battery INFINITI QX56 2007 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 277 of 3061

SHIFT CONTROL SYSTEM

AT-207

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

SHIFT CONTROL SYSTEM

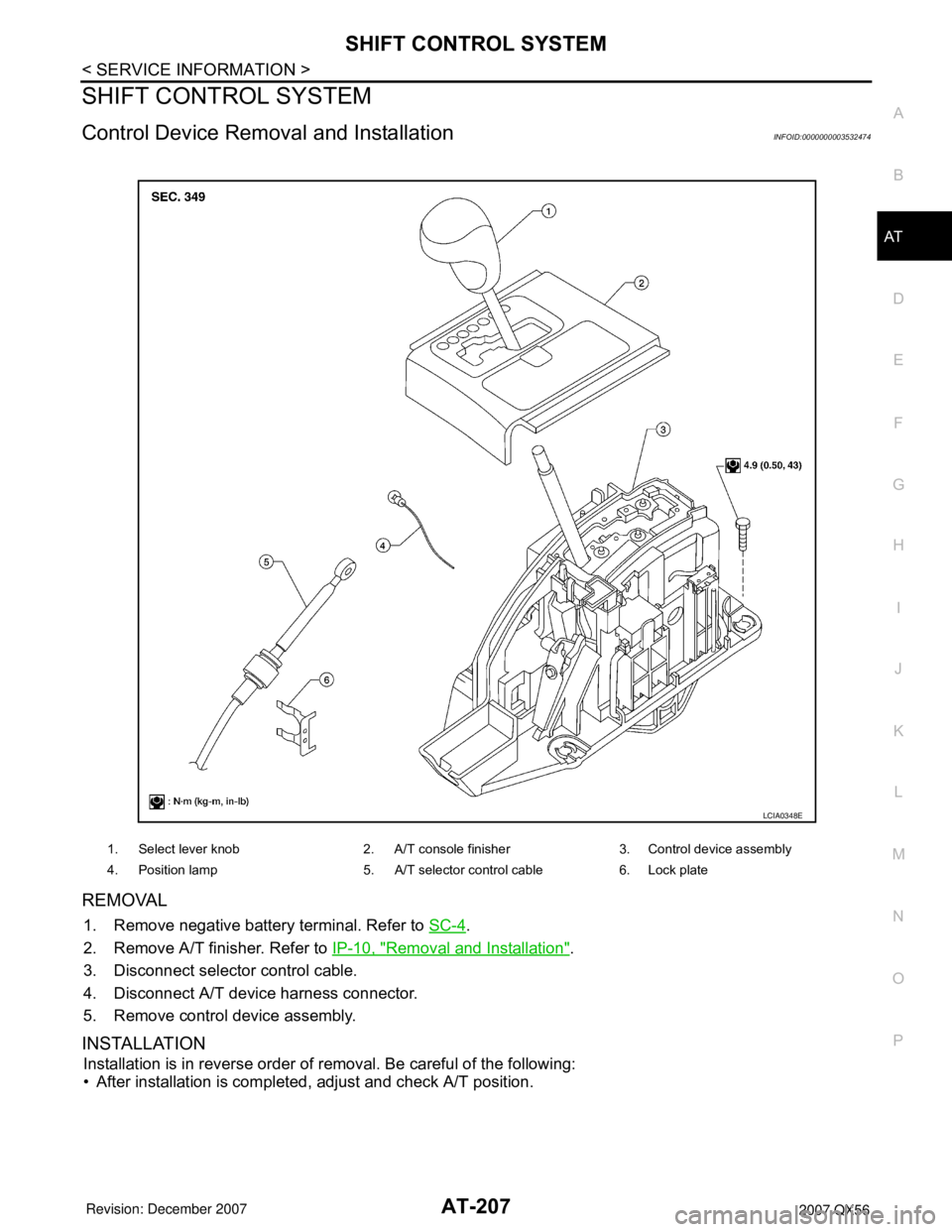

Control Device Removal and InstallationINFOID:0000000003532474

REMOVAL

1. Remove negative battery terminal. Refer to SC-4.

2. Remove A/T finisher. Refer to IP-10, "

Removal and Installation".

3. Disconnect selector control cable.

4. Disconnect A/T device harness connector.

5. Remove control device assembly.

INSTALLATION

Installation is in reverse order of removal. Be careful of the following:

• After installation is completed, adjust and check A/T position.

