INFINITI QX56 2007 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 3011 of 3061

WT-22

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Ignition Signal

INFOID:0000000003585170

MALFUNCTION CODE NO. 54 (DTC C1735)

1.CAN IGNITION SIGNAL

Check BCM IGN RLY signal with CONSULT-II.

Are the inspection results normal with the ignition switch ON?

YES >> GO TO 2.

NO >> Check CAN system.

2.BCM POWER SUPPLY

Check BCM power supply (ignition ON). Refer to BCS-15, "

BCM Power Supply and Ground Circuit Inspec-

tion".

Is the power supply with the ignition switch ON normal?

YES >> GO TO 3.

NO >> Repair power supply as necessary.

3.DRIVE VEHICLE

Clear DTC and then test drive the vehicle and check the low tire pressure warning lamp.

Does the vehicle operate without any low tire pressure warning lamp?

YES >> Inspection End.

NO >> Replace BCM. Refer to BCS-24, "

BCM".

Page 3012 of 3061

TROUBLE DIAGNOSIS FOR SYMPTOMS

WT-23

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

WT

N

O

P

TROUBLE DIAGNOSIS FOR SYMPTOMS

Low Tire Pressure Warning Lamp Does Not Come On When Ignition Switch Is Turned

On

INFOID:0000000003532708

DIAGNOSTIC PROCEDURE

1.SELF-DIAGNOSTIC RESULT CHECK

Using CONSULT-II, check display contents in self-diagnostic results.

Is "CAN COMM CIRCUIT" displayed in the self-diagnosis display items?

YES >> Malfunction in CAN communication system. GO TO LAN-40.

NO >> GO TO 2.

2.CHECK COMBINATION METER

Check combination meter operation. Refer to DI-12, "

Self-Diagnosis Mode of Combination Meter".

Inspection results OK?

OK >> GO TO 3.

NG >> Replace combination meter. Refer to IP-10, "

Removal and Installation".

3.CHECK LOW TIRE PRESSURE WARNING LAMP

Disconnect BCM harness connector.

Does the low tire pressure warning lamp activate?

YES >> Replace BCM. Refer to BCS-24, "BCM".

NO >> Check combination meter operation. Refer to DI-12, "

Self-Diagnosis Mode of Combination

Meter".

Low Tire Pressure Warning Lamp Stays On When Ignition Switch Is Turned On

INFOID:0000000003532709

DIAGNOSTIC PROCEDURE

1.CHECK BCM CONNECTORS

1. Turn ignition switch OFF.

2. Disconnect BCM harness connectors M18 and M20.

3. Check terminals for damage or loose connections.

Inspection results OK?

