wheel INFINITI QX56 2007 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 983 of 3061

![INFINITI QX56 2007 Factory Workshop Manual ON-VEHICLE SERVICE

BRC-55

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

4. Touch "START".

CAUTION:

Set vehicle as shown in the display.

5. After approximately 10 seconds, touch INFINITI QX56 2007 Factory Workshop Manual ON-VEHICLE SERVICE

BRC-55

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

4. Touch "START".

CAUTION:

Set vehicle as shown in the display.

5. After approximately 10 seconds, touch](/img/42/57029/w960_57029-982.png)

ON-VEHICLE SERVICE

BRC-55

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

4. Touch "START".

CAUTION:

Set vehicle as shown in the display.

5. After approximately 10 seconds, touch "END". (After approxi-

mately 60 seconds, it ends automatically.)

6. Turn ignition switch OFF, then turn it ON again.

CAUTION:

Be sure to carry out above operation

7. Run vehicle with front wheels in straight-ahead position, then

stop.

8. Select "DATA MONITOR", "SELECTION FROM MENU", and

"DECEL G SEN" on CONSULT-II screen. Then check that "DECEL G SEN" is within ±0.08G. If value is

more than specification, repeat steps 3 to 7.

9. Erase memory of ABS actuator and electric unit (control unit) and ECM.

10. Turn ignition switch to OFF.

SFIA1162E

Page 984 of 3061

![INFINITI QX56 2007 Factory Workshop Manual BRC-56

< SERVICE INFORMATION >[VDC/TCS/ABS]

WHEEL SENSOR

WHEEL SENSOR

Removal and InstallationINFOID:0000000003532811

REMOVAL

1. Remove wheel sensor bolt.

• When removing the front wheel sensor, fir INFINITI QX56 2007 Factory Workshop Manual BRC-56

< SERVICE INFORMATION >[VDC/TCS/ABS]

WHEEL SENSOR

WHEEL SENSOR

Removal and InstallationINFOID:0000000003532811

REMOVAL

1. Remove wheel sensor bolt.

• When removing the front wheel sensor, fir](/img/42/57029/w960_57029-983.png)

BRC-56

< SERVICE INFORMATION >[VDC/TCS/ABS]

WHEEL SENSOR

WHEEL SENSOR

Removal and InstallationINFOID:0000000003532811

REMOVAL

1. Remove wheel sensor bolt.

• When removing the front wheel sensor, first remove the disc rotor to gain access to the front wheel sen-

sor bolt. Refer to BR-19, "

Removal and Installation of Brake Caliper and Disc Rotor" .

• When removing the rear wheel sensor, first remove the rear hub and bearing assembly to gain access to

the rear wheel sensor bolt. Refer to FA X - 5 , "

Removal and Installation" .

2. Pull out the sensor, being careful to turn it as little as possible.

CAUTION:

• Do not pull on the sensor harness.

3. Disconnect wheel sensor harness electrical connector, then remove harness from attaching points.

INSTALLATION

Installation is in the reverse order of removal. Tighten wheel sensor bolt to specification.

CAUTION:

Installation should be performed while paying attention to the following.

• Inspect wheel sensor O-ring, replace sensor assembly if damaged.

• Before installing wheel sensor, make sure no foreign materials (such as iron fragments) are adhered

to the pick-up part of the sensor, to the inside of the sensor hole or on the rotor mating surface.

• Apply a coat of suitable grease to the wheel sensor O-ring and hole. Refer to MA-10

.

WFIA0376E

Page 985 of 3061

![INFINITI QX56 2007 Factory Workshop Manual SENSOR ROTOR

BRC-57

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SENSOR ROTOR

Removal and InstallationINFOID:0000000003532812

NOTE:

The wheel sensor rotors are built into the INFINITI QX56 2007 Factory Workshop Manual SENSOR ROTOR

BRC-57

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SENSOR ROTOR

Removal and InstallationINFOID:0000000003532812

NOTE:

The wheel sensor rotors are built into the](/img/42/57029/w960_57029-984.png)

SENSOR ROTOR

BRC-57

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SENSOR ROTOR

Removal and InstallationINFOID:0000000003532812

NOTE:

The wheel sensor rotors are built into the wheel hubs and are not removable. If damaged, replace wheel hub

and bearing assembly. Refer to FAX-5, "

Removal and Installation" (front), RAX-5, "Removal and Installation"

(rear).

