sensor INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 1358 of 4210

EC-5

C

DE

F

G H

I

J

K L

M

EC A

N

O P

P1140, P1145 IVT CONTROL POSITION

SENSOR ......................................................... ..

295

Component Description ....................................... ..295

On Board Diagnosis Logic ....................................295

DTC Confirmation Procedure ................................295

Diagnosis Procedure .............................................295

Component Inspection ..........................................298

P1148, P1168 CLOSED LOOP CONTROL .....299

On Board Diagnosis Logic .................................. ..299

P1211 TCS CONTROL UNIT ...........................300

Description .......................................................... ..300

On Board Diagnosis Logic ....................................300

DTC Confirmation Procedure ................................300

Diagnosis Procedure .............................................300

P1212 TCS COMMUNICATION LINE ..............301

Description .......................................................... ..301

On Board Diagnosis Logic ....................................301

DTC Confirmation Procedure ................................301

Diagnosis Procedure .............................................301

P1217 ENGINE OVER TEMPERATURE .........302

On Board Diagnosis Logic .................................. ..302

Overall Function Check .........................................302

Diagnosis Procedure .............................................303

Main 13 Causes of Overheating ............................304

P1225 TP SENSOR ..........................................306

Component Description ....................................... ..306

On Board Diagnosis Logic ....................................306

DTC Confirmation Procedure ................................306

Diagnosis Procedure .............................................306

P1226 TP SENSOR ..........................................308

Component Description ....................................... ..308

On Board Diagnosis Logic ....................................308

DTC Confirmation Procedure ................................308

Diagnosis Procedure .............................................308

P1421 COLD START CONTROL .....................310

Description .......................................................... ..310

On Board Diagnosis Logic ....................................310

DTC Confirmation Procedure ................................310

Diagnosis Procedure .............................................310

P1550 BATTERY CURRENT SENSOR ...........312

Component Description ....................................... ..312

On Board Diagnosis Logic ....................................312

DTC Confirmation Procedure ................................312

Diagnosis Procedure .............................................312

Component Inspection ..........................................314

P1551, P1552 BATTERY CURRENT SEN-

SOR ..................................................................

