glove box INFINITI QX56 2007 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2127 of 3061

INSTRUMENT PANEL ASSEMBLY

IP-15

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

IP

N

O

P Disassembly

1. Remove damper clip from glove box.

2. Remove glove box pins and glove box.

3. Remove glove box striker screws, using power tool and remove glove box striker.

4. Remove fuse block cover.

5. Remove glove box damper screws and remove glove box damper.

Assembly

Assembly is in the reverse order of disassembly.

CENTER CONSOLE

1. Glove box damper 2. Lower instrument panel RH 3. Clips

4. Rubber stoppers 5. Glove box pins 6. Glove box

7. Glove box striker 8. Fuse block cover 9. Glove box assembly

WIIA0301E

Page 2328 of 3061

![INFINITI QX56 2007 Factory User Guide ILLUMINATION

LT-121

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

• to BCM terminal 38, and

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal INFINITI QX56 2007 Factory User Guide ILLUMINATION

LT-121

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

• to BCM terminal 38, and

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal](/img/42/57029/w960_57029-2327.png)

ILLUMINATION

LT-121

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

• to BCM terminal 38, and

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal 24.

Ground is supplied

• to BCM terminal 67

• to combination meter terminal 17

• through grounds M57, M61 and M79, and

• to IPDM E/R terminals 38 and 59

• through grounds E9, E15 and E24.

ILLUMINATION OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST or 2ND position (or if the auto light system is activated), the BCM receives

input signal requesting the illumination lamps to illuminate. This input signal is communicated to the IPDM E/R

across the CAN communication lines. The CPU of the IPDM E/R controls the tail lamp relay coil, which, when

energized, directs power

• through 10A fuse (No. 36, located in the IPDM E/R)

• through IPDM E/R terminal 49

• to illumination control switch terminal 1

• to power liftgate switch terminal 3

• to front room/map lamp assembly (console box illumination) terminal 7

• to hazard switch terminal 3

• to rear sonar system OFF switch terminal 3

• to glove box lamp terminal 1

• to door mirror remote control switch terminal 16

• to display control unit terminal 14

• to power window and door lock/unlock switch RH terminal 5 (early production)

• to main power window and door lock/unlock switch LH terminal 16 (early production)

• to 4WD shift switch terminal 7 (with 4-wheel drive)

• to front air control terminal 23

• to rear power vent window switch terminal 5

• to DVD player terminal 12 (with DVD entertainment system)

• to NAVI control unit terminal 61

• to pedal adjusting switch terminal 5

• to electric brake (pre-wiring) terminal 4 (with trailer tow)

• to front and rear heated seat switch LH and RH terminal 5

• to A/T device terminal 11

• to VDC OFF switch terminal 3

• to tow mode switch terminal 3

• to headlamp aiming switch terminal 3

• to clock terminal 3, and

• through 10A fuse (No. 37, located in the IPDM E/R)

• through IPDM E/R terminal 57

• to AV switch terminal 3

• to audio unit terminal 8

• to rear air control terminal 1 and

• to rear audio remote control unit terminal 6.

The illumination control switch controls illumination intensity by varying the ground to the following

• through illumination control switch terminal 2

• to power liftgate switch terminal 4

• to front room/map lamp assembly (console box illumination) terminal 8

• to AV switch terminal 4

• to hazard switch terminal 4

• to audio unit terminal 7

• to rear sonar system OFF switch terminal 4

• to power window and door lock/unlock switch RH terminal 1 (early production)

• to main power window and door lock/unlock switch LH terminal 12 (early production)

• to 4WD switch terminal 8 (with 4-wheel drive)

• to front air control terminal 24

• to rear power vent window switch terminal 6

• to DVD player terminal 10 (with DVD entertainment system)

• to pedal adjusting switch terminal 6

• to A/T device terminal 12

Page 2329 of 3061

LT-122

< SERVICE INFORMATION >

ILLUMINATION

• to front heated seat switch LH and RH terminal 6

• to VDC OFF switch terminal 4

• to tow mode switch terminal 4

• to headlamp aiming switch terminal 4

• to clock terminal 4 and

• to combination meter terminal 18.