Page 996 of 3061

OVERHEATING CAUSE ANALYSIS

CO-7

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or paper

clogging

Blocked radiator —

Blocked condenser

Blocked air flow

Installed large fog lamp Symptom Check items

Page 1108 of 3061

ENGINE CONTROL SYSTEM

EC-25

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

*1: This sensor is not used to control the engine system. This is used only for the on board diagnosis.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the crankshaft position sensor and the mass air

flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compensated to improve engine performance under various operat-

ing conditions as listed below.

• When starting the engine

• During acceleration

• Hot-engine operation

• When selector lever is changed from N to D

• High-load, high-speed operation

• During deceleration

• During high engine speed operation

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Engine speed*

3

Piston position

Fuel injection

& mixture ratio

controlFuel injector Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch Gear position

Knock sensor Engine knocking condition

Battery

Battery voltage*

3

Power steering pressure sensor Power steering operation

Heated oxygen sensor 2*

1Density of oxygen in exhaust gas

ABS actuator and electric unit (control unit)

VDC/TCS operation command*

2

Air conditioner switch

Air conditioner operation*2

Wheel sensor

Vehicle speed*2

PBIB3020E

Page 1110 of 3061

ENGINE CONTROL SYSTEM

EC-27

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

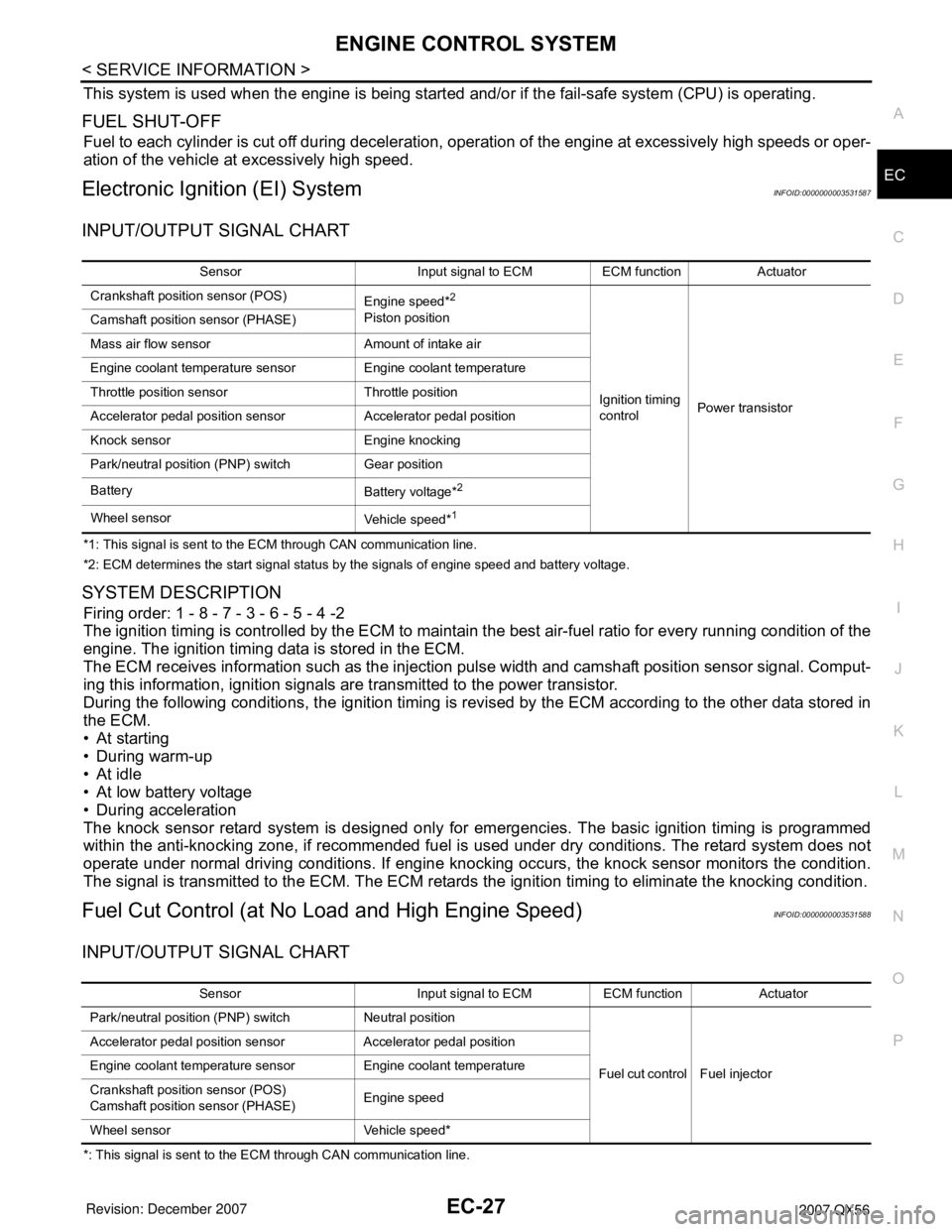

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

FUEL SHUT-OFF