1. Select lever knob 2. A/T console finisher 3. Control device assembly

4. Position lamp 5. A/T selector control cable 6. Lock plate

LCIA0348E

Page 281 of 3061

ON-VEHICLE SERVICE

AT-211

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

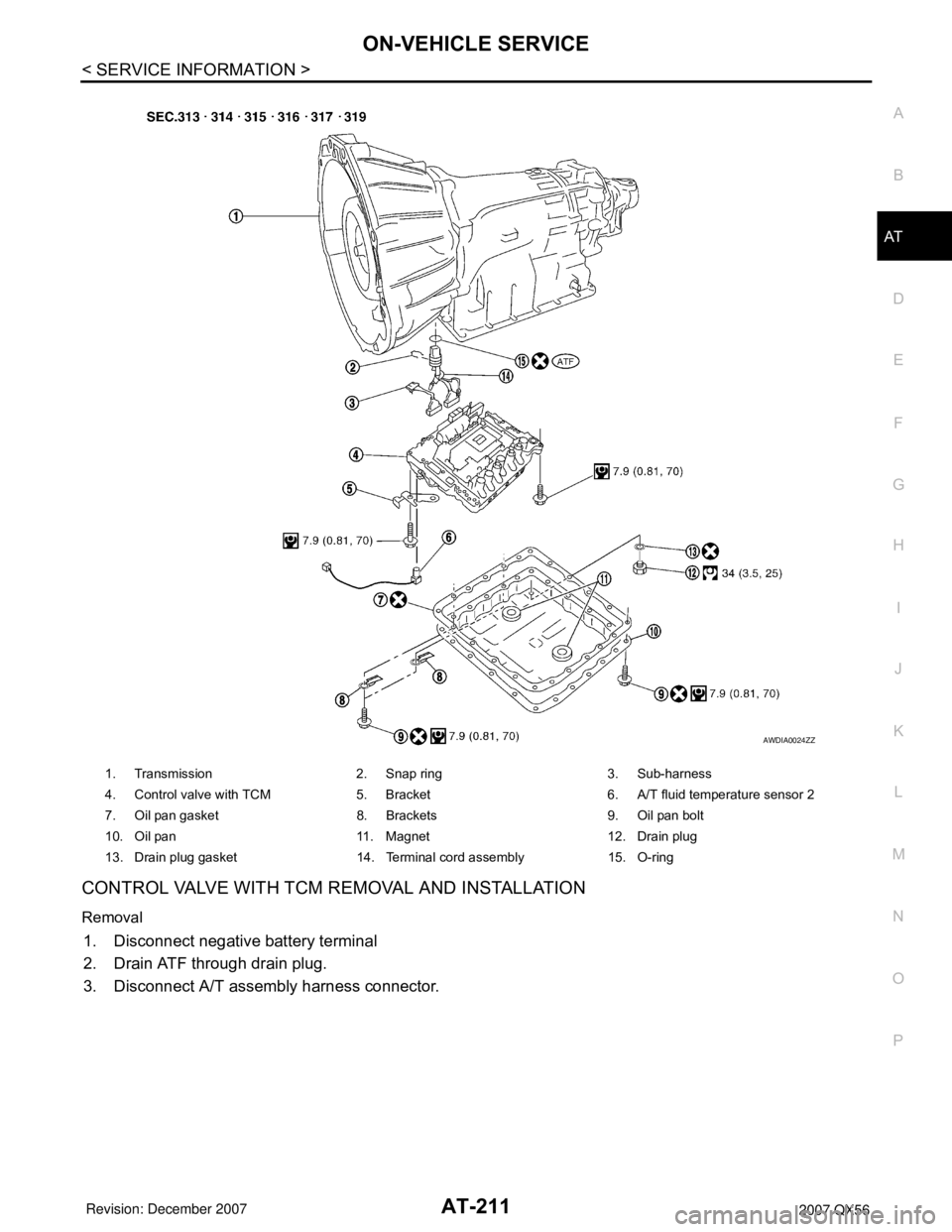

CONTROL VALVE WITH TCM REMOVAL AND INSTALLATION

Removal

1. Disconnect negative battery terminal

2. Drain ATF through drain plug.

3. Disconnect A/T assembly harness connector.

1. Transmission 2. Snap ring 3. Sub-harness

4. Control valve with TCM 5. Bracket 6. A/T fluid temperature sensor 2

7. Oil pan gasket 8. Brackets 9. Oil pan bolt

10. Oil pan 11. Magnet 12. Drain plug

13. Drain plug gasket 14. Terminal cord assembly 15. O-ring

AWDIA0024ZZ

Page 288 of 3061

AT-218

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

17. Install snap ring to A/T assembly harness connector.

18. Connect A/T assembly harness connector.

19. Connect the negative battery terminal

20. Refill the A/T with fluid and check fluid level and for fluid leak-

age. Refer to AT-13, "

Changing Automatic Transmission Fluid

(ATF)".

CAUTION:

After completing installation, check A/T fluid leakage and fluid

level. Refer to AT-13, "

Changing Automatic Transmission Fluid

(ATF)", AT-13, "Checking Automatic Transmission Fluid (ATF)".