316

Component Description ....................................... ..316

On Board Diagnosis Logic ....................................316

DTC Confirmation Procedure ................................316

Diagnosis Procedure .............................................316

Component Inspection ..........................................318

P1553 BATTERY CURRENT SENSOR ..........320

Component Description ....................................... ..320

On Board Diagnosis Logic .....................................320

DTC Confirmation Procedure ................................320

Diagnosis Procedure .............................................320

Component Inspection ...........................................322

P1554 BATTERY CURRENT SENSOR ..........324

Component Description .........................................324

On Board Diagnosis Logic .....................................324

Overall Function Check .........................................324

Diagnosis Procedure .............................................325

Component Inspection ...........................................326

P1564 ICC STEERING SWITCH .....................328

Component Description .........................................328

On Board Diagnosis Logic .....................................328

DTC Confirmation Procedure ................................328

Diagnosis Procedure .............................................328

Component Inspection ...........................................330

P1564 ASCD STEERING SWITCH .................332

Component Description .........................................332

On Board Diagnosis Logic .....................................332

DTC Confirmation Procedure ................................332

Diagnosis Procedure .............................................332

Component Inspection ...........................................334

P1568 ICC FUNCTION ....................................336

On Board Diagnosis Logic .....................................336

DTC Confirmation Procedure ................................336

Diagnosis Procedure .............................................336

P1572 ICC BRAKE SWITCH ..........................337

Component Description .........................................337

On Board Diagnosis Logic .....................................337

DTC Confirmation Procedure ................................337

Diagnosis Procedure .............................................338

Component Inspection ...........................................343

P1572 ASCD BRAKE SWITCH ......................344

Component Description .........................................344

On Board Diagnosis Logic .....................................344

DTC Confirmation Procedure ................................344

Diagnosis Procedure .............................................345

Component Inspection ...........................................348

P1574 ICC VEHICLE SPEED SENSOR .........349

Component Description .........................................349

On Board Diagnosis Logic .....................................349

DTC Confirmation Procedure ................................349

Diagnosis Procedure .............................................349

P1574 ASCD VEHICLE SPEED SENSOR .....351

Component Description .........................................351

On Board Diagnosis Logic .....................................351

DTC Confirmation Procedure ................................351

Diagnosis Procedure .............................................351

P1805 BRAKE SWITCH .................................353

Description .............................................................353

Revision: April 20092010 QX56

Page 1359 of 4210

EC-6

On Board Diagnosis Logic .....................................353

DTC Confirmation Procedure ................................353

Diagnosis Procedure .............................................353

Component Inspection ...........................................355

P2100, P2103 THROTTLE CONTROL MO-

TOR RELAY .....................................................

356

Component Description ....................................... ..356

On Board Diagnosis Logic .....................................356

DTC Confirmation Procedure ................................356

Diagnosis Procedure .............................................356

P2101 ELECTRIC THROTTLE CONTROL

FUNCTION .......................................................

359

Description ........................................................... ..359

On Board Diagnosis Logic .....................................359

DTC Confirmation Procedure ................................359

Diagnosis Procedure .............................................359

Component Inspection ...........................................362

P2118 THROTTLE CONTROL MOTOR ..........363

Component Description ....................................... ..363

On Board Diagnosis Logic .....................................363

DTC Confirmation Procedure ................................363

Diagnosis Procedure .............................................363

Component Inspection ...........................................364

P2119 ELECTRIC THROTTLE CONTROL

ACTUATOR .....................................................

365

Component Description ....................................... ..365

On Board Diagnosis Logic .....................................365

DTC Confirmation Procedure ................................365

Diagnosis Procedure .............................................366

P2122, P2123 APP SENSOR ..........................367

Component Description ....................................... ..367

On Board Diagnosis Logic .....................................367

DTC Confirmation Procedure ................................367

Diagnosis Procedure .............................................367

Component Inspection ...........................................369

P2127, P2128 APP SENSOR ..........................370

Component Description ....................................... ..370

On Board Diagnosis Logic .....................................370

DTC Confirmation Procedure ................................370

Diagnosis Procedure .............................................370

Component Inspection ...........................................373

P2135 TP SENSOR .........................................374

Component Description ....................................... ..374

On Board Diagnosis Logic .....................................374

DTC Confirmation Procedure ................................374

Diagnosis Procedure .............................................374

Component Inspection ...........................................377

P2138 APP SENSOR ......................................378

Component Description ....................................... ..378

On Board Diagnosis Logic .....................................378

DTC Confirmation Procedure ................................378

Diagnosis Procedure .............................................379

Component Inspection ......................................... .381

P2A00, P2A03 A/F SENSOR 1 ........................382

Component Description ....................................... .382

On Board Diagnosis Logic ....................................382

DTC Confirmation Procedure ................................382

Diagnosis Procedure .............................................383

ASCD BRAKE SWITCH ...................................388

Component Description ....................................... .388

Diagnosis Procedure .............................................388

Component Inspection ..........................................390

ASCD INDICATOR ...........................................391

Component Description ....................................... .391

Diagnosis Procedure .............................................391

COOLING FAN .................................................392

Diagnosis Procedure ............................................ .392

Component Inspection ..........................................392

ELECTRICAL LOAD SIGNAL ..........................394

Description ........................................................... .394

Diagnosis Procedure .............................................394

FUEL INJECTOR ..............................................396

Component Description ....................................... .396

Diagnosis Procedure .............................................396

Component Inspection ..........................................398

FUEL PUMP .....................................................399

Description ........................................................... .399

Diagnosis Procedure .............................................399

Component Inspection ..........................................402

ICC BRAKE SWITCH ..................................... ..403

Component Description ....................................... .403

Diagnosis Procedure .............................................403

Component Inspection ..........................................405

IGNITION SIGNAL ............................................407

Component Description ....................................... .407

Diagnosis Procedure .............................................407

Component Inspection ..........................................410

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) .....................................................