Fuel to each cylinder is cut off during deceleration, operation of the engine at excessively high speeds or oper-

ation of the vehicle at excessively high speed.

Electronic Ignition (EI) SystemINFOID:0000000003531587

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

Firing order: 1 - 8 - 7 - 3 - 6 - 5 - 4 -2

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of the

engine. The ignition timing data is stored in the ECM.

The ECM receives information such as the injection pulse width and camshaft position sensor signal. Comput-

ing this information, ignition signals are transmitted to the power transistor.

During the following conditions, the ignition timing is revised by the ECM according to the other data stored in

the ECM.

• At starting

• During warm-up

•At idle

• At low battery voltage

• During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions. If engine knocking occurs, the knock sensor monitors the condition.

The signal is transmitted to the ECM. The ECM retards the ignition timing to eliminate the knocking condition.

Fuel Cut Control (at No Load and High Engine Speed)INFOID:0000000003531588

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line.Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Engine speed*

2

Piston position

Ignition timing

controlPower transistor Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Knock sensor Engine knocking

Park/neutral position (PNP) switch Gear position

Battery

Battery voltage*

2

Wheel sensor

Vehicle speed*1

Sensor Input signal to ECM ECM function Actuator

Park/neutral position (PNP) switch Neutral position

Fuel cut control Fuel injector Accelerator pedal position sensor Accelerator pedal position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed

