fuel INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1671 of 3061

EC-588

< SERVICE INFORMATION >

DTC P2A00, P2A03 A/F SENSOR 1

DTC P2A00, P2A03 A/F SENSOR 1

Component DescriptionINFOID:0000000003532141

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The sensor element of the A/F sensor 1 is composed an elec-

trode layer, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusion layer at

the sensor cell. An electrode layer is applied voltage, and this current

relative oxygen density in lean. Also this current relative hydrocar-

bon density in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In addition, a heater is integrated in the

sensor to ensure the required operating temperature of about 800°C

(1,472°F).

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003532142

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000003532143

To judge the malfunction, the A/F signal computed by ECM from the A/F sensor 1 signal is monitored not to be

shifted to LEAN side or RICH side.

DTC Confirmation ProcedureINFOID:0000000003532144

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

WITH CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

PBIB3353E

PBIB3354E

MONITOR ITEM CONDITION SPECIFICATION

A/F SEN1 (B1)

A/F SEN1 (B2)• Engine: After warming up Maintaining engine speed at 2,000 rpm Fluctuates around 2.2V

DTC No. Trouble diagnosis name DTC detecting condition Possible Cause

P2A00

2A00

(Bank 1)

Air fuel ratio (A/F) sensor 1

circuit range/performance• The output voltage computed by ECM from the

A/F sensor 1 signal is shifted to the lean side for

a specified period.

• The A/F signal computed by ECM from the A/F

sensor 1 signal is shifted to the rich side for a

specified period.• A/F sensor 1

• A/F sensor 1 heater

• Fuel pressure

• Fuel injector

• Intake air leaks P2A03

2A03

(Bank 2)

Page 1674 of 3061

DTC P2A00, P2A03 A/F SENSOR 1

EC-591

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

2 LG/B A/F sensor 1 heater (bank 1)[Engine is running]

•Warm-up condition

• Idle speed

(More than 140 seconds after starting en-

gine)Approximately 2.9 - 8.8V

35 BR/R A/F sensor 1 (bank 1)[Engine is running]

•Warm-up condition

• Engine speed: 2,000 rpmApproximately 1.8V

Output voltage varies with air fuel

ratio.