412

System Description .............................................. .412

Diagnosis Procedure .............................................412

Component Inspection ..........................................414

POSITIVE CRANKCASE VENTILATION .........417

Description ........................................................... .417

Component Inspection ..........................................417

REFRIGERANT PRESSURE SENSOR ...........419

Component Description ....................................... .419

Diagnosis Procedure .............................................419

ECU DIAGNOSIS ......................................422

ECM ................................................................ ..422

Revision: April 20092010 QX56

Page 1360 of 4210

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

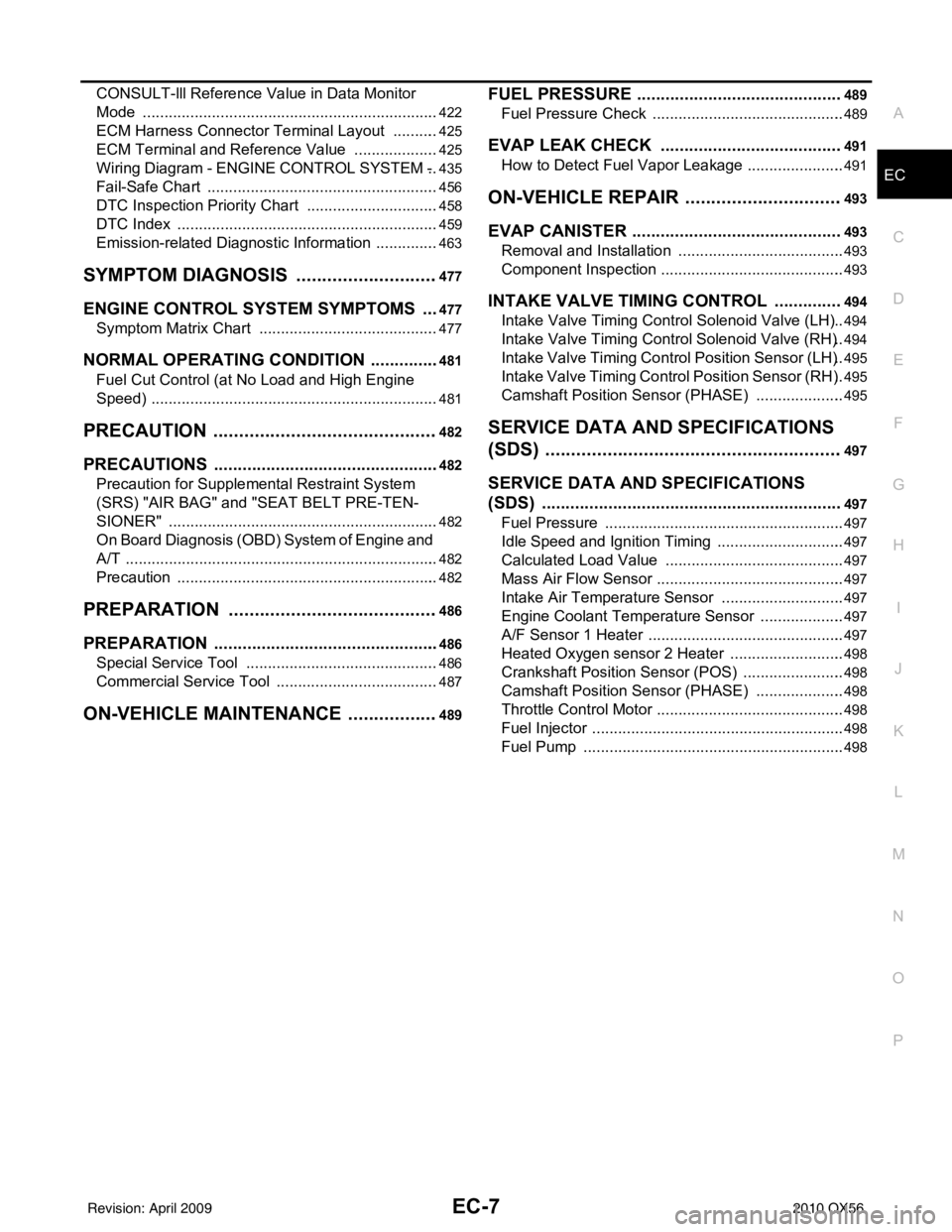

CONSULT-lll Reference Va

lue in Data Monitor

Mode ................................................................... ..