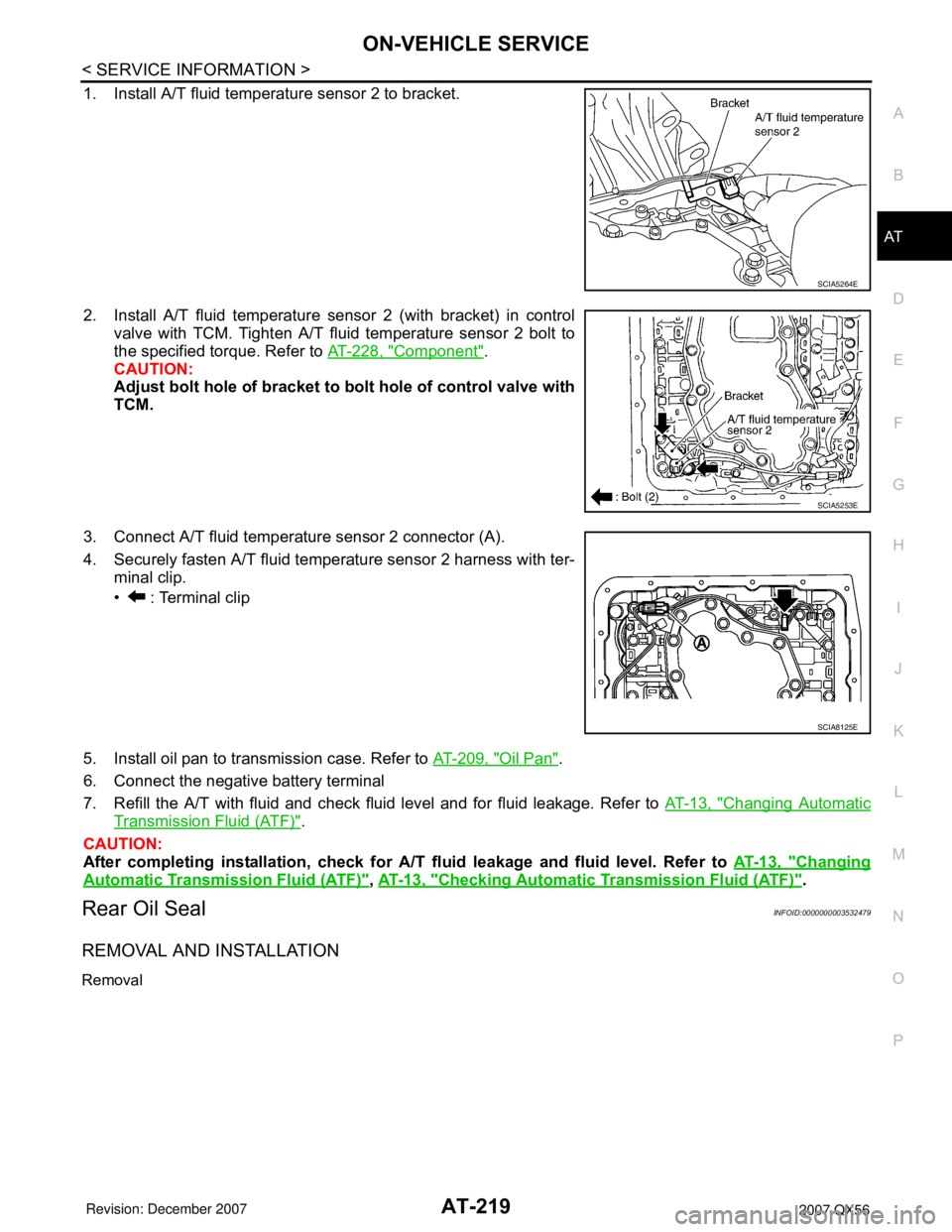

A/T FLUID TEMPERATURE SENSOR 2 REMOVAL AND INSTALLATION

Removal

1. Disconnect negative battery terminal

2. Remove oil pan and oil pan gasket. Refer to AT-209, "

Oil Pan".

3. Disconnect A/T fluid temperature sensor 2 connector (A).

CAUTION:

Be careful not to damage connector.

4. Straighten terminal clip to free A/T fluid temperature sensor 2

harness.

• : Terminal clip

5. Remove A/T fluid temperature sensor 2 with bracket from con-

trol valve with TCM.

6. Remove bracket from A/T fluid temperature sensor 2.

Installation

SCIA5039E

SCIA8125E

SCIA5253E

SCIA5264E

Page 289 of 3061

ON-VEHICLE SERVICE

AT-219

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

1. Install A/T fluid temperature sensor 2 to bracket.

2. Install A/T fluid temperature sensor 2 (with bracket) in control

valve with TCM. Tighten A/T fluid temperature sensor 2 bolt to

the specified torque. Refer to AT-228, "

Component".

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve with

TCM.

3. Connect A/T fluid temperature sensor 2 connector (A).

4. Securely fasten A/T fluid temperature sensor 2 harness with ter-

minal clip.

• : Terminal clip

5. Install oil pan to transmission case. Refer to AT-209, "

Oil Pan".

6. Connect the negative battery terminal

7. Refill the A/T with fluid and check fluid level and for fluid leakage. Refer to AT-13, "

Changing Automatic

Transmission Fluid (ATF)".

CAUTION:

After completing installation, check for A/T fluid leakage and fluid level. Refer to AT-13, "

Changing

Automatic Transmission Fluid (ATF)", AT-13, "Checking Automatic Transmission Fluid (ATF)".