56 BR/G A/F sensor 1 (bank 1)[Ignition switch: ON]Approximately 2.2V

PBIA8148J

Page 1676 of 3061

DTC P2A00, P2A03 A/F SENSOR 1

EC-593

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000003532146

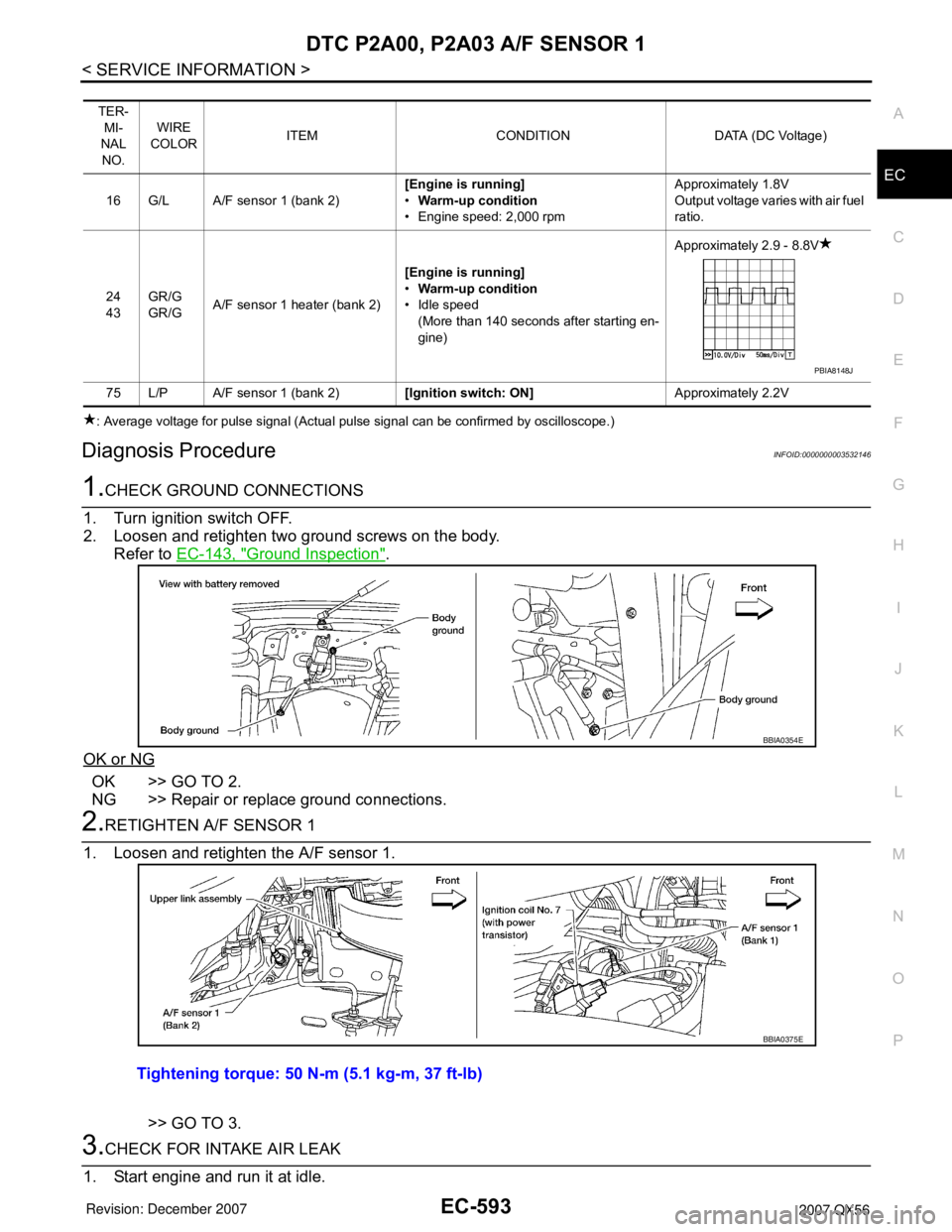

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten two ground screws on the body.

Refer to EC-143, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.RETIGHTEN A/F SENSOR 1

1. Loosen and retighten the A/F sensor 1.

>> GO TO 3.

3.CHECK FOR INTAKE AIR LEAK

1. Start engine and run it at idle.

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

16 G/L A/F sensor 1 (bank 2)[Engine is running]

•Warm-up condition

• Engine speed: 2,000 rpmApproximately 1.8V

Output voltage varies with air fuel

ratio.

24

43GR/G

GR/GA/F sensor 1 heater (bank 2)[Engine is running]

•Warm-up condition

• Idle speed

(More than 140 seconds after starting en-

gine)Approximately 2.9 - 8.8V

75 L/P A/F sensor 1 (bank 2)[Ignition switch: ON]Approximately 2.2V

PBIA8148J

BBIA0354E

Tightening torque: 50 N-m (5.1 kg-m, 37 ft-lb)

BBIA0375E

Page 1679 of 3061

EC-596

< SERVICE INFORMATION >

DTC P2A00, P2A03 A/F SENSOR 1

OK >> GO TO 10.

NG >> GO TO 11.

10.CHECK INTERMITTENT INCIDENT

Perform EC-138

.

OK or NG

OK >> GO TO 11.

NG >> Repair or replace.

11 .REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace malfunctioning air fuel ratio (A/F) sensor 1.

CAUTION:

• Discard any A/F sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

• Before installing new A/F sensor, clean exhaust system threads using Oxygen Sensor Thread

Cleaner tool J-43897-18 or J-43897-12 and approved anti-seize lubricant.

>> GO TO 12.

