transmission INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2014 of 3061

GI-48

< SERVICE INFORMATION >

IDENTIFICATION INFORMATION

ENGINE SERIAL NUMBER

TRANSFER SERIAL NUMBER

AUTOMATIC TRANSMISSION NUMBER

DimensionsINFOID:0000000003531505

Unit: mm (in)

Wheels & TiresINFOID:0000000003531506

LAIA0044E

LAIA0048E

PAIA0054E

Drive type2WD 4WD

Overall length 5255 (206.9) 5255 (206.9)

Overall width 2001 (78.8) 2001 (78.8)

Overall height (with roof rack) 1976.8 (77.0) 1997.7 (77.8)

Front tread width 1725 (67.9) 1725 (67.9)

Rear tread width 1725 (67.9) 1725 (67.9)

Wheelbase 3130 (123.2) 3130 (123.2)

Minimum Running Ground Clearance (at front suspen-

sion)With standard

undercover254.8 (10.03) 273.7 (10.77)

With oil pan skid

plate250.5 (9.86) 269.5 (10.61)

Page 2019 of 3061

TERMINOLOGY

GI-53

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P

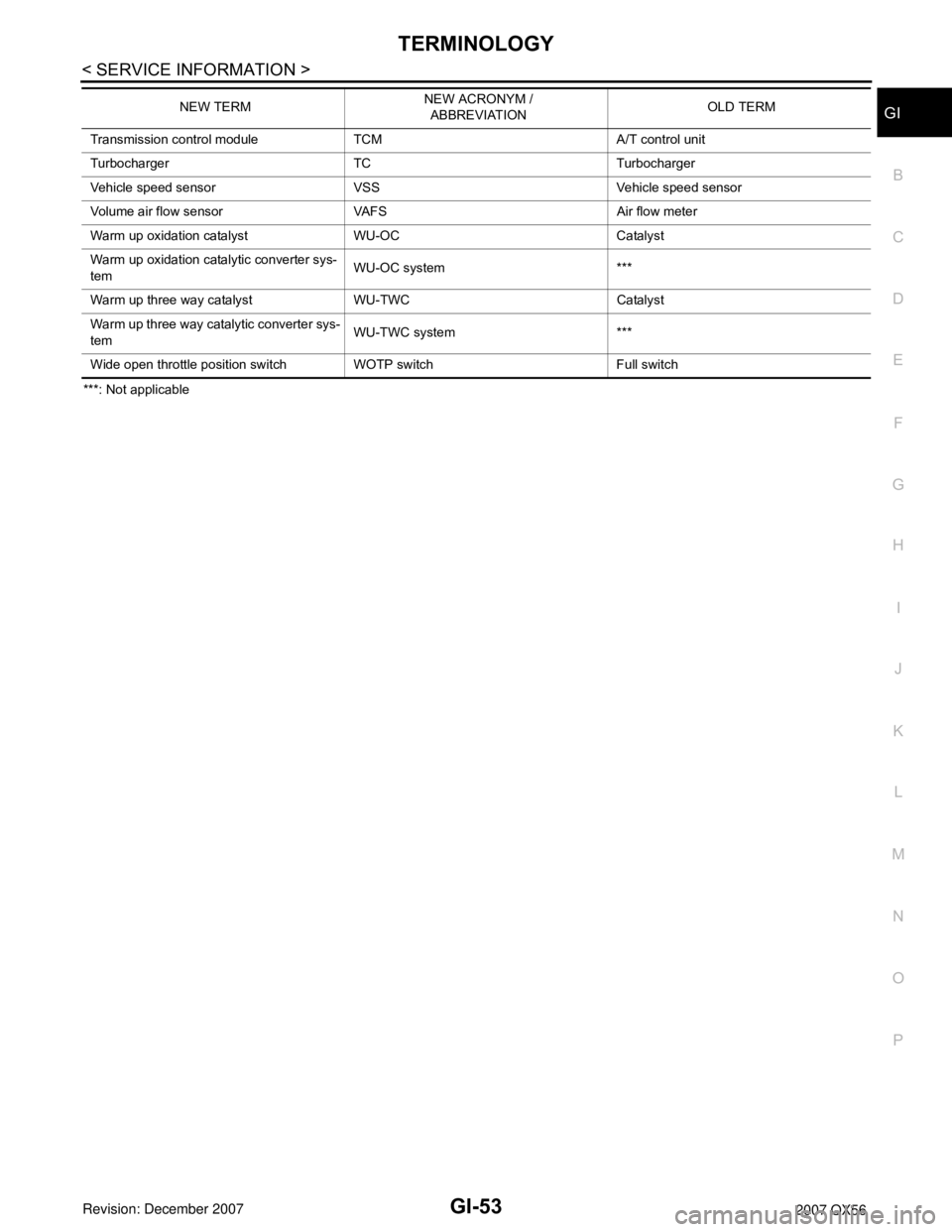

***: Not applicableTransmission control module TCM A/T control unit

Turbocharger TC Turbocharger

Vehicle speed sensor VSS Vehicle speed sensor

Volume air flow sensor VAFS Air flow meter

Warm up oxidation catalyst WU-OC Catalyst

Warm up oxidation catalytic converter sys-

temWU-OC system ***

Warm up three way catalyst WU-TWC Catalyst

Warm up three way catalytic converter sys-

temWU-TWC system ***

Wide open throttle position switch WOTP switch Full switchNEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Page 2106 of 3061

IDX-2

ALPHABETICAL INDEX

Numerics

2-4WD shift solenoid valve ..... TF-93

, TF-154, TF-167

4WD - Wiring diagram ....................................... TF-24

4WD shift switch ................................................ TF-65

4WD solenoid valve ................ TF-89, TF-154, TF-167

4WD system description .................................... TF-15

4WD system diagram ........................................ TF-19

A

A/C air flow ...................................................... ATC-30

A/C compressor clutch removal and installation .. ATC-

180

A/C compressor mounting ............................. ATC-179

A/C compressor precaution ............................. ATC-11

A/C compressor special service tool ................ ATC-14

A/C control operation (auto A/C) ...................... ATC-27

A/C diagnostic work flow (auto A/C) .............. ATC-133

A/C evaporator ............................................... ATC-186

A/C HFC134a (R134a) system identification ..... ATC-6

A/C HFC134a (R134a) system precaution ........ ATC-5

A/C HFC134a (R134a) system service procedure ATC-

175

A/C HFC134a (R134a) system service tools ... ATC-14

A/C HFC134a system service equipment precaution ...

