ABS INFINITI QX56 2007 Factory Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1003 of 3061

CO-14

< SERVICE INFORMATION >

RADIATOR

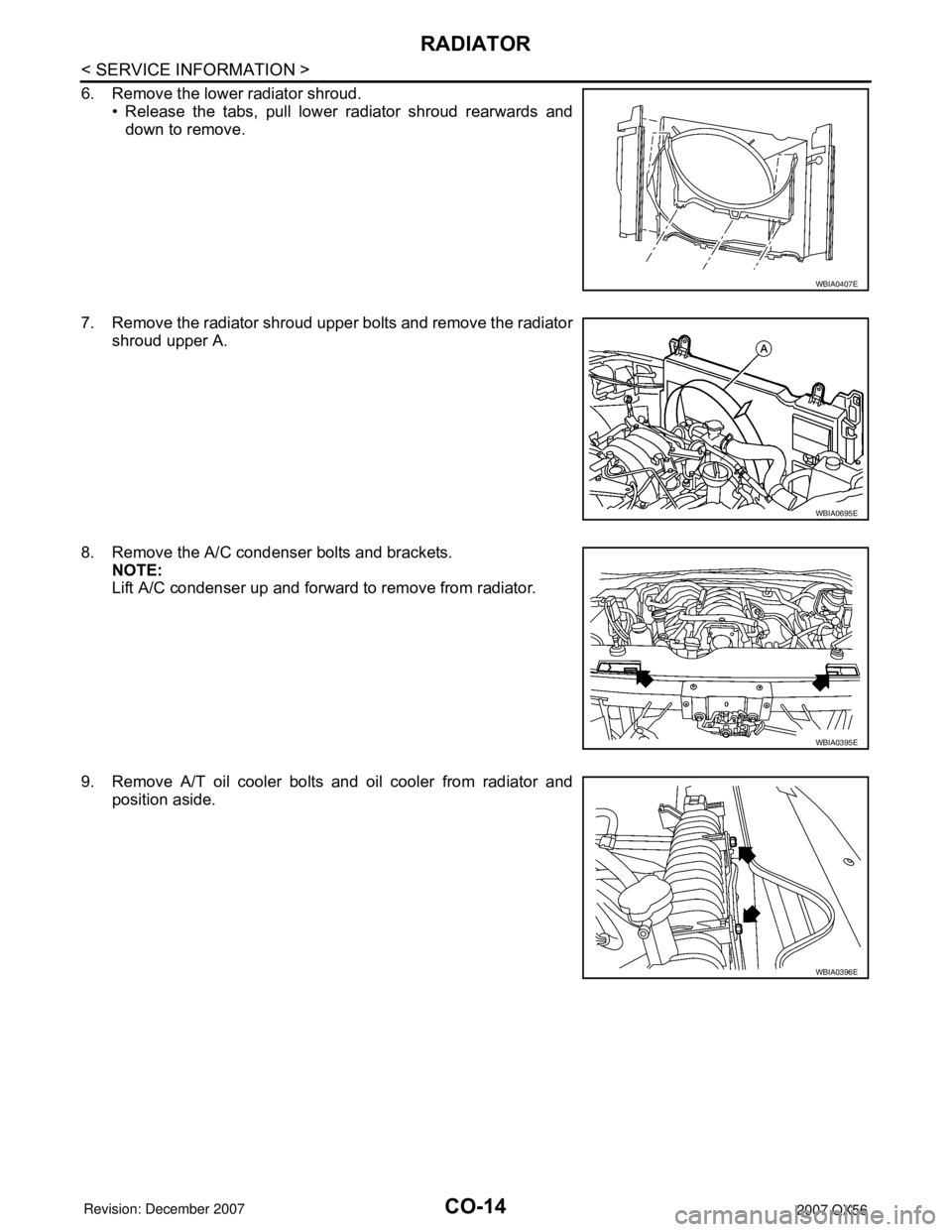

6. Remove the lower radiator shroud.

• Release the tabs, pull lower radiator shroud rearwards and

down to remove.