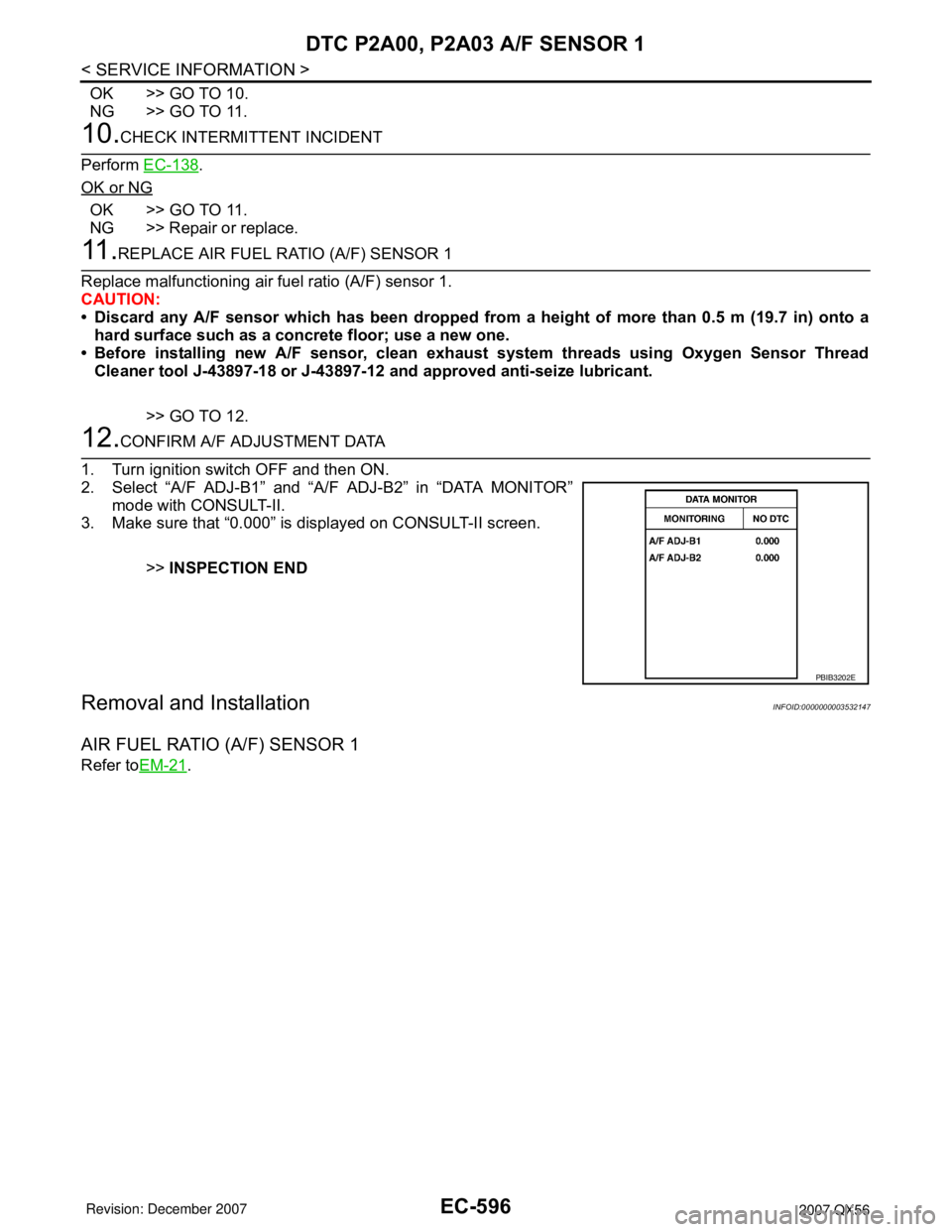

12.CONFIRM A/F ADJUSTMENT DATA

1. Turn ignition switch OFF and then ON.

2. Select “A/F ADJ-B1” and “A/F ADJ-B2” in “DATA MONITOR”

mode with CONSULT-II.

3. Make sure that “0.000” is displayed on CONSULT-II screen.

>>INSPECTION END

Removal and InstallationINFOID:0000000003532147

AIR FUEL RATIO (A/F) SENSOR 1

Refer toEM-21.