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

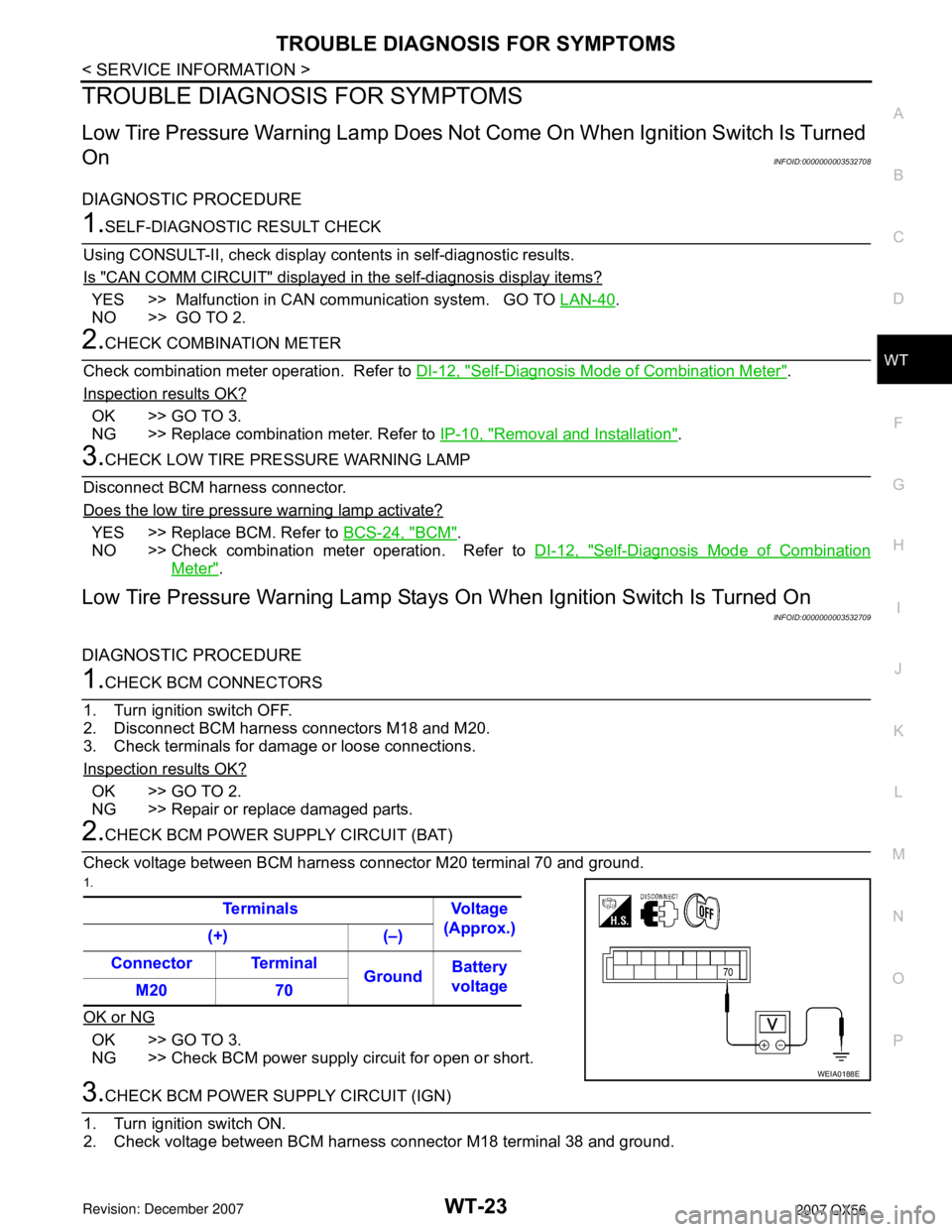

2.CHECK BCM POWER SUPPLY CIRCUIT (BAT)

Check voltage between BCM harness connector M20 terminal 70 and ground.

1.

OK or NG

OK >> GO TO 3.

NG >> Check BCM power supply circuit for open or short.

3.CHECK BCM POWER SUPPLY CIRCUIT (IGN)

1. Turn ignition switch ON.

2. Check voltage between BCM harness connector M18 terminal 38 and ground.Terminals Voltage

(Approx.)

(+) (–)