7. Remove the radiator shroud upper bolts and remove the radiator

shroud upper A.

8. Remove the A/C condenser bolts and brackets.

NOTE:

Lift A/C condenser up and forward to remove from radiator.

9. Remove A/T oil cooler bolts and oil cooler from radiator and

position aside.

WBIA0407E

WBIA0695E

WBIA0395E

WBIA0396E

Page 1016 of 3061

COMBINATION METERSDI-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

COMBINATION METERS

Component Parts and Har ness Connector LocationINFOID:0000000003533479

System DescriptionINFOID:0000000003533480

UNIFIED METER CONTROL UNIT

• Speedometer, odometer, tachometer, fuel gauge, oil pressure gauge, voltage gauge, A/T oil temperature

gauge, and water temperature gauge are controlled by the unified meter control unit, which is built into the

combination meter.

• Warning indicators are controlled by signals drawn fr om the CAN communication system, BCM (body control

module), and components connected directly to the combination meter.

• Digital meter is adopted for odometer/trip meters*, as well as the A/T position indicator display. *The record of the odometer is kept ev en if the battery cable is disconnected.

• Odometer/trip meters and A/T indicator segments can be checked in diagnosis mode.

• Meters/gauges can be checked in diagnosis mode.

Illumination control

The unified meter control unit outputs the speedometer, odometer/trip meters, tachometer, oil pressure gauge,

voltage meter, A/T indicator, A/T temperature gauge, fuel and temperature gauge lighting when the ignition

switch is turned on. When the lighting switch is turned on, the illumination control switch can be used to adjust

the brightness of the combination meter illuminati on and the odometer/trip meters and meter illumination.

When the ignition switch is turned from the OFF to the ON position, the combination meter dial lighting will

remain off for 0.7 seconds. For additional combination meter illumination control information, refer to LT-120,

"System Description".

1. IPDM E/R E122 2. Combination meter M24 3. Fuel level sensor unit and fuel pump

C5 (view with inspection hole cover

removed)

4. ECM E16 (view with battery re- moved) 5. ABS actuator and electric unit (con-

trol unit) E125 6. Oil pressure switch F4

A. Oil pan (upper)

7. A/T assembly F9

WKIA5718E

Page 1017 of 3061

![INFINITI QX56 2007 Factory Manual Online

DI-6

< SERVICE INFORMATION >

COMBINATION METERS

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

• through 10A fuse [No.19, located in the fuse block (J/B)]

• to combination meter t INFINITI QX56 2007 Factory Manual Online

DI-6

< SERVICE INFORMATION >

COMBINATION METERS

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

• through 10A fuse [No.19, located in the fuse block (J/B)]

• to combination meter t](/img/42/57029/w960_57029-1016.png)

DI-6

< SERVICE INFORMATION >

COMBINATION METERS

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

• through 10A fuse [No.19, located in the fuse block (J/B)]

• to combination meter terminal 8.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No.14, located in the fuse block (J/B)]

• to combination meter terminal 24.

Ground is supplied

• to combination meter terminal 17

• through body grounds M57, M61 and M79.

WATER TEMPERATURE GAUGE

The water temperature gauge indicates the engine coolant temperature.

ECM provides an engine coolant temperature signal to combination meter via CAN communication lines.

ENGINE OIL PRESSURE GAUGE

The engine oil pressure gauge indicates whether the engine oil pressure is low or normal.

The oil pressure gauge is controlled by the IPDM E/R (intelligent power distribution module engine room). Low

oil pressure causes oil pressure switch terminal 1 to provide ground to IPDM E/R terminal 42. The IPDM E/R

then signals the combination meter (unified meter control unit) via CAN communication lines and a low oil

pressure indication is displayed by the oil pressure gauge.

