transmission INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1065 of 3061

DI-54

< SERVICE INFORMATION >

REAR SONAR SYSTEM

Symptom Chart

INFOID:0000000003533533

Symptom Repair order

When the rear sonar system OFF switch is OFF, the indicator

lamp does not light and the buzzer does not sound.1. Check rear sonar system OFF switch for malfunction. Refer

to DI-55, "

Component Inspection".

2. Check rear sonar system OFF switch ground circuit.

3. Check harness and connections between rear sonar system

OFF switch and sonar control unit.

4. Replace sonar control unit. Refer to DI-55, "

Removal and In-

stallation".

When the rear sonar system OFF switch is OFF, the indicator

lamp does not light but buzzer sounds.1. Check rear sonar system OFF indicator for malfunction. Re-

fer to DI-55, "

Component Inspection".

2. Check harness and connections between rear sonar system

OFF indicator and sonar control unit.

3. Replace sonar control unit. Refer to DI-55, "

Removal and In-

stallation".

When the rear sonar system OFF switch is OFF, the sonar buzzer

does not sound but indicator lamp illuminates.1. Check sonar buzzer. Refer to DI-55, "

Component Inspec-

tion".

2. Check harness and connections between sonar buzzer and

sonar control unit.

3. Replace sonar control unit. Refer to: DI-55, "

Removal and

Installation".

When rear sonar system OFF switch is ON, the rear sonar system

OFF indicator lamp lights up and the sonar buzzer sounds inter-

mittently (for about 4 seconds).1. Check harness between rear sonar sensors and sonar con-

trol unit for an open condition.

2. Check rear sonar sensors for malfunction.

3. Replace sonar control unit. Refer to DI-55, "

Removal and In-

stallation".

The rear sonar system operates with the rear sonar system OFF

switch OFF.1. Check rear sonar system OFF switch for malfunction. Refer

to DI-55, "

Component Inspection".

2. Check rear sonar system OFF switch ground circuit.

3. Check harness and connections between rear sonar system

OFF switch and sonar control unit.

4. Replace sonar control unit. Refer to DI-55, "

Removal and In-

stallation".

When the transmission gear selector lever is in the R position and

the rear sonar system OFF switch is OFF, the sonar system does

not operate.1. Check for PNP switch failure. Refer to AT- 8 3 , "

CONSULT-II

Function (A/T)".

2. Check harness and connections between sonar control unit

and PNP/reverse lamp circuits.

3. Replace sonar control unit. Refer to DI-55, "

Removal and In-

stallation".

When the rear sonar system OFF switch is OFF, the indicator

lamp lights up and buzzer sounds although there is no obstacle

within the detection range.1. Check for adhesion of snow, mud, or other foreign objects to

rear sonar sensors; dew condensation; etc. Refer to DI-51,

"Pre-diagnosis Inspection".

2. Check that the rear sonar sensor is properly aligned

(bumper is not misaligned, no deformation in sensor mount-

ing area

3. Check harness and connections between rear sonar sen-

sors and sonar control unit.

4. Check rear sonar sensors for malfunction.

5. Replace sonar control unit. Refer to DI-55, "

Removal and In-

stallation".

The rear sonar sensors do not operate according to the distance

between each sensor and the obstacle. (There is a large error in

the obstacle detection distance.1. Check rear sonar sensors for malfunction.

2. Replace sonar control unit. Refer to DI-55, "

Removal and In-

stallation".

3. Check for adhesion of snow, mud, or other foreign objects to

rear sonar sensors; dew condensation; etc. Refer to DI-51,

"Pre-diagnosis Inspection".

4. Check that the rear sonar sensor is properly aligned

(bumper is not misaligned, no deformation in sensor mount-

ing area

Page 1100 of 3061

PRECAUTIONS

EC-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003531580

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

On Board Diagnosis (OBD) System of Engine and A/TINFOID:0000000003531581

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect the negative battery cable before any repair

or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc. will

cause the MIL to light up.

• Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector. For description and how to disconnect, refer to PG-66

.

• Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MIL to light up due to the short circuit.

• Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfunction of the EVAP system or fuel injection system,

etc.

• Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

PrecautionINFOID:0000000003531582

•Always use a 12 volt battery as power source.

•Do not attempt to disconnect battery cables while engine is

running.

•Before connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

•Before removing parts, turn ignition switch OFF and then dis-

connect negative battery cable.

SEF289H

Page 1115 of 3061

EC-32

< SERVICE INFORMATION >

CAN COMMUNICATION

CAN COMMUNICATION

System DescriptionINFOID:0000000003531593

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

Refer to LAN-44, "

CAN System Specification Chart", about CAN communication for detail.

Page 1143 of 3061

EC-60

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

• Sea level

• Flat road

• Ambient air temperature: 20 - 30°C (68 - 86°F)

• Diagnosis is performed as quickly as possible under normal conditions.

Under different conditions [For example: ambient air temperature other than 20 - 30°C (68 - 86°F)], diagno-

sis may also be performed.

Pattern 1:

•The engine is started at the engine coolant temperature of −10 to 35°C (14 to 95°F)

(where the voltage between the ECM terminal 73 and ground is 3.0 - 4.3V).

•The engine must be operated at idle speed until the engine coolant temperature is greater than 70°C

(158°F) (where the voltage between the ECM terminal 73 and ground is lower than 1.4V).

•The engine is started at the fuel tank temperature of warmer than 0°C (32°F) (where the voltage

between the ECM terminal 107 and ground is less than 4.1V).

Pattern 2:

• When steady-state driving is performed again even after it is interrupted, each diagnosis can be conducted.

In this case, the time required for diagnosis may be extended.

Pattern 3:

• Operate vehicle following the driving pattern shown in the figure.

• Release the accelerator pedal during decelerating vehicle speed

from 90 km/h (56 MPH) to 0 km/h (0 MPH).

Pattern 4:

• The accelerator pedal must be held very steady during steady-

state driving.

• If the accelerator pedal is moved, the test must be conducted all

over again.

*1: Depress the accelerator pedal until vehicle speed is 90 km/h (56

MPH), then release the accelerator pedal and keep it released for

more than 10 seconds. Depress the accelerator pedal until vehicle

speed is 90 km/h (56 MPH) again.

*2: Checking the vehicle speed with GST is advised.

Suggested Transmission Gear Position

Set the selector lever in the D position with the overdrive switch turned ON.

TEST VALUE AND TEST LIMIT (GST ONLY — NOT APPLICABLE TO CONSULT-II)

The following is the information specified in Service $06 of SAE J1979.

The test value is a parameter used to determine whether a system/circuit diagnostic test is OK or NG while

being monitored by the ECM during self-diagnosis. The test limit is a reference value which is specified as the

maximum or minimum value and is compared with the test value being monitored.

These data (test value and test limit) are specified by Test ID (TID) and Component ID (CID) and can be dis-

played on the GST screen.

PBIB2244E

Item Self-diagnostic test item DTCTest value (GST display)

Test limit Conversion

TID CID

CATALYSTThree way catalyst function (Bank 1)P0420 01H 01H Max. 1/128

P0420 02H 81H Min. 1

Three way catalyst function (Bank 2)P0430 03H 02H Max. 1/128

P0430 04H 82H Min. 1

EVAP

SYSTEMEVAP control system (Small leak) P0442 05H 03H Max.

1/128 mm

2

EVAP control system purge flow monitoring P0441 06H 83H Min. 20 mV

EVAP control system (Very small leak) P0456 07H 03H Max.

1/128 mm

2

Page 1144 of 3061

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-61

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

HOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION

How to Erase DTC

WITH CONSULT-II

The emission related diagnostic information in the ECM can be erased by selecting “ERASE” in the “SELF-

DIAG RESULTS” mode with CONSULT-II.

If DTCs are displayed for both ECM and TCM (Transmission control module), they need to be erased individu-

ally from the ECM and TCM (Transmission control module).

NOTE:

If the DTC is not for A/T related items (see EC-9

), skip steps 2 through 4.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Turn CONSULT-II ON and touch “A/T”.