Connector Terminal

GroundBattery

voltage

M20 70

WEIA0188E

Page 3013 of 3061

WT-24

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

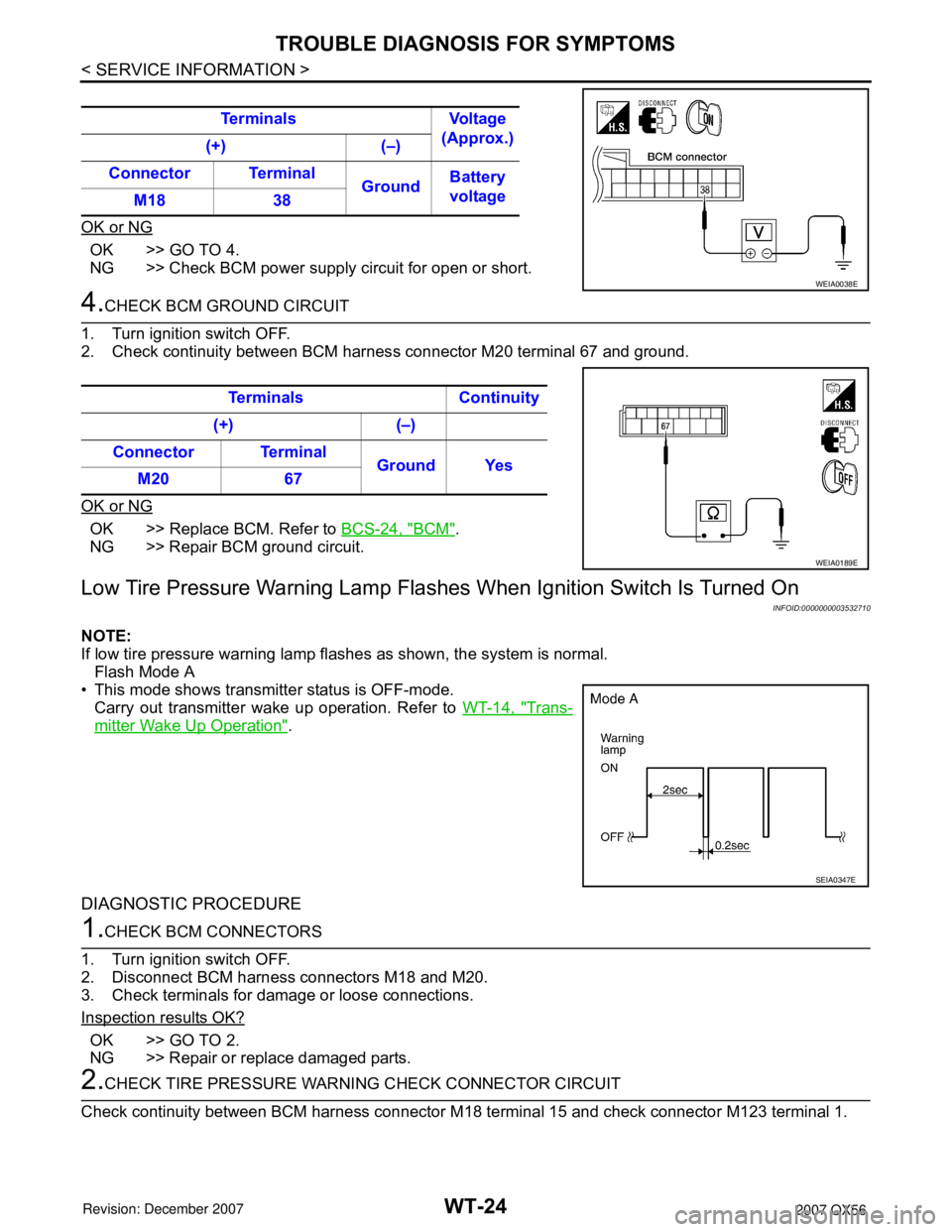

OK or NG

OK >> GO TO 4.

NG >> Check BCM power supply circuit for open or short.

4.CHECK BCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between BCM harness connector M20 terminal 67 and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-24, "BCM".

NG >> Repair BCM ground circuit.

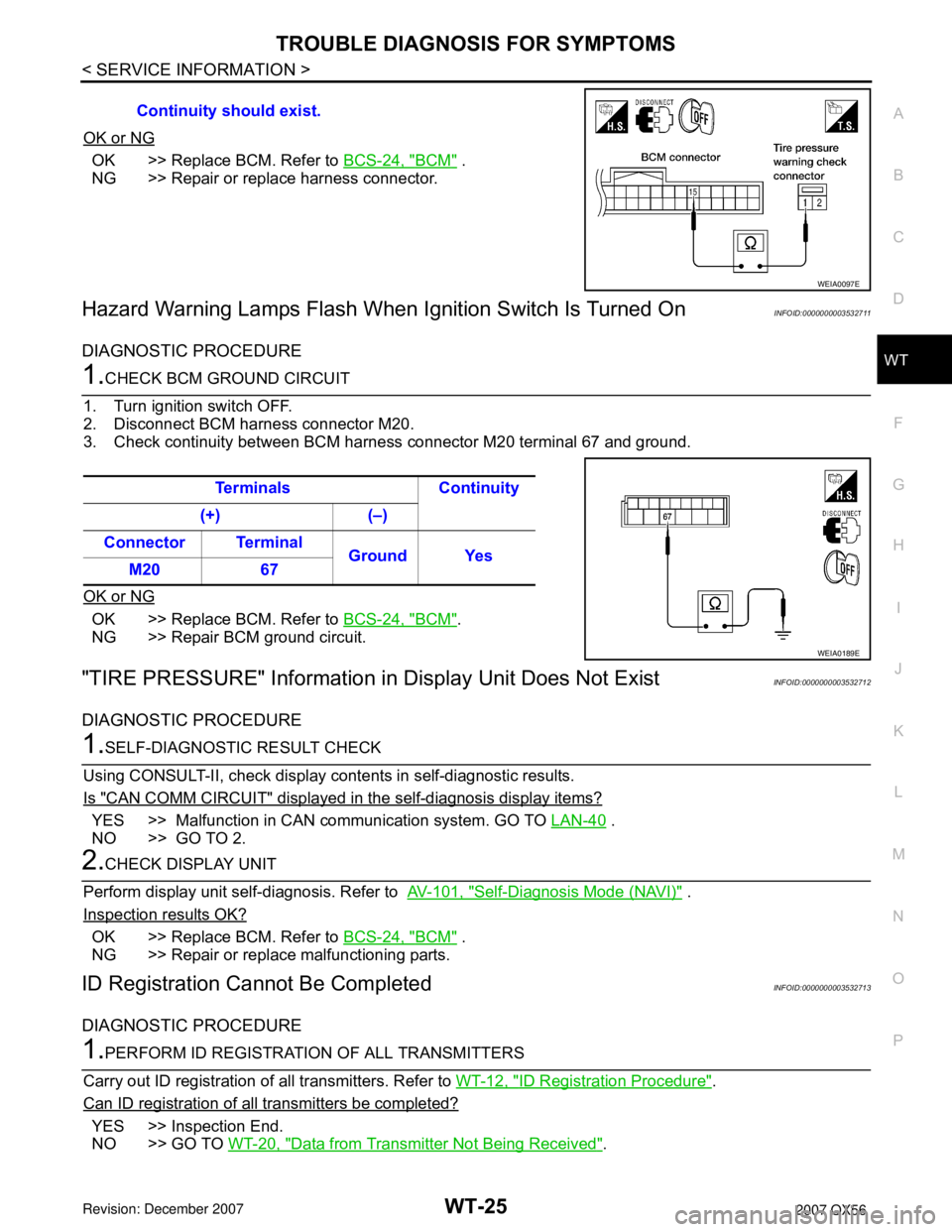

Low Tire Pressure Warning Lamp Flashes When Ignition Switch Is Turned On

INFOID:0000000003532710

NOTE:

If low tire pressure warning lamp flashes as shown, the system is normal.

