transmission INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2152 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-21

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

• For abbreviations, refer to LAN-37, "Abbreviation List".

DETECT THE ROOT CAUSE

Identify INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-21

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

• For abbreviations, refer to LAN-37, "Abbreviation List".

DETECT THE ROOT CAUSE

Identify](/img/42/57029/w960_57029-2151.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-21

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

• For abbreviations, refer to LAN-37, "Abbreviation List".

DETECT THE ROOT CAUSE

Identify the root cause using the created diagnosis sheet.

Identifying the root cause• Draw a line on the diagnosis sheet to indicate the possible cause. Narrow the search.

NOTE:

• Color-code when drawing lines.

• Do not draw a line onto a existing line.

• Drawing a line is not necessary if the circuit is shorted. Refer to "Present Error — Short Circuit —", "Past

Error — Short Circuit —".

Refer to the following for details of the trouble diagnosis procedure.

• "Present Error — Open Circuit —"

• "Present Error — Short Circuit —"

• "Past Error — Open Circuit —"

• "Past Error — Short Circuit —"

NOTE:

When the root cause appears to be a branch line or short circuit, be sure to check the control unit as well as

the communication line.

Present Error — Open Circuit —

Identify the error circuit using information from the “SELECT SYSTEM” and “CAN DIAG SUPPORT MNTR”

screens.

1. SELECT SYSTEM: Check the items indicated in “SELECT SYSTEM”. Draw a line on the diagnosis sheet

to indicate the error circuit.

NOTE:

CAN communication line has no error if units other than Diag on CAN units are indicated. An error may be

on the power supply of the control unit, DDL1 line or DDL2 line.

a. “TRANSMISSION” which is Diag on CAN unit, is not indicated on “SELECT SYSTEM” screen. This indi-

cates that DLC is not receiving a signal from TCM. Draw a line to indicate an error between DLC and TCM

(line 1-a in the figure).

NOTE:

• Diag on CAN units are not indicated on the “SELECT SYSTEM” screen when the CAN line between

Diag on CAN unit and the data link connector is open.

SKIB8891E

Page 2161 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-30

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSES WORK FLOW

b. Reception item of “METER”: “VDC/TCS/ABS”, “3” is indicated in the “PAST”. This means M&A could not

receiv INFINITI QX56 2007 Factory Service Manual LAN-30

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSES WORK FLOW

b. Reception item of “METER”: “VDC/TCS/ABS”, “3” is indicated in the “PAST”. This means M&A could not

receiv](/img/42/57029/w960_57029-2160.png)

LAN-30

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSES WORK FLOW

b. Reception item of “METER”: “VDC/TCS/ABS”, “3” is indicated in the “PAST”. This means M&A could not

receive the signal from ABS in the past. Draw a line between M&A and ABS (line 2-b in the figure).

c. Reception item of “TRANSMISSION”: “VDC/TCS/ABS”, “3” is indicated in the “PAST”. This means TCM

could not receive the signal from ABS in the past. Draw a line between TCM and ABS (line 2-c in the fig-

ure).

3. CAN DIAG SUPPORT MNTR (without PAST): Check the CAN DIAG SUPPORT MNTR (without PAST) of

units indicating “U1000” or “U1001” on SELF-DIAG RESULTS. Draw a line on the diagnosis sheet to indi-

cate the possible error circuit.

NOTE:

• While an error occurred in the past according to SELF-DIAG RESULTS, it is unclear which signal is not

received. Assume that errors were detected from all reception items.

• Draw a single line among the unit and all reception items. (Work flow differs from CAN DIAG SUPPORT

MNTR (with PAST).)

a. Reception item of “EPS”: Assume that the unit could not receive the signals from ECM, ABS, and M&A.

Draw a line among EPS, ECM, ABS, and M&A (line 3-a in the figure).

SKIB8732E

Page 2171 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-40

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

CAN Diagnostic Support MonitorINFOID:0000000003533626

Use “CAN DIAG SUPPORT MNTR” for detecting the root cause.

MONITOR ITEM INFINITI QX56 2007 Factory Service Manual LAN-40

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

CAN Diagnostic Support MonitorINFOID:0000000003533626

Use “CAN DIAG SUPPORT MNTR” for detecting the root cause.

