check engine INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 23 of 3061

![INFINITI QX56 2007 Factory Service Manual ACS-10

< SERVICE INFORMATION >[ICC]

ACTION TEST

1. Start the engine. Then, check that the following operations are

performed correctly.

2. Vehicle-to-vehicle distance control mode is displayed when O INFINITI QX56 2007 Factory Service Manual ACS-10

< SERVICE INFORMATION >[ICC]

ACTION TEST

1. Start the engine. Then, check that the following operations are

performed correctly.

2. Vehicle-to-vehicle distance control mode is displayed when O](/img/42/57029/w960_57029-22.png)

ACS-10

< SERVICE INFORMATION >[ICC]

ACTION TEST

1. Start the engine. Then, check that the following operations are

performed correctly.

2. Vehicle-to-vehicle distance control mode is displayed when ON/

OFF switch is pressed ON. Vehicle-to-vehicle distance control

mode goes off when ON/OFF switch is turned to OFF.

3. Turn off the ignition switch while ON/OFF switch is ON. Turn the

ignition switch back to ON and confirm that CRUISE lamp and

ICC system display are OFF.

CHECK FOR ACCEL/RES, COAST/SET, CANCEL SWITCHES

1. Check if ACCEL/RES, COAST/SET, CANCEL switches operate smoothly.

2. Check if switch buttons rebound as the buttons are released.

CHECK FOR DISTANCE SWITCH

1. Start the engine.

2. Press the ON/OFF switch for less than 1.5 seconds.

3. Press the DISTANCE switch.

4. Check if the set distance indicator changes display in order of:

(long)→(middle)→(short).

NOTE:

The set distance indicator shows long immediately after the engine starts.

CONVENTIONAL (FIXED SPEED) CRUISE CONTROL MODE

SET CHECKING

1. Press the ON/OFF switch for more than 1.5 seconds.

2. Drive the vehicle between 40 km/h (25 MPH) and 144 km/h (89 MPH).

3. Push the COAST/SET switch.

4. Confirm that the desired speed is set when the COAST/SET switch is released.

NOTE:

• ICC system display in the combination meter shows nothing.

CHECK FOR INCREASE OF THE CRUISING SPEED

1. Set the conventional (fixed speed) cruise control mode at desired speed.

2. Check if the set speed increases by 1.6 km/h (1 MPH) as ACCEL/RES switch is pushed.

NOTE:

• If the ACCEL/RES switch is held, the vehicle speed increases until the switch is released.

• The maximum set speed is 144 km/h (89 MPH).

WKIA1978E

SKIA6178E

Page 24 of 3061

![INFINITI QX56 2007 Factory Service Manual ACTION TEST

ACS-11

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P CHECK FOR DECREASE OF THE CRUISING SPEED

1. Set the conventional (fixed speed) cruise control mode at desired speed.

2. INFINITI QX56 2007 Factory Service Manual ACTION TEST

ACS-11

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P CHECK FOR DECREASE OF THE CRUISING SPEED

1. Set the conventional (fixed speed) cruise control mode at desired speed.

2.](/img/42/57029/w960_57029-23.png)

ACTION TEST

ACS-11

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P CHECK FOR DECREASE OF THE CRUISING SPEED

1. Set the conventional (fixed speed) cruise control mode at desired speed.

2. Check if the set speed decreases by 1.6 km/h (1 MPH) as COAST/SET switch is pushed.

NOTE:

• Conventional (fixed speed) cruise control mode is automatically turned off when the driving speed lowers to

32 km/h (20 MPH).

• The lowest set speed is 40 km/h (25 MPH).

CHECK FOR THE CANCELLATION OF CONVENTIONAL (FIXED SPEED) CRUISE CONTROL MODE (NORMAL

DRIVING CONDITION) IN THE FOLLOWING CASES:

Refer to "CHECK FOR THE CANCELLATION OF VEHICLE-TO-VEHICLE DISTANCE CONTROL MODE

(NORMAL DRIVING CONDITION) IN THE FOLLOWING CASES:" .

