................104

Insufficient Cooling .................................................. 112

Insufficient Heating ..................................................121

Noise ........................................................................123

Self-diagnosis ..........................................................124

Memory Function .....................................................126

ECON (ECONOMY) Mode ......................................128

Ambient Sensor Circuit ............................................129

In-vehicle Sensor Circuit..........................................132

Sunload Sensor Circuit ............................................135

Intake Sensor Circuit ...............................................139

Air Mix Door Motor PBR Circuit ..............................141

Multiplex Communication Circuit .............................142

SERVICE PROCEDURE..............................................144

HFC-134a (R-134a) Service Procedure ..................144

Maintenance of Lubricant Quantity in

Compressor .............................................................146

Compressor .............................................................149

Compressor Clutch ..................................................150

Refrigerant Lines .....................................................154

Belt ...........................................................................159

Ventilation Air Filter ..................................................159

SERVICE DATA AND SPECIFICATIONS (SDS).......160

Compressor .............................................................160

Lubricant ..................................................................160

Refrigerant ...............................................................160

Engine Idling Speed (When A/C is ON) ..................160

Belt Tension .............................................................160

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

Page 1805 of 2395

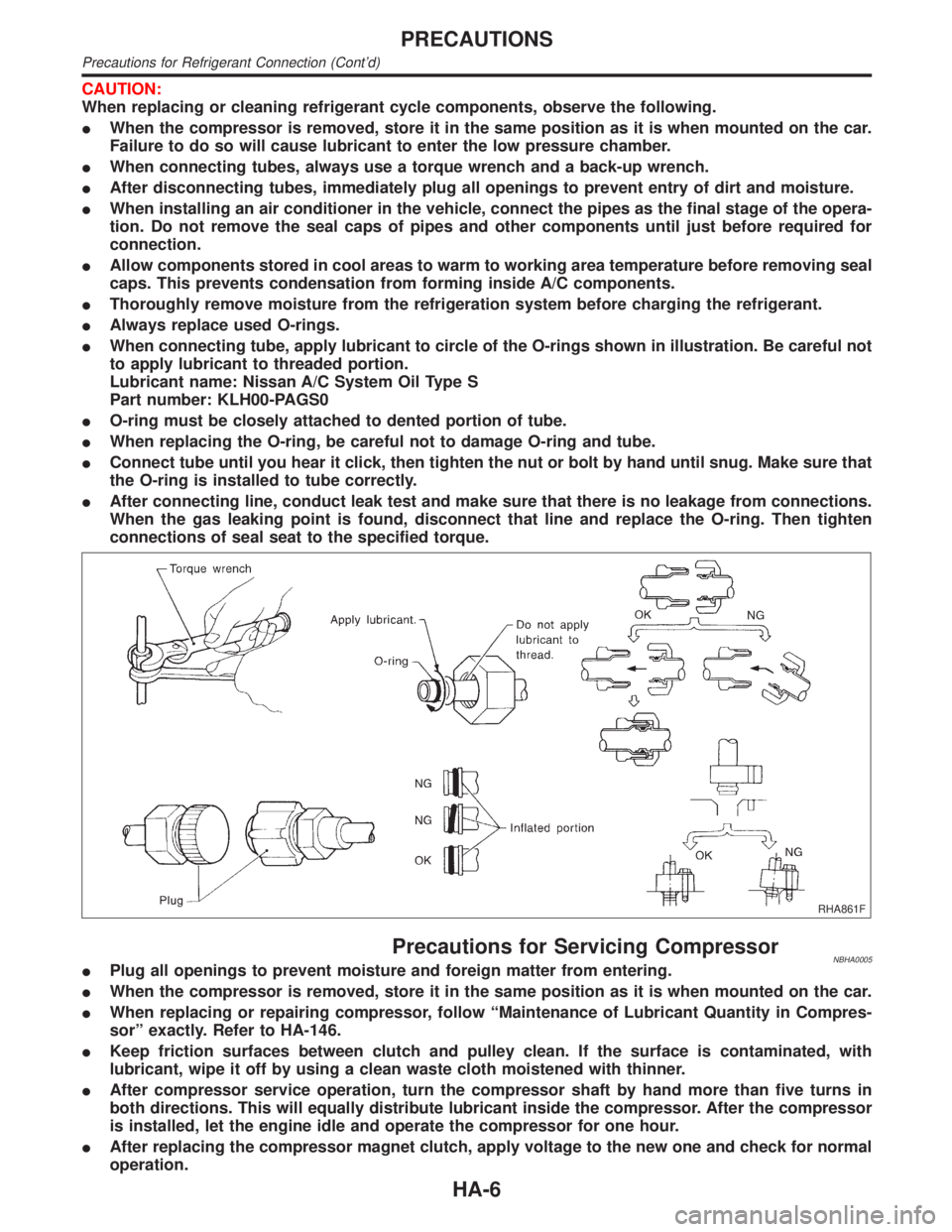

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

IWhen the compressor is removed, store it in the same position as it is when mounted on the car.

