service indicator INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2708 of 3061

SE-36

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

A part of seat system does not operate (both automatical-

ly and manually).1. Sliding motor circuit inspection SE-37

2. Reclining motor LH circuit inspection SE-38

3. Lifting motor (front) circuit inspectionSE-39

4. Lifting motor (rear) circuit inspectionSE-40

5. If the above systems are normal, replace the driver seat

control unit.SE-83

A part of pedal adjust and door mirror does not operate

(both automatically and manually).1. Pedal adjusting motor circuit inspectionSE-412. Mirror motor LH circuit check SE-42

3. Mirror motor RH circuit check SE-44

4. If the above systems are normal, replace the automatic

drive positioner control unit.SE-11

A part of seat system does not operate (only automatic

operation).1. Sliding sensor circuit inspectionSE-46

2. Reclining sensor circuit inspectionSE-47

3. Lifting sensor (front) circuit inspectionSE-48

4. Lifting sensor (rear) circuit inspectionSE-49

5. If the above systems are normal, replace the driver seat

control unit.SE-83

A part of door mirror system does not operate (only auto-

matic operation).1. Mirror sensor LH circuit checkSE-512. Mirror sensor RH circuit checkSE-53

3. If the above systems are normal, replace the automatic

drive positioner control unit.SE-11

All of the automatic operations do not operate.1.A/T device (park position switch) circuit inspectionSE-69

2. UART communication line circuit inspectionSE-73

3. Pedal adjusting sensor circuit inspectionSE-50

4. Steering wheel tilt sensor circuit inspectionSE-54

4. If all the above systems are normal, replace the automatic

drive positioner control unit.SE-11

A part of seat system does not operate (only manual op-

eration).1. Sliding switch circuit inspectionSE-55

2. Reclining switch circuit inspectionSE-56

3. Lifting switch (front) circuit inspectionSE-58

4. Lifting switch (rear) circuit inspectionSE-59

5. If the above systems are normal, replace the driver seat

control unit.SE-83

A part of pedal adjust and door mirror does not operate

(only manual operation).1. Pedal adjusting switch circuit inspection SE-61

2. Door mirror remote control switch (change over switch)

circuit inspection SE-62

3. Door mirror remote control switch (mirror switch) switch-

ing circuit inspection SE-64

4. If the above systems are normal, replace the automatic

drive positioner control unit.SE-11

Automatic drive positioner system does not operate (only

memory switch operation).1. Seat memory switch circuit inspectionSE-672. If the above systems are normal, replace the driver seat

control unit.SE-83

Seat memory indicator lamps 1 and 2 do not illuminate.1. Seat memory indicator lamp circuit inspectionSE-672. If all the above systems are normal, replace the driver seat

control unit.SE-83

Symptom Diagnoses / service procedure Refer to page

Page 2739 of 3061

AUTOMATIC DRIVE POSITIONER

SE-67

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

OK or NG

OK >> GO TO 3.

NG >> Replace seat memory switch.

3.CHECK HARNESS CONTINUITY

1. Disconnect automatic drive positioner control unit.

2. Check continuity between automatic drive positioner control unit

connector M33 terminals 9, 24, 25 and seat memory switch con-

nector D5 terminals 1, 2, 3.

3. Check continuity between automatic drive positioner control unit

connector M41 terminals 9, 24, 25 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK SEAT MEMORY SWITCH GROUND CIRCUIT

Check continuity between seat memory switch D5 terminal 4 and

ground.

OK or NG

OK >> Replace automatic drive positioner control unit.

NG >> Repair or replace harness.

Seat Memory Indicator Lamp Circuit InspectionINFOID:0000000003533199

1.CHECK FUNCTION

With CONSULT-II

Terminal Condition Continuity

1

4Memory switch 1: ON Yes

Memory switch 1: OFF No

2Memory switch 2: ON Yes

Memory switch 2: OFF No

3Set switch: ON Yes

Set switch: OFF No

9 - 1 : Continuity should exist.

24 - 3 : Continuity should exist.

25 - 2 : Continuity should exist.

9 - Ground : Continuity should not exist.

24 - Ground : Continuity should not exist.

25 - Ground : Continuity should not exist.

PIIA4576E

4 - Ground : Continuity should exist.

PIIA4821E

Page 2740 of 3061

SE-68

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

With “MEMORY SW INDCTR” in ACTIVE TEST, check operation.