Flash Mode A

• This mode shows transmitter status is OFF-mode.

Carry out transmitter wake up operation. Refer to WT-14, "

Trans-

mitter Wake Up Operation".

DIAGNOSTIC PROCEDURE

1.CHECK BCM CONNECTORS

1. Turn ignition switch OFF.

2. Disconnect BCM harness connectors M18 and M20.

3. Check terminals for damage or loose connections.

Inspection results OK?

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2.CHECK TIRE PRESSURE WARNING CHECK CONNECTOR CIRCUIT

Check continuity between BCM harness connector M18 terminal 15 and check connector M123 terminal 1. Terminals Voltage

(Approx.)

(+) (–)

Connector Terminal

GroundBattery

voltage

M18 38

WEIA0038E

Terminals Continuity

(+) (–)

Connector Terminal

Ground Yes

M20 67

WEIA0189E

SEIA0347E

Page 3014 of 3061

TROUBLE DIAGNOSIS FOR SYMPTOMS

WT-25

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

WT

N

O

P

OK or NG

OK >> Replace BCM. Refer to BCS-24, "BCM" .

NG >> Repair or replace harness connector.

Hazard Warning Lamps Flash When Ignition Switch Is Turned OnINFOID:0000000003532711

DIAGNOSTIC PROCEDURE

1.CHECK BCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM harness connector M20.

3. Check continuity between BCM harness connector M20 terminal 67 and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-24, "BCM".

NG >> Repair BCM ground circuit.

"TIRE PRESSURE" Information in Display Unit Does Not ExistINFOID:0000000003532712

DIAGNOSTIC PROCEDURE

1.SELF-DIAGNOSTIC RESULT CHECK

Using CONSULT-II, check display contents in self-diagnostic results.

Is "CAN COMM CIRCUIT" displayed in the self-diagnosis display items?

YES >> Malfunction in CAN communication system. GO TO LAN-40 .

NO >> GO TO 2.

2.CHECK DISPLAY UNIT

Perform display unit self-diagnosis. Refer to AV-101, "

Self-Diagnosis Mode (NAVI)" .

Inspection results OK?

OK >> Replace BCM. Refer to BCS-24, "BCM" .

NG >> Repair or replace malfunctioning parts.

ID Registration Cannot Be CompletedINFOID:0000000003532713

DIAGNOSTIC PROCEDURE

1.PERFORM ID REGISTRATION OF ALL TRANSMITTERS

Carry out ID registration of all transmitters. Refer to WT-12, "

ID Registration Procedure".

Can ID registration of all transmitters be completed?

YES >> Inspection End.

NO >> GO TO WT-20, "

Data from Transmitter Not Being Received". Continuity should exist.

WEIA0097E

Terminals Continuity

(+) (–)

Connector Terminal

Ground Yes

M20 67

WEIA0189E

Page 3015 of 3061

WT-26

< SERVICE INFORMATION >

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Transmitter (Pressure Sensor)INFOID:0000000003532714