Failure to do so will cause lubricant to enter the low pressure chamber.

IWhen connecting tubes, always use a torque wrench and a back-up wrench.

IAfter disconnecting tubes, immediately plug all openings to prevent entry of dirt and moisture.

IWhen installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for

connection.

IAllow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

IThoroughly remove moisture from the refrigeration system before charging the refrigerant.

IAlways replace used O-rings.

IWhen connecting tube, apply lubricant to circle of the O-rings shown in illustration. Be careful not

to apply lubricant to threaded portion.

Lubricant name: Nissan A/C System Oil Type S

Part number: KLH00-PAGS0

IO-ring must be closely attached to dented portion of tube.

IWhen replacing the O-ring, be careful not to damage O-ring and tube.

IConnect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

IAfter connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

RHA861F

Precautions for Servicing CompressorNBHA0005IPlug all openings to prevent moisture and foreign matter from entering.

IWhen the compressor is removed, store it in the same position as it is when mounted on the car.

IWhen replacing or repairing compressor, follow ªMaintenance of Lubricant Quantity in Compres-

sorº exactly. Refer to HA-146.

IKeep friction surfaces between clutch and pulley clean. If the surface is contaminated, with

lubricant, wipe it off by using a clean waste cloth moistened with thinner.

IAfter compressor service operation, turn the compressor shaft by hand more than five turns in

both directions. This will equally distribute lubricant inside the compressor. After the compressor

is installed, let the engine idle and operate the compressor for one hour.

IAfter replacing the compressor magnet clutch, apply voltage to the new one and check for normal

operation.

PRECAUTIONS

Precautions for Refrigerant Connection (Cont'd)