MONITOR ITEM](/img/42/57029/w960_57029-2170.png)

LAN-40

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

CAN Diagnostic Support MonitorINFOID:0000000003533626

Use “CAN DIAG SUPPORT MNTR” for detecting the root cause.

MONITOR ITEM LIST (CONSULT-II)

ECM

0: Error at present, 1 – 39: Error in the past (Number means the number of times the ignition switch is turned OFF→ON)

*: 39 or higher number is fixed at 39 until the self-diagnosis result is erased.

TCM

NOTE:

Replace the unit when “NG” is indicated on the “INITIAL DIAG”.

ICC Unit

NOTE:

Replace the unit when “NG” is indicated on the “INITIAL DIAG”.

SELECT SYS-

TEMCAN DIAG SUP-

PORT MNTRDescriptionNormal Error

PRSNT PAST PRSNT PAST

ENGINETRANSMIT DIAG Signal transmission status

OKOK

or

1 – 39

*UNKWN 0 VDC/TCS/ABSSignal receiving status from the ABS actu-

ator and electric unit (control unit)

METER/M&ASignal receiving status from the combina-

tion meter

BCM/SEC Signal receiving status from the BCM

ICC Signal receiving status from the ICC unit

HVAC Not used even though indicated

TCM Signal receiving status from the TCM OKOK

or

1 – 39

*UNKWN 0

EPS Not used even though indicated

IPDM E/R Signal receiving status from the IPDM E/R OKOK

or

1 – 39

*UNKWN 0

e4WD Not used even though indicated

AWD/4WDSignal receiving status from the transfer

control unitOKOK

or

1 – 39

*UNKWN 0

SELECT SYS-

TEMCAN DIAG SUP-

PORT MNTRDescriptionNormal Error

PRSNT

A/TINITIAL DIAG Status of CAN controller

OKNG

TRANSMIT DIAG Signal transmission status

UNKWN ECM Signal receiving status from the ECM

VDC/TCS/ABSSignal receiving status from the ABS actuator and electric unit

(control unit)

METER/M&A Signal receiving status from the combination meter

ICC/e4WD Signal receiving status from the ICC unit

AWD/4WD Signal receiving status from the transfer control unit

Page 2172 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-41

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P Driver Seat Control Unit

0: Error at present, 1 – 39: Error in the past (Number means the number of times the i INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-41

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P Driver Seat Control Unit

0: Error at present, 1 – 39: Error in the past (Number means the number of times the i](/img/42/57029/w960_57029-2171.png)

TROUBLE DIAGNOSIS

LAN-41

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P Driver Seat Control Unit

0: Error at present, 1 – 39: Error in the past (Number means the number of times the ignition switch is turned OFF→ON)

*: 39 or higher number is fixed at 39 until the self-diagnosis result is erased.

BCM

NOTE:

Replace the unit when “NG” is indicated on the “INITIAL DIAG”.

Front Air Control

SELECT SYS-

TEMCAN DIAG SUP-

PORT MNTRDescriptionNormal Error

PRSNT

ICCINITIAL DIAG Status of CAN controller

OKNG

TRANSMIT DIAG Signal transmission status

UNKWN ECM Signal receiving status from the ECM

VDC/TCS/ABSSignal receiving status from the ABS actuator and electric unit

(control unit)

TCM Signal receiving status from the TCM

METER/M&A

Not used even though indicated LANE KEEP

ECM(l)

ICC SENSOR Signal receiving status from the ICC sensor OK UNKWN

STRG

Not used even though indicated METER/M&A(l)

ERROR(l)

LANE DETEC-

TOR

TCM(l)

BCM/SEC Signal receiving status from the BCM OK UNKWN

SELECT SYS-

TEMCAN DIAG SUP-

PORT MNTRDescriptionNormal Error

PRSNT PAST PRSNT PAST

AUTO DRIVE

POS.TRANSMIT DIAG Not used even though indicated

METER/M&ASignal receiving status from the combina-

tion meter

OKOK

or

1 – 39

*UNKWN 0

BCM/SEC Signal receiving status from the BCM

TCM Signal receiving status from the TCM

SELECT SYS-

TEMCAN DIAG SUP-

PORT MNTRDescriptionNormal Error

PRSNT

BCMINITIAL DIAG Status of CAN controller

OKNG

TRANSMIT DIAG Signal transmission status

UNKWN ECM Signal receiving status from the ECM

IPDM E/R Signal receiving status from the IPDM E/R

METER/M&A Signal receiving status from the combination meter

I-KEY Not used even though indicated

Page 2173 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-42

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

0: Error at present, 1 – 39: Error in the past (Number means the number of times the ignition switch is turned OFF→ON)