Ground is supplied

• to illumination control switch terminal 3

• to glove box lamp terminal 2

• to door mirror remote control switch terminal 15

• to display control unit terminal 3

• to rear heated seat switches terminal 6

• to electric brake (pre-wiring) terminal 1 (with trailer tow)

• to combination meter terminal 17

• through grounds M57, M61 and M79, and

• to NAVI control unit terminal 1

• to rear air control terminal 3

• to rear audio remote control unit terminal 15

• through grounds B117 and B132.

With power and ground supplied, illumination lamps illuminate.

EXTERIOR LAMP BATTERY SAVER CONTROL

When the combination switch (lighting switch) is in the 1ST or 2ND position (or if auto light system is acti-

vated), and the ignition switch is turned from ON or ACC to OFF, the battery saver control function is activated.

Under this condition, the illumination lamps remain illuminated for 5 minutes, then the illumination lamps are

turned off.

When the lighting switch is turned from OFF to 1ST or 2ND position (or if auto light system is activated) after

illumination lamps are turned off by the battery saver control, the illumination lamps illuminate again.

Exterior lamp battery saver control mode can be changed by the function setting of CONSULT-II.

CAN Communication System DescriptionINFOID:0000000003533470

Refer to LAN-4, "CAN Communication System" .

Page 2345 of 3061

LT-138

< SERVICE INFORMATION >

BULB SPECIFICATIONS

BULB SPECIFICATIONS

HeadlampINFOID:0000000003533474

*: Always check with the Parts Department for the latest parts information.

Exterior LampINFOID:0000000003533475

*: Always check with the Parts Department for the latest parts information.

Interior Lamp/IlluminationINFOID:0000000003533476

*: Always check with the Parts Department for the latest parts information.Item Wattage (W)*

Low35 (D2R)

High60 (HB3)

Item Wattage (W)*

Front combination lampParking lamp (inner) 7

Parking lamp (outer) 7

Side marker lamp (front) 7

Rear combination lampStop/Tail lamp *

Side marker lamp (rear) *

Turn signal lamp 27

Back-up lamp*

Turn/fog lampFog 55 (H3)