PBIB3202E

Page 1691 of 3061

EC-608

< SERVICE INFORMATION >

FUEL INJECTOR

FUEL INJECTOR

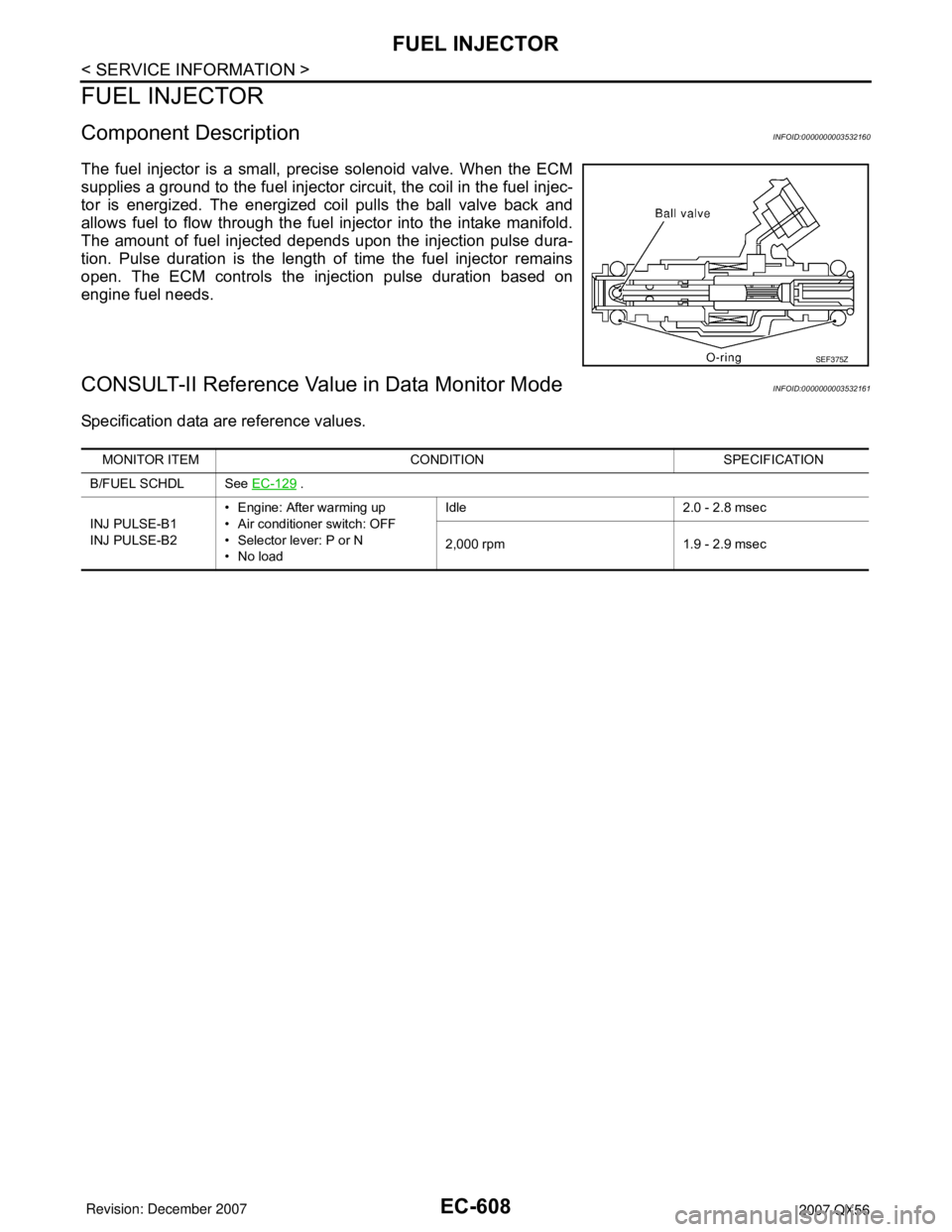

Component DescriptionINFOID:0000000003532160

The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the fuel injector circuit, the coil in the fuel injec-

tor is energized. The energized coil pulls the ball valve back and

allows fuel to flow through the fuel injector into the intake manifold.

The amount of fuel injected depends upon the injection pulse dura-

tion. Pulse duration is the length of time the fuel injector remains

open. The ECM controls the injection pulse duration based on

engine fuel needs.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003532161

Specification data are reference values.