Rear Oil SealINFOID:0000000003532479

REMOVAL AND INSTALLATION

Removal

SCIA5264E

SCIA5253E

SCIA8125E

Page 293 of 3061

TRANSMISSION ASSEMBLY

AT-223

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

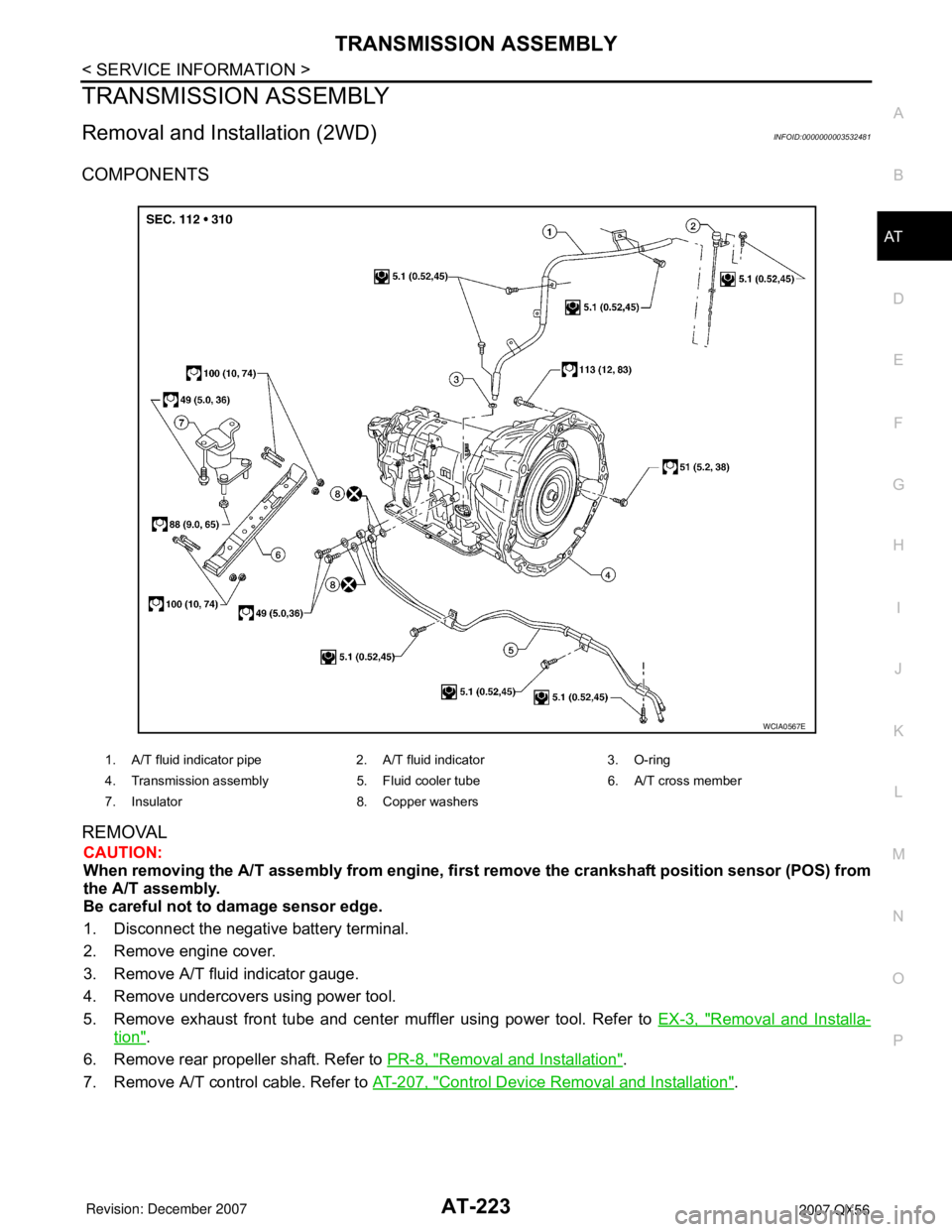

TRANSMISSION ASSEMBLY

Removal and Installation (2WD)INFOID:0000000003532481

COMPONENTS

REMOVAL

CAUTION:

When removing the A/T assembly from engine, first remove the crankshaft position sensor (POS) from

the A/T assembly.

Be careful not to damage sensor edge.

1. Disconnect the negative battery terminal.

2. Remove engine cover.

3. Remove A/T fluid indicator gauge.

4. Remove undercovers using power tool.

5. Remove exhaust front tube and center muffler using power tool. Refer to EX-3, "

Removal and Installa-

tion".

6. Remove rear propeller shaft. Refer to PR-8, "

Removal and Installation".

7. Remove A/T control cable. Refer to AT-207, "

Control Device Removal and Installation".

1. A/T fluid indicator pipe 2. A/T fluid indicator 3. O-ring

4. Transmission assembly 5. Fluid cooler tube 6. A/T cross member

7. Insulator 8. Copper washers

WCIA0567E

Page 296 of 3061

AT-226

< SERVICE INFORMATION >

TRANSMISSION ASSEMBLY

REMOVAL

CAUTION:

When removing the A/T assembly from engine, first remove the crankshaft position sensor (POS) from

the A/T assembly.

Be careful not to damage sensor edge.

1. Disconnect the negative battery terminal.

2. Remove engine cover using power tool.

3. Remove A/T fluid indicator.

4. Remove undercovers using power tool.

5. Remove exhaust front tube and center muffler using power tool. Refer to EX-3, "

Removal and Installa-

tion".

6. Remove propeller shafts. Refer to PR-4, "

Removal and Installation" and PR-8, "Removal and Installation".

7. Remove A/T control cable. Refer to AT-207, "

Control Device Removal and Installation".

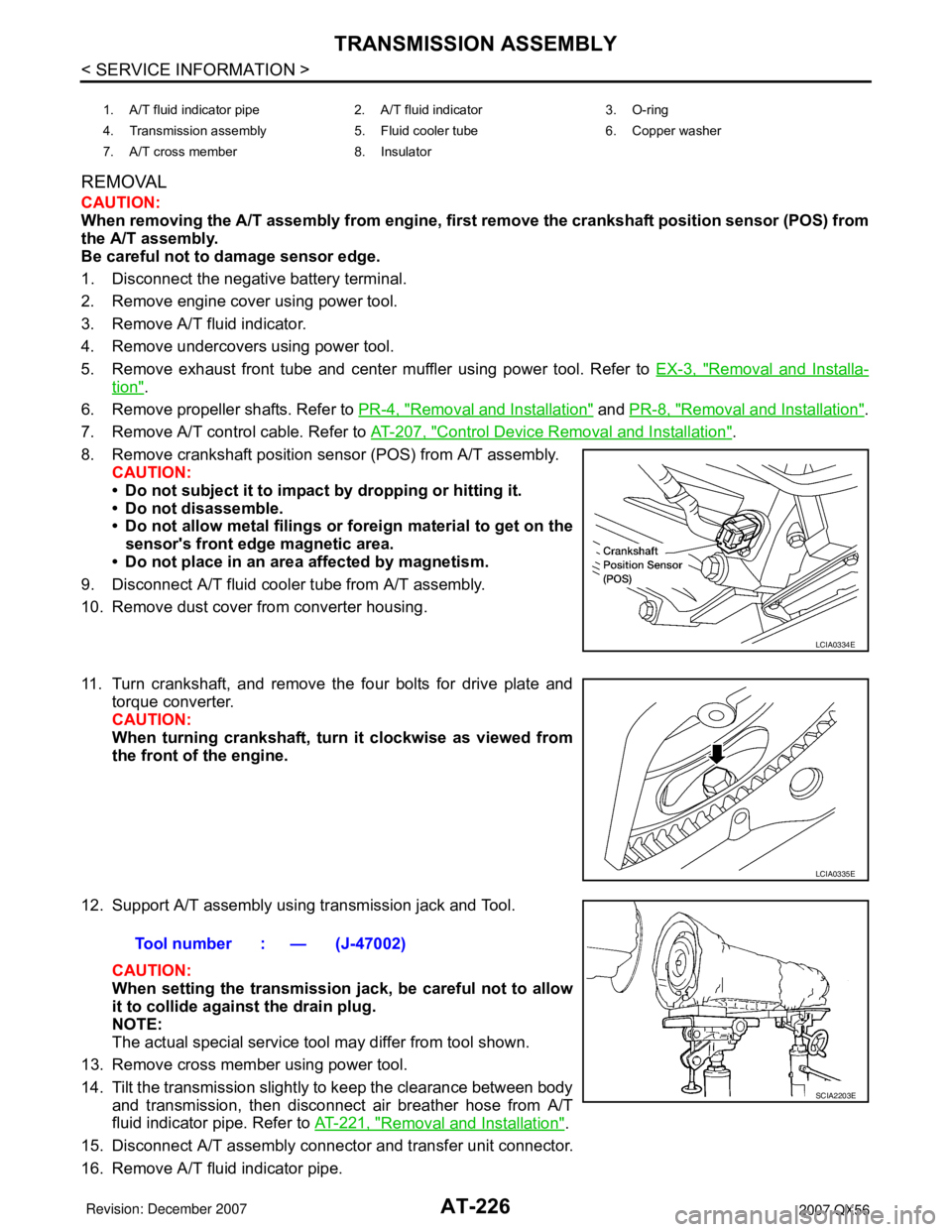

8. Remove crankshaft position sensor (POS) from A/T assembly.

CAUTION:

• Do not subject it to impact by dropping or hitting it.