HA-6

Page 1809 of 2395

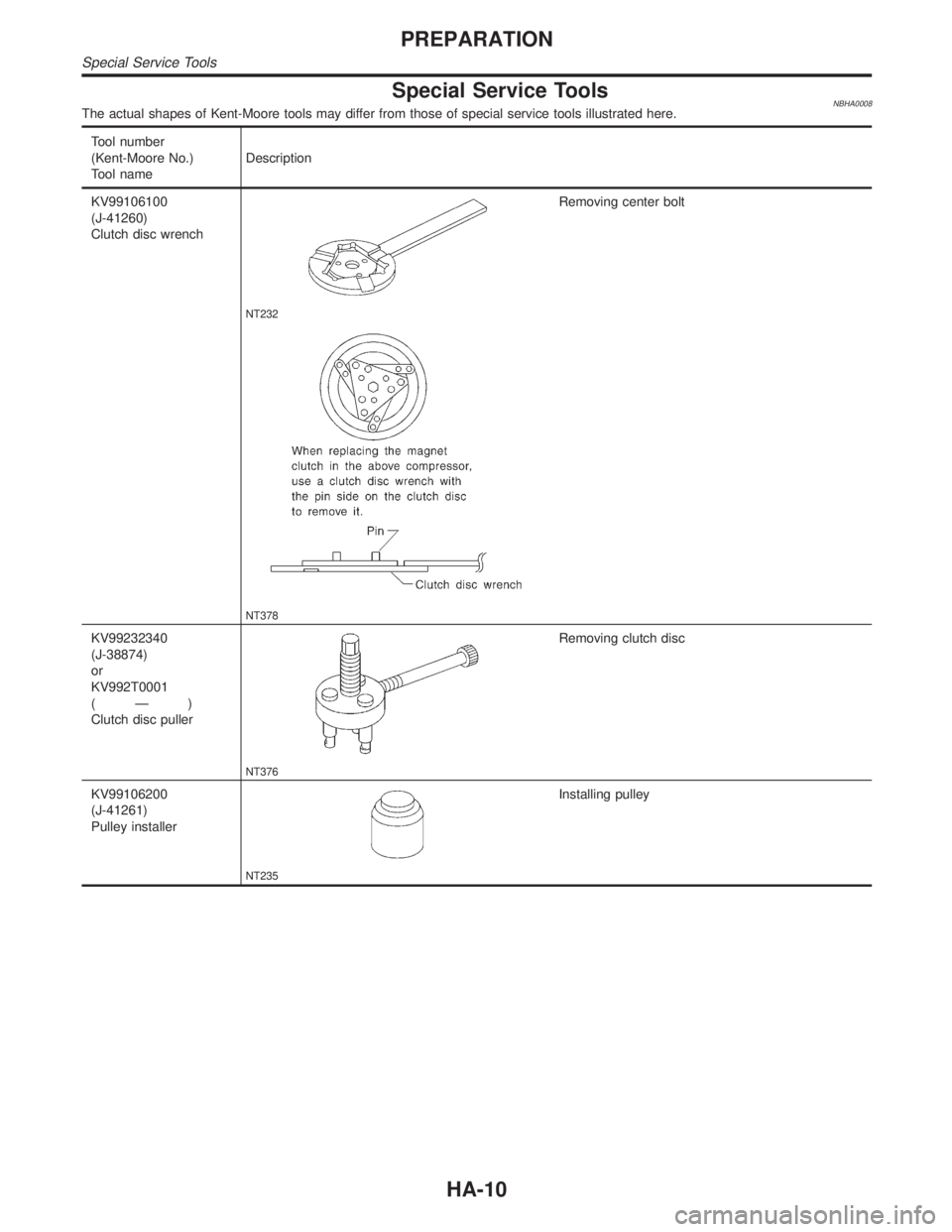

Special Service ToolsNBHA0008The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

KV99106100

(J-41260)

Clutch disc wrench

NT232

Removing center bolt

NT378

KV99232340

(J-38874)

or

KV992T0001

(Ð)

Clutch disc puller

NT376

Removing clutch disc

KV99106200

(J-41261)

Pulley installer

NT235

Installing pulley

PREPARATION

Special Service Tools

HA-10

Page 1814 of 2395

V-6 Variable Displacement Compressor

GENERAL INFORMATION=NBHA00861. The V-6 variable compressor differs from previous units. The vent temperatures of the V-6 variable com-

press do not drop too far below 5ÉC (41ÉF) when:

Ievaporator intake air temperature is less than 20ÉC (68ÉF)

Iengine is running at speeds less than 1,500 rpm.

This is because the V-6 compressor provides a means of ªcapacityº control.

2. The V-6 variable compressor provides refrigerant control under varying conditions. During cold winters, it

may not produce high refrigerant pressure discharge (compared to previous units) when used with air

conditioning systems.

3. A ªclankingº sound may occasionally be heard during refrigerant charge. The sound indicates that the tilt

angle of the swash plate has changed and is not a problem.

4. For air conditioning systems with the V-6 compressor, the clutch remains engaged unless: the system main

switch, fan switch or ignition switch is turned OFF. When ambient (outside) temperatures are low or when

the amount of refrigerant is insufficient, the clutch is disengaged to protect the compressor.

5. A constant range of suction pressure is maintained when engine speed is greater than a certain value. It

normally ranges from 147 to 177 kPa (1.5 to 1.8 kg/cm

2, 21 to 26 psi) under varying conditions.

In previous compressors, however, suction pressure was reduced with increases in engine speed.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

DESCRIPTION

V-6 Variable Displacement Compressor

HA-15

Page 1821 of 2395

Fan Speed ControlNBHA0014S0804Blower speed is automatically controlled based on temperature setting, ambient temperature, in-vehicle

temperature, intake temperature, amount of sunload and air mix door position.

With FAN switch set to ªAUTOº, the blower motor starts to gradually increase air flow volume.

When engine coolant temperature is low, the blower motor operation is delayed to prevent cool air from flow-

ing.

Intake Door ControlNBHA0014S0805The intake doors are automatically controlled by: The temperature setting, ambient temperature, in-vehicle

temperature, intake temperature, amount of sunload and ON-OFF operation of the compressor.

Outlet Door ControlNBHA0014S0806The outlet door is automatically controlled by: The temperature setting, ambient temperature, in-vehicle

temperature, intake temperature and amount of sunload.

Magnet Clutch ControlNBHA0014S0807The ECM controls compressor operation using input signals from the throttle position sensor and auto ampli-

fier.

Self-diagnostic SystemNBHA0014S0808The self-diagnostic system is built into the auto amplifier (LCU) to quickly locate the cause of problems.