3. Touch “SELF-DIAG RESULTS”.

HO2SAir fuel ratio (A/F) sensor 1 (Bank 1)P0131 41H 8EH Min. 5mV

P0132 42H 0EH Max. 5mV

P2A00 43H 0EH Max. 0.002

P2A00 44H 8EH Min. 0.002

P0133 45H 8EH Min. 0.002

P0130 46H 0EH Max. 5mV

P0130 47H 8EH Min. 5mV

P0133 48H 8EH Min. 0.002

Air fuel ratio (A/F) sensor 1 (Bank 2)P0151 4CH 8FH Min. 5mV

P0152 4DH 0FH Max. 5mV

P2A03 4EH 0FH Max. 0.002

P2A03 4FH 8FH Min. 0.002

P0153 50H 8FH Min. 0.002

P0150 51H 0FH Max. 5mV

P0150 52H 8FH Min. 5mV

P0153 53H 8FH Min. 0.002

Heated oxygen sensor 2 (Bank 1)P0139 19H 86H Min. 10mV/500 ms

P0137 1AH 86H Min. 10 mV

P0138 1BH 06H Max. 10 mV

P0138 1CH 06H Max. 10mV

Heated oxygen sensor 2 (Bank 2)P0159 21H 87H Min. 10 mV/500 ms

P0157 22H 87H Min. 10 mV

P0158 23H 07H Max. 10 mV

P0158 24H 07H Max. 10mV

HO2S

HTRA/F sensor 1 heater (Bank 1) P0032 57H 10H Max. 5 mV

P0031 58H 90H Min. 5 mV

A/F sensor 1 heater (Bank 2)P0052 59H 11H Max. 5 mV

P0051 5AH 91H Min. 5 mV

Heated oxygen sensor 2 heater (Bank 1)P0038 2DH 0AH Max. 20 mV

P0037 2EH 8AH Min. 20 mV

Heated oxygen sensor 2 heater (Bank 2)P0058 2FH 0BH Max. 20 mV

P0057 30H 8BH Min. 20 mV Item Self-diagnostic test item DTCTest value (GST display)

Test limit Conversion

TID CID

Page 1145 of 3061

![INFINITI QX56 2007 Factory Service Manual EC-62

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

4. Touch “ERASE”. [The DTC in the TCM (Transmission control module) will be erased.] Then touch “BACK”

twice.

5. Touch “ENGINE� INFINITI QX56 2007 Factory Service Manual EC-62

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

4. Touch “ERASE”. [The DTC in the TCM (Transmission control module) will be erased.] Then touch “BACK”

twice.

5. Touch “ENGINE�](/img/42/57029/w960_57029-1144.png)

EC-62

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

4. Touch “ERASE”. [The DTC in the TCM (Transmission control module) will be erased.] Then touch “BACK”

twice.

5. Touch “ENGINE”.

6. Touch “SELF-DIAG RESULTS”.

7. Touch “ERASE”. (The DTC in the ECM will be erased.)

WITH GST

The emission related diagnostic information in the ECM can be erased by selecting Service $04 with GST.

NOTE:

If the DTC is not for A/T related items (see EC-9

), skip step 2.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform AT-39, "

OBD-II Diagnostic Trouble Code (DTC)". (The DTC in TCM will be erased)

3. Select Service $04 with GST (Generic Scan Tool).

No Tools

NOTE:

If the DTC is not for AT related items (see EC-9

), skip step 2.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once.

Wait at least 10 seconds and then turn it ON (engine stopped) again.

2. Perform AT-39, "

OBD-II Diagnostic Trouble Code (DTC)". (The DTC in the TCM will be erased.)

3. Change the diagnostic test mode from Mode II to Mode I by depressing the accelerator pedal. Refer to

EC-63, "

Malfunction Indicator Lamp (MIL)".

•If the battery is disconnected, the emission-related diagnostic information will be lost within 24

hours.