SEF375Z

MONITOR ITEM CONDITION SPECIFICATION

B/FUEL SCHDL See EC-129

.

INJ PULSE-B1

INJ PULSE-B2• Engine: After warming up

• Air conditioner switch: OFF

• Selector lever: P or N

•No loadIdle 2.0 - 2.8 msec

2,000 rpm 1.9 - 2.9 msec

Page 1692 of 3061

FUEL INJECTOR

EC-609

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Wiring DiagramINFOID:0000000003532162

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

BBWA2124E

Page 1693 of 3061

EC-610

< SERVICE INFORMATION >

FUEL INJECTOR

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000003532163

1.INSPECTION START

Turn ignition switch to START.

Is any cylinder ignited?

Ye s o r N o

Ye s > > G O T O 2 .

No >> GO TO 3.

2.CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Perform “POWER BALANCE” in “ACTIVE TEST” mode with

CONSULT-II.

3. Make sure that each circuit produces a momentary engine

speed drop.

Without CONSULT-II

1. Start engine.

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

21

22

23

40

41

42

44

63O/L

BR

GR/W

Y/G

P

L

O

GFuel injector No. 5

Fuel injector No. 3

Fuel injector No. 1

Fuel injector No. 6

Fuel injector No. 4

Fuel injector No. 2

Fuel injector No. 7

Fuel injector No. 8[Engine is running]

•Warm-up condition

• Idle speed

NOTE:

The pulse cycle changes depending on rpm at idle. BATTERY VOLTAGE

(11 - 14V)

[Engine is running]

•Warm-up condition

• Engine speed: 2,000 rpmBATTERY VOLTAGE

(11 - 14V)

PBIB0042E

PBIB0043E

PBIB0133E

Page 1694 of 3061

FUEL INJECTOR

EC-611

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

2. Listen to each fuel injector operating sound.

Clicking noise should be heard.

OK or NG

OK >>INSPECTION END

NG >> GO TO 3.

3.CHECK FUEL INJECTOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect fuel injector harness connector.

3. Turn ignition switch ON.

4. Check voltage between fuel injector terminal 1 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• IPDM E/R connector E119

• 15A fuse

• Harness for open or short between fuel injector and fuse

>> Repair harness or connectors.

5.CHECK FUEL INJECTOR OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between fuel injector terminal 2 and ECM terminals 21, 22, 23, 40, 41, 42, 44,

63.

Refer to Wiring Diagram.

PBIB1986E

Voltage: Battery voltage

BBIA0374E

PBIB0582E

Continuity should exist.

Page 1695 of 3061

EC-612

< SERVICE INFORMATION >

FUEL INJECTOR

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK FUEL INJECTOR

Refer to EC-612, "

Component Inspection" .

OK or NG

OK >> GO TO 7.

NG >> Replace malfunctioning fuel injector.

7.CHECK INTERMITTENT INCIDENT

Refer to EC-138

.