422

ECM Harness Connector Terminal Layout ...........425

ECM Terminal and Reference Value ....................425

Wiring Diagram - ENGINE CONTROL SYSTEM - ..435

Fail-Safe Chart .................................................... ..456

DTC Inspection Priority Chart ............................. ..458

DTC Index ........................................................... ..459

Emission-related Diagnostic Information ...............463

SYMPTOM DIAGNOSIS ..... .......................477

ENGINE CONTROL SYSTEM SYMPTOMS .. ..477

Symptom Matrix Chart ........................................ ..477

NORMAL OPERATING CONDITION ...............481

Fuel Cut Control (at No Load and High Engine

Speed) ................................................................. ..

481

PRECAUTION ............................................482

PRECAUTIONS .............................................. ..482

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

482

On Board Diagnosis (OBD) System of Engine and

A/T .........................................................................

482

Precaution .............................................................482

PREPARATION .........................................486

PREPARATION .............................................. ..486

Special Service Tool ........................................... ..486

Commercial Service Tool ......................................487

ON-VEHICLE MAINTENANCE ..................489

FUEL PRESSURE ...........................................489

Fuel Pressure Check ........................................... ..489

EVAP LEAK CHECK ......................................491

How to Detect Fuel Vapor Leakage .......................491

ON-VEHICLE REPAIR ...............................493

EVAP CANISTER ............................................493

Removal and Installation ..................................... ..493

Component Inspection ...........................................493

INTAKE VALVE TIMING CONTROL ..............494

Intake Valve Timing Control Solenoid Valve (LH) ..494

Intake Valve Timing Cont rol Solenoid Valve (RH) ..494

Intake Valve Timing Control Position Sensor (LH) ..495

Intake Valve Timing Control Position Sensor (RH) ..495

Camshaft Position Sensor (PHASE) .....................495

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... .

497

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

497

Fuel Pressure ...................................................... ..497

Idle Speed and Ignition Timing ..............................497

Calculated Load Value ..........................................497

Mass Air Flow Sensor ............................................497

Intake Air Temperature Sensor .............................497

Engine Coolant Temperature Sensor ....................497

A/F Sensor 1 Heater ..............................................497

Heated Oxygen sensor 2 Heater ...........................498

Crankshaft Position Sensor (POS) ........................498

Camshaft Position Sensor (PHASE) .....................498

Throttle Control Motor ............................................498

Fuel Injector ...........................................................498

Fuel Pump .............................................................498

Revision: April 20092010 QX56

Page 1361 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-8

< BASIC INSPECTION >[VK56DE]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Trouble Diagnosis IntroductionINFOID:0000000005149054

INTRODUCTION

The engine has an ECM INFINITI QX56 2010 Factory Service Manual EC-8

< BASIC INSPECTION >[VK56DE]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Trouble Diagnosis IntroductionINFOID:0000000005149054

INTRODUCTION

The engine has an ECM](/img/42/57032/w960_57032-1360.png)

EC-8

< BASIC INSPECTION >[VK56DE]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Trouble Diagnosis IntroductionINFOID:0000000005149054

INTRODUCTION

The engine has an ECM to control major systems such as fuel con-

trol, ignition control, idle air control system, etc. The ECM accepts

input signals from sensors and instantly drives actuators. It is essen-

tial that both input and output signals are proper and stable. At the

same time, it is important that there are no malfunctions such as vac-

uum leaks, fouled spark plugs, or

other malfunctions with the engine.