Without CONSULT-II

GO TO 2.

OK or NG

OK >> Seat memory switch indicator lamp circuit is OK.

NG >> GO TO 2.

2.CHECK SEAT MEMORY SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect seat memory switch.

3. Check voltage between seat memory switch connector D5 ter-

minal 5 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK SEAT MEMORY INDICATOR CIRCUIT HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit.

3. Check continuity between automatic drive positioner control unit

connector M33 terminals 12, 13 and seat memory switch con-

nector D5 terminals 6, 7.

4. Check continuity between automatic drive positioner control unit

connector M33 terminals 12, 13 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK SEAT MEMORY SWITCH INDICATOR SIGNAL

1. Connect seat memory switch.

2. Turn ignition switch ON.

3. Check voltage between automatic drive positioner control unit

connector M33 terminals 12, 13 and ground.

OK or NG

OK >> Replace automatic drive positioner control unit.

NG >> Replace seat memory switch.

Te s t i t e m D e s c r i p t i o n

MEMORY SW INDCTRThe memory switch indicator is lit by receiving the

drive signal.

PIIA0319E

5 - Ground : Battery voltage

PIIA4595E

12 - 6 : Continuity should exist.

13 - 7 : Continuity should exist.

12 - Ground : Continuity should not exist.

13 - Ground : Continuity should not exist.

LIIA1022E

12 - Ground : Battery voltage

13 - Ground : Battery voltage

LIIA1134E

Page 2776 of 3061

SRS-6

< SERVICE INFORMATION >

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Front Seat Belt Pre-tensioner with Load Limiter

INFOID:0000000003532858

The seat belt pre-tensioner system with load limiter is installed for

both the driver's seat and the front passenger's seat. It operates

simultaneously with the SRS air bag system in the event of a frontal

collision with an impact exceeding a specified level.

When the frontal collision with an impact exceeding a specified level

occurs, seat belt slack resulting from clothing or other factors is

immediately taken up by the pre-tensioner. Vehicle passengers are

securely restrained.

When passengers in a vehicle are thrown forward in a collision and

the restraining force of the seat belt exceeds a specified level, the

load limiter permits the specified extension of the seat belt by the

twisting of the ELR shaft, and a relaxation of the chest-area seat belt

web tension while maintaining force.