ATC-11

A/C lubricant (R134a) ...................................... ATC-22

A/C lubrication oil ............................................. ATC-22

A/C operational check ....................... ATC-56, ATC-58

A/C self-diagnoses (auto A/C) ........ ATC-54, ATC-133

A/C service data specification ........................ ATC-193

A/C trouble diagnoses (auto A/C) .................... ATC-34

A/C, A - Wiring diagram ................................... ATC-42

A/T fluid checking ...................... AT-12, AT-51, MA-22

A/T fluid cooler cleaning .................................... AT-14

A/T fluid replacement ............................. AT-12, MA-24

A/T fluid temperature sensor ........................... AT-123

A/T IND - Wiring diagram .................................... DI-36

A/T indicator ........................................................ DI-36

A/T shift lock system ........................................ AT-216

A/T trouble diagnoses ........................................ AT-42

ABS - Wiring diagram ..................................... BRC-16

ABS (anti-lock brake system) ........................... BRC-7

Accelerator control system ............................... ACC-3

Accelerator pedal position (APP) sensor . EC-608, EC-

614, EC-628

Accelerator pedal released position learning ..... EC-80

AF1B1-Wiring diagram EC-242, EC-250, EC-258, EC-

267, EC-638

AF1B2-Wiring diagram EC-244, EC-252, EC-260, EC-

269, EC-640

AF1HB1-Wiring diagram .................................. EC-175

AF1HB2-Wiring diagram .................................. EC-177

Aiming adjustment .................................. LT-23, LT-61

Air bag .............................................................. SRS-3

Air bag precautions .............................................. AV-4

Air cleaner and air duct ..................................... EM-15

Air cleaner filter replacement ................ EM-16, MA-16

Air conditioner cut control ................................. EC-29

Air flow meter - See Mass air flow sensor EC-197, EC-

206

Air fuel ratio sensor 1 .. EC-239, EC-248, EC-256, EC-

264, EC-636

Air fuel ratio sensor 1 heater ........................... EC-174

Air mix. door motor .......................................... ATC-69

Ambient sensor ............................. ATC-138, ATC-149

Angular tightening application ............................. EM-4

Antenna .............................................................. AV-58

APPS1 - Wiring diagram ................................. EC-610

APPS2 - Wiring diagram ................................. EC-616

APPS3 - Wiring diagram ................................. EC-630

ASC/BS - Wiring diagram ............................... EC-574

ASC/SW - Wiring diagram .............................. EC-557

ASCBOF - Wiring diagram .............................. EC-648

ASCD ................................................................ EC-30

ASCD (automatic speed control device) ........... ACS-3

ASCD brake switch ........................... EC-572, EC-647

ASCD indicator lamp ....................................... EC-654

ASCD steering switch ..................................... EC-555

ASCIND - Wiring diagram ............................... EC-655

ATP switch ............................ TF-106, TF-109, TF-114

Audio .................................................................... AV-6

AUDIO - Wiring diagram .................................... AV-11

AUT/DP - Wiring diagram .................................. SE-16

Auto air conditioner - Wiring diagram .............. ATC-42

Auto anti-dazzling inside mirror ........... GW-69, GW-70

Autolamp ............................................................ LT-38

Automatic amplifier ......................................... ATC-59

Automatic drive positioner .................................. SE-11

Automatic transmission number .......................... GI-50

B

Back door ........................................................... BL-88

Back door trim ..................................................... EI-32

Back sonar .......................................................... DI-50

BACK/L - Wiring diagram ................................... LT-87

Back-up lamp ..................................................... LT-87

Ball joint (front) ................................................ FSU-15

Basic inspection ................................................ EC-73

Battery ................................................................. SC-4

Battery current sensor . EC-520, EC-527, EC-534, EC-

541

Battery/Starting/Charging System Tester SC-6, SC-12,

SC-20

BCM (Body control module) ................ BCS-3, AV-106

Block heater ...................................................... EM-78

Blower motor ................................... ATC-93, ATC-153

Body alignment ................................................ BL-164

Body component parts ..................................... BL-151

Body construction ............................................ BL-163

Body exterior paint color .................................. BL-150

Body mounting ................................................. BL-149

Body repair ....................................................... BL-150

Body sealing .................................................... BL-160

Bose speaker amp. .............................................. AV-8

Brake booster .................................................... BR-17

Page 2112 of 3061

IDX-8

ALPHABETICAL INDEX

Three way catalyst ............................................ EM-21

Three way catalyst function (Bank 1) ............... EC-376

Three way catalyst function (Bank 2) ............... EC-376

Three way catalyst precautions ............................ GI-5

Throttle control motor ....................................... EC-601

Throttle control motor relay .............................. EC-589

Throttle position sensor (TPS) .. EC-224, EC-343, EC-