DESCRIPTION

Features (Cont'd)

HA-22

Page 1847 of 2395

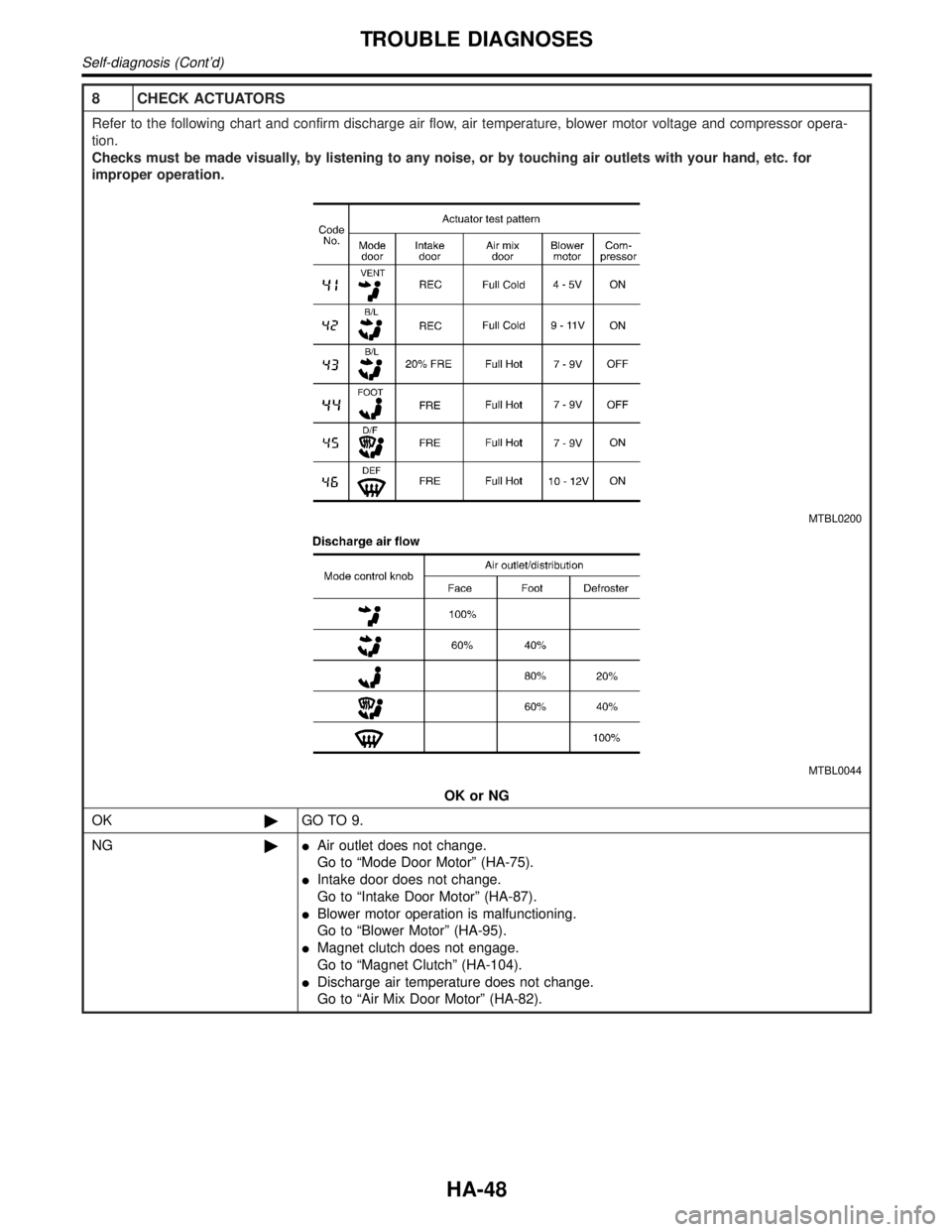

8 CHECK ACTUATORS

Refer to the following chart and confirm discharge air flow, air temperature, blower motor voltage and compressor opera-

tion.

Checks must be made visually, by listening to any noise, or by touching air outlets with your hand, etc. for

improper operation.

MTBL0200

MTBL0044

OK or NG

OK©GO TO 9.

NG©IAir outlet does not change.

Go to ªMode Door Motorº (HA-75).

IIntake door does not change.

Go to ªIntake Door Motorº (HA-87).

IBlower motor operation is malfunctioning.

Go to ªBlower Motorº (HA-95).

IMagnet clutch does not engage.

Go to ªMagnet Clutchº (HA-104).

IDischarge air temperature does not change.

Go to ªAir Mix Door Motorº (HA-82).