It is much more difficult to diagnose an incident that occurs intermit-

tently rather than continuously. Most intermittent incidents are

caused by poor electric connections or improper wiring. In this case,

careful checking of suspected circuits may help prevent the replace-

ment of good parts.

A visual check only may not find the cause of the incidents. A road

test with CONSULT-III (or GST) or a circuit tester connected should

be performed. Follow the Work Flow on "WORK FLOW" .

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such incidents, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A Di agnostic Worksheet like the example

on "Worksheet Sample" should be used.

Start your diagnosis by looking fo r conventional malfunctions first.

This will help troubleshoot driveability malfunctions on an electroni-

cally controlled engine vehicle.

WORK FLOW

MEF036D

SEF233G

SEF234G

Revision: April 20092010 QX56

Page 1364 of 4210

![INFINITI QX56 2010 Factory Service Manual DIAGNOSIS AND REPAIR WORKFLOWEC-11

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Are they within the SP value?

Yes >> GO TO 9.

No >> GO TO 8.

8.DETECT MALFUNCTIONING PART BY TROUBLE DI INFINITI QX56 2010 Factory Service Manual DIAGNOSIS AND REPAIR WORKFLOWEC-11

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Are they within the SP value?

Yes >> GO TO 9.

No >> GO TO 8.

8.DETECT MALFUNCTIONING PART BY TROUBLE DI](/img/42/57032/w960_57032-1363.png)

DIAGNOSIS AND REPAIR WORKFLOWEC-11

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Are they within the SP value?

Yes >> GO TO 9.

No >> GO TO 8.

8.DETECT MALFUNCTIONING PART BY TROUBLE DIAGNOSIS - SPECIFICATION VALUE

Detect malfunctioning part according to EC-75, "

Diagnosis Procedure".

Is malfunctioning part detected?

Yes >> GO TO 11.

No >> GO TO 9.

9.DETECT MALFUNCTIONING SYST EM BY SYMPTOM MATRIX CHART

Detect malfunctioning system according to EC-477, "

Symptom Matrix Chart" based on the confirmed symp-

tom in step 4, and determine the trouble diagnosis order based on possible causes and symptom.

>> GO TO 10.

10.DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the system.

NOTE:

The Diagnostic Procedure in EC section described based on open circuit inspection. A short circuit inspection

is also required for the circuit check in the Diagnostic Procedure. For details, refer to Circuit Inspection in GI-

34, "Work Flow".

Is malfunctioning part detected?

Yes >> GO TO 11.

No >> Monitor input data from related sensors or check voltage of related ECM terminals using CON- SULT-III. Refer to EC-425, "

ECM Terminal and Reference Value", EC-422, "CONSULT-lll Refer-

ence Value in Data Monitor Mode".

11 .REPAIR OR REPLACE THE MALFUNCTIONING PART

1. Repair or replace the malfunctioning part.

2. Reconnect parts or connectors disconnected during Diagnostic Procedure again after repair and replace-

ment.

3. Check DTC. If DTC is displayed, erase it, refer to EC-459, "

DTC Index".

>> GO TO 12.

12.FINAL CHECK

When DTC was detected in step 2, perform DTC Confirmation Procedure or Overall Function Check again,

and then make sure that the malfunction have been repaired securely.

When symptom was described from the customer, refer to confirmed symptom in step 3 or 4, and make sure

that the symptom is not detected.

OK or NG

NG (DTC*1 is detected)>>GO TO 10.

NG (Symptom remains)>>GO TO 6.

OK >> 1. Before returning the vehicle to the cu stomer, make sure to erase unnecessary DTC*

1 in ECM

and TCM (Transmission Control Module). (Refer to EC-459, "

DTC Index" and TM-30, "OBD-

II Diagnostic Trouble Code (DTC)".)

2. If the completion of SRT is needed, drive vehicle under the specific driving pattern. Refer to EC-459, "

DTC Index".

3. INSPECTION END

*1: Include 1st trip DTC.

*2: Include 1st trip freeze frame data.