*: 39 or higher number INFINITI QX56 2007 Factory Service Manual LAN-42

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

0: Error at present, 1 – 39: Error in the past (Number means the number of times the ignition switch is turned OFF→ON)

*: 39 or higher number](/img/42/57029/w960_57029-2172.png)

LAN-42

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

0: Error at present, 1 – 39: Error in the past (Number means the number of times the ignition switch is turned OFF→ON)

*: 39 or higher number is fixed at 39 until the self-diagnosis result is erased.

Transfer Control Unit

0: Error at present, 1 – 39: Error in the past (Number means the number of times the ignition switch is turned OFF→ON)

*: 39 or higher number is fixed at 39 until the self-diagnosis result is erased.

ABS Actuator and Electric Unit (Control Unit)

CAUTION:SELECT SYS-

TEMCAN DIAG SUP-

PORT MNTRDescriptionNormal Error

PRSNT PAST PRSNT PAST

HVACTRANSMIT DIAG Signal transmission status

OKOK

or

1 – 39

*UNKWN 0

ECM Signal receiving status from the ECM

TCM Not used even though indicated

BCM/SEC Signal receiving status from the BCM

OKOK

or

1 – 39

*UNKWN 0

VDC/TCS/ABSSignal receiving status from the ABS actu-

ator and electric unit (control unit)

IPDM E/R Not used even though indicated

DISPLAYSignal receiving status from the display

control unitOKOK

or

1 – 39

*UNKWN 0

I-KEY

Not used even though indicated EPS

AWD/4WD

e4WD

ICC

LANE KEEP

TIRE-P

SELECT SYS-

TEMCAN DIAG SUP-

PORT MNTRDescriptionNormal Error

PRSNT PAST PRSNT PAST

ALL MODE AWD/

4WDTRANSMIT DIAG Signal transmission status

OKOK

or

1 – 39

*UNKWN 0 ECM Signal receiving status from the ECM

VDC/TCS/ABSSignal receiving status from the ABS actu-

ator and electric unit (control unit)

TCM Signal receiving status from the TCM

STRGSignal receiving status from the steering

angle sensor

SELECT SYSTEMCAN DIAG SUP-

PORT MNTRDescriptionNormal Error

PRSNT

ABSINITIAL DIAG Status of CAN controller

OKNG

Caution

TRANSMIT DIAG Signal transmission status

UNKWN ECM Signal receiving status from the ECM

TCM Signal receiving status from the TCM

METER/M&A Not used even though indicated

STRG Signal receiving status from the steering angle sensor

OK UNKWN ICC Signal receiving status from the ICC unit

AWD/4WD Signal receiving status from the transfer control unit

Page 2174 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-43

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Never replace the unit even when “NG” is indicated on the “INITIAL DIAG” at this stage. Follow the troubl INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-43

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Never replace the unit even when “NG” is indicated on the “INITIAL DIAG” at this stage. Follow the troubl](/img/42/57029/w960_57029-2173.png)

TROUBLE DIAGNOSIS

LAN-43

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Never replace the unit even when “NG” is indicated on the “INITIAL DIAG” at this stage. Follow the trouble diagnosis proce-

dures.

IPDM E/R

0: Error at present, 1 – 39: Error in the past (Number means the number of times the ignition switch is turned OFF→ON)

*: 39 or higher number is fixed at 39 until the self-diagnosis result is erased.

MONITOR ITEM LIST (ON-BOARD DIAGNOSIS)

Display Control Unit

NOTE:

CAN diagnostic support monitor of the display control unit is indicated on the vehicle display. Refer to AV-123,

"CAN Communication Line Check".