TROUBLE DIAGNOSES

Self-diagnosis (Cont'd)

HA-48

Page 1857 of 2395

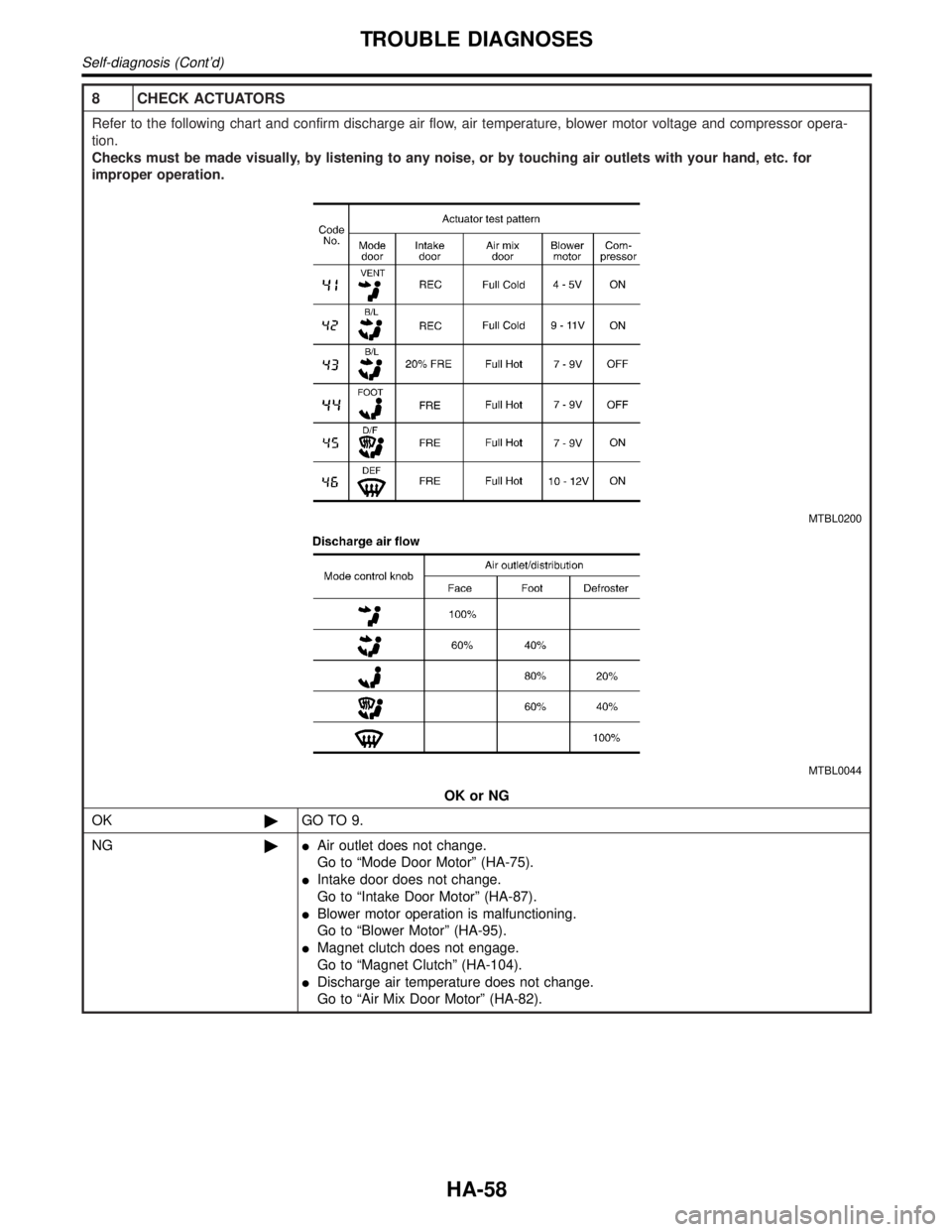

8 CHECK ACTUATORS

Refer to the following chart and confirm discharge air flow, air temperature, blower motor voltage and compressor opera-

tion.

Checks must be made visually, by listening to any noise, or by touching air outlets with your hand, etc. for

improper operation.

MTBL0200

MTBL0044

OK or NG

OK©GO TO 9.

NG©IAir outlet does not change.

Go to ªMode Door Motorº (HA-75).

IIntake door does not change.

Go to ªIntake Door Motorº (HA-87).

IBlower motor operation is malfunctioning.

Go to ªBlower Motorº (HA-95).

IMagnet clutch does not engage.

Go to ªMagnet Clutchº (HA-104).

IDischarge air temperature does not change.

Go to ªAir Mix Door Motorº (HA-82).

TROUBLE DIAGNOSES

Self-diagnosis (Cont'd)

HA-58