Wheel sensor Vehicle speed*

Page 1112 of 3061

AIR CONDITIONING CUT CONTROL

EC-29

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

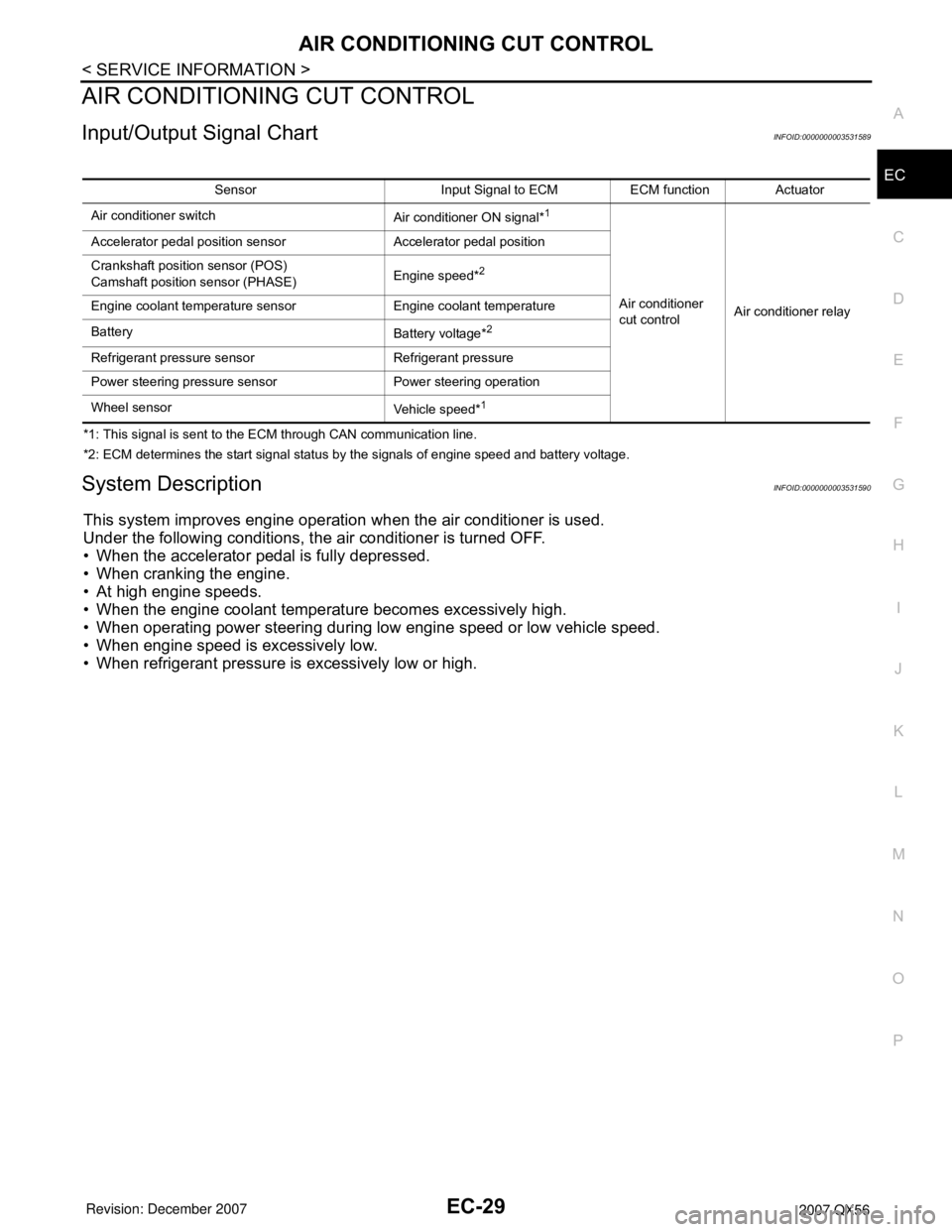

AIR CONDITIONING CUT CONTROL

Input/Output Signal ChartINFOID:0000000003531589

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

System DescriptionINFOID:0000000003531590

This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned OFF.

• When the accelerator pedal is fully depressed.

• When cranking the engine.

• At high engine speeds.

• When the engine coolant temperature becomes excessively high.

• When operating power steering during low engine speed or low vehicle speed.

• When engine speed is excessively low.

• When refrigerant pressure is excessively low or high.

Sensor Input Signal to ECM ECM function Actuator

Air conditioner switch

Air conditioner ON signal*

1

Air conditioner

cut controlAir conditioner relay Accelerator pedal position sensor Accelerator pedal position

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

2

Engine coolant temperature sensor Engine coolant temperature

Battery

Battery voltage*

2

Refrigerant pressure sensor Refrigerant pressure

Power steering pressure sensor Power steering operation

Wheel sensor

Vehicle speed*

1

Page 1113 of 3061

EC-30

< SERVICE INFORMATION >

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System DescriptionINFOID:0000000003531591

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line

BASIC ASCD SYSTEM

Refer to Owner's Manual for ASCD operating instructions.

Automatic Speed Control Device (ASCD) allows a driver to keep vehicle at predetermined constant speed

without depressing accelerator pedal. Driver can set vehicle speed in advance between approximately 40 km/

h (25 MPH) and 144 km/h (89 MPH).

ECM controls throttle angle of electric throttle control actuator to regulate engine speed.

Operation status of ASCD is indicated by CRUISE indicator and SET indicator in combination meter. If any

malfunction occurs in ASCD system, it automatically deactivates control.

NOTE:

Always drive vehicle in safe manner according to traffic conditions and obey all traffic laws.

SET OPERATION

Press MAIN switch. (The CRUISE indicator in combination meter illuminates.)

When vehicle speed reaches a desired speed between approximately 40 km/h (25 MPH) and 144 km/h (89

MPH), press SET/COAST switch. (Then SET indicator in combination meter illuminates.)

