IDX INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1912 of 2395

With Navigation SystemNBHA0096S0102

RHA881H

*1: HA-44

*2: HA-85

*3: HA-116

*4: HA-53

*5: STEP-BY-STEP PROCEDURE

(HA-45), see No. 13.*6: HA-77

*7: HA-89

*8: HA-97

*9: HA-106

*10: HA-114*11: HA-66

*12: HA-45

*13: HA-2

*14: MA-13

*15: LC-20

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Insufficient Cooling (Cont'd)

HA-113

Page 1914 of 2395

RHA576H

*1: HA-149 *2: HA-95 *3: MA-13

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Insufficient Cooling (Cont'd)

HA-115

Page 1916 of 2395

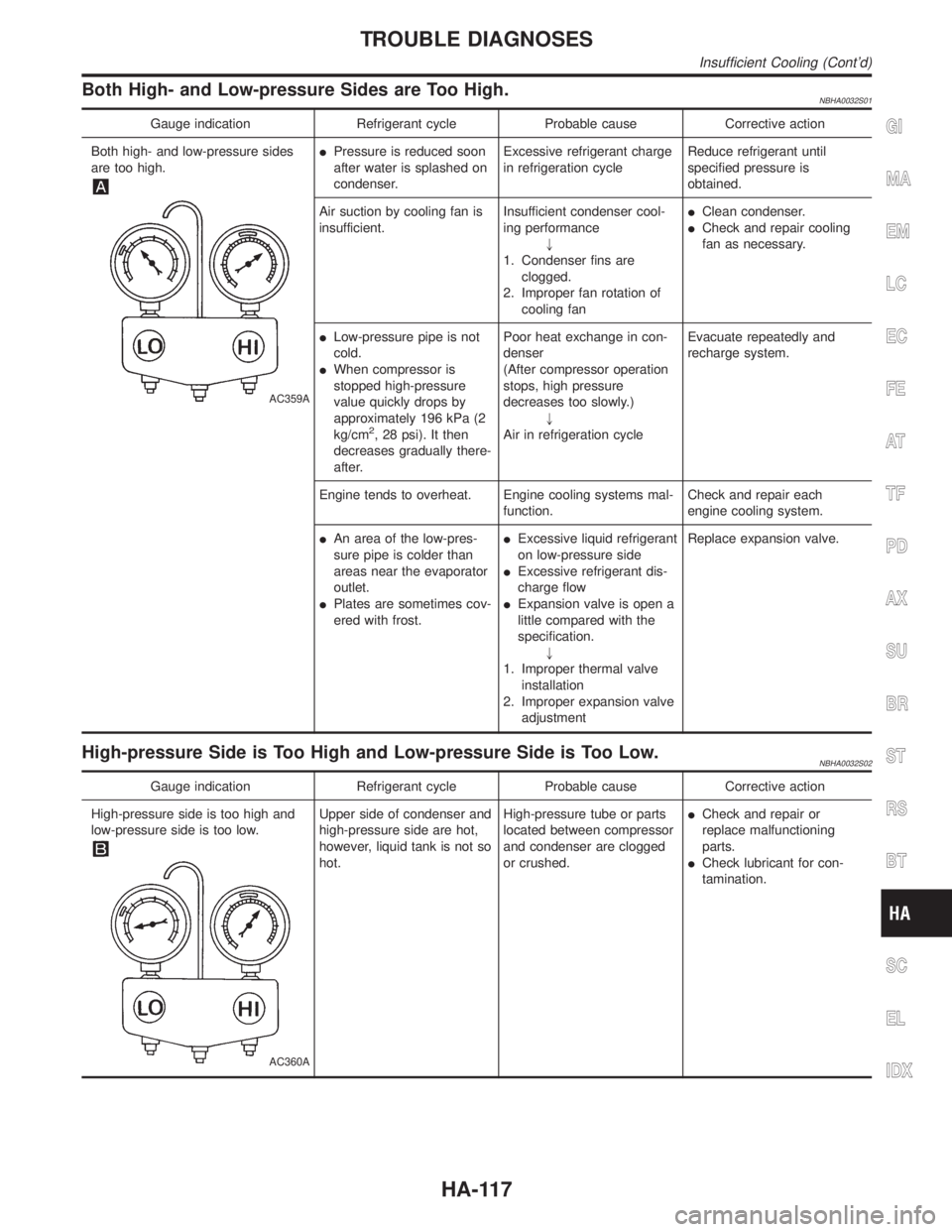

Both High- and Low-pressure Sides are Too High.NBHA0032S01

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure sides

are too high.