• Do not disassemble.

• Do not allow metal filings or foreign material to get on the

sensor's front edge magnetic area.

• Do not place in an area affected by magnetism.

9. Disconnect A/T fluid cooler tube from A/T assembly.

10. Remove dust cover from converter housing.

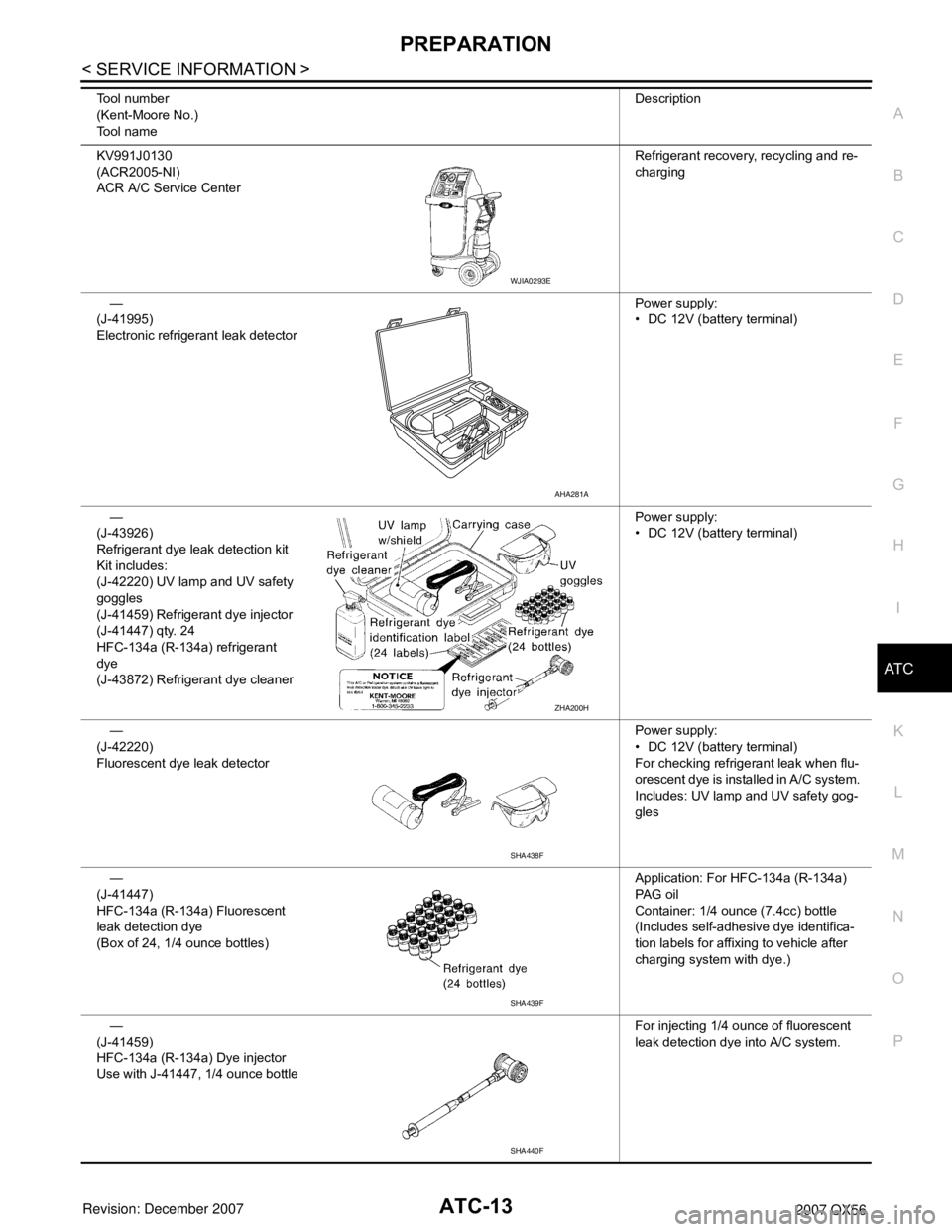

11. Turn crankshaft, and remove the four bolts for drive plate and

torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of the engine.

12. Support A/T assembly using transmission jack and Tool.

CAUTION:

When setting the transmission jack, be careful not to allow

it to collide against the drain plug.

NOTE:

The actual special service tool may differ from tool shown.

13. Remove cross member using power tool.

14. Tilt the transmission slightly to keep the clearance between body

and transmission, then disconnect air breather hose from A/T

fluid indicator pipe. Refer to AT-221, "

Removal and Installation".

15. Disconnect A/T assembly connector and transfer unit connector.

16. Remove A/T fluid indicator pipe.

1. A/T fluid indicator pipe 2. A/T fluid indicator 3. O-ring

4. Transmission assembly 5. Fluid cooler tube 6. Copper washer

7. A/T cross member 8. Insulator

LCIA0334E

LCIA0335E

Tool number : — (J-47002)