DIAGNOSTIC WORKSHEET

Description

Revision: April 20092010 QX56

Page 1368 of 4210

![INFINITI QX56 2010 Factory Service Manual INSPECTION AND ADJUSTMENTEC-15

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

Refer to EC-17, "

Idl INFINITI QX56 2010 Factory Service Manual INSPECTION AND ADJUSTMENTEC-15

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

Refer to EC-17, "

Idl](/img/42/57032/w960_57032-1367.png)

INSPECTION AND ADJUSTMENTEC-15

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

Refer to EC-17, "

Idle Speed and Ignition Timing Check" .

OK or NG

OK >> GO TO 10.

NG >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the following.

• Check camshaft position sensor (PHASE) and circuit. Refer to EC-205

.

• Check crankshaft position sensor (POS) and circuit. Refer to EC-201

.

OK or NG

OK >> GO TO 9.

NG >> 1. Repair or replace. 2. GO TO 4.

9.CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM f unction. (ECM may be the cause of an incident, but

this is a rare case.)

2. Perform initialization of IVIS (NAT S) system and registration of all IVIS (NATS) ignition key IDs. Refer to

SEC-14, "

System Diagram".

>> GO TO 4.

10.CHECK IGNITION TIMING

1. Run engine at idle.

2. Check ignition timing with a timing light. Refer to EC-17, "

Idle Speed and Ignition Timing Check" .

OK or NG

OK >> GO TO 19.

NG >> GO TO 11.

11 .PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

1. Stop engine.

2. Perform EC-18, "

Accelerator Pedal Released Position Learning" .

>> GO TO 12.

12.PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Perform EC-18, "

Throttle Valve Closed Position Learning" .

>> GO TO 13.

13.PERFORM IDLE AIR VOLUME LEARNING

Refer to EC-18, "

Idle Air Volume Learning" .

Is Idle Air Volume Learning carried out successfully?

Ye s o r N o

Yes >> GO TO 14.

No >> 1. Follow the instruction of Idle Air Volume Learning. 650

± 50 rpm (in P or N position)

15 ± 5 ° BTDC (in P or N position)

BBIA0379E

Revision: April 20092010 QX56

Page 1369 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-16

< BASIC INSPECTION >[VK56DE]

INSPECTION AND ADJUSTMENT

2. GO TO 4.

14.CHECK TARGET IDLE SPEED AGAIN

With CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Read idle INFINITI QX56 2010 Factory Service Manual EC-16

< BASIC INSPECTION >[VK56DE]

INSPECTION AND ADJUSTMENT

2. GO TO 4.

14.CHECK TARGET IDLE SPEED AGAIN

With CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Read idle](/img/42/57032/w960_57032-1368.png)

EC-16

< BASIC INSPECTION >[VK56DE]

INSPECTION AND ADJUSTMENT

2. GO TO 4.

14.CHECK TARGET IDLE SPEED AGAIN

With CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Read idle speed in “DATA MONITOR” mode with CONSULT-III.

Refer to EC-17, "

Idle Speed and Ignition Timing Check" .

Without CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

Refer to EC-17, "

Idle Speed and Ignition Timing Check" .

OK or NG

OK >> GO TO 15.

NG >> GO TO 17.

15.CHECK IGNITION TIMING AGAIN

1. Run engine at idle.

2. Check ignition timing with a timing light. Refer to EC-17, "

Idle Speed and Ignition Timing Check" .

OK or NG

OK >> GO TO 19.

NG >> GO TO 16.

16.CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-45, "

Removal and Installation".

OK or NG

OK >> GO TO 17.

NG >> 1. Repair the timing chain installation. 2. GO TO 4.

17.DETECT MALFUNCTIONING PART

Check the following.

• Check camshaft position sensor (PHASE) and circuit. Refer to EC-205

.

• Check crankshaft position sensor (POS) and circuit. Refer to EC-201

.

OK or NG

OK >> GO TO 18.

NG >> 1. Repair or replace. 2. GO TO 4.

18.CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function. (ECM may be the cause of an incident, but this is a rare case.)