AC359A

IPressure is reduced soon

after water is splashed on

condenser.Excessive refrigerant charge

in refrigeration cycleReduce refrigerant until

specified pressure is

obtained.

Air suction by cooling fan is

insufficient.Insufficient condenser cool-

ing performance

"

1. Condenser fins are

clogged.

2. Improper fan rotation of

cooling fanIClean condenser.

ICheck and repair cooling

fan as necessary.

ILow-pressure pipe is not

cold.

IWhen compressor is

stopped high-pressure

value quickly drops by

approximately 196 kPa (2

kg/cm

2, 28 psi). It then

decreases gradually there-

after.Poor heat exchange in con-

denser

(After compressor operation

stops, high pressure

decreases too slowly.)

"

Air in refrigeration cycleEvacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems mal-

function.Check and repair each

engine cooling system.

IAn area of the low-pres-

sure pipe is colder than

areas near the evaporator

outlet.

IPlates are sometimes cov-

ered with frost.IExcessive liquid refrigerant

on low-pressure side

IExcessive refrigerant dis-

charge flow

IExpansion valve is open a

little compared with the

specification.

"

1. Improper thermal valve

installation

2. Improper expansion valve

adjustmentReplace expansion valve.

High-pressure Side is Too High and Low-pressure Side is Too Low.NBHA0032S02

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too high and

low-pressure side is too low.

AC360A

Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts

located between compressor

and condenser are clogged

or crushed.ICheck and repair or

replace malfunctioning

parts.

ICheck lubricant for con-

tamination.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Insufficient Cooling (Cont'd)

HA-117

Page 1918 of 2395

Both High- and Low-pressure Sides are Too Low.NBHA0032S04

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure sides

are too low.

AC353A

IThere is a big temperature

difference between

receiver drier outlet and

inlet. Outlet temperature is

extremely low.

ILiquid tank inlet and

expansion valve are

frosted.Compressor discharge

capacity does not change.

(Compressor stroke is set at

maximum.)IReplace liquid tank.

ICheck lubricant for con-

tamination.

ITemperature of expansion

valve inlet is extremely low

as compared with areas

near liquid tank.

IExpansion valve inlet may

be frosted.

ITemperature difference

occurs somewhere in high-

pressure sideHigh-pressure pipe located

between receiver drier and

expansion valve is clogged.ICheck and repair malfunc-

tioning parts.

ICheck lubricant for con-

tamination.

IExpansion valve and liquid

tank are warm or only cool

when touched.Low refrigerant charge

"

Leaking fittings or compo-

nentsCheck refrigerant for leaks.

Refer to ªChecking Refriger-

ant Leaksº, HA-155.

There is a big temperature

difference between expan-

sion valve inlet and outlet

while the valve itself is

frosted.Expansion valve closes a

little compared with the

specification.

"

1. Improper expansion valve

adjustment

2. Malfunctioning thermal

valve

3. Outlet and inlet may be

clogged.IRemove foreign particles

by using compressed air.

ICheck lubricant for con-

tamination.

An area of the low-pressure

pipe is colder than areas

near the evaporator outlet.Low-pressure pipe is clogged

or crushed.ICheck and repair malfunc-

tioning parts.

ICheck lubricant for con-

tamination.

Air flow volume is not

enough or is too low.Evaporator is frozen.

"

Compressor discharge

capacity does not change.