CHECK FOR RESTORING THE SPEED THAT IS SET BY CONVENTIONAL (FIXED SPEED) CRUISE CONTROL

MODE BEFORE ICC CANCELLATION

Refer to "CHECK FOR RESTORING THE SPEED THAT IS SET BY VEHICLE-TO-VEHICLE DISTANCE

CONTROL MODE BEFORE CANCELLATION" .

CHECK ON/OFF SWITCH OPERATION

1. Start the engine. Then, check that the following operations are

performed correctly.

2. CRUISE lamp (green) illuminates and ICC system indicator

goes off when ON/OFF switch is pressed ON for more than 1.5

seconds. The CRUISE lamp goes off when ON/OFF switch is

turned to OFF.

3. Turn off the ignition switch while ON/OFF switch is ON. Turn the

ignition switch back to ON and confirm that CRUISE lamp is

OFF.

CHECK FOR ACCEL/RES, COAST/SET, CANCEL SWITCHES

1. Check if ACCEL/RES, COAST/SET, CANCEL switches operate smoothly.

2. Check if switch buttons rebound as the buttons are released.

WKIA2038E

Page 25 of 3061

![INFINITI QX56 2007 Factory Service Manual ACS-12

< SERVICE INFORMATION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

Outline of Laser Beam Aiming Adjustment ProcedureINFOID:0000000003533782

CAUTION:

• The laser beam aimin INFINITI QX56 2007 Factory Service Manual ACS-12

< SERVICE INFORMATION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

Outline of Laser Beam Aiming Adjustment ProcedureINFOID:0000000003533782

CAUTION:

• The laser beam aimin](/img/42/57029/w960_57029-24.png)

ACS-12

< SERVICE INFORMATION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

Outline of Laser Beam Aiming Adjustment ProcedureINFOID:0000000003533782

CAUTION:

• The laser beam aiming adjustment cannot be performed without CONSULT-II.

• The laser beam aiming adjustment must be performed every time the ICC sensor is removed,

installed or has been moved as a result of a collision.

1. Prepare the vehicle and the work area.

2. Set up the ICC target board. For details, refer to Technical Service Bulletin.

3. Adjust the sensor following the procedure on CONSULT-II.

4. Check system operation after the adjustment.

PreparationINFOID:0000000003533783

• Place the vehicle on level ground. Shift the transmission into "P" position and release the parking brake.

• Adjust the tire pressure to the specified value.

• See that there is no load in the vehicle. Coolant, engine oil and fuel should be filled to correct level.

• Check that the vehicle suspension has been adjusted to the standard height by the load leveling rear air sus-

pension system. Refer to RSU-10, "

Basic Inspection" .

• Clean the sensor with a soft cloth.

Setting up the ICC Target BoardINFOID:0000000003533784

CAUTION:

Accuracy in setting up the ICC target board is essential for the laser beam aiming adjustment. For

details, refer to Technical Service Bulletin.

ADJUSTING HEIGHT OF THE TARGET

1. Attach a triangle scale as shown.Tool number : KV99110100 (J-45718)

LKIA0632E

WKIA1849E

Page 42 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

ACS-29

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Touch “ACTIVE TEST” on "SELECT DIAG MODE" screen.

2. Touch any of “ICC BUZZER 1� INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

ACS-29

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Touch “ACTIVE TEST” on "SELECT DIAG MODE" screen.

2. Touch any of “ICC BUZZER 1�](/img/42/57029/w960_57029-41.png)

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

ACS-29

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Touch “ACTIVE TEST” on "SELECT DIAG MODE" screen.

2. Touch any of “ICC BUZZER 1”, “METER LAMP”, “STOP LAMP”

and “BOOSTER SOL/V 3” on "SELECT TEST ITEM" screen.

3. Touch “START”.

4. Active test screen will be shown.

ICC BUZZER 1

• Touch “ON” and “OFF” to check that ICC warning chime operates

as in the following chart.

METER LAMP

• Start engine.

• Touch “ON” and “OFF” to check that ICC system displays operate as required.

• The following ICC lamps will illuminate at the same time, CRUISE

(orange), CRUISE (green), SET and ICC digital display.