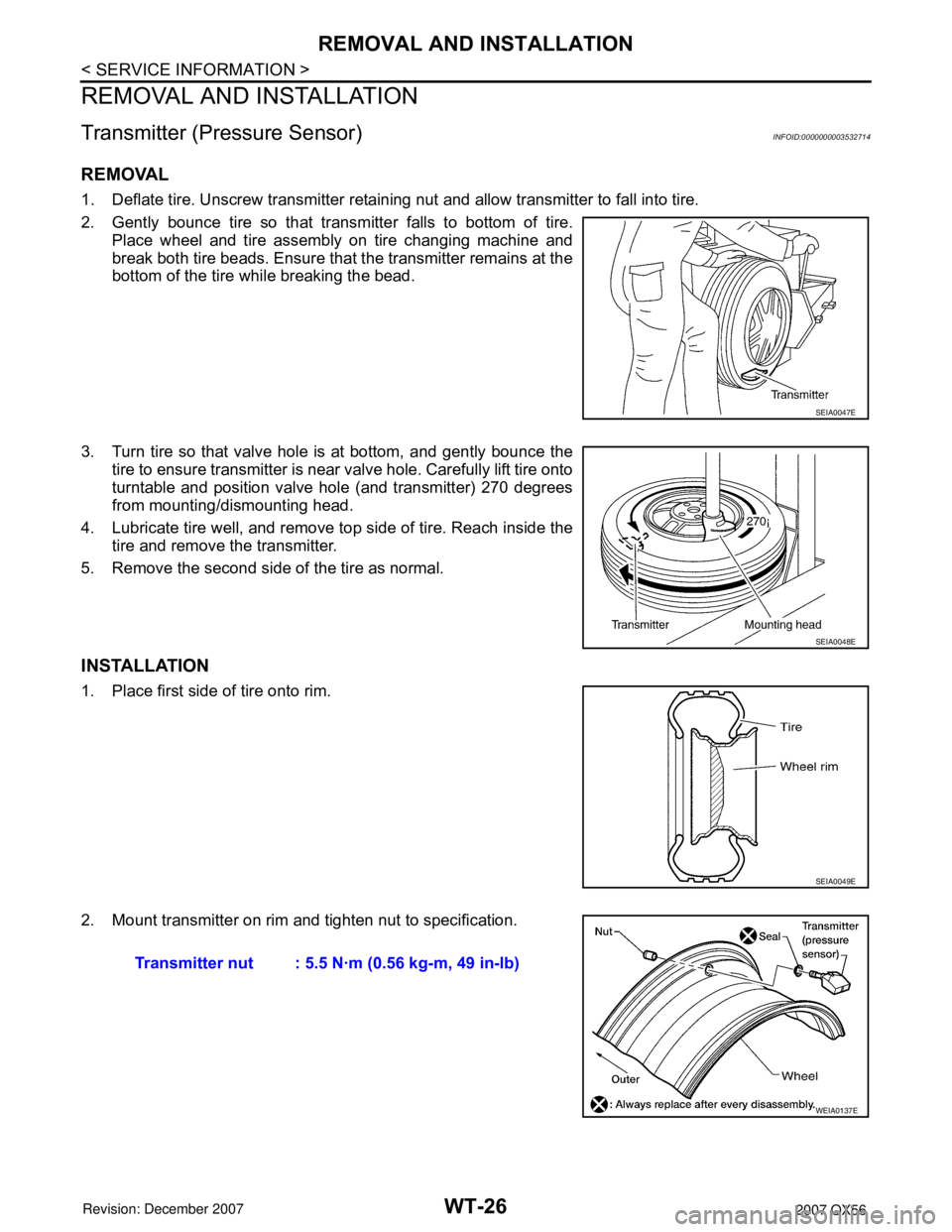

REMOVAL

1. Deflate tire. Unscrew transmitter retaining nut and allow transmitter to fall into tire.

2. Gently bounce tire so that transmitter falls to bottom of tire.

Place wheel and tire assembly on tire changing machine and

break both tire beads. Ensure that the transmitter remains at the

bottom of the tire while breaking the bead.

3. Turn tire so that valve hole is at bottom, and gently bounce the

tire to ensure transmitter is near valve hole. Carefully lift tire onto

turntable and position valve hole (and transmitter) 270 degrees

from mounting/dismounting head.

4. Lubricate tire well, and remove top side of tire. Reach inside the

tire and remove the transmitter.

5. Remove the second side of the tire as normal.

INSTALLATION

1. Place first side of tire onto rim.

2. Mount transmitter on rim and tighten nut to specification.

SEIA0047E

SEIA0048E

SEIA0049E

Transmitter nut : 5.5 N·m (0.56 kg-m, 49 in-lb)