514, EC-516, EC-621

Throttle valve closed position learning ............... EC-80

Tie-rod ............................................................... PS-15

Timing chain ..................................................... EM-37

Tire rotation ....................................................... MA-28

Tire size .............................................................. GI-51

Torque converter installation AT-239, AT-240, AT-243,

AT-244

Torque convertor clutch solenoid valve ... AT-114, AT-

116

Tow truck towing ................................................. GI-44

Towing point ....................................................... GI-45

TPS1 - Wiring diagram .................................... EC-345

TPS2 - Wiring diagram .................................... EC-226

TPS3 - Wiring diagram .................................... EC-623

Traction control system - Wiring diagram ....... BRC-16

Transfer control device ............. TF-75, TF-79, TF-138

Transfer control unit inspection table ................. TF-35

Transfer dropping resistor .................................. TF-89

Transfer fluid temperature sensor TF-103, TF-154, TF-

167

Transfer motor .................................... TF-101, TF-142

Transfer motor relay ........................................ TF-101

Transfer oil replacement ................................... MA-24

Transfer serial number ........................................ GI-50

Transmission serial number ................................ GI-50

Tread-FR&RR (Dimensions) ............................... GI-51

Trim ..................................................................... EI-35

TRNSCV - Wiring diagram .................. BL-130, BL-146

Trouble diagnoses .............................................. GI-11

Turbine revolution sensor ................................ AT-105

TURN - Wiring diagram ...................................... LT-67

Turn signal lamp ................................................. LT-63

Two trip detection logic ...................................... EC-49

Two-pole lift ........................................................ GI-43

V

Vacuum hose (brake system) ............................ BR-20

Vacuum hose drawing (Engine control) ........... EC-106

Valve clearance ................................................ EM-55

Valve guide ....................................................... EM-69

Vanity mirror lamp ............................................. LT-110

VDC (vehicle dynamics control) ........................ BRC-7

VDC -Wiring diagram ...................................... BRC-16

Vehicle identification number .............................. GI-49

Vehicle recovery (freeing a stuck vehicle) .......... GI-45

Vehicle security (theft warning) system ............. BL-67

Vehicle speed sensor (VSS) ............................ EC-464

VEHSEC - Wiring diagram ................................. BL-71

VENT/V - Wiring diagram .................. EC-412, EC-419

VIN registration .................................................. EC-79

Viscosity number (SAE) .................................... MA-12

VSS A/T - Wiring diagram .................. AT-107, AT-109

W

W/ANT - Wiring diagram .................................... AV-59

Wait detection switch ......................................... TF-68

WARN - Wiring diagram ...................................... DI-29

Warning chime .................................................... DI-38

Warning lamps .................................................... DI-28

Washer, front ..................................................... WW-4

Washer, rear .................................................... WW-29

Water pump ...................................................... CO-19

Water temperature gauge ..................................... DI-5

Wheel alignment (front) ..................................... FSU-6

Wheel alignment (rear) ................................... RSU-25

Wheel bearing (front) ........................................ FAX-5

Wheel bearing (rear) ......................................... RAX-5

Wheel hub (rear) ............................................... RAX-5

Wheel size .......................................................... GI-51

Wheelbase (Dimensions) .................................... GI-51

Width (Dimensions) ............................................. GI-51

WINDOW - Wiring diagram .............................. GW-22

Window, door ...................................... GW-62, GW-65

Windshield ....................................................... GW-11

WIP/R - Wiring diagram ................................... WW-33

WIPER - Wiring diagram .................................... WW-8

Wiper, front ........................................................ WW-4

Wiper, rear ....................................................... WW-29

Wiring Diagram (Cell code) list ......................... PG-62

Wiring diagrams .................................................. GI-15

WT-T/WARN - Wiring diagram .......................... WT-11

Page 2129 of 3061

INSTRUMENT PANEL ASSEMBLY

IP-17

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

IP

N

O

P Disassembly

1. Remove mats from storage compartment and console bin.

2. Remove latch from console lid and remove key cylinder from latch.

3. Remove console lid.

4. Remove console bin.

5. Disconnect electrical harness from DVD player (if equipped).

6. Remove hinge.

7. Remove rear upper finisher.

8. Remove rear cup holder assembly.

9. Remove rear finisher assembly.

10. Disconnect rear finisher assembly electrical connectors.

11. Remove console power socket.

12. Remove upper side finishers LH/RH.

13. Remove heat duct and console rear duct.

14. Disconnect clips and remove console covers LH/RH.

15. Remove mask and storage compartment.

16. Remove console front bracket.

17. Remove console rear bracket.

Assembly

Assembly is in the reverse order of disassembly.