Turn 21

License plate lamp5

High-mounted stop lamp*

Item Wattage (W)*

Glove box lamp3.4

Room/Map lamp8

Console box illumination lamp*

A/T device lamp2

Foot lamp3.4

Ste p lam p3.8

Cargo lamp7

Vanity lamp1.32

Personal lamp5

Puddle lamp8

Ignition keyhole illumination lamp0.74

Page 2382 of 3061

MA-20

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

CHASSIS AND BODY MAINTENANCE

Changing In-cabin MicrofilterINFOID:0000000003533875

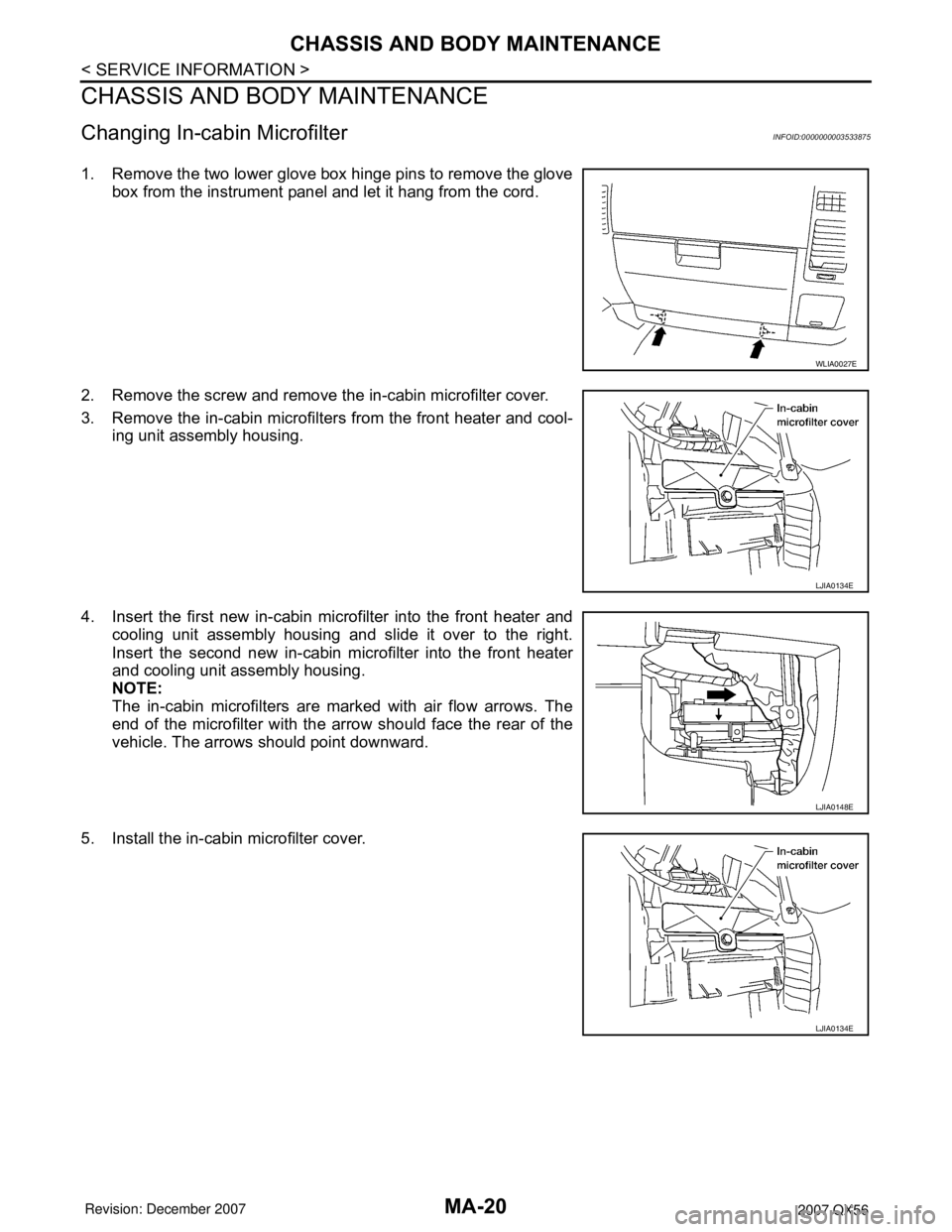

1. Remove the two lower glove box hinge pins to remove the glove

box from the instrument panel and let it hang from the cord.

2. Remove the screw and remove the in-cabin microfilter cover.

3. Remove the in-cabin microfilters from the front heater and cool-

ing unit assembly housing.

4. Insert the first new in-cabin microfilter into the front heater and

cooling unit assembly housing and slide it over to the right.

Insert the second new in-cabin microfilter into the front heater

and cooling unit assembly housing.

NOTE:

The in-cabin microfilters are marked with air flow arrows. The

end of the microfilter with the arrow should face the rear of the

vehicle. The arrows should point downward.