WEIA0137E

Page 3016 of 3061

REMOVAL AND INSTALLATION

WT-27

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

WT

N

O

P

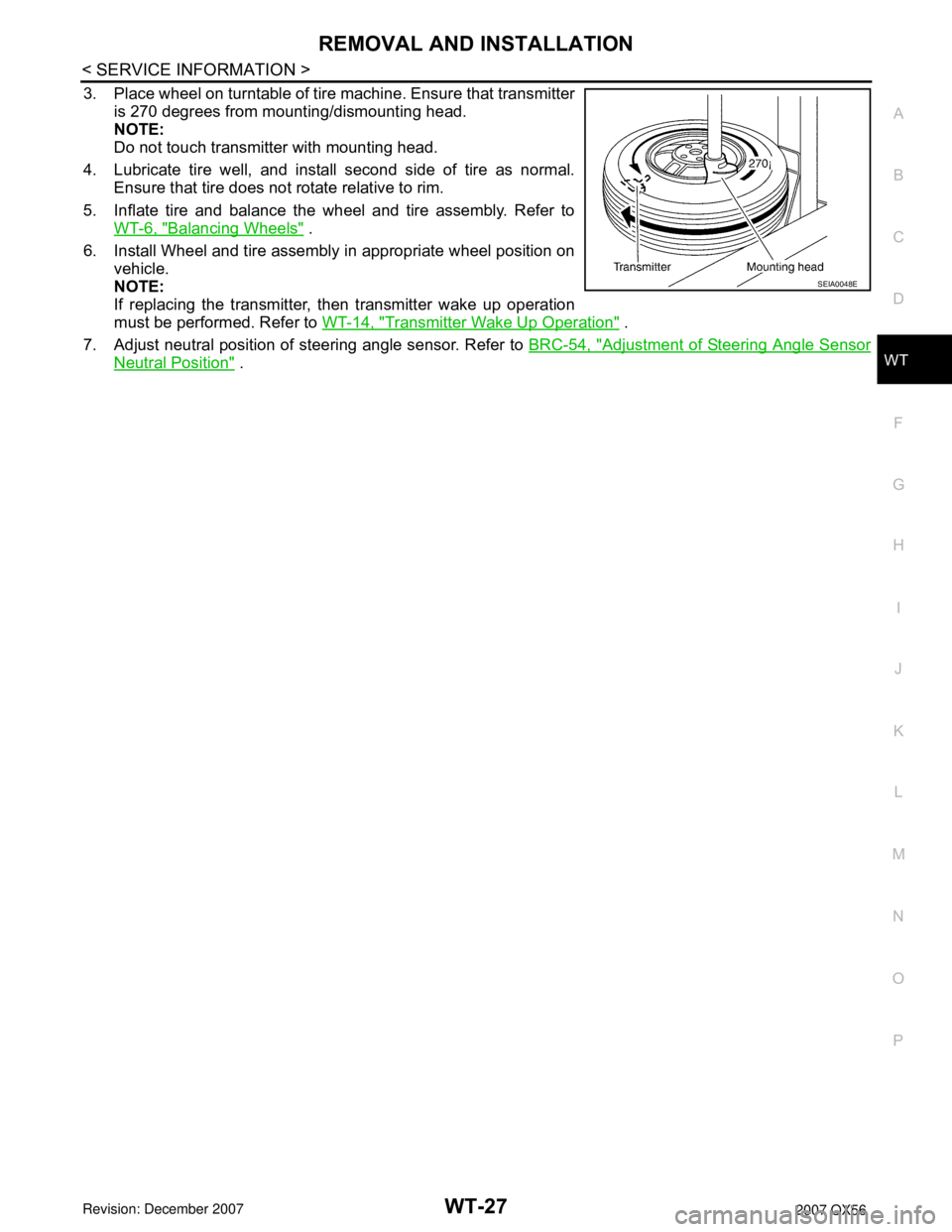

3. Place wheel on turntable of tire machine. Ensure that transmitter

is 270 degrees from mounting/dismounting head.

NOTE:

Do not touch transmitter with mounting head.

4. Lubricate tire well, and install second side of tire as normal.

Ensure that tire does not rotate relative to rim.

5. Inflate tire and balance the wheel and tire assembly. Refer to

WT-6, "

Balancing Wheels" .

6. Install Wheel and tire assembly in appropriate wheel position on

vehicle.

NOTE:

If replacing the transmitter, then transmitter wake up operation

must be performed. Refer to WT-14, "

Transmitter Wake Up Operation" .

7. Adjust neutral position of steering angle sensor. Refer to BRC-54, "

Adjustment of Steering Angle Sensor

Neutral Position" .