SCIA2203E

Page 383 of 3061

PREPARATIONATC-13

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

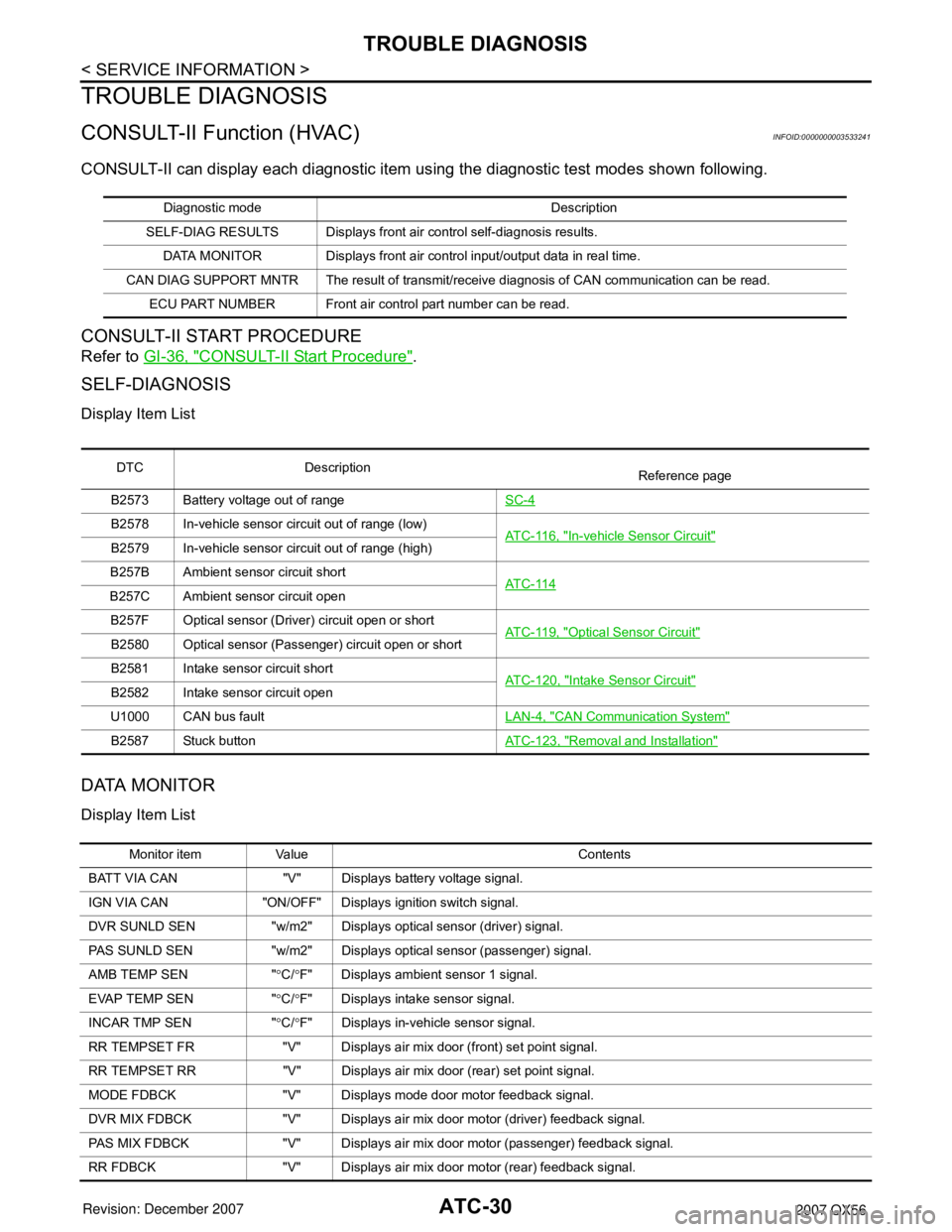

KV991J0130

(ACR2005-NI)

ACR A/C Service Center Refrigerant recovery

, recycling and re-

charging

—

(J-41995)

Electronic refrigerant leak detector Power supply:

• DC 12V (battery terminal)

—

(J-43926)

Refrigerant dye leak detection kit

Kit includes:

(J-42220) UV lamp and UV safety

goggles

(J-41459) Refrigerant dye injector

(J-41447) qty. 24

HFC-134a (R-134a) refrigerant

dye

(J-43872) Refrigerant dye cleaner Power supply:

• DC 12V (battery terminal)

—

(J-42220)

Fluorescent dye leak detector Power supply:

• DC 12V (battery terminal)

For checking refrigerant leak when flu-

orescent dye is installed in A/C system.

Includes: UV lamp and UV safety gog-

gles

—

(J-41447)

HFC-134a (R-134a) Fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles) Application: For HFC-134a (R-134a)

PA G o i l

Container: 1/4 ounce (7.4cc) bottle

(Includes self-adhesive dye identifica-

tion labels for affixing to vehicle after

charging system with dye.)

—

(J-41459)

HFC-134a (R-134a) Dye injector

Use with J-41447, 1/4 ounce bottle For injecting 1/4 ounce of fluorescent

leak detection dye into A/C system.

Tool number

(Kent-Moore No.)

Tool name

Description

WJIA0293E

AHA281A

ZHA200H

SHA438F

SHA439F

SHA440F

Page 400 of 3061

ATC-30

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

CONSULT-II Function (HVAC)INFOID:0000000003533241

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

SELF-DIAGNOSIS

Display Item List

DATA MONITOR

Display Item List

Diagnostic mode Description

SELF-DIAG RESULTS Displays front ai r control self-diagnosis results.

DATA MONITOR Displays front air control input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ECU PART NUMBER Front air control part number can be read.

DTC Description Reference page

B2573 Battery voltage out of range SC-4

B2578 In-vehicle sensor circuit out of range (low)

AT C - 11 6 , "In-vehicle Sensor Circuit"B2579 In-vehicle sensor circuit out of range (high)

B257B Ambient sensor circuit short AT C - 11 4

B257C Ambient sensor circuit open

B257F Optical sensor (Driver) circuit open or short AT C - 11 9 , "

Optical Sensor Circuit"B2580 Optical sensor (Passenger) circuit open or short

B2581 Intake sensor circuit shortATC-120, "

Intake Sensor Circuit"B2582 Intake sensor circuit open

U1000 CAN bus fault LAN-4, "

CAN Communication System"

B2587 Stuck buttonATC-123, "Removal and Installation"

Monitor item Value Contents

BATT VIA CAN "V" Displays battery voltage signal.

IGN VIA CAN "ON/OFF" Displays ignition switch signal.

DVR SUNLD SEN "w/m2" Displays optical sensor (driver) signal.

PAS SUNLD SEN "w/m2" Displays optical sensor (passenger) signal.