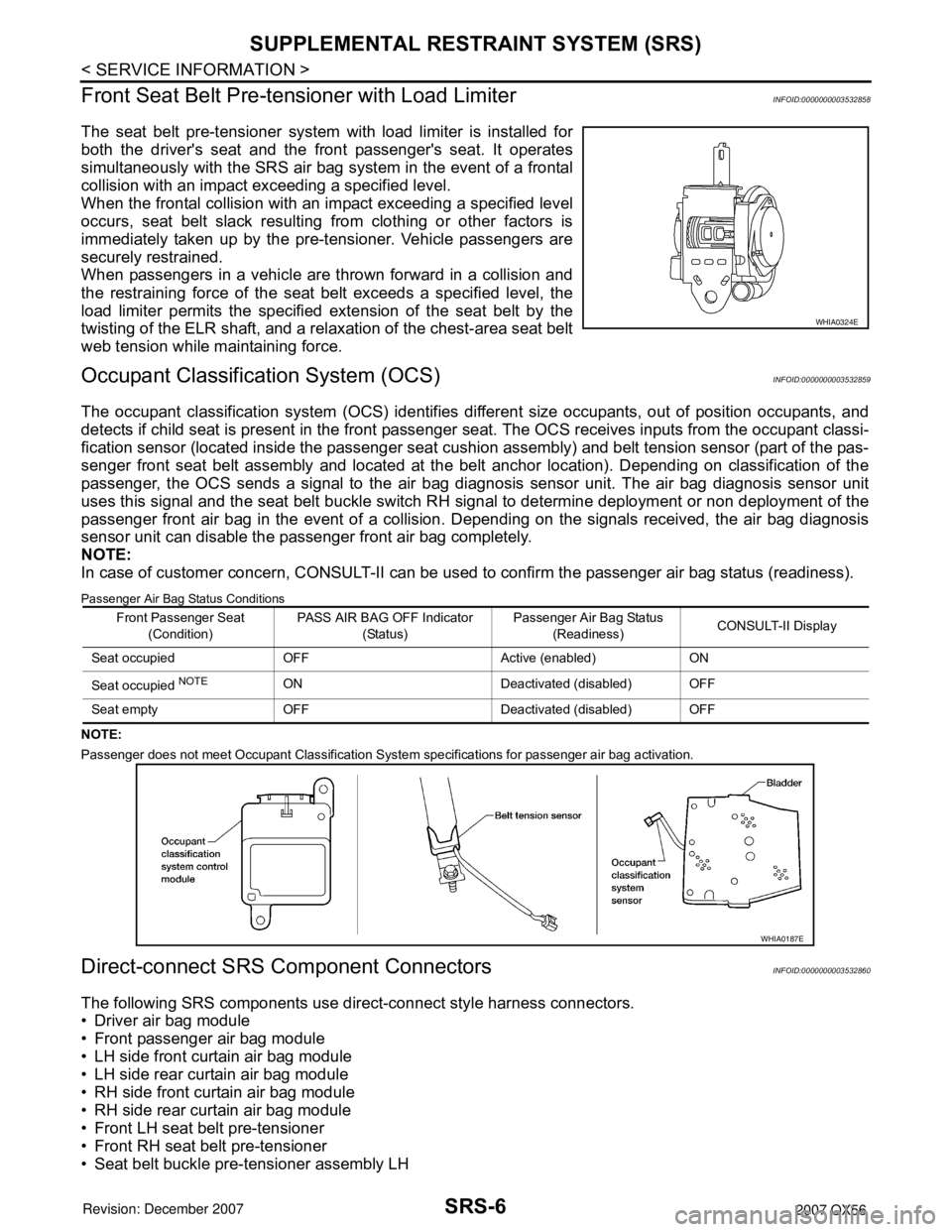

Occupant Classification System (OCS)INFOID:0000000003532859

The occupant classification system (OCS) identifies different size occupants, out of position occupants, and

detects if child seat is present in the front passenger seat. The OCS receives inputs from the occupant classi-

fication sensor (located inside the passenger seat cushion assembly) and belt tension sensor (part of the pas-

senger front seat belt assembly and located at the belt anchor location). Depending on classification of the

passenger, the OCS sends a signal to the air bag diagnosis sensor unit. The air bag diagnosis sensor unit

uses this signal and the seat belt buckle switch RH signal to determine deployment or non deployment of the

passenger front air bag in the event of a collision. Depending on the signals received, the air bag diagnosis

sensor unit can disable the passenger front air bag completely.

NOTE:

In case of customer concern, CONSULT-II can be used to confirm the passenger air bag status (readiness).

Passenger Air Bag Status Conditions

NOTE:

Passenger does not meet Occupant Classification System specifications for passenger air bag activation.

Direct-connect SRS Component ConnectorsINFOID:0000000003532860

The following SRS components use direct-connect style harness connectors.

• Driver air bag module

• Front passenger air bag module

• LH side front curtain air bag module

• LH side rear curtain air bag module

• RH side front curtain air bag module

• RH side rear curtain air bag module

• Front LH seat belt pre-tensioner

• Front RH seat belt pre-tensioner

• Seat belt buckle pre-tensioner assembly LH

WHIA0324E

Front Passenger Seat

(Condition)PASS AIR BAG OFF Indicator

(Status)Passenger Air Bag Status

(Readiness)CONSULT-II Display

Seat occupied OFF Active (enabled) ON

Seat occupied

NOTEON Deactivated (disabled) OFF

Seat empty OFF Deactivated (disabled) OFF

WHIA0187E

Page 2780 of 3061

SRS-10

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

SRS Component Parts Location

INFOID:0000000003532862

1. Side curtain air bag modules 2. Front RH side air bag module 3. Belt tension sensor

4. RH side air bag (satellite) sensor 5. Front RH seat belt pre-tension-

er6. Seat belt buckle pre-tensioner assembly

RH

7. Occupant classification system sen-

sor8. Occupant classification system

control unit9. Front passenger air bag off indicator

10. Front passenger air bag module 11. Crash zone sensor 12. Air bag warning lamp

13. Spiral cable 14. Driver air bag module 15. LH side air bag (satellite) sensor

16. Front LH seat belt pre-tensioner 17. Air bag diagnosis sensor unit 18. Front LH side air bag module

WHIA0216E

Page 2796 of 3061

SRS-26

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

NOTE:

Follow the procedures in numerical order when repairing malfunctioning parts. Confirm whether malfunction is

eliminated using air bag warning lamp or CONSULT-II each time repair is finished. If malfunction is still

observed, proceed to the next step. When malfunction is eliminated, further repair work is not required.