SEIA0048E

Page 3017 of 3061

WT-28

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

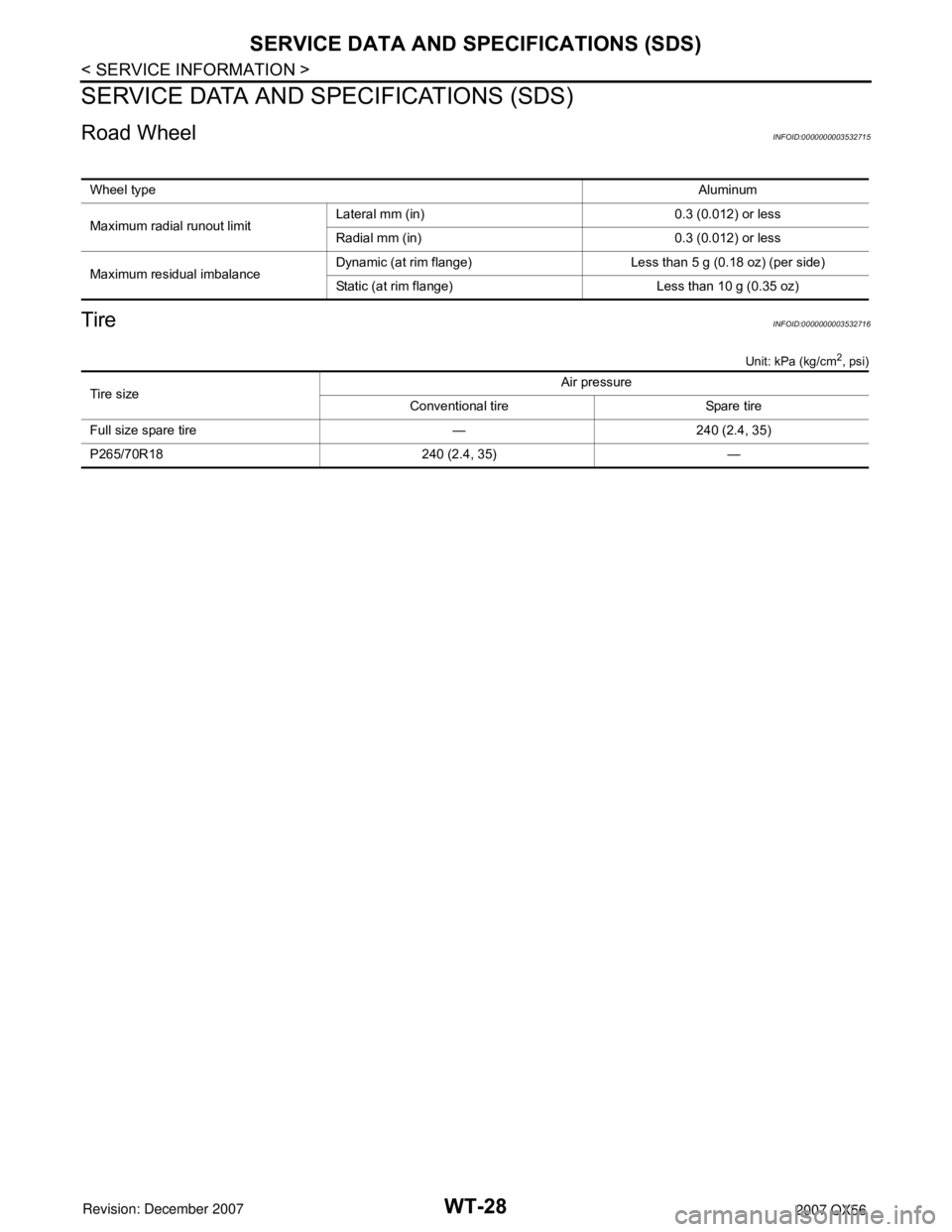

Road WheelINFOID:0000000003532715

TireINFOID:0000000003532716

Unit: kPa (kg/cm2, psi)

Wheel typeAluminum

Maximum radial runout limitLateral mm (in) 0.3 (0.012) or less

Radial mm (in) 0.3 (0.012) or less

Maximum residual imbalanceDynamic (at rim flange) Less than 5 g (0.18 oz) (per side)

Static (at rim flange) Less than 10 g (0.35 oz)

Tire sizeAir pressure

Conventional tire Spare tire

Full size spare tire — 240 (2.4, 35)

P265/70R18 240 (2.4, 35) —

Page 3018 of 3061

WW-1

ELECTRICAL

C

D

E

F

G

H

I

J

L

M

SECTION WW

A

B

WW

N

O

P

CONTENTS

WIPER, WASHER & HORN

SERVICE INFORMATION ............................2

PRECAUTION .....................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

FRONT WIPER AND WASHER SYSTEM ..........3

Component Parts and Harness Connector Loca-

tion ............................................................................

3

System Description ...................................................3

CAN Communication System Description .................5

Schematic .................................................................6

Wiring Diagram - WIPER - ........................................7

Terminal and Reference Value for BCM ...................9

Terminal and Reference Value for IPDM E/R ...........9

Work Flow ...............................................................10

Preliminary Check ...................................................10

CONSULT-II Function (BCM) ..................................11

CONSULT-II Function (IPDM E/R) ..........................12

Front Wiper Does Not Operate ...............................13

Front Wiper Arms ....................................................21

Wiper Motor and Linkage ........................................22

Washer Nozzle Adjustment .....................................23

Washer Tube Layout ...............................................23

Wiper and Washer Switch .......................................23

Washer Fluid Reservoir ...........................................24

Washer Motor ..........................................................24

REAR WIPER AND WASHER SYSTEM ...........26

Component Parts and Harness Connector Loca-

tion ..........................................................................

26

System Description ..................................................26

Wiring Diagram - WIP/R - ........................................29

Terminal and Reference Value for BCM ..................30

How to Proceed with Trouble Diagnosis ..................30

Preliminary Check ...................................................31

CONSULT-II Function (BCM) ..................................31

Rear Wiper Does Not Operate ................................33

Rear Wiper Stop Position Is Incorrect .....................34

Only Rear Wiper Does Not Operate ........................36

Only Rear Wiper Intermittent Does Not Operate .....36

Wiper Does Not Wipe When Rear Washer Oper-

ates ..........................................................................

36

Rear Wiper Arm .......................................................37

Rear Wiper Motor ....................................................37

Rear Washer Nozzle Adjustment ............................38

Rear Washer Tube Layout ......................................39

Rear Washer Nozzle ...............................................39

Rear Wiper and Washer Switch ..............................39

Washer Fluid Reservoir ...........................................40

Washer Motor ..........................................................40

POWER SOCKET .............................................41

Wiring Diagram - P/SCKT - .....................................41

Front Power Socket LH, Rear Cargo Power Sock-

et ..............................................................................

41

Front Power Socket RH (For Cigarette Lighter),

Console Power Socket ............................................