>>INSPECTION END

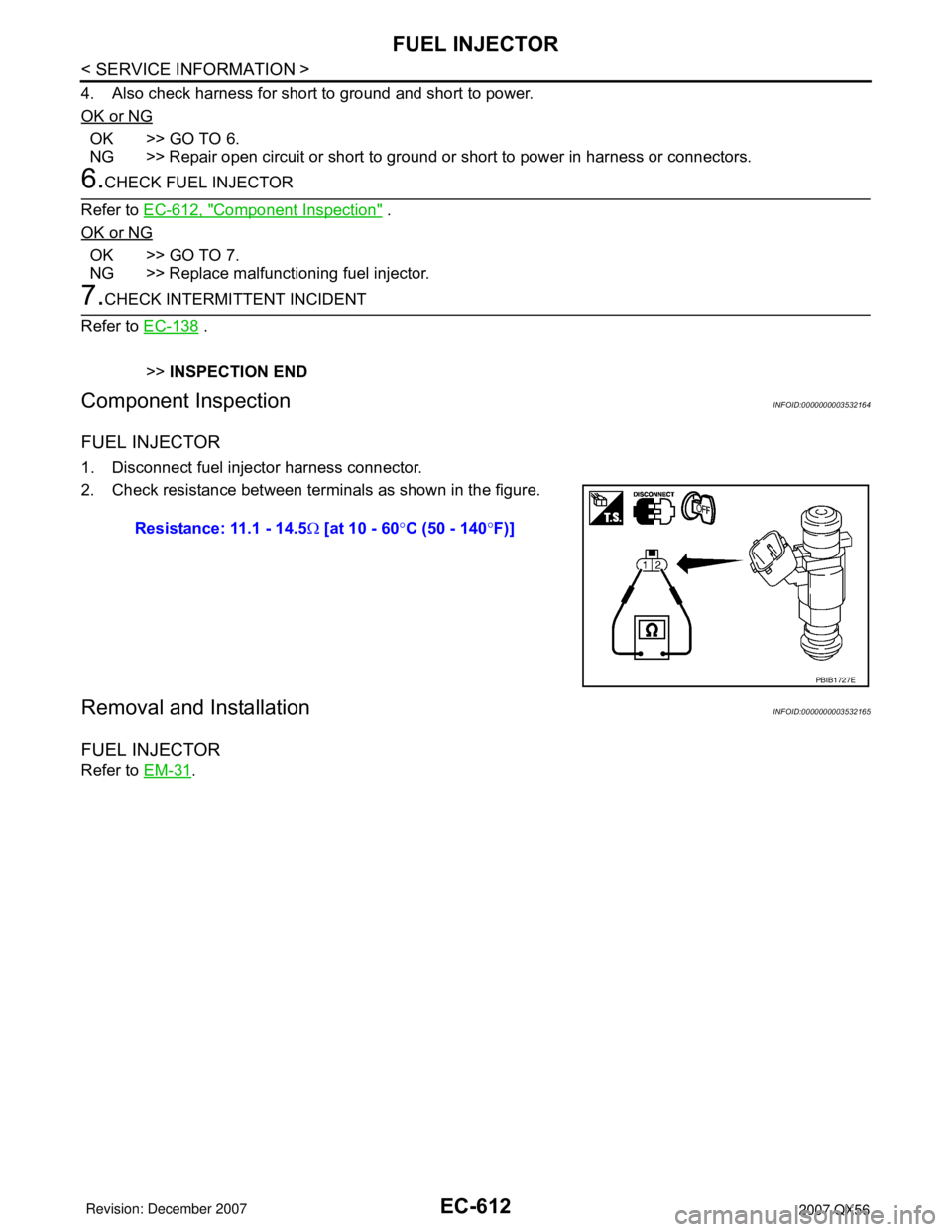

Component InspectionINFOID:0000000003532164

FUEL INJECTOR

1. Disconnect fuel injector harness connector.

2. Check resistance between terminals as shown in the figure.

Removal and InstallationINFOID:0000000003532165

FUEL INJECTOR

Refer to EM-31. Resistance: 11.1 - 14.5Ω [at 10 - 60°C (50 - 140°F)]

PBIB1727E

Page 1696 of 3061

FUEL PUMP

EC-613

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

FUEL PUMP

DescriptionINFOID:0000000003532166

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the signals of engine speed and battery voltage.

The ECM activates the fuel pump for several seconds after the ignition switch is turned ON to improve engine

startability. If the ECM receives a engine speed signal from the camshaft position sensor (PHASE), it knows

that the engine is rotating, and causes the pump to operate. If the engine speed signal is not received when

the ignition switch is ON, the engine stalls. The ECM stops pump operation and prevents battery discharging,

thereby improving safety. The ECM does not directly drive the fuel pump. It controls the ON/OFF fuel pump

relay, which in turn controls the fuel pump.