DIAGNOSTIC PROCEDURE 3

Final Check of SRS Using CONSULT-II—Diagnosis Mode

Refer to GI-36, "CONSULT-II Start Procedure" .

OCCUPANT SENS C/U

[COMM FAIL]

[B1022]Communication between the occupant classification system

control unit and air bag diagnosis sensor unit is interrupted.1. Visually check the wiring harness

connection.

2. Replace the harness if it has visi-

ble damage.

3. Replace RH front seat cushion/

occupant classification system

control unit assembly.

4. Replace the air bag diagnosis

sensor unit.

5. Replace the related harness.

OCCUPANT SENS

[UNIT FAIL]

[B1018]Occupant classification sensor is malfunctioning. 1. Replace RH front seat cushion/

occupant classification system

control unit assembly.

BELT TENSION SENS

[UNIT FAIL]

[B1019]Belt tension sensor is malfunctioning. 1. Visually check the wiring harness

connection.

2. Replace the harness if it has visi-

ble damage.

3. Replace RH front seat belt as-

sembly.

4. Replace RH front seat cushion/

occupant classification system

control unit assembly.

5. Replace the related harness.

PASS A/B INDCTR CKT

[B1023]Front passenger air bag off indicator is malfunctioning. 1. Visually check the wiring harness

connection.

2. Replace the harness if it has visi-

ble damage.

3. Replace front passenger air bag

off indicator.

4. Replace the air bag diagnosis

sensor unit.

5. Replace the related harness.

FRONTAL COLLISION

DETECTION

[B1209]Driver and front passenger air bag modules are deployed. 1. Refer to SRS-49

.

SIDE COLLISION

DETECTION

[B1210]Side or curtain air bag modules are deployed (with side air

bags only).

ROLLOVER DETECTION

[B1211]Curtain air bag module and seat belt pre-tensioner are de-

ployed. Diagnostic item ExplanationRepair order

Recheck SRS at each replacement

Page 2823 of 3061

TF-1

DRIVELINE/AXLE

C

E

F

G

H

I

J

K

L

M

SECTION TF

A

B

TF

N

O

P

CONTENTS

TRANSFER

SERVICE INFORMATION ............................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for Transfer Assembly and Transfer

Control Unit Replacement .........................................

3

Precaution .................................................................4

Service Notice ...........................................................4

PREPARATION ...................................................6

Special Service Tool .................................................6

Commercial Service Tool ..........................................9

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

10

NVH Troubleshooting Chart ....................................10

TRANSFER FLUID .............................................11

Replacement ...........................................................11

Inspection ................................................................11

ALL-MODE 4WD SYSTEM ................................12

Cross-Sectional View ..............................................12

Power Transfer ........................................................12

System Description .................................................14

Schematic ...............................................................19

CAN Communication ...............................................20

TROUBLE DIAGNOSIS .....................................21

How to Perform Trouble Diagnosis .........................21

Location of Electrical Parts ......................................22

Circuit Diagram .......................................................23

Wiring Diagram - T/F - .............................................24

Inspections Before Trouble Diagnosis ....................31

Trouble Diagnosis Chart by Symptom ....................34

Transfer Control Unit Input/Output Signal Refer-

ence Value ..............................................................

35

CONSULT-II Function (ALL MODE AWD/4WD) .....42

Self-Diagnosis Procedure .......................................48

TROUBLE DIAGNOSIS FOR SYSTEM ............51

Power Supply Circuit for Transfer Control Unit ........51

Transfer Control Unit ...............................................53

Output Shaft Revolution Signal (TCM) ....................53

Vehicle Speed Sensor (ABS) ..................................54

Neutral-4LO Switch .................................................54

4WD Shift Switch .....................................................57

Wait Detection Switch ..............................................60

PNP Switch Signal (TCM) .......................................63

Actuator Motor .........................................................64

Actuator Position Switch ..........................................69

Transfer Control Device ...........................................72

Engine Speed Signal (ECM) ....................................76

Clutch Pressure Solenoid ........................................76

2-4WD Solenoid ......................................................80

Transfer Motor .........................................................84

Transfer Fluid Temperature .....................................90

Clutch Pressure Switch ...........................................92

Line Pressure Switch ...............................................94

Throttle Position Signal (ECM) ................................97

ABS Operation Signal (ABS) ...................................97

VDC Operation Signal (ABS) ...................................98

TCS Operation Signal (ABS) ...................................98

CAN Communication Line .......................................99

ATP Switch ..............................................................99

TROUBLE DIAGNOSIS FOR SYMPTOMS ....102

4WD Shift Indicator Lamp and 4LO Indicator

Lamp Do Not Turn ON ...........................................