*: The error counter stops counting when it reaches “50” and holds “50” until it is deleted.SELECT SYS-

TEMCAN DIAG SUP-

PORT MNTRDescriptionNormal Error

PRSNT PAST PRSNT PAST

IPDM E/RTRANSMIT DIAG Signal transmission status

OKOK

or

1 – 39

*UNKWN 0 ECM Signal receiving status from the ECM

BCM/SEC Signal receiving status from the BCM

PKIB6080E

Unit name Diagnosis item DescriptionIndicated items on CAN DIAG SUPPORT MONITOR

Normal Error

Result indi-

catedError

counter

(Reference)Result indi-

catedError

counter

(Reference)

Display control

unitCAN_COMM Status of CAN controller

OK0

or

1 – 50*NG

1 – 50* CAN_CIRC_1 Signal transmission status

UNKWN CAN_CIRC_2Signal receiving status from the

BCM

CAN_CIRC_3Signal receiving status from the

ECM

CAN_CIRC_4Signal receiving status from the

front air control

CAN_CIRC_5Signal receiving status from the

combination meter

CAN_CIRC_6 Not used even though indicated

CAN_CIRC_7Signal receiving status from the

IPDM E/ROK0

or

1 – 50*UNKWN 1 – 50*

CAN_CIRC_8

Not used even though indicated

CAN_CIRC_9

Page 2175 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-44

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

CAN System Specification Chart

INFOID:0000000003533627

Determine CAN system type from the following specification chart. Then choose the correct d INFINITI QX56 2007 Factory Service Manual LAN-44

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

CAN System Specification Chart

INFOID:0000000003533627

Determine CAN system type from the following specification chart. Then choose the correct d](/img/42/57029/w960_57029-2174.png)

LAN-44

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

CAN System Specification Chart

INFOID:0000000003533627

Determine CAN system type from the following specification chart. Then choose the correct diagnosis sheet.

NOTE:

Refer to LAN-14, "

Trouble Diagnosis Procedure" for how to use CAN system specification chart.

X: Applicable

VEHICLE EQUIPMENT IDENTIFICATION INFORMATION

NOTE:

Check CAN system type from the vehicle shape and equipment.

CAN Communication Signal ChartINFOID:0000000003533628

Refer to LAN-13, "How to Use CAN Communication Signal Chart" for how to use CAN communication signal

chart.

TYPE 1/TYPE 2

NOTE:

Refer to LAN-37, "

Abbreviation List" for the abbreviations of the connecting units.

T: Transmit R: Receive

Body typeWagon

Axle 2WD AWD

EngineVK56DE

Transmission A/T

Brake controlVDC

ICC system X X

CAN system type 1234

Diagnosis sheetLAN-57

LAN-58LAN-59LAN-60

CAN communication signal chartLAN-44, "CAN Communication Sig-

nal Chart"

LAN-44, "CAN Communication Sig-

nal Chart"