ACCELERATE OPERATION

If the RESUME/ACCELERATE switch is pressed during cruise control driving, increase the vehicle speed until

the switch is released or vehicle speed reaches maximum speed controlled by the system.

And then ASCD will keep the new set speed.

CANCEL OPERATION

When any of following conditions exist, cruise operation will be canceled.

• CANCEL switch is pressed

• More than 2 switches at ASCD steering switch are pressed at the same time (Set speed will be cleared)

• Brake pedal is depressed

• Selector lever is changed to N, P, R position

• Vehicle speed decreased to 13 km/h (8 MPH) lower than the set speed

• VDC system is operated

When the ECM detects any of the following conditions, the ECM will cancel the cruise operation and inform

the driver by blinking indicator lamp.

• Engine coolant temperature is slightly higher than the normal operating temperature, CRUISE lamp may

blink slowly.

When the engine coolant temperature decreases to the normal operating temperature, CRUISE lamp will

stop blinking and the cruise operation will be able to work by pressing SET/COAST switch or RESUME/

ACCELERATE switch.

• Malfunction for some self-diagnoses regarding ASCD control: SET lamp will blink quickly.

If MAIN switch is turned to OFF during ASCD is activated, all of ASCD operations will be canceled and vehicle

speed memory will be erased.

COAST OPERATION

When the SET/COAST switch is pressed during cruise control driving, decrease vehicle set speed until the

switch is released. And then ASCD will keep the new set speed.

RESUME OPERATION

Sensor Input signal to ECM ECM function Actuator

ASCD brake switch Brake pedal operation

ASCD vehicle speed controlElectric throttle control

actuator Stop lamp switch Brake pedal operation

ASCD steering switch ASCD steering switch operation

Park/neutral position (PNP) switch Gear position

Wheel sensor Vehicle speed*

TCM Powertrain revolution*

Page 1154 of 3061

BASIC SERVICE PROCEDURE

EC-71

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

BASIC SERVICE PROCEDURE

Basic InspectionINFOID:0000000003531609

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinches and cut

- Vacuum hoses for splits, kinks and improper connections

- Hoses and ducts for leaks

- Air cleaner clogging

- Gasket

3. Confirm that electrical or mechanical loads are not applied.

- Headlamp switch is OFF.

- Air conditioner switch is OFF.

- Rear window defogger switch is OFF.

- Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature

indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no

load.

6. Make sure that no DTC is displayed with CONSULT-II or GST.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding Diagnostic Procedure.

>> GO TO 3.

3.CHECK TARGET IDLE SPEED

With CONSULT-II

1. Run engine at about 2,000 rpm for about 2 minutes under no load.

SEF983U

SEF976U

SEF977U

Page 1161 of 3061

EC-78

< SERVICE INFORMATION >

BASIC SERVICE PROCEDURE

3. Turn ignition switch OFF wait at least 10 seconds.

Make sure that throttle valve moves during above 10 seconds by confirming the operating sound.

Idle Air Volume LearningINFOID:0000000003531615

DESCRIPTION

Idle Air Volume Learning is an operation to learn the idle air volume that keeps each engine within the specific

range. It must be performed under any of the following conditions:

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

PREPARATION

Before performing Idle Air Volume Learning, make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are missed for even a moment.

• Battery voltage: More than 12.9V (At idle)

• Engine coolant temperature: 70 - 100°C (158 - 212°F)

• Park/Neutral position (PNP) switch: ON

• Electric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

start the headlamp will not be illuminated.

• Steering wheel: Neutral (Straight-ahead position)

• Vehicle speed: Stopped

• Transmission: Warmed-up

- With CONSULT-II: Drive vehicle until “ATF TEMP SE 1” in “DATA MONITOR” mode of “A/T” system indi-

cates less than 0.9V.

- Without CONSULT-II: Drive vehicle for 10 minutes.

OPERATION PROCEDURE

With CONSULT-II

1. Perform EC-77, "Accelerator Pedal Released Position Learning" .

2. Perform EC-77, "

Throttle Valve Closed Position Learning" .

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic PREPARATION (previously mentioned) are in good order.

5. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

6. Touch “START” and wait 20 seconds.

SEF217Z

SEF454Y