REAR CONSOLE

19. Console bin 20. Console cover RH 21. Center console lower cover RH

22. Lower side finisher RH 23. A/T transmission control 24. Mask

25. Cup holder insert

Page 2136 of 3061

![INFINITI QX56 2007 Factory Service Manual SYSTEM DESCRIPTION

LAN-5

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

CAN COMMUNICATION CONTROL CIRCUIT

*: These are the only control units wired with both ends of CAN com INFINITI QX56 2007 Factory Service Manual SYSTEM DESCRIPTION

LAN-5

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

CAN COMMUNICATION CONTROL CIRCUIT

*: These are the only control units wired with both ends of CAN com](/img/42/57029/w960_57029-2135.png)

SYSTEM DESCRIPTION

LAN-5

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

CAN COMMUNICATION CONTROL CIRCUIT

*: These are the only control units wired with both ends of CAN communication system.

Diag on CANINFOID:0000000003533610

DESCRIPTION

“Diag on CAN” is a diagnosis using CAN communication instead of previous DDL1 and DDL2 communication

line, between control unit and diagnosis unit.

SKIB8713E

Component System description

CAN controller It controls CAN communication signal transmission and reception, error detection, etc.

Transceiver ICIt converts digital signal into CAN communication signal, and CAN communication signal into digital

signal.

Noise filter It eliminates noise of CAN communication signal.

Termination circuit

*

(Resistance of approx. 120 Ω)It produces potential difference.

Page 2139 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-8

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Data link connector branch line open circuit

NOTE:

• When data link connector branch line is open, transmission and receptio INFINITI QX56 2007 Factory Service Manual LAN-8

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Data link connector branch line open circuit

NOTE:

• When data link connector branch line is open, transmission and receptio](/img/42/57029/w960_57029-2138.png)

LAN-8

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Data link connector branch line open circuit

NOTE:

• When data link connector branch line is open, transmission and reception of CAN communication signals is

not affected. Therefore, no symptoms occur. However, be sure to repair malfunctioning circuit.

• When data link connector branch line is open, the screen-display of the CONSULT-II “SELECT SYSTEM”

screen may be the same as when the CAN communication line has short-circuit. However, symptoms differ

depending on the case. See below chart for the differences.

Unit name Symptom

ECM Engine torque limiting is affected, and shift harshness increases.

BCM Reverse warning chime does not sound.

EPS control unit Normal operation.

Combination meter• Shift position indicator and OD OFF indicator turn OFF.

• Warning lamps turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R Normal operation.

SKIB8739E

Unit name Symptom

ECM

Normal operation. BCM

EPS control unit

Combination meter

ABS actuator and electric unit (control unit)

TCM

IPDM E/R

SELECT SYSTEM

(CONSULT-II)Difference of symptom

Data link connector branch line open circuit

All Diag on CAN units are not

indicated.Normal operation.

CAN-H, CAN-L harness short-circuitMost the units which are connected to the CAN com-

munication system enter fail-safe mode or are deac-

tivated.

Page 2142 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-11

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Example: CAN DIAG SUPPORT MNTR indication

Without PAST

With PAST

MONITOR ITEM (ON-BOARD DIAGNOSIS)

NO INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-11

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Example: CAN DIAG SUPPORT MNTR indication

Without PAST

With PAST

MONITOR ITEM (ON-BOARD DIAGNOSIS)

NO](/img/42/57029/w960_57029-2141.png)

TROUBLE DIAGNOSIS

LAN-11

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Example: CAN DIAG SUPPORT MNTR indication

Without PAST

With PAST

MONITOR ITEM (ON-BOARD DIAGNOSIS)

NOTE:

• For some models, CAN communication diagnosis result is received from the vehicle monitor. (CONSULT-II

is not available.)

• Refer to LAN-40, "

CAN Diagnostic Support Monitor" for the details.

