INFINITI QX4 2005 Factory Service Manual

QX4 2005

INFINITI

INFINITI

https://www.carmanualsonline.info/img/42/57035/w960_57035-0.png

INFINITI QX4 2005 Factory Service Manual

Trending: suspension, phone, trunk release, immobilizer, clock reset, battery location, fuel

Page 331 of 3419

AT-260

OVERHAUL

Revision: October 20052005 QX56

Locations of Adjusting Shims, Needle Bearings, Thrust Washers and Snap

Rings

ECS00CL4

2WD models

SCIA5196E

Page 332 of 3419

OVERHAUL

AT-261

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: October 20052005 QX56

4WD models

SCIA5197E

Page 333 of 3419

AT-262

DISASSEMBLY

Revision: October 20052005 QX56

DISASSEMBLYPFP:31020

DisassemblyECS00CL5

CAUTION:

Do not disassemble parts behind Drum Support. Refer to AT-1 6, "

Cross-Sectional View (2WD models)"

or AT-17, "Cross-Sectional View (4WD models)" .

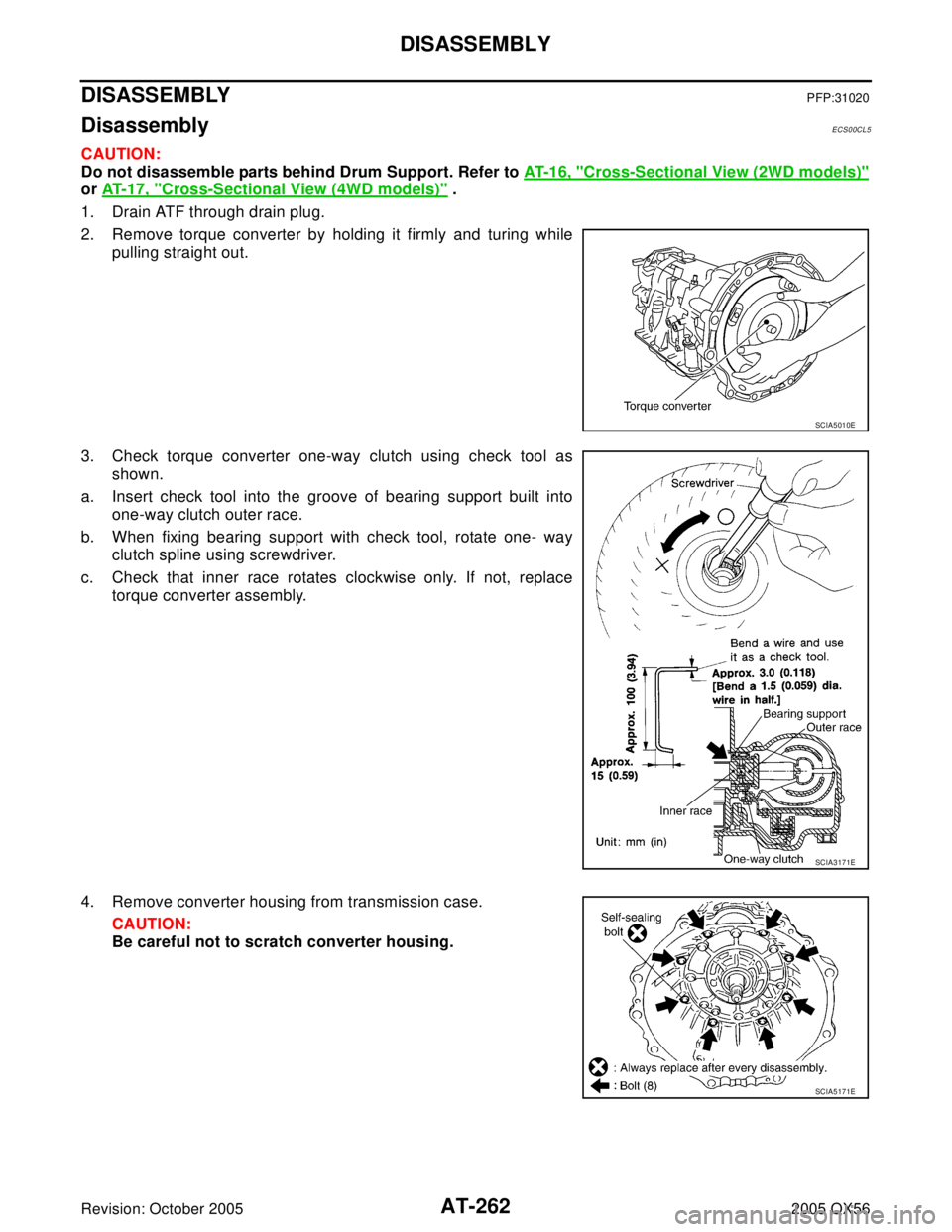

1. Drain ATF through drain plug.

2. Remove torque converter by holding it firmly and turing while

pulling straight out.