AMB TEMP SEN " °C/ °F" Displays ambient sensor 1 signal.

EVAP TEMP SEN " °C/ °F" Displays intake sensor signal.

INCAR TMP SEN " °C/ °F" Displays in-vehicle sensor signal.

RR TEMPSET FR "V" Displays air mix door (front) set point signal.

RR TEMPSET RR "V" Displays air mi x door (rear) set point signal.

MODE FDBCK "V" Displays mode door motor feedback signal.

DVR MIX FDBCK "V" Displays air mix do or motor (driver) feedback signal.

PAS MIX FDBCK "V" Displays air mix door motor (passenger) feedback signal.

RR FDBCK "V" Displays air mix door motor (rear) feedback signal.

Page 417 of 3061

TROUBLE DIAGNOSISATC-47

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

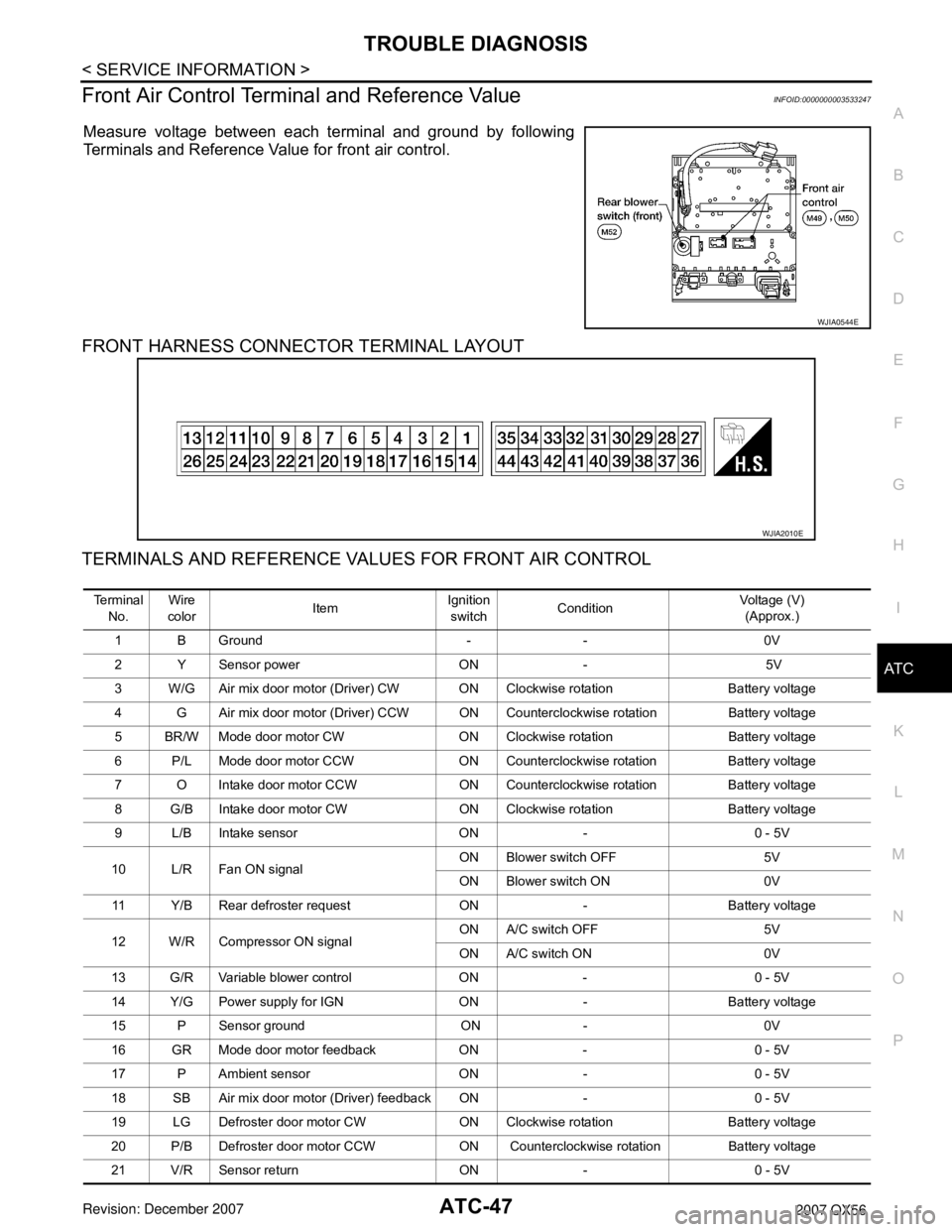

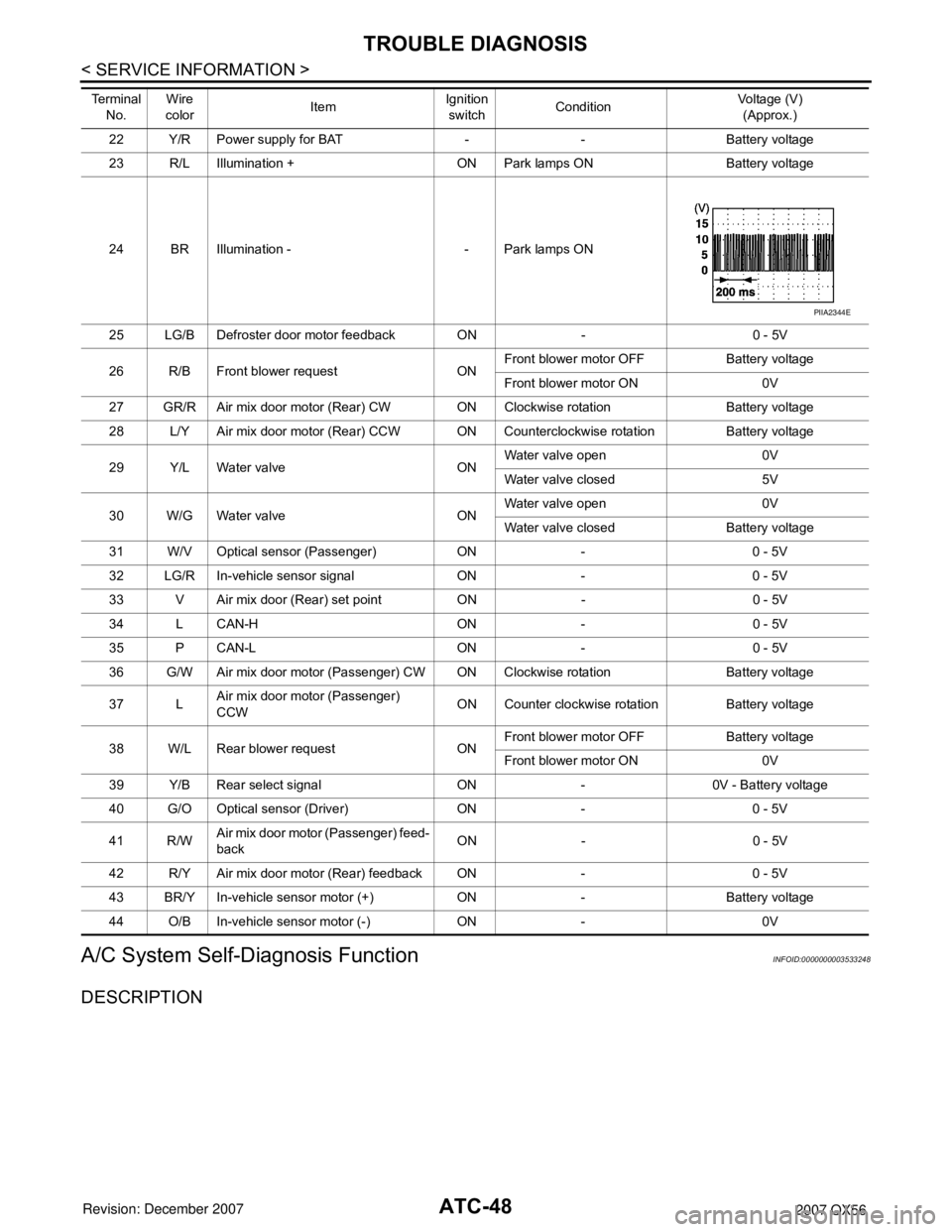

Front Air Control Termina l and Reference ValueINFOID:0000000003533247

Measure voltage between each terminal and ground by following

Terminals and Reference Value for front air control.

FRONT HARNESS CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUES FOR FRONT AIR CONTROL

WJIA0544E

WJIA2010E

Te r m i n a l

No. Wire

color ItemIgnition

switch Condition Voltage (V)

(Approx.)

1 B Ground - - 0V

2 Y Sensor power ON - 5V

3 W/G Air mix door motor (Driver) CW ON Clockwise rotation Battery voltage

4 G Air mix door motor (Driver) CCW ON Coun terclockwise rotation Battery voltage

5 BR/W Mode door motor CW ON Clockwise rotation Battery voltage

6 P/L Mode door motor CCW ON Counterclockw ise rotation Battery voltage

7 O Intake door motor CCW ON Counterclockwise rotation Battery voltage

8 G/B Intake door motor CW ON Clockwise rotation Battery voltage

9 L/B Intake sensor ON - 0 - 5V

10 L/R Fan ON signal ON Blower switch OFF 5V

ON Blower switch ON 0V

11 Y/B Rear defroster requ est ON - Battery voltage

12 W/R Compressor ON signal ON A/C switch OFF 5V

ON A/C switch ON 0V

13 G/R Variable blower control ON - 0 - 5V

14 Y/G Power supply for IGN ON - Battery voltage