STOP LAMP

BCIA0031E

SKIA6195E

ICC BUZZER 1 ON OFF

Buzzer sound Beep Not activated

SKIA1228E

METER LAMP ON OFF

All ICC system displays Full illumination OFF

SKIA1231E

Page 43 of 3061

![INFINITI QX56 2007 Factory Service Manual ACS-30

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

• Touch “ON” and “OFF” to check that the stop lamps operate as in

the following chart.

BOOSTER SOL/V 3

• Touch INFINITI QX56 2007 Factory Service Manual ACS-30

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

• Touch “ON” and “OFF” to check that the stop lamps operate as in

the following chart.

BOOSTER SOL/V 3

• Touch](/img/42/57029/w960_57029-42.png)

ACS-30

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

• Touch “ON” and “OFF” to check that the stop lamps operate as in

the following chart.

BOOSTER SOL/V 3

• Touch any of “MODE 1”, “MODE 2”, “MODE 3” to check that follow-

ing operation condition is caused by operating monitor and brake

pedal.

• “START” is displayed 10 seconds after operation start. (Active test

is completed.)

Self-Diagnostic FunctionINFOID:0000000003533793

WITH CONSULT-II

1. Go to operation check after asking the customer for symptom information. Refer to ACS-9 .

2. Stop vehicle, turn ignition switch OFF, then connect CONSULT-II and CONSULT-II CONVERTER to data

link connector.

3. With engine started, touch “START”, “ICC”, “SELF-DIAG RESULTS” on CONSULT-II screen in this order.

CAUTION:

If “ICC” cannot be shown after several attempts, the ICC unit may be malfunctioning and should

be replaced. Refer to ACS-55

.

4. Self-diagnostic result appears on screen. If “NO DTC ···” is shown, check ICC warning lamp. If any mal-

function is indicated, GO TO step 5.

5. Refer to ACS-34, "

Diagnostic Trouble Code (DTC) Chart", perform appropriate check, and repair or

replace malfunctioning part as necessary.

6. Turn ignition switch OFF.

7. Start engine and touch “START”, “ICC”, “SELF-DIAG RESULTS”, and “ERASE” on CONSULT-II.

CAUTION:

DTC of an existing malfunction will not erase. If the memory does not erase, GO TO step 5.

8. Perform ICC system running test (drive vehicle with ICC system ON), and make sure that ICC warning

lamp does not illuminate.

WITHOUT CONSULT-II

STOP LAMP ON OFF

Stop lamp Lamp ON Lamp OFF

SKIA1232E

SKIA1233E

PKIA0363J

Page 44 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

ACS-31

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Go to operation check after asking the customer for symptom information. Refer to ACS- INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

ACS-31

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Go to operation check after asking the customer for symptom information. Refer to ACS-](/img/42/57029/w960_57029-43.png)

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

ACS-31

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Go to operation check after asking the customer for symptom information. Refer to ACS-9.

2. Stop the vehicle to start the self-diagnosis.

3. Turn ignition switch OFF.

4. Turn ignition switch ON, and wait 5 seconds. Press ACCEL/RES

switch 5 times, and then press COAST/SET switch 5 times all

within 5 seconds to start self-diagnosis.

CAUTION:

• Do not start the engine.

• Do not press the ICC ON/OFF switch ON.

• When operation above is not completed within the 5 to 10 sec-

ond window, DTC will not be displayed.

• If self-diagnosis mode cannot be started after several

attempts, the ICC unit may be malfunctioning and should be

replaced. Refer to "SELF-DIAGNOSIS BY ICC SYSTEM DIS-

PLAY WILL NOT RUN".

5. When self-diagnosis mode is started, DTCs are shown on set vehicle speed indicator.

CAUTION:

• DTC will disappear after 5 minutes.

• When multiple malfunctions are detected, a maximum of 3 code numbers can be stored; the lat-

est malfunction will be displayed first.

6. Check ACS-34, "

Diagnostic Trouble Code (DTC) Chart" , and repair or replace if necessary.

7. After repair, erase DTC stored in the ICC unit. Refer to "Self-Diagnostic Erasing Method".

8. DTC 55 will be shown.

9. Turn ignition switch OFF to exit the diagnosis.

10. Perform ICC system running test (drive vehicle with ICC system ON), and make sure that ICC warning

lamp does not illuminate.