102

4WD Warning Lamp Does Not Turn ON ...............104

4WD Shift Indicator Lamp or 4LO Indicator Lamp

Does Not Change ..................................................

107

ATP Warning Lamp Turns ON ...............................109

4LO Indicator Lamp Repeats Flashing ..................110

4WD Warning Lamp Flashes Rapidly ....................111

4WD Warning Lamp Flashes Slowly .....................112

Heavy Tight-corner Braking Symptom Occurs ......113

4WD System Does Not Operate ............................114

TRANSFER CONTROL UNIT .........................115

Removal and Installation .......................................115

Page 2825 of 3061

PRECAUTIONS

TF-3

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003532506

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Transfer Assembly and Transfer Control Unit ReplacementINFOID:0000000003532507

When replacing transfer assembly or transfer control unit, check the 4WD shift indicator lamp as follows.

1. Turn ignition switch “ON”.

2. Check 4WD shift indicator lamp is turned ON for approx. 1 second.

• If OK, the position between transfer assembly and transfer control unit is correct.

• If NG, the position is different between transfer assembly and transfer control unit.

Adjust the position between transfer assembly and transfer control unit. Refer to "METHOD FOR POSITION

ADJUSTMENT".

METHOD FOR POSITION ADJUSTMENT

1. Start engine. Run the engine for at least 10 seconds.

2. Stop vehicle and move A/T selector lever to “N” position with brake pedal depressed. Stay in "N" for at

least 2 seconds.

3. Turn 4WD shift switch to “2WD” position. Stay in "2WD" for at least 2 seconds.

4. Turn ignition switch “OFF”.

5. Start engine.

6. Erase self-diagnosis. Refer to TF-42, "

CONSULT-II Function (ALL MODE AWD/4WD)" (with CONSULT-II)

or TF-48, "

Self-Diagnosis Procedure" (without CONSULT-II).

7. Check 4WD shift indicator lamp. Refer to TF-31, "

Inspections Before Trouble Diagnosis".

If 4WD shift indicator lamp does not indicate "2WD", install new transfer control unit and retry the above

check.

Page 2839 of 3061

ALL-MODE 4WD SYSTEM

TF-17

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

*: After 2.5 seconds have elapsed.

• 4WD shift switch, PNP switch, Neutral-4LO switch, vehicle speed sensor and throttle position sensor are

used in conjunction with the transfer motor.

WAIT DETECTION SWITCH

• The wait detection switch operates when there is “circulating” torque produced in the propeller shaft (L→H)

or when there is a phase difference between 2-4 sleeve and clutch drum (H→L). After the release of the “cir-

culating” torque, the wait detection switch helps provide the 4WD lock gear (clutch drum) shifts. A difference

may occur between the operation of the 4WD shift switch and actual drive mode. At this point, the wait

detection switch senses an actual drive mode.

• The wait detection switch operates as follows.

- 4WD lock gear (clutch drum) locked: ON

- 4WD lock gear (clutch drum) released: OFF

• The wait detection switch senses an actual drive mode and the 4WD shift indicator lamp indicates the vehi-

cle drive mode.

NEUTRAL-4LO SWITCH

The neutral-4LO switch detects that transfer gear is in neutral or 4LO (or shifting from neutral to 4LO) condi-

tion by L-H shift fork position.

AT P S W I T C H

ATP switch detects if transfer gear is in a neutral condition by L-H shift fork position.

NOTE:

Transfer gear may be in a neutral condition in 4H-4LO.

2-4WD SHIFT SOLENOID VALVE

The 2-4WD shift solenoid valve operates to apply oil pressure to the wet-multiplate clutch, depending on the

drive mode. The driving force is transmitted to the front wheels through the clutch so the vehicle is set in the

4WD mode. Setting the vehicle in the 2WD mode requires no pressure buildup. In other words, pressure force

applied to the wet-multiplate clutch becomes zero.

CLUTCH PRESSURE SOLENOID VALVE

The clutch pressure solenoid valve distributes torque (front and rear) in AUTO mode.