42

HORN ................................................................43

Wiring Diagram - HORN - ........................................43

Removal and Installation .........................................43

Page 3019 of 3061

WW-2

< SERVICE INFORMATION >

PRECAUTION

SERVICE INFORMATION

PRECAUTION

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003533550

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Page 3020 of 3061

FRONT WIPER AND WASHER SYSTEM

WW-3

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

WW

N

O

P

FRONT WIPER AND WASHER SYSTEM

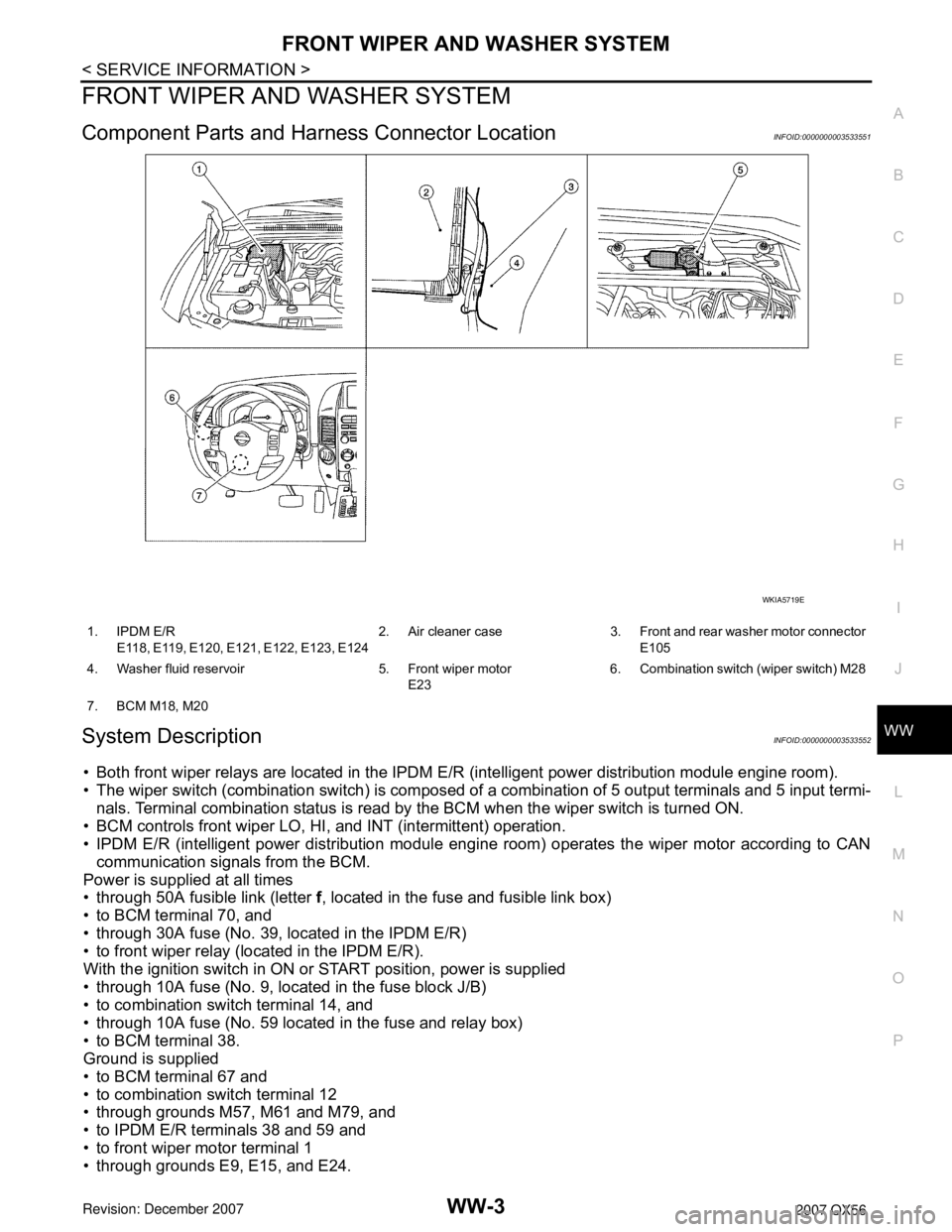

Component Parts and Harness Connector LocationINFOID:0000000003533551

System DescriptionINFOID:0000000003533552

• Both front wiper relays are located in the IPDM E/R (intelligent power distribution module engine room).

• The wiper switch (combination switch) is composed of a combination of 5 output terminals and 5 input termi-

nals. Terminal combination status is read by the BCM when the wiper switch is turned ON.

• BCM controls front wiper LO, HI, and INT (intermittent) operation.

• IPDM E/R (intelligent power distribution module engine room) operates the wiper motor according to CAN

communication signals from the BCM.

Power is supplied at all times

• through 50A fusible link (letter f, located in the fuse and fusible link box)

• to BCM terminal 70, and

• through 30A fuse (No. 39, located in the IPDM E/R)

• to front wiper relay (located in the IPDM E/R).

With the ignition switch in ON or START position, power is supplied

• through 10A fuse (No. 9, located in the fuse block J/B)

• to combination switch terminal 14, and

• through 10A fuse (No. 59 located in the fuse and relay box)

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67 and

• to combination switch terminal 12

• through grounds M57, M61 and M79, and

• to IPDM E/R terminals 38 and 59 and

• to front wiper motor terminal 1

• through grounds E9, E15, and E24.

WKIA5719E

1. IPDM E/R

E118, E119, E120, E121, E122, E123, E1242. Air cleaner case 3. Front and rear washer motor connector

E105

4. Washer fluid reservoir 5. Front wiper motor

E236. Combination switch (wiper switch) M28

7. BCM M18, M20