Self-Diagnostic Erasing Method

1. Stop the vehicle and turn the ignition switch OFF.

2. Turn ignition switch ON and start self-diagnosis.

3. During self-diagnosis mode, press CANCEL switch 5 times, and DISTANCE switch 5 times within a 10

second time period.

CAUTION:

• Switch inputs must be received within a 10 second time period.

• When operation is not completed within 10 seconds start again from step 1.

4. DTC 55 will be shown.

CAUTION:

DTC of an existing malfunction will not be erased.

5. Turn ignition switch OFF to exit the diagnosis.

WKIA1921E

WKIA1922E

Page 66 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SYMPTOMS

ACS-53

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

• Perform ICC system running test. Refer to ACS-9, "ICC System Running Test" . Then perform

self-d INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SYMPTOMS

ACS-53

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

• Perform ICC system running test. Refer to ACS-9, "ICC System Running Test" . Then perform

self-d](/img/42/57029/w960_57029-65.png)

TROUBLE DIAGNOSIS FOR SYMPTOMS

ACS-53

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

• Perform ICC system running test. Refer to ACS-9, "ICC System Running Test" . Then perform

self-diagnosis of ICC system again.

Symptom 8 the System Does Not Detect the Vehicle Ahead at AllINFOID:0000000003533822

1.VISUAL CHECK

1. With ignition switch turned ON (engine not started), check that all indicator lamps in ICC system display

are continuously lit. (Check for a missing segment in preceding vehicle detection display.)

OK or NG

OK >> GO TO 2.

NG >> Check combination meter. Refer to DI-15, "

How to Proceed with Trouble Diagnosis".

2. VISUAL CHECK

• Check ICC sensor body window for contamination and foreign materials.

OK or NG

OK >> If any contamination or foreign materials are found, remove them. Perform ICC system running

test. Refer to ACS-9, "

ICC System Running Test".

NG >> GO TO 3.

3.VISUAL CHECK

• Check ICC sensor body window for cracks and scratches.

OK or NG

OK >> GO TO 4.

NG >> • Replace ICC sensor and perform laser beam aiming adjustment. Refer to ACS-55, "

ICC Sen-

sor".

• Perform ICC system running test. Refer to ACS-9, "

ICC System Running Test". Then perform

self-diagnosis of ICC system again.

4.ADJUST ICC SENSOR

• After performing laser beam aiming adjustment, perform ICC system running test. Refer to ACS-9, "

ICC Sys-

tem Running Test". Check that preceding vehicle detection performance has been improved.

OK or NG

OK >> Inspection End.

NG >> • Replace ICC sensor and perform laser beam aiming adjustment. Refer to ACS-55, "

ICC Sen-

sor".

• Perform ICC system running test. Refer to ACS-9, "

ICC System Running Test". Then perform

self-diagnosis of ICC system again.

Page 71 of 3061

AT-1

TRANSMISSION/TRANSAXLE

D

E

F

G

H

I

J

K

L

M

SECTION AT

A

B

AT

N

O

P

CONTENTS

AUTOMATIC TRANSMISSION

SERVICE INFORMATION ............................6

INDEX FOR DTC .................................................6

Alphabetical Index .....................................................6

DTC No. Index ..........................................................6

PRECAUTIONS ...................................................8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

8

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine .....................................................