A/T OIL TEMPERATURE GAUGE

The A/T oil temperature gauge indicates the A/T fluid temperature.

TCM (transmission control module) provides an A/T flui d temperature signal to combination meter via CAN

communication lines.

VOLTAGE GAUGE

The voltage gauge indicates the battery/charging system voltage.

The voltage gauge is regulated by the unified meter control unit.

TA C H O M E T E R

The tachometer indicates engine speed in revolutions per minute (rpm).

ECM provides an engine speed signal to combination meter via CAN communication lines.

FUEL GAUGE

The fuel gauge indicates the approximate fuel level in the fuel tank.

The fuel gauge is regulated by the unified meter control unit and a variable resistor signal supplied

• to combination meter terminal 15.

• through fuel level sensor unit and fuel pump terminal 2

• through fuel level sensor unit and fuel pump terminal 5

• from combination meter terminal 16

SPEEDOMETER

ABS actuator and electric unit (contro l unit) provides a vehicle speed signal to the combination meter via CAN

communication lines.

ODO/TRIP METER

The vehicle speed signal and the memory signals from the meter memory circuit are processed by the combi-

nation meter and the mileage is displayed.

How to Change the Display

Refer to Owner's Manual for odo/tr ip meter operating instructions.

CAN COMMUNICATION SYSTEM DESCRIPTION

Refer to LAN-4.

Page 1028 of 3061

COMBINATION METERSDI-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

Refer to DI-9, "Wiring Diagram - METER -".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate caus e of malfunction before installing new fuse. Refer to PG-

3.

2.CHECK POWER SUPPLY CIRCUIT

1. Disconnect combination meter connector.

2. Check voltage between combination meter harness connector terminals and ground.

OK or NG

OK >> GO TO 3.

NG >> Check the harness for open between combination meter and fuse.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between combination meter harness connector terminal and ground.

OK or NG

OK >> Inspection End.

NG >> Repair harness or connector.

Vehicle Speed Signal InspectionINFOID:0000000003533491

1.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS

Refer to BRC-26, "

CONSULT-II Function (ABS)".

OK or NG

OK >> Replace the combination meter. Refer to IP-10, "Removal and Installation".

NG >> Perform "Diagnostic Procedure" for displayed DTC. Refer to BRC-26, "

CONSULT-II Function

(ABS)".

Engine Oil Pressure Signal InspectionINFOID:0000000003533492

1.CHECK SELF-DIAGNOSTIC RESULTS OF IPDM E/R

Select "IPDM E/R" on CONSULT-II, and perform self-diagnosis of IPDM E/R. Refer to PG-18, "

CONSULT-II

Function (IPDM E/R)".

Unit Power source Fuse No.

Combination meter Battery 19

Ignition switch ON or START 14

Terminals Ignition switch position

(+) (–) OFF ACC ON

Connector Terminal

M24 8

Ground Battery

voltage Battery

voltage Battery

voltage

24 0V 0V Battery

voltage

WKIA5606E

Te r m i n a l s

Continuity

(+)

(–)

Connector Terminal

M24 17 Ground Yes

WKIA1526E

Page 1108 of 3061

ENGINE CONTROL SYSTEM

EC-25

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

*1: This sensor is not used to control the engine system. This is used only for the on board diagnosis.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the crankshaft position sensor and the mass air

flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compensated to improve engine performance under various operat-

ing conditions as listed below.