4H (LOCK) and 4LO“N” position 0 — ON

“P” position 00 - 0.07/8 OFF*

0.07/8 - 1/8 HOLD

1/8 - MAX ON

Other than “R” position0 < VSS ≤ 50 km/h (31 MPH)

— ON

50 km/h (31 MPH) < VSS < 55

km/h (34 MPH) HOLD

55 km/h (34 MPH) ≤ VSS OFF

“R” position — — ON

“R” position — — ON

AUTO“P” or “N” position00 - 0.07/8 OFF*

0.07/8 - 1/8 HOLD

1/8 - MAX ON

0 < VSS ≤ 50 km/h (31 MPH)

— ON

50 km/h (31 MPH) < VSS < 55

km/h (34 MPH) HOLD

55 km/h (34 MPH) ≤ VSS OFF

Other than “R”, "P" and "N"

position0 < VSS ≤ 50 km/h (31 MPH)

— ON

50 km/h (31 MPH) < VSS < 55

km/h (34 MPH) HOLD

55 km/h (34 MPH) ≤ VSS OFF 4WD shift switch A/T selector lever positionVehicle speed

(VSS)Accelerator pedal positionMotor relay drive

command

Page 2840 of 3061

TF-18

< SERVICE INFORMATION >

ALL-MODE 4WD SYSTEM

LINE PRESSURE SWITCH

• With the transfer system design, control of the oil pressure provides the transmission of drive torque to the

front wheels. The main pressure to control the oil pressure is referred to as the line pressure.

• The line pressure switch determines whether or not adequate line pressure has built up under different oper-

ating conditions.

• The line pressure switch turns ON when line pressure is produced.

• The line pressure switch senses line pressure abnormalities and turns the 4WD warning lamp ON.

CLUTCH PRESSURE SWITCH

• The clutch pressure switch determines whether or not adequate clutch pressure has built up under different

operating conditions.

• The clutch pressure switch turns ON when clutch pressure is produced.

• The clutch pressure switch senses clutch pressure abnormalities and turns the 4WD warning lamp ON.

TRANSFER FLUID TEMPERATURE SENSOR

The transfer temperature sensor detects the transfer fluid temperature and sends a signal to the transfer con-

trol unit.

TRANSFER CONTROL UNIT

• Transfer control unit controls transfer control device by input signals of each sensor and each switch.

• Self-diagnosis can be done.

TRANSFER CONTROL DEVICE

The transfer control device changes the state of transfer assembly between 2WD, AUTO, 4H⇔4LO with the

2WD, AUTO, 4H and 4LO signals of 4WD shift switch.

NOTE:

• To shift between 4H⇔4LO, stop the vehicle, depress the brake pedal and shift the transmission selector to

the "N" position. Depress and turn the 4WD shift switch. The shift switch will not shift to the desired mode if

the transmission is not in "N" or the vehicle is moving. The 4LO indicator lamp will be lit when the 4LO is

engaged.

• Actuator motor and actuator position switch are integrated.

4WD SHIFT SWITCH AND INDICATOR LAMP

4WD Shift Switch

The 4WD shift switch allows selection from 2WD, AUTO, 4H or 4LO.

4WD Shift Indicator Lamp

• Displays driving conditions selected by 4WD shift switch with 2WD, AUTO and 4H indicators while engine is

running. (When 4WD warning lamp is turned on, all 4WD shift indicator lamps are turned off.)

• Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4LO Indicator Lamp

• Displays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H⇔4LO. (When 4WD warning lamp is turned on, 4LO indicator lamp is

turned off.)

• Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4WD WARNING LAMP

Turns ON or FLASH when there is a malfunction in 4WD system.

Also turns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF for approximately 1

second after the engine starts if system is normal.

4WD Warning Lamp Indication

Condition Content 4WD warning lamp

During self-diagnosis Indicates the malfunction position by number of flickers. Flickers at malfunction mode.

Lamp check*Checks the lamp by turning ON during engine starting. After

engine starts, it turns OFF if there are no malfunctions.ON

Malfunction in 4WD system*Turns ON to indicate malfunction. When ignition switch is

turned to “OFF” or the malfunction is corrected, it turns OFF.ON

When vehicle is driven with different

diameters of front and rear tiresFlickers once every 2 seconds.

Turns OFF when ignition switch is “OFF”.Flickers once every 2 sec-

onds.