(Compressor stroke is set at

maximum length.)Replace compressor.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Insufficient Cooling (Cont'd)

HA-119

Page 1920 of 2395

Insufficient Heating

TROUBLE DIAGNOSIS PROCEDURE FOR INSUFFICIENT HEATING=NBHA0097SYMPTOM:

IInsufficient heating

Inspection FlowNBHA0097S01Without Navigation SystemNBHA0097S0101

SHA894EA

*1: HA-66

*2: HA-44

*3: HA-45

*4: HA-45

*5: HA-85*6: STEP-BY-STEP PROCEDURE

(HA-45), see No. 13.

*7: HA-78

*8: HA-90

*9: HA-98*10: HA-82

*11: MA-14

*12: LC-11

*13: LC-16

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Insufficient Heating

HA-121

Page 1922 of 2395

Noise

TROUBLE DIAGNOSIS PROCEDURE FOR NOISE=NBHA0100SYMPTOM:

INoise

RHA883H

*1: HA-150

*2: HA-152*3: HA-146

*4: HA-66*5: MA-13

*6: MA-14

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Noise

HA-123

Page 1924 of 2395

With Navigation SystemNBHA0101S0102

RHA884H

*1: HA-72

*2: HA-129

*3: HA-132

*4: HA-135*5: HA-139

*6: HA-141

*7: HA-66*8: HA-65

*9: HA-66

*10: HA-142

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Self-diagnosis (Cont'd)

HA-125

Page 1926 of 2395

With Navigation SystemNBHA0102S0102

RHA886H

*1: HA-72 *2: HA-66 *3: HA-45

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Memory Function (Cont'd)

HA-127

Page 1928 of 2395

With Navigation SystemNBHA0103S0102

RHA887H

*1: HA-72 *2: HA-66 *3: HA-45

RHA050G

Ambient Sensor Circuit

COMPONENT DESCRIPTIONNBHA0039The ambient sensor is attached in front of the driver's side con-

denser. It detects ambient temperature and converts it into a resis-

tance value which is then input into the auto amplifier.

AMBIENT TEMPERATURE INPUT PROCESSNBHA0040The automatic amplifier includes a ªprocessing circuitº for the ambi-

ent sensor input. However, when the temperature detected by the

ambient sensor increases quickly, the processing circuit retards the

auto amp. function. It only allows the auto amp. to recognize an

ambient temperature increase of 0.33ÉC (0.6ÉF) per 100 seconds.

As an example, consider stopping for a cup of coffee after high

speed driving. Although the actual ambient temperature has not

changed, the temperature detected by the ambient sensor will

increase. This is because the heat from the engine compartment

can radiate to the front grille area, location of the ambient sensor.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

ECON (ECONOMY) Mode (Cont'd)

HA-129

Page 1930 of 2395

3 CHECK AMBIENT SENSOR

Refer to HA-131.

OK or NG

OK©1. Replace auto amp. (LCU).

2. Go to self-diagnosis step-by-step procedure (HA-45) and perform self-diagnosis STEP

2.

Confirm that code No. 20 is displayed.

NG©Replace ambient sensor.

4 CHECK AMBIENT SENSOR CIRCUIT BETWEEN AMBIENT SENSOR AND AUTO AMP. (LCU)

1. Disconnect auto amp. (LCU) harness connector.

2. Check circuit continuity between ambient sensor harness terminal No. 1 and auto amp. (LCU) harness terminal No. 2.

RHA830H

Continuity should exist.

If OK, check harness for short.

OK or NG

OK©1. Replace auto amp. (LCU).

2. Go to self-diagnosis step-by-step procedure (HA-45) and perform self-diagnosis STEP

2.

Confirm that code No. 20 is displayed.

NG©Repair harness or connector.

SHA304F

COMPONENT INSPECTIONNBHA0042Ambient SensorNBHA0042S01After disconnecting ambient sensor harness connector, measure

resistance between terminals 2 and 1 at sensor harness side, using

the table below.

Temperature ÉC (ÉF) Resistance kW

þ15 (5) 12.73

þ10 (14) 9.92

þ5 (23) 7.80

0 (32) 6.19

5 (41) 4.95

10 (50) 3.99

15 (59) 3.24

20 (68) 2.65

25 (77) 2.19

30 (86) 1.81

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Ambient Sensor Circuit (Cont'd)

HA-131