SKIB8742E

Item PRSNT Description

Initial diagnosisOK Normal at present

NG Control unit error (Except for some control units)

Transmission diagnosisOK Normal at present

UNKWNUnable to transmit signals for 2 seconds or more.

Diagnosis not performed

Control unit name

(Reception diagnosis)OK Normal at present

UNKWNUnable to receive signals for 2 seconds or more.

Diagnosis not performed

No control unit for receiving signals. (No applicable optional parts)

Item PRSNT PAST Description

Transmission diagnosisOKOK Normal at present and in the past

1 – 39Normal at present, but unable to transmit signals for 2 seconds or more

in the past. (The number indicates the number of ignition switch cycles

from OFF to ON.)

UNKWN 0 Unable to transmit signals for 2 seconds or more at present.

Control unit name

(Reception diagnosis)OKOK Normal at present and in the past

1 – 39Normal at present, but unable to receive signals for 2 seconds or more

in the past. (The number indicates the number of ignition switch cycles

from OFF to ON.)

UNKWN 0 Unable to receive signals for 2 seconds or more at present

––Diagnosis not performed.

No control unit for receiving signals. (No applicable optional parts)

Page 2143 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-12

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Vehicle Display

ItemResult indi-

catedError counter Description

CAN_COMM

(Initial diagnosis)OK 0 Normal at present

NG 1 – INFINITI QX56 2007 Factory Service Manual LAN-12

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Vehicle Display

ItemResult indi-

catedError counter Description

CAN_COMM

(Initial diagnosis)OK 0 Normal at present

NG 1 –](/img/42/57029/w960_57029-2142.png)

LAN-12

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Vehicle Display

ItemResult indi-

catedError counter Description

CAN_COMM

(Initial diagnosis)OK 0 Normal at present

NG 1 – 50Control unit error

(The number indicates how many times diagnosis has been

run.)

CAN_CIRC_1

(Transmission diagnosis)OK 0 Normal at present

UNKWN 1 – 50Unable to transmit for 2 seconds or more at present.

(The number indicates how many times diagnosis has been

run.)

CAN_CIRC_2 – 9

(Reception diagnosis of each unit)OK 0 Normal at present

UNKWN 1 – 50Unable to transmit for 2 seconds or more at present.

(The number indicates how many times diagnosis has been

run.)

Diagnosis not performed.

No control unit for receiving signals. (No applicable optional

parts)

Page 2144 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-13

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

TROUBLE DIAGNOSES WORK FLOW

Information Needed for Trouble DiagnosisINFOID:0000000003533615 INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-13

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

TROUBLE DIAGNOSES WORK FLOW

Information Needed for Trouble DiagnosisINFOID:0000000003533615](/img/42/57029/w960_57029-2143.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-13

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

TROUBLE DIAGNOSES WORK FLOW

Information Needed for Trouble DiagnosisINFOID:0000000003533615

CAN communication system performs trouble diagnosis with the following tools.

How to Use CAN Communication Signal ChartINFOID:0000000003533616

The CAN communication signal chart lists the signals needed for trouble diagnosis. It is useful for detecting

the root cause by finding a signal related to the symptom, and by checking transmission and reception unit.

To o l U s a g e

Interview sheet For filling in vehicle information and interview with customer.

Data sheet For attaching CONSULT-II data or on-board diagnosis data.

Diagnosis sheet For detecting the root cause. (Diagnosis sheet includes system diagram for every CAN system type)

SELECT SYSTEM

(CONSULT-II)

For checking the condition of control units and the status of CAN communication. SELF-DIAG RESULTS

(CONSULT-II)

CAN DIAG SUPPORT MNTR

(CONSULT-II)

CAN communication signal

chartFor converting information received from a customer into CAN communication signal transmission

and reception. This information can be used to judge whether a circuit between control units is nor-

mal or abnormal.

Abbreviation list For checking abbreviations in CAN communication signal chart and diagnosis sheet.

SKIB8715E