BKIA0219E

Signal name/Connecting unitECM

TCM

LASER

ICC

ADP

BCM

DISP

HVAC

M&A

STRG

ABS

IPDM-E

A/C compressor request signal TR

Accelerator pedal position signal T R R R

ASCD CRUISE lamp signal T R

ASCD OD cancel request signal T R

ASCD operation signal T R

ASCD SET lamp signal T R

Battery voltage signal T R

Closed throttle position signal T R R

Cooling fan speed request signal TR

Engine coolant temperature signal T R R

Page 2363 of 3061

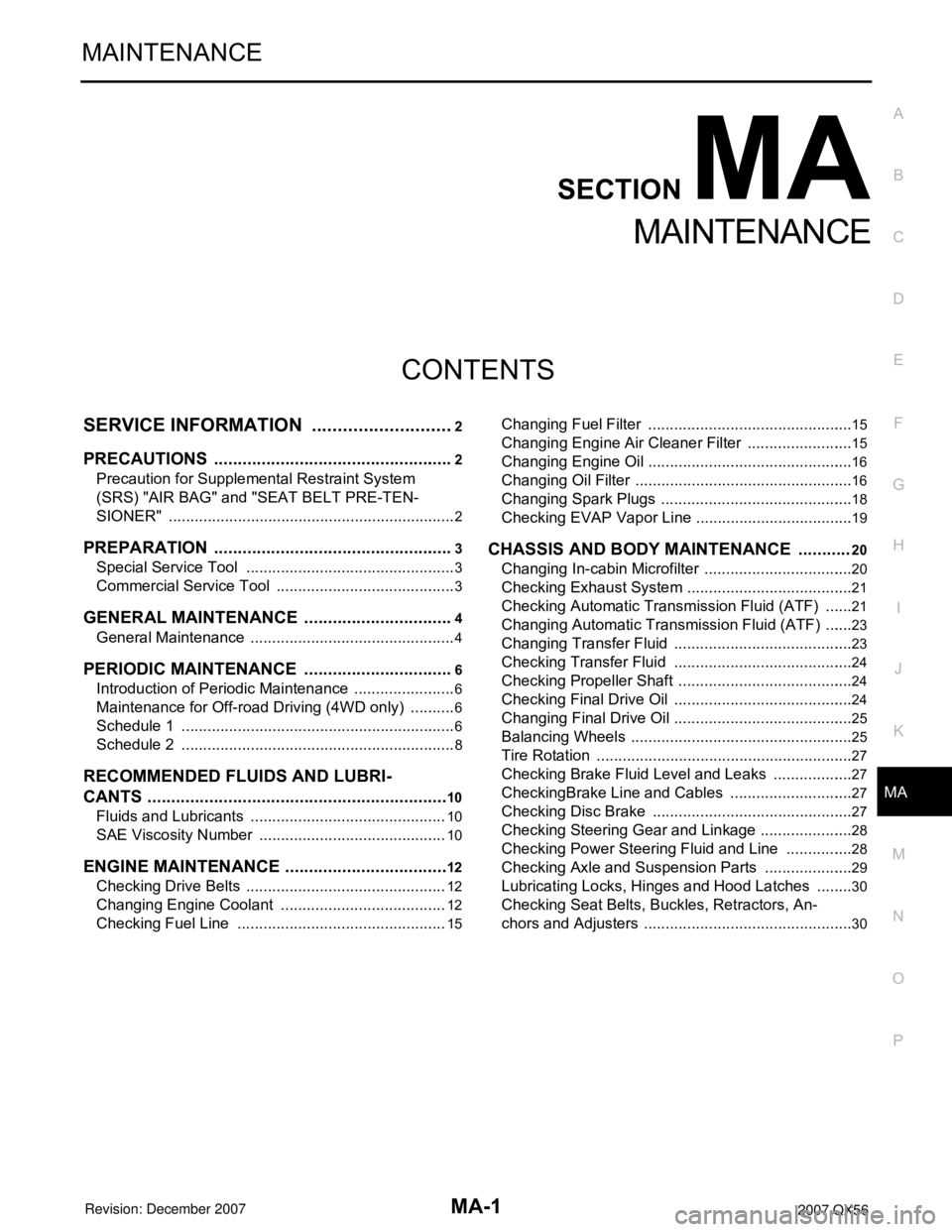

MA-1

MAINTENANCE

C

D

E

F

G

H

I

J

K

M

SECTION MA

A

B

MA

N

O

P

CONTENTS

MAINTENANCE

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................3

GENERAL MAINTENANCE ................................4

General Maintenance ................................................4

PERIODIC MAINTENANCE ................................6

Introduction of Periodic Maintenance ........................6

Maintenance for Off-road Driving (4WD only) ...........6

Schedule 1 ................................................................6

Schedule 2 ................................................................8

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

10

Fluids and Lubricants ..............................................10

SAE Viscosity Number ............................................10

ENGINE MAINTENANCE ...................................12

Checking Drive Belts ...............................................12

Changing Engine Coolant .......................................12

Checking Fuel Line .................................................15

Changing Fuel Filter ................................................15

Changing Engine Air Cleaner Filter .........................15

Changing Engine Oil ................................................16

Changing Oil Filter ...................................................16

Changing Spark Plugs .............................................18

Checking EVAP Vapor Line .....................................19

CHASSIS AND BODY MAINTENANCE ...........20

Changing In-cabin Microfilter ...................................20

Checking Exhaust System .......................................21

Checking Automatic Transmission Fluid (ATF) .......21

Changing Automatic Transmission Fluid (ATF) .......23

Changing Transfer Fluid ..........................................23

Checking Transfer Fluid ..........................................24

Checking Propeller Shaft .........................................24

Checking Final Drive Oil ..........................................24

Changing Final Drive Oil ..........................................25

Balancing Wheels ....................................................25

Tire Rotation ............................................................27

Checking Brake Fluid Level and Leaks ...................27

CheckingBrake Line and Cables .............................27

Checking Disc Brake ...............................................27

Checking Steering Gear and Linkage ......................28

Checking Power Steering Fluid and Line ................28

Checking Axle and Suspension Parts .....................29

Lubricating Locks, Hinges and Hood Latches .........30

Checking Seat Belts, Buckles, Retractors, An-

chors and Adjusters .................................................