• When starting the engine

• During acceleration

• Hot-engine operation

• When selector lever is changed from N to D

• High-load, high-speed operation

• During deceleration

• During high engine speed operation

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Engine speed*

3

Piston position

Fuel injection

& mixture ratio

controlFuel injector Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch Gear position

Knock sensor Engine knocking condition

Battery

Battery voltage*

3

Power steering pressure sensor Power steering operation

Heated oxygen sensor 2*

1Density of oxygen in exhaust gas

ABS actuator and electric unit (control unit)

VDC/TCS operation command*

2

Air conditioner switch

Air conditioner operation*2

Wheel sensor

Vehicle speed*2

PBIB3020E

Page 1123 of 3061

EC-40

< SERVICE INFORMATION >

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

System DescriptionINFOID:0000000003531598

From the beginning of refueling, the air and vapor inside the fuel tank go through refueling EVAP vapor cut

valve and EVAP/ORVR line to the EVAP canister. The vapor is absorbed by the EVAP canister and the air is

released to the atmosphere.

When the refueling has reached the full level of the fuel tank, the refueling EVAP vapor cut valve is closed and

refueling is stopped because of auto shut-off. The vapor which was absorbed by the EVAP canister is purged

during driving.

WARNING:

When conducting inspections below, be sure to observe the following:

• Put a “CAUTION: FLAMMABLE” sign in workshop.

• Do not smoke while servicing fuel system. Keep open flames and sparks away from work area.

• Be sure to furnish the workshop with a CO

2 fire extinguisher.

CAUTION:

• Before removing fuel line parts, carry out the following procedures:

- Put drained fuel in an explosion-proof container and put lid on securely.

- Release fuel pressure from fuel line. Refer to EC-80, "

Fuel Pressure Check" .

- Disconnect battery ground cable.

• Always replace O-ring when the fuel gauge retainer is removed.

• Do not kink or twist hose and tube when they are installed.

• Do not tighten hose and clamps excessively to avoid damaging hoses.

• After installation, run engine and check for fuel leaks at connection.

• Do not attempt to top off the fuel tank after the fuel pump nozzle shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray and possibly a fire.

Diagnosis ProcedureINFOID:0000000003531599

SYMPTOM: FUEL ODOR FROM EVAP CANISTER IS STRONG.

1.CHECK EVAP CANISTER

1. Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

2. Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 2.5 kg (5.5 lb).

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK IF EVAP CANISTER SATURATED WITH WATER

PBIB1068E

Page 1137 of 3061

EC-54

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

A sample of CONSULT-II display for DTC and 1st trip DTC is shown below. DTC or 1st trip DTC of a malfunc-

tion is displayed in SELF-DIAGNOSTIC RESULTS mode of CONSULT-II. Time data indicates how many times

the vehicle was driven after the last detection of a DTC.

If the DTC is being detected currently, the time data will be [0].

If a 1st trip DTC is stored in the ECM, the time data will be [1t].

FREEZE FRAME DATA AND 1ST TRIP FREEZE FRAME DATA

The ECM records the driving conditions such as fuel system status, calculated load value, engine coolant tem-

perature, short term fuel trim, long term fuel trim, engine speed, vehicle speed, absolute throttle position, base

fuel schedule and intake air temperature at the moment a malfunction is detected.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data.

The data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-II or

GST. The 1st trip freeze frame data can only be displayed on the CONSULT-II screen, not on the GST. For

details, see E C - 111 , "

CONSULT-II Function (ENGINE)".

Only one set of freeze frame data (either 1st trip freeze frame data or freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

For example, the EGR malfunction (Priority: 2) was detected and the freeze frame data was stored in the 2nd

trip. After that when the misfire (Priority: 1) is detected in another trip, the freeze frame data will be updated

from the EGR malfunction to the misfire. The 1st trip freeze frame data is updated each time a different mal-

function is detected. There is no priority for 1st trip freeze frame data. However, once freeze frame data is

stored in the ECM memory, 1st trip freeze data is no longer stored (because only one freeze frame data or 1st

trip freeze frame data can be stored in the ECM). If freeze frame data is stored in the ECM memory and freeze

frame data with the same priority occurs later, the first (original) freeze frame data remains unchanged in the

ECM memory.