5. Install the in-cabin microfilter cover.

WLIA0027E

LJIA0134E

LJIA0148E

LJIA0134E

Page 2383 of 3061

CHASSIS AND BODY MAINTENANCE

MA-21

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

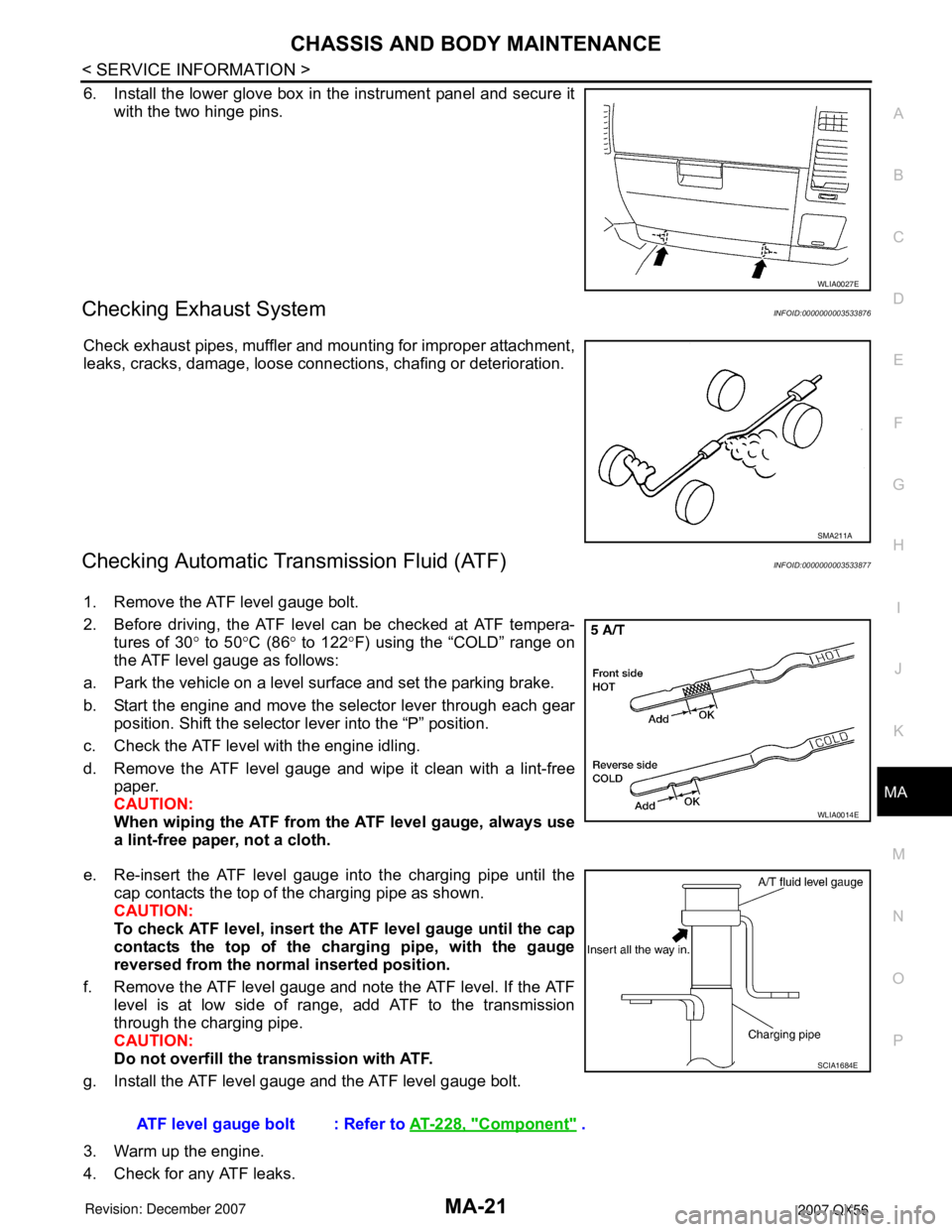

6. Install the lower glove box in the instrument panel and secure it

with the two hinge pins.

Checking Exhaust SystemINFOID:0000000003533876

Check exhaust pipes, muffler and mounting for improper attachment,

leaks, cracks, damage, loose connections, chafing or deterioration.

Checking Automatic Transmission Fluid (ATF)INFOID:0000000003533877

1. Remove the ATF level gauge bolt.

2. Before driving, the ATF level can be checked at ATF tempera-

tures of 30° to 50°C (86° to 122°F) using the “COLD” range on

the ATF level gauge as follows:

a. Park the vehicle on a level surface and set the parking brake.

b. Start the engine and move the selector lever through each gear

position. Shift the selector lever into the “P” position.

c. Check the ATF level with the engine idling.

d. Remove the ATF level gauge and wipe it clean with a lint-free

paper.

CAUTION:

When wiping the ATF from the ATF level gauge, always use

a lint-free paper, not a cloth.

e. Re-insert the ATF level gauge into the charging pipe until the

cap contacts the top of the charging pipe as shown.

CAUTION:

To check ATF level, insert the ATF level gauge until the cap

contacts the top of the charging pipe, with the gauge

reversed from the normal inserted position.

f. Remove the ATF level gauge and note the ATF level. If the ATF

level is at low side of range, add ATF to the transmission

through the charging pipe.