•The following data are cleared when the ECM memory is erased.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

- Freeze frame data

- 1st trip freeze frame data

- System readiness test (SRT) codes

- Test values

SCIA5671E

Page 1161 of 3061

EC-78

< SERVICE INFORMATION >

BASIC SERVICE PROCEDURE

3. Turn ignition switch OFF wait at least 10 seconds.

Make sure that throttle valve moves during above 10 seconds by confirming the operating sound.

Idle Air Volume LearningINFOID:0000000003531615

DESCRIPTION

Idle Air Volume Learning is an operation to learn the idle air volume that keeps each engine within the specific

range. It must be performed under any of the following conditions:

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

PREPARATION

Before performing Idle Air Volume Learning, make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are missed for even a moment.

• Battery voltage: More than 12.9V (At idle)

• Engine coolant temperature: 70 - 100°C (158 - 212°F)

• Park/Neutral position (PNP) switch: ON

• Electric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

start the headlamp will not be illuminated.

• Steering wheel: Neutral (Straight-ahead position)

• Vehicle speed: Stopped

• Transmission: Warmed-up

- With CONSULT-II: Drive vehicle until “ATF TEMP SE 1” in “DATA MONITOR” mode of “A/T” system indi-

cates less than 0.9V.

- Without CONSULT-II: Drive vehicle for 10 minutes.

OPERATION PROCEDURE

With CONSULT-II

1. Perform EC-77, "Accelerator Pedal Released Position Learning" .

2. Perform EC-77, "

Throttle Valve Closed Position Learning" .

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic PREPARATION (previously mentioned) are in good order.

5. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

6. Touch “START” and wait 20 seconds.

SEF217Z

SEF454Y

Page 1168 of 3061

TROUBLE DIAGNOSIS

EC-85

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

7.PERFORM DATA MONITOR (SPEC) MODE

With CONSULT-II

Make sure that “MAS A/F SE-B1”, “B/FUEL SCHDL”, and “A/F

ALPHA-B1”, “A/F ALPHA-B2” are within the SP value using CON-

SULT-II “DATA MONITOR (SPEC)” mode. Refer to EC-129

.

Are they within the SP value?

Yes >> GO TO 9.

No >> GO TO 8.

8.DETECT MALFUNCTIONING PART BY TROUBLE DIAGNOSIS - SPECIFICATION VALUE

Detect malfunctioning part according to EC-130, "

Diagnosis Procedure" .

Is malfunctioning part detected?

Yes >> GO TO 11.

No >> GO TO 9.

9.DETECT MALFUNCTIONING SYSTEM BY SYMPTOM MATRIX CHART

Detect malfunctioning system according to EC-90, "

Symptom Matrix Chart" based on the confirmed symptom

in step 4, and determine the trouble diagnosis order based on possible causes and symptom.

>> GO TO 10.

10.DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the system.

NOTE:

The Diagnostic Procedure in EC section described based on open circuit inspection. A short circuit inspection

is also required for the circuit check in the Diagnostic Procedure. For details, refer to Circuit Inspection in GI-

25, "How to Perform Efficient Diagnosis for an Electrical Incident".

Is malfunctioning part detected?

Yes >> GO TO 11.

No >> Monitor input data from related sensors or check voltage of related ECM terminals using CON-

SULT-II. Refer to EC-103, "

ECM Terminal and Reference Value" , EC-124, "CONSULT-II Refer-

ence Value in Data Monitor Mode" .

11 .REPAIR OR REPLACE THE MALFUNCTIONING PART

1. Repair or replace the malfunctioning part.

2. Reconnect parts or connectors disconnected during Diagnostic Procedure again after repair and replace-

ment.

3. Check DTC. If DTC is displayed, erase it, refer to EC-49, "

Emission-related Diagnostic Information" .

>> GO TO 12.

12.FINAL CHECK

When DTC was detected in step 2, perform DTC Confirmation Procedure or Overall Function Check again,

and then make sure that the malfunction have been repaired securely.

When symptom was described from the customer, refer to confirmed symptom in step 3 or 4, and make sure

that the symptom is not detected.

OK or NG

NG (DTC*1 is detected)>>GO TO 10.