30

Page 2368 of 3061

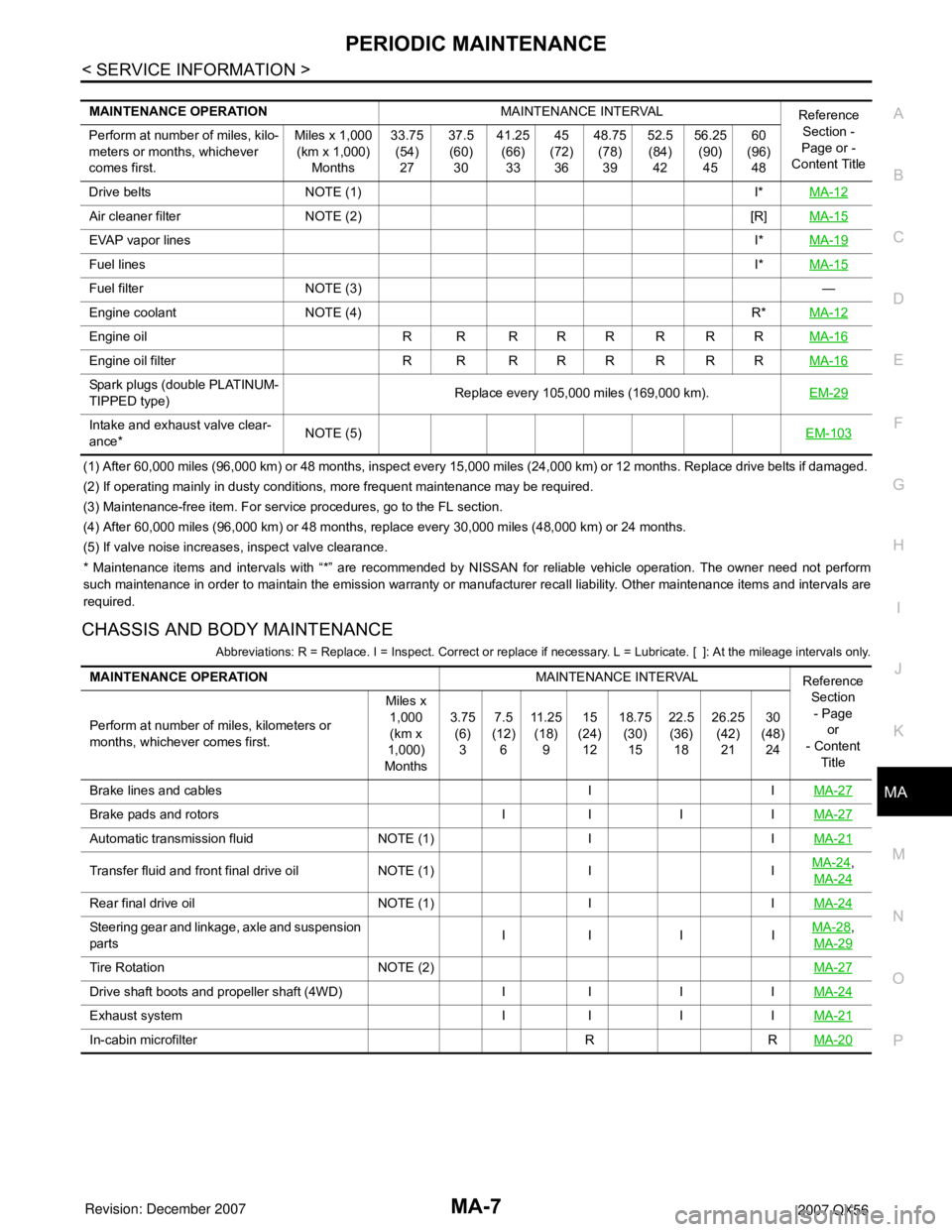

MA-6

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

Introduction of Periodic MaintenanceINFOID:0000000003533860

Two different maintenance schedules are provided, and should be used, depending upon the conditions in

which the vehicle is mainly operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage or time intervals, whichever comes first.