15 P Sensor ground ON - 0V

16 GR Mode door motor feedback ON - 0 - 5V

17 P Ambient sensor ON - 0 - 5V

18 SB Air mix door motor (D river) feedback ON - 0 - 5V

19 LG Defroster door motor CW ON Clockwise rotation Battery voltage

20 P/B Defroster door motor CCW ON Counterclockwise rotation Battery voltage

21 V/R Sensor return ON - 0 - 5V

Page 418 of 3061

ATC-48

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

A/C System Self-Diagnosis Function

INFOID:0000000003533248

DESCRIPTION

22 Y/R Power supply for BAT - - Battery voltage

23 R/L Illumination + ON Park lamps ON Battery voltage

24 BR Illumination - - Park lamps ON

25 LG/B Defroster door motor feedback ON - 0 - 5V

26 R/B Front blower request ON Front blower motor OFF Battery voltage

Front blower motor ON 0V

27 GR/R Air mix door motor (Rear) CW ON Clockwise rotation Battery voltage

28 L/Y Air mix door motor (Rear) CCW ON Coun terclockwise rotation Battery voltage

29 Y/L Water valve ON Water valve open 0V

Water valve closed 5V

30 W/G Water valve ON Water valve open 0V

Water valve closed Battery voltage

31 W/V Optical sensor (Passenger) ON - 0 - 5V

32 LG/R In-vehicle sensor signal ON - 0 - 5V

33 V Air mix door (Rear) set point ON - 0 - 5V

34 L CAN-H ON - 0 - 5V

35 P CAN-L ON - 0 - 5V

36 G/W Air mix door motor (Passenger) CW ON Clockwise rotation Battery voltage

37 L Air mix door motor (Passenger)

CCW ON Counter clockwise rotation Battery voltage

38 W/L Rear blower request ON Front blower motor OFF Battery voltage

Front blower motor ON 0V

39 Y/B Rear select signal ON - 0V - Battery voltage

40 G/O Optical sensor (Driver) ON - 0 - 5V

41 R/W Air mix door motor (Passenger) feed-

back ON - 0 - 5V

42 R/Y Air mix door motor (Rear) feedback ON - 0 - 5V

43 BR/Y In-vehicle sensor motor (+) ON - Battery voltage

44 O/B In-vehicle sensor motor (-) ON - 0V

Te r m i n a l

No. Wire

color ItemIgnition

switch Condition Voltage (V)

(Approx.)

PIIA2344E