8

Precaution .................................................................8

Service Notice or Precaution .....................................9

PREPARATION ..................................................11

Special Service Tool ...............................................11

Commercial Service Tool ........................................12

A/T FLUID ...........................................................13

Changing Automatic Transmission Fluid (ATF) ......13

Checking Automatic Transmission Fluid (ATF) .......13

A/T Fluid Cooler Cleaning .......................................15

A/T CONTROL SYSTEM ....................................19

Cross-Sectional View (2WD models) ......................19

Cross-Sectional View (4WD models) ......................20

Shift Mechanism ......................................................20

TCM Function ..........................................................31

CAN Communication ...............................................32

Input/Output Signal of TCM .....................................33

Line Pressure Control .............................................33

Shift Control ............................................................35

Lock-up Control .......................................................36

Engine Brake Control ..............................................37

Control Valve ...........................................................37

ON BOARD DIAGNOSTIC (OBD) SYSTEM ......39

Introduction .............................................................39

OBD-II Function for A/T System ..............................39

One or Two Trip Detection Logic of OBD-II ............39

OBD-II Diagnostic Trouble Code (DTC) ..................39

Malfunction Indicator Lamp (MIL) ............................41

TROUBLE DIAGNOSIS ....................................43

DTC Inspection Priority Chart ..................................43

Fail-Safe ..................................................................43

How To Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

44

A/T Electrical Parts Location ...................................50

Circuit Diagram ........................................................51

Inspections Before Trouble Diagnosis .....................51

Check Before Engine Is Started ..............................55

Check at Idle ............................................................55

Cruise Test - Part 1 .................................................56

Cruise Test - Part 2 .................................................58

Cruise Test - Part 3 .................................................59

Vehicle Speed When Shifting Gears .......................59

Vehicle Speed When Performing and Releasing

Complete Lock-up ...................................................

60

Vehicle Speed When Performing and Releasing

Slip Lock-up .............................................................

60

Symptom Chart ........................................................60

TCM Input/Output Signal Reference Value .............82

CONSULT-II Function (A/T) ....................................83

DTC U1000 CAN COMMUNICATION LINE .....91

Description ...............................................................91

On Board Diagnosis Logic .......................................91

Possible Cause ........................................................91

DTC Confirmation Procedure ..................................91

Wiring Diagram - AT - CAN .....................................92

Diagnosis Procedure ...............................................93

DTC P0615 START SIGNAL CIRCUIT .............94

Description ...............................................................94

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................

94

On Board Diagnosis Logic .......................................94

Possible Cause ........................................................94

DTC Confirmation Procedure ..................................94

Wiring Diagram - AT - STSIG ..................................95

Diagnosis Procedure ...............................................95

Page 74 of 3061

AT-4

DTC Confirmation Procedure ................................152

Diagnosis Procedure .............................................152

DTC P1845 ATF PRESSURE SWITCH 5 ........154

Description .............................................................154

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

154

On Board Diagnosis Logic .....................................154

Possible Cause ......................................................154

DTC Confirmation Procedure ................................154

Diagnosis Procedure .............................................154

DTC P1846 ATF PRESSURE SWITCH 6 ........156

Description .............................................................156

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

156

On Board Diagnosis Logic .....................................156

Possible Cause ......................................................156

DTC Confirmation Procedure ................................156

Diagnosis Procedure .............................................156

MAIN POWER SUPPLY AND GROUND CIR-

CUIT .................................................................

158

Wiring Diagram - AT - MAIN ..................................158

Diagnosis Procedure .............................................159

CLOSED THROTTLE POSITION AND WIDE

OPEN THROTTLE POSITION CIRCUIT .........