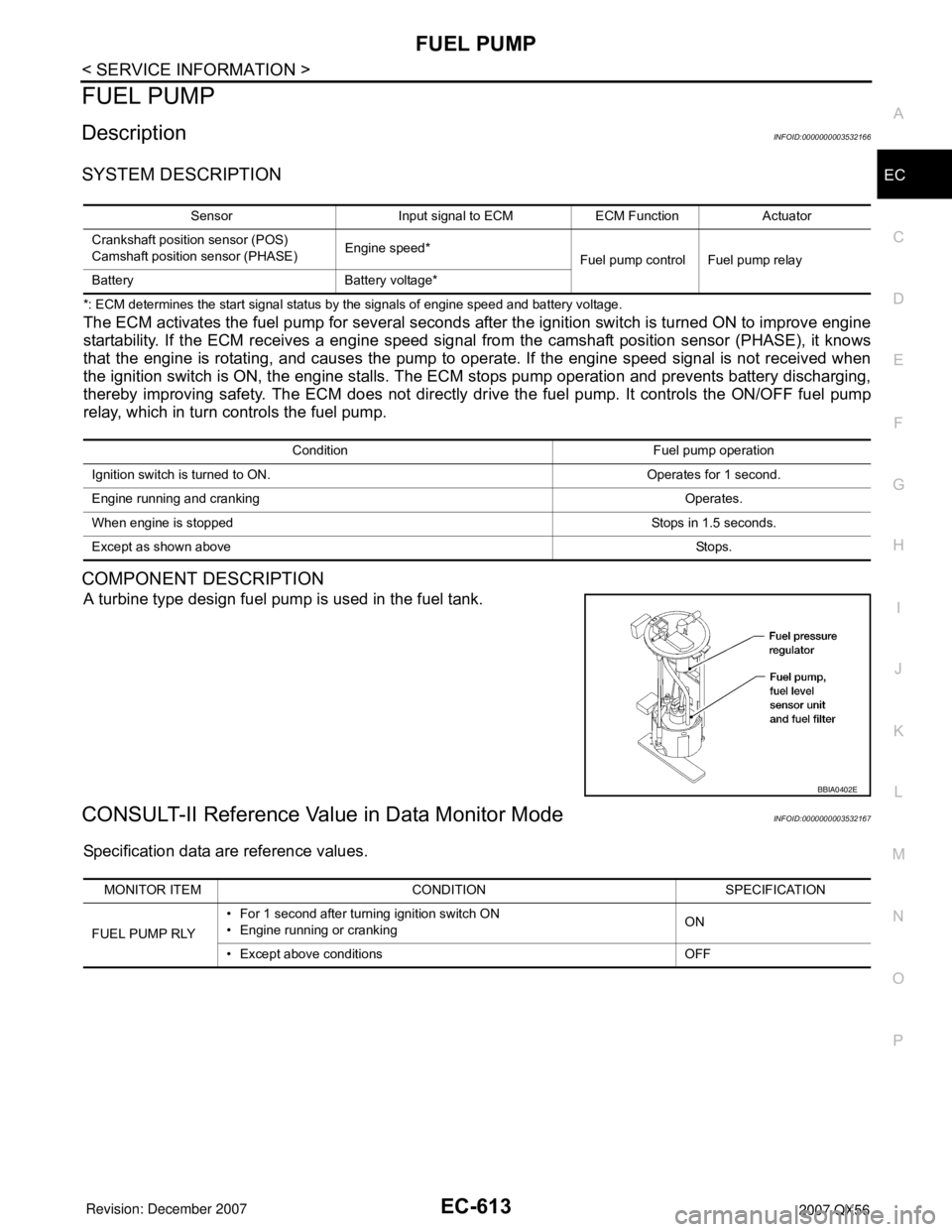

COMPONENT DESCRIPTION

A turbine type design fuel pump is used in the fuel tank.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003532167

Specification data are reference values.

Sensor Input signal to ECM ECM Function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

Fuel pump control Fuel pump relay

Battery Battery voltage*

Condition Fuel pump operation

Ignition switch is turned to ON. Operates for 1 second.

Engine running and crankingOperates.

When engine is stopped Stops in 1.5 seconds.

Except as shown aboveSto ps .

BBIA0402E

MONITOR ITEM CONDITION SPECIFICATION

FUEL PUMP RLY• For 1 second after turning ignition switch ON

• Engine running or crankingON

• Except above conditions OFF