Maintenance for Off-road Driving (4WD only)INFOID:0000000003533861

After driving the vehicle off-road through sand, mud, or water; more frequent maintenance may be required for

the following items:

Brake pads and rotors

Brake lines and hoses

Rear final drive oil, transmission fluid, and transfer fluid

Steering linkage

Drive shafts

Engine air cleaner filter

In-cabin microfilters

Schedule 1INFOID:0000000003533862

EMISSION CONTROL SYSTEM MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

Schedule 1Follow Periodic Maintenance Schedule 1 if your driving habits frequently includes

one or more of the following driving conditions:

• Repeated short trips of less than 5 miles (8 km).

• Repeated short trips of less than 10 miles (16 km) with outside temperatures re-

maining below freezing.

• Operating in hot weather in stop-and-go “rush hour” traffic.

• Extensive idling and/or low speed driving for long distances, such as police, taxi

or door-to-door delivery use.

• Driving in dusty conditions.

• Driving on rough, muddy, or salt spread roads.

• Towing a trailer or using a car-top carrier.Emission Control Sys-

tem MaintenanceMA-6

Chassis and Body

MaintenanceMA-6

Schedule 2Follow Periodic Maintenance Schedule 2 if none of the driving conditions shown

in Schedule 1 apply to the driving habits.Emission Control Sys-

tem MaintenanceMA-8Chassis and Body

MaintenanceMA-8

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title Perform at number of miles, kilo-

meters or months, whichever

comes first.Miles x 1,000

(km x 1,000)

Months3.75

(6)

37.50

(12)

611 . 2 5

(18)

915

(24)

1218.75

(30)

1522.5

(36)

1826.25

(42)

2130

(48)

24

Drive belts NOTE (1)MA-12

Air cleaner filter NOTE (2) [R]MA-15

EVAP vapor linesI*MA-19

Fuel linesI*MA-15

Fuel filter NOTE (3)—

Engine coolant NOTE (4)MA-12

Engine oil R R R R R R R RMA-16

Engine oil filter R R R R R R R RMA-16

Spark plugs (double PLATINUM-

TIPPED type)Replace every 105,000 miles (169,000 km).EM-29

Intake and exhaust valve clear-

ance*NOTE (5)EM-103

Page 2369 of 3061

PERIODIC MAINTENANCE

MA-7

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace drive belts if damaged.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, go to the FL section.

(4) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(5) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are

required.

CHASSIS AND BODY MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. L = Lubricate. [ ]: At the mileage intervals only.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title Perform at number of miles, kilo-

meters or months, whichever

comes first.Miles x 1,000

(km x 1,000)

Months33.75

(54)

2737.5

(60)

3041.25

(66)

3345

(72)

3648.75

(78)

3952.5

(84)

4256.25

(90)

4560

(96)

48

Drive belts NOTE (1) I*MA-12

Air cleaner filter NOTE (2) [R]MA-15

EVAP vapor linesI*MA-19

Fuel linesI*MA-15

Fuel filter NOTE (3)—

Engine coolant NOTE (4) R*MA-12

Engine oil R R R R R R R RMA-16

Engine oil filter R R R R R R R RMA-16

Spark plugs (double PLATINUM-

TIPPED type)Replace every 105,000 miles (169,000 km).EM-29

Intake and exhaust valve clear-

ance*NOTE (5)EM-103

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section

- Page

or

- Content

Title Perform at number of miles, kilometers or

months, whichever comes first.Miles x

1,000

(km x

1,000)

Months3.75

(6)

37.5

(12)

611 . 2 5

(18)

915

(24)

1218.75

(30)

1522.5

(36)

1826.25

(42)

2130

(48)

24

Brake lines and cables I IMA-27

Brake pads and rotors I I I IMA-27

Automatic transmission fluid NOTE (1) I IMA-21

Transfer fluid and front final drive oil NOTE (1) I IMA-24,

MA-24

Rear final drive oil NOTE (1) I IMA-24

Steering gear and linkage, axle and suspension

partsII I IMA-28,

MA-29

Tire Rotation NOTE (2)MA-27

Drive shaft boots and propeller shaft (4WD) I I I IMA-24

Exhaust system I I I IMA-21

In-cabin microfilter R RMA-20