CAUTION:

Do not overfill the transmission with ATF.

g. Install the ATF level gauge and the ATF level gauge bolt.

3. Warm up the engine.

4. Check for any ATF leaks.

WLIA0027E

SMA211A

WLIA0014E

ATF level gauge bolt : Refer to AT-228, "Component" .

SCIA1684E

Page 2809 of 3061

FRONT PASSENGER AIR BAG MODULE

SRS-39

< SERVICE INFORMATION >

C

D

E

F

G

I

J

K

L

MA

B

SRS

N

O

P

FRONT PASSENGER AIR BAG MODULE

Removal and InstallationINFOID:0000000003532875

The passenger air bag module originally installed in the vehicle uses direct-connect style harness connectors.

Service replacement passenger air bag modules use tab-locking style harness connectors. If the passenger

air bag module is replaced or if the direct-connect harness connectors are damaged, the vehicle wiring har-

ness must be modified to allow connection of the service replacement passenger air bag module. Refer to

"WIRING HARNESS MODIFICATION" for wiring harness modification procedure.

REMOVAL

CAUTION:

• Do not attempt to repair or replace damaged direct-connect front passenger air bag module connec-

tors. If a direct-connect harness connector is damaged, the front passenger air bag must be

replaced and the wiring harness modified.

• Before servicing SRS, turn the ignition switch off, disconnect both battery cables and wait at least 3

minutes.

• Always work from the side of or under front passenger air bag module.

1. Remove the glove box. Refer to IP-10

.

2. Remove 2 nuts (through glove box opening) retaining front pas-

senger air bag module to instrument panel crossmember.

3. Disconnect the air bag module electrical connectors.

• For removal/installation of the direct-connect SRS connectors,

refer to SRS-6, "

Direct-connect SRS Component Connectors"

.

4. Remove the instrument panel assembly from the vehicle. Refer

to IP-10

.

5. Remove front passenger air bag module nuts and remove air

bag module from the instrument panel assembly.

CAUTION:

• When servicing the SRS, do not work from directly in front of

air bag module.

• Always place front passenger air bag module with caution

label side facing upward.

• Do not insert any foreign objects (screwdriver, etc.) into air

bag module or harness connectors.

• Do not disassemble air bag module.

• Do not use old nuts after removal; replace with new nuts.

• Do not expose the front passenger air bag module to tempera-

tures exceeding 90°C (194°F).

• Replace the air bag module if it has been dropped or sus-

tained an impact.

• Do not allow oil, grease or water to come in contact with the

air bag module.

• For removal/installation of the direct-connect SRS connec-

tors, refer to SRS-6, "

Direct-connect SRS Component Con-

nectors" .

INSTALLATION

Original Passenger Air Bag Module

WHIA0110E

WHIA0111E

SBF814E

Page 2937 of 3061

TRANSFER CONTROL UNIT

TF-115

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

TRANSFER CONTROL UNIT

Removal and InstallationINFOID:0000000003532562

REMOVAL

1. Set transfer state as 2WD when 4WD shift switch is at 2WD, or as AUTO when 4WD shift switch is at

AUTO.

CAUTION:

When removing transfer control unit, transfer state must be at 2WD or AUTO.

2. Turn the ignition switch OFF and disconnect negative battery terminal.

3. Remove the glove box assembly. Refer to IP-10, "

Removal and Installation".

4. Disconnect the two transfer control unit connectors.

5. Remove the transfer control unit bolts.

6. Remove the transfer control unit.

INSTALLATION

Installation is in the reverse order of removal.

• When installing the transfer control unit, tighten bolts to the specified torque.

CAUTION:

• Do not connect harness connector to transfer control unit when 4WD shift switch is at 4LO.

• After the installation, check perform self-diagnosis. Refer to TF-48, "

Self-Diagnosis Procedure". If NG, adjust

position between transfer assembly and transfer control unit. Refer to TF-3, "

Precaution for Transfer Assem-

bly and Transfer Control Unit Replacement".

BDIA0014E

Transfer control unit bolts : 5.1 N·m (0.52 kg-m, 45 in-lb)