NG (Symptom remains)>>GO TO 6.

OK >> 1. Before returning the vehicle to the customer, make sure to erase unnecessary DTC*

1 in ECM

and TCM (Transmission Control Module). (Refer to EC-49, "

Emission-related Diagnostic

Information" and AT-39, "OBD-II Diagnostic Trouble Code (DTC)".)

SEF601Z

Page 1212 of 3061

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-129

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000003531630

The specification (SP) value indicates the tolerance of the value that is displayed in “DATA MONITOR (SPEC)”

mode of CONSULT-II during normal operation of the Engine Control System. When the value in “DATA MONI-

TOR (SPEC)” mode is within the SP value, the Engine Control System is confirmed OK. When the value in

“DATA MONITOR (SPEC)” mode is NOT within the SP value, the Engine Control System may have one or

more malfunctions.

The SP value is used to detect malfunctions that may affect the Engine Control System, but will not light the

MIL.

The SP value will be displayed for the following three items:

• B/FUEL SCHDL (The fuel injection pulse width programmed into ECM prior to any learned on board correc-

tion)

• A/F ALPHA-B1/B2 (The mean value of air-fuel ratio feedback correction factor per cycle)

• MAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Testing ConditionINFOID:0000000003531631

• Vehicle driven distance: More than 5,000 km (3,107 miles)

• Barometric pressure: 98.3 - 104.3 kPa (1.003 - 1.064 kg/cm

2 , 14.25 - 15.12 psi)

• Atmospheric temperature: 20 - 30°C (68 - 86°F)

• Engine coolant temperature: 75 - 95°C (167 - 203°F)

• Engine speed: Idle

• Transmission: Warmed-up

- After the engine is warmed up to normal operating temperature, drive vehicle until “ATF TEMP SE 1” (A/T

fluid temperature sensor signal) indicates more than 60°C (140°F).

• Electrical load: Not applied

- Rear window defogger switch, air conditioner switch, lighting switch are OFF. Steering wheel is straight

ahead.

Inspection ProcedureINFOID:0000000003531632

NOTE:

Perform “DATA MONITOR (SPEC)” mode in maximum scale display.

1. Perform EC-71, "

Basic Inspection" .

2. Confirm that the testing conditions indicated above are met.

3. Select “B/FUEL SCHDL”, “A/F ALPHA-B1”, “A/F ALPHA-B2”

and “MAS A/F SE-B1” in “DATA MONITOR (SPEC)” mode with

CONSULT-II.

4. Make sure that monitor items are within the SP value.

5. If NG, go to EC-130, "

Diagnosis Procedure" .

SEF601Z

Page 1218 of 3061

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-135

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

- Noise from transmission, etc.

2. Check for the cause of insufficient combustion. Refer to the following.

- Valve clearance malfunction

- Intake valve timing control function malfunction

- Camshaft sprocket installation malfunction, etc.

>> Repair or replace malfunctioning part, and then GO TO 30.

19.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system

OK or NG

OK >> GO TO 21.

NG >> Repair or replace malfunctioning part, and then GO TO 20.

20.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1”, “A/F ALPHA-B2”, and “B/FUEL SCHDL” in “DATA MONITOR (SPEC)” mode, and

make sure that the each indication is within the SP value.

OK or NG

OK >>INSPECTION END

NG (“B/FUEL SCHDL” is more, “A/F ALPHA-B1”, “A/F ALPHA-B2” are less than the SP value)>>GO TO 21.

21.DISCONNECT AND RECONNECT MASS AIR FLOW SENSOR HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect mass air flow sensor harness connector. Check pin terminal and connector for damage and

then reconnect it again.

>> GO TO 22.

22.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F ALPHA-B2” in “DATA MONITOR (SPEC)” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >> 1. Detect malfunctioning part of mass air flow sensor circuit and repair it. Refer to EC-194 .

2. GO TO 29.

NG >> GO TO 23.