Both 1st trip freeze frame data and freeze frame data (along with the DTCs) are cleared when the ECM mem-

ory is erased. Procedures for clearing the ECM memory are described in "HOW TO ERASE EMISSION-

RELATED DIAGNOSTIC INFORMATION".

SYSTEM READINESS TEST (SRT) CODE

System Readiness Test (SRT) code is specified in Service $01 of SAE J1979.

As part of an enhanced emissions test for Inspection & Maintenance (I/M), certain states require the status of

SRT be used to indicate whether the ECM has completed self-diagnosis of major emission systems and com-

ponents. Completion must be verified in order for the emissions inspection to proceed.

If a vehicle is rejected for a State emissions inspection due to one or more SRT items indicating “INCMP”, use

the information in this Service Manual to set the SRT to “CMPLT”.

In most cases the ECM will automatically complete its self-diagnosis cycle during normal usage, and the SRT

status will indicate “CMPLT” for each application system. Once set as “CMPLT”, the SRT status remains

“CMPLT” until the self-diagnosis memory is erased.

Occasionally, certain portions of the self-diagnostic test may not be completed as a result of the customer's

normal driving pattern; the SRT will indicate “INCMP” for these items.

PBIB0911E

Priority Items

1Freeze frame data Misfire — DTC: P0300 - P0308

Fuel Injection System Function — DTC: P0171, P0172, P0174, P0175

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

Page 1174 of 3061

TROUBLE DIAGNOSIS

EC-91

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

SYSTEM — ENGINE MECHANICAL & OTHER

Camshaft position sensor (PHASE) circuit 3 2EC-342

Vehicle speed signal circuit 2 3 3 3EC-429

Power steering pressure sensor circuit 2 3 3EC-435

ECM 22333333333EC-440,

EC-444

Intake valve timing control solenoid valve cir-

cuit32 13223 3EC-178

Park/Neutral position (PNP) switch circuit 3 3 3 3 3EC-452

Refrigerant pressure sensor circuit 2 3 3 4EC-638

Electrical load signal circuit 3EC-606

Air conditioner circuit 223333333 3 2AT C - 3 0

ABS actuator and electric unit (control unit) 4EC-467

,

EC-468

or BRC-11

SYMPTOM

Refer-

ence page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Page 1197 of 3061

EC-114

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

*: This function is not necessary in the usual service procedure.

SELF-DIAG RESULTS MODE

Self Diagnostic Item

Regarding items of DTC and 1st trip DTC, refer to EC-49, "Emission-related Diagnostic Information".

Freeze Frame Data and 1st Trip Freeze Frame Data

EVAP SYSTEM CLOSE CLOSE THE EVAP CANISTER VENT CONTROL VALVE IN

ORDER TO MAKE EVAP SYSTEM CLOSE UNDER THE

FOLLOWING CONDITIONS.

• IGN SW ON

• ENGINE NOT RUNNING

• AMBIENT TEMPERATURE IS ABOVE 0°C (32°F).

• NO VACUUM AND NO HIGH PRESSURE IN EVAP SYS-

TEM

• FUEL TANK TEMP. IS MORE THAN 0°C (32°F).

• WITHIN 10 MINUTES AFTER STARTING “EVAP SYS-

TEM CLOSE”

• WHEN TRYING TO EXECUTE “EVAP SYSTEM CLOSE”

UNDER THE CONDITION EXCEPT ABOVE, CONSULT-

II WILL DISCONTINUE IT AND DISPLAY APPROPRIATE

INSTRUCTION.

NOTE:

WHEN STARTING ENGINE, CONSULT-II MAY DISPLAY

“BATTERY VOLTAGE IS LOW. CHARGE BATTERY”,

EVEN IN USING CHARGED BATTERY.When detecting EVAP vapor leak

point of EVAP system

VIN REGISTRATION • IN THIS MODE, VIN IS REGISTERED IN ECM When registering VIN in ECM

TARGET IDLE RPM ADJ* • IDLE CONDITION When setting target idle speed

TARGET IGN TIM ADJ* • IDLE CONDITION When adjusting target ignition tim-

ing WORK ITEM CONDITION USAGE

Freeze frame data

item*Description

DIAG TROUBLE

CODE

[PXXXX]• The engine control component part/control system has a trouble code, it is displayed as PXXXX. (Refer to

EC-9

.)