3. Check torque converter one-way clutch using check tool as

shown.

a. Insert check tool into the groove of bearing support built into

one-way clutch outer race.

b. When fixing bearing support with check tool, rotate one- way

clutch spline using screwdriver.

c. Check that inner race rotates clockwise only. If not, replace

torque converter assembly.

4. Remove converter housing from transmission case.

CAUTION:

Be careful not to scratch converter housing.

SCIA5010E

SCIA3171E

SCIA5171E

Page 334 of 3419

DISASSEMBLY

AT-263

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: October 20052005 QX56

5. Remove O-ring from input clutch assembly.

6. Remove tightening bolts for oil pump assembly and transmis-

sion case.

7. Attach sliding hammer to oil pump assembly and extract it

evenly from transmission case.

CAUTION:

�Fully tighten sliding hammer screw.

�Make sure that bearing race is installed to the oil pump

assembly edge surface.

8. Remove O-ring from oil pump assembly.

SCIA5 011 E

SCIA2300E

SCIA5474E

SCIA5172E

Page 335 of 3419

AT-264

DISASSEMBLY

Revision: October 20052005 QX56

9. Remove bearing race from oil pump assembly.

10. Remove needle bearing from front sun gear assembly.

11. Remove front sun gear assembly from front carrier assembly.

NOTE:

Remove front sun gear assembly by rotating left/right.

12. Remove seal rings from input clutch assembly.

13. Remove front carrier assembly, input clutch assembly and rear

internal gear as a unit.

CAUTION:

Be careful to remove it with needle bearing.

SCIA5252E

SCIA2808E

SCIA5014E

SCIA5269E

SCIA5173E

Page 336 of 3419

DISASSEMBLY

AT-265

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: October 20052005 QX56

14. Loosen lock nut and remove band servo anchor end pin from

transmission case.

15. Remove brake band from transmission case.

�To prevent brake linings from cracking or peeling, do not

stretch the flexible band unnecessarily. When removing

the brake band, always secure it with a clip as shown in

the figure at left.

Leave the clip in position after removing the brake band.

�Check brake band facing for damage, cracks, wear or

burns.

16. Remove mid carrier assembly and rear carrier assembly as a

unit.

SCIA5016E

SCIA5345E

SAT6 5 5

SCIA5344E

Page 337 of 3419

AT-266

DISASSEMBLY

Revision: October 20052005 QX56

17. Remove mid carrier assembly from rear carrier assembly.

18. Remove needle bearing (front side) from mid carrier assembly.

19. Remove needle bearing (rear side) from mid carrier assembly.

20. Remove bearing race from rear carrier assembly.

21. Remove needle bearing from rear carrier assembly.

SCIA5174E

SCIA5176E

SCIA5177E

SCIA5178E

SCIA5179E

Page 338 of 3419

DISASSEMBLY

AT-267

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: October 20052005 QX56

22. Remove mid sun gear assembly, rear sun gear assembly and

high and low reverse clutch hub as a unit.

CAUTION:

Be careful to remove then with bearing races and needle

bearing.

23. Remove high and low reverse clutch assembly from direct clutch

assembly.

CAUTION:

Make sure that needle bearing is installed to the high and

low reverse clutch assembly edge surface.

24. Remove direct clutch assembly from reverse brake.

25. Remove needle bearing from drum support edge surface.

26. Remove snap ring from A/T assembly harness connector.

SCIA5018E

SCIA2306E

SCIA5019E

SCIA5198E

SCIA5021E

Page 339 of 3419

AT-268

DISASSEMBLY

Revision: October 20052005 QX56

27. Push A/T assembly harness connector.

CAUTION:

Be careful not to damage connector.

28. Remove oil pan and oil pan gasket, refer to AT-229, "

Removal" .

29. Disconnect A/T fluid temperature sensor 2 connector.

CAUTION:

Be careful not to damage connector.

30. Straighten terminal clip to free terminal cord assembly and A/T

fluid temperature sensor 2 harness.

31. Disconnect revolution sensor connector.

CAUTION:

Be careful not to damage connector.

SCIA5022E

SCIA5023E

SCIA5446E

SCIA5024E

Page 340 of 3419

DISASSEMBLY

AT-269

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: October 20052005 QX56

32. Straighten terminal clips to free revolution sensor harness.

33. Remove bolts A, B and C from control valve with TCM.

34. Remove control valve with TCM from transmission case.

CAUTION:

When removing, be careful with transmission assembly ter-

minal connector and the manual valve notch and manual

plate height. Remove it vertically.

35. Remove A/T fluid temperature sensor 2 with bracket from con-

trol valve with TCM.

36. Remove bracket from A/T fluid temperature sensor 2.

SCIA5293E

Bolt symbol Length mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA5025E

SCIA5308E

SCIA5301E

SCIA5264E

Trending: key, radio controls, ESP, manual transmission, fuse chart, low oil pressure, keyless entry