161

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

161

Diagnosis Procedure .............................................161

BRAKE SIGNAL CIRCUIT ..............................162

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

162

Diagnosis Procedure .............................................162

TOW MODE SWITCH ......................................163

Description .............................................................163

Wiring Diagram - AT - TMSW ................................163

Diagnosis Procedure .............................................164

TROUBLE DIAGNOSIS FOR SYMPTOMS .....165

Wiring Diagram - AT - NONDTC ............................165

A/T Check Indicator Lamp Does Not Come On .....167

Engine Cannot Be Started in "P" or "N" Position ...168

In "P" Position, Vehicle Moves When Pushed .......168

In "N" Position, Vehicle Moves ..............................169

Large Shock ("N" to "D" Position) ..........................170

Vehicle Does Not Creep Backward in "R" Position ..172

Vehicle Does Not Creep Forward in "D" Position ..175

Vehicle Cannot Be Started from D1 .......................177

A/T Does Not Shift: D1→ D2 ..................................179

A/T Does Not Shift: D2→ D3 ..................................181

A/T Does Not Shift: D3→ D4 ..................................183

A/T Does Not Shift: D4→ D5 ..................................185

A/T Does Not Perform Lock-up .............................187

A/T Does Not Hold Lock-up Condition ...................189

Lock-up Is Not Released .......................................190

Engine Speed Does Not Return to Idle .................191

A/T Does Not Shift: 5th gear → 4th gear ..............192

A/T Does Not Shift: 4th gear → 3rd gear ..............194

A/T Does Not Shift: 3rd gear → 2nd gear .............196

A/T Does Not Shift: 2nd gear → 1st gear .............197

Vehicle Does Not Decelerate By Engine Brake ....199

A/T SHIFT LOCK SYSTEM ..............................202

Description ............................................................202

Shift Lock System Electrical Parts Location ..........202

Wiring Diagram - AT - SHIFT ................................203

Shift Lock Control Unit Reference Value ..............204

Component Inspection ..........................................204

SHIFT CONTROL SYSTEM .............................207

Control Device Removal and Installation ..............207

Adjustment of A/T Position ....................................208

Checking of A/T Position .......................................208

ON-VEHICLE SERVICE ...................................209

Oil Pan ..................................................................209

Control Valve with TCM and A/T Fluid Tempera-

ture Sensor 2 ........................................................

210

Rear Oil Seal .........................................................219

AIR BREATHER HOSE ....................................221

Removal and Installation .......................................221

TRANSMISSION ASSEMBLY ..........................223

Removal and Installation (2WD) ...........................223

Removal and Installation (4WD) ...........................225

OVERHAUL ......................................................228

Component ...........................................................228

Oil Channel ...........................................................235

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ..........................

237

DISASSEMBLY ................................................240

Disassembly ..........................................................240

REPAIR FOR COMPONENT PARTS ..............258

Oil Pump ...............................................................258

Front Sun Gear, 3rd One-Way Clutch ...................260

Front Carrier, Input Clutch, Rear Internal Gear .....262

Mid Sun Gear, Rear Sun Gear, High and Low Re-

verse Clutch Hub ..................................................

267

High and Low Reverse Clutch ..............................272

Direct Clutch .........................................................274

ASSEMBLY ......................................................277

Assembly (1) .........................................................277

Adjustment ............................................................290

Assembly (2) .........................................................292

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

298

General Specification ............................................298

Vehicle Speed When Shifting Gears .....................298

Vehicle Speed When Performing and Releasing

Complete Lock-up .................................................