FUEL SYS-B1 • “Fuel injection system status” at the moment a malfunction is detected is displayed.

• One mode in the following is displayed.

Mode2: Open loop due to detected system malfunction

Mode3: Open loop due to driving conditions (power enrichment, deceleration enleanment)

Mode4: Closed loop - using oxygen sensor(s) as feedback for fuel control

Mode5: Open loop - has not yet satisfied condition to go to closed loop FUEL SYS-B2

CAL/LD VALUE [%] • The calculated load value at the moment a malfunction is detected is displayed.

COOLANT TEMP

[°C] or [°F]• The engine coolant temperature at the moment a malfunction is detected is displayed.

L-FUEL TRM-B1 [%] • “Long-term fuel trim” at the moment a malfunction is detected is displayed.

• The long-term fuel trim indicates much more gradual feedback compensation to the base fuel schedule than

short-term fuel trim. L-FUEL TRM-B2 [%]

S-FUEL TRM-B1 [%] • “Short-term fuel trim” at the moment a malfunction is detected is displayed.

• The short-term fuel trim indicates dynamic or instantaneous feedback compensation to the base fuel sched-

ule. S-FUEL TRM-B2 [%]

ENGINE SPEED [rpm] • The engine speed at the moment a malfunction is detected is displayed.

VEHICL SPEED

[km/h] or [mph]• The vehicle speed at the moment a malfunction is detected is displayed.

ABSOL TH-P/S

[%]• The throttle valve opening at the moment a malfunction is detected is displayed.

Page 1512 of 3061

DTC P0500 VSS

EC-429

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P0500 VSS

DescriptionINFOID:0000000003531931

NOTE:

•If DTC P0500 is displayed with DTC U1000 or U1001, first perform the trouble diagnosis for DTC

U1000, U1001. Refer to EC-145

.

•If DTC P0500 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer

to EC-147

.

The vehicle speed signal is sent to the combination meter from the “ABS actuator and electric unit (control

unit)” by CAN communication line. The c combination meter then sends a signal to the ECM by CAN commu-

nication line.

On Board Diagnosis LogicINFOID:0000000003531932

FA I L - S A F E M O D E

When the malfunction is detected, the ECM enters fail-safe mode.

DTC Confirmation ProcedureINFOID:0000000003531933

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Steps 1 and 2 may be conducted with the drive wheels lifted in the shop or by driving the vehicle. If a

road test is expected to be easier, it is unnecessary to lift the vehicle.

WITH CONSULT-II

1. Start engine (VDC switch OFF).

2. Read “VHCL SPEED SE” in “DATA MONITOR” mode with CONSULT-II. The vehicle speed on CONSULT-

II should exceed 10 km/h (6 MPH) when rotating wheels with suitable gear position.

If NG, go to EC-430, "

Diagnosis Procedure".

If OK, go to following step.

3. Select “DATA MONITOR” mode with CONSULT-II.

4. Warm engine up to normal operating temperature.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0500

0500Vehicle speed sensorThe almost 0 km/h (0 MPH) signal from

vehicle speed sensor is sent to ECM even

when vehicle is being driven.• Harness or connectors

(The CAN communication line is open or short-

ed)

• Harness or connectors

(The vehicle speed signal circuit is open or

shorted)

• Wheel sensor

• Combination meter

• ABS actuator and electric unit (control unit)

Detected items Engine operating condition in fail-safe mode

Vehicle speed sensorWhen the fail-safe system for vehicle speed sensor is activated, the cooling fan operates (High) while

engine is running.