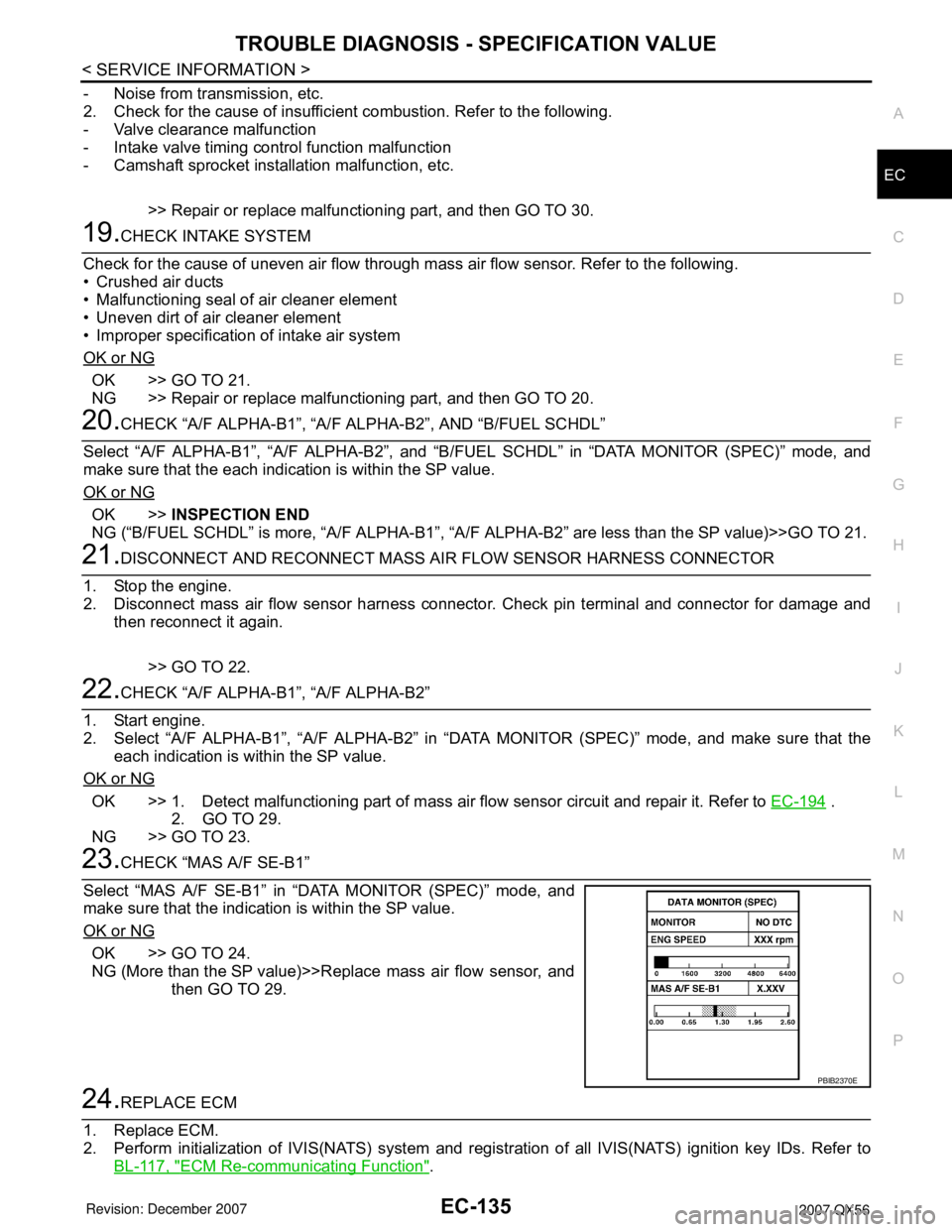

23.CHECK “MAS A/F SE-B1”

Select “MAS A/F SE-B1” in “DATA MONITOR (SPEC)” mode, and

make sure that the indication is within the SP value.

OK or NG

OK >> GO TO 24.

NG (More than the SP value)>>Replace mass air flow sensor, and

then GO TO 29.

24.REPLACE ECM

1. Replace ECM.

2. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs. Refer to

BL-117, "

ECM Re-communicating Function".

PBIB2370E