299

Stall Speed ............................................................299

Page 83 of 3061

A/T FLUID

AT-13

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

A/T FLUID

Changing Automatic Transmission Fluid (ATF)INFOID:0000000003532224

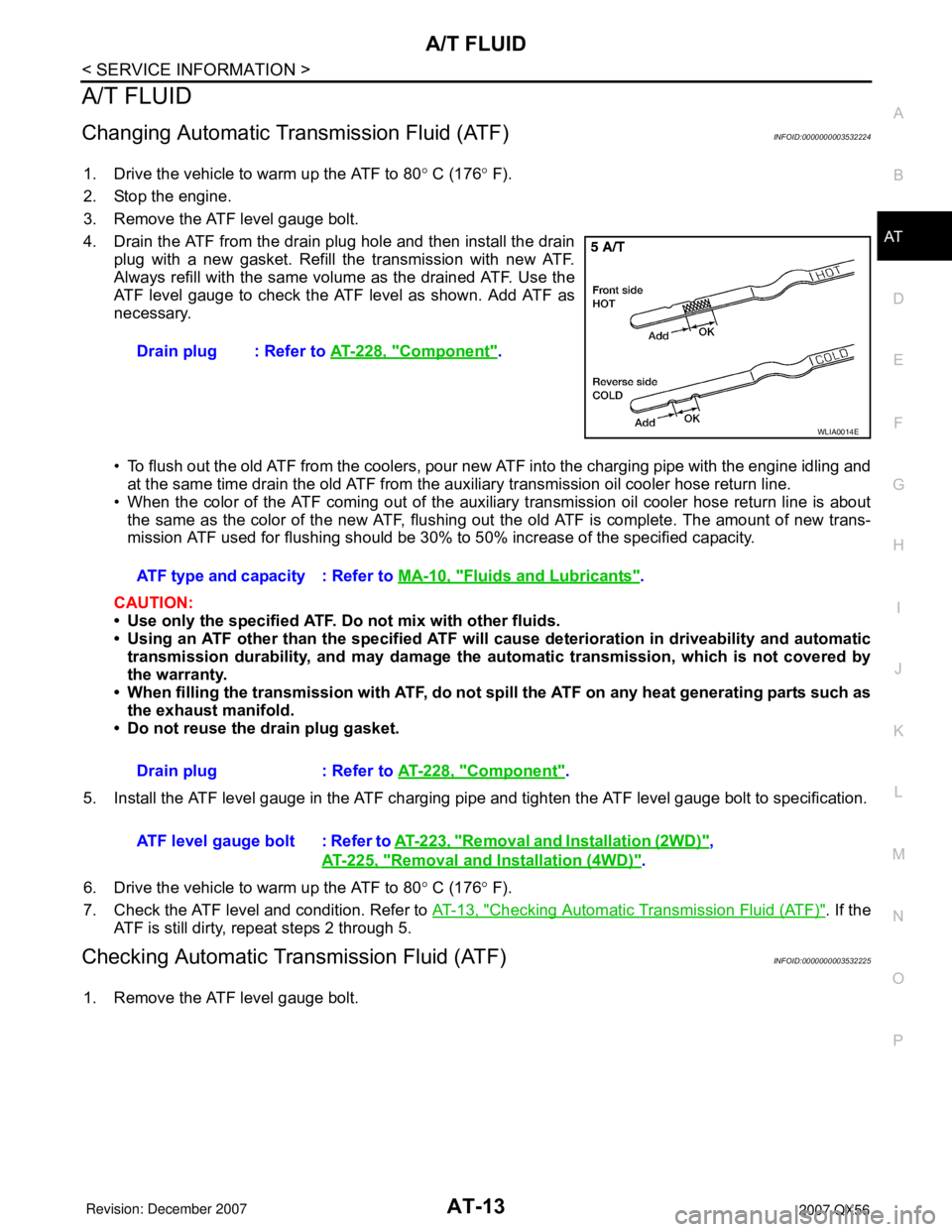

1. Drive the vehicle to warm up the ATF to 80° C (176° F).

2. Stop the engine.

3. Remove the ATF level gauge bolt.

4. Drain the ATF from the drain plug hole and then install the drain

plug with a new gasket. Refill the transmission with new ATF.

Always refill with the same volume as the drained ATF. Use the

ATF level gauge to check the ATF level as shown. Add ATF as

necessary.

• To flush out the old ATF from the coolers, pour new ATF into the charging pipe with the engine idling and

at the same time drain the old ATF from the auxiliary transmission oil cooler hose return line.

• When the color of the ATF coming out of the auxiliary transmission oil cooler hose return line is about

the same as the color of the new ATF, flushing out the old ATF is complete. The amount of new trans-

mission ATF used for flushing should be 30% to 50% increase of the specified capacity.

CAUTION:

• Use only the specified ATF. Do not mix with other fluids.

• Using an ATF other than the specified ATF will cause deterioration in driveability and automatic

transmission durability, and may damage the automatic transmission, which is not covered by

the warranty.

• When filling the transmission with ATF, do not spill the ATF on any heat generating parts such as

the exhaust manifold.

• Do not reuse the drain plug gasket.

5. Install the ATF level gauge in the ATF charging pipe and tighten the ATF level gauge bolt to specification.

6. Drive the vehicle to warm up the ATF to 80° C (176° F).

7. Check the ATF level and condition. Refer to AT-13, "

Checking Automatic Transmission Fluid (ATF)". If the

ATF is still dirty, repeat steps 2 through 5.

Checking Automatic Transmission Fluid (ATF)INFOID:0000000003532225

1. Remove the ATF level gauge bolt.Drain plug : Refer to AT-228, "

Component".

WLIA0014E

ATF type and capacity : Refer to MA-10, "Fluids and Lubricants".

Drain plug : Refer to AT-228, "

Component".

ATF level gauge bolt : Refer to AT-223, "

Removal and Installation (2WD)",

AT-225, "

Removal and Installation (4WD)".