2. Perform initialization of IVIS (NATS) system and regist ration of all IVIS (NATS) ignition key IDs. Refer to

SEC-14, "

System Diagram".

>> GO TO 4.

19.INSPECTION END 650

± 50 rpm (in P or N position)

650 ± 50 rpm (in P or N position)

15 ± 5 ° BTDC (in P or N position)

BBIA0379E

Revision: April 20092010 QX56

Page 1371 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-18

< BASIC INSPECTION >[VK56DE]

INSPECTION AND ADJUSTMENT

With CONSULT-III

1. Check the VIN of the vehicle and note it. Refer to

GI-20, "Model Variation".

2. Turn ignition switch ON and engine st INFINITI QX56 2010 Factory Service Manual EC-18

< BASIC INSPECTION >[VK56DE]

INSPECTION AND ADJUSTMENT

With CONSULT-III

1. Check the VIN of the vehicle and note it. Refer to

GI-20, "Model Variation".

2. Turn ignition switch ON and engine st](/img/42/57032/w960_57032-1370.png)

EC-18

< BASIC INSPECTION >[VK56DE]

INSPECTION AND ADJUSTMENT

With CONSULT-III

1. Check the VIN of the vehicle and note it. Refer to

GI-20, "Model Variation".

2. Turn ignition switch ON and engine stopped.

3. Select “VIN REGISTRATION ” in “WORK SUPPORT” mode.

4. Follow the instruction of CONSULT-III display.

Accelerator Pedal Released Position LearningINFOID:0000000005149059

DESCRIPTION

Accelerator Pedal Released Position Learning is an operation to learn the fully released position of the accel-

erator pedal by monitoring the accelerator pedal positi on sensor output signal. It must be performed each time

harness connector of accelerator pedal pos ition sensor or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON and wait at least 2 seconds.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON and wait at least 2 seconds.

5. Turn ignition switch OFF and wait at least 10 seconds.

Throttle Valve Closed Position LearningINFOID:0000000005149060

DESCRIPTION

Throttle Valve Closed Position Learning is an operation to l earn the fully closed position of the throttle valve by

monitoring the throttle position sensor output signal . It must be performed each time harness connector of

electric throttle control actuator or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON.

3. Turn ignition switch OFF wait at least 10 seconds. Make sure that throttle valve moves during above 10 seconds by confirming the operating sound.

Idle Air Volume LearningINFOID:0000000005149061

DESCRIPTION

Idle Air Volume Learning is an operation to learn the idle air volume that keeps each engine within the specific

range. It must be performed under any of the following conditions:

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

PREPARATION

Before performing Idle Air Volume Learning, make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the follo wing conditions are missed for even a moment.

• Battery voltage: More than 12.9V (At idle)

• Engine coolant temperature: 70 - 100 °C (158 - 212° F)

• Select lever: P or N

• Electric load switch: OFF (Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

start the headlamp will not be illuminated.

• Steering wheel: Neutral (Straight-ahead position)

• Vehicle speed: Stopped

• Transmission: Warmed-up

- With CONSULT-III: Drive vehicle until “ATF TEMP SE 1” in “DATA MONITOR” mode of “A/T” system indi- cates less than 0.9V.

- Without CONSULT-III: Drive vehicle for 10 minutes.

OPERATION PROCEDURE

Revision: April 20092010 QX56

Page 1372 of 4210

![INFINITI QX56 2010 Factory Service Manual INSPECTION AND ADJUSTMENTEC-19

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

With CONSULT-III

1. Perform

EC-18, "Accelerator Pedal Released Position Learning" .

2. Perform EC-18, "

INFINITI QX56 2010 Factory Service Manual INSPECTION AND ADJUSTMENTEC-19

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

With CONSULT-III

1. Perform

EC-18, "Accelerator Pedal Released Position Learning" .

2. Perform EC-18, "](/img/42/57032/w960_57032-1371.png)

INSPECTION AND ADJUSTMENTEC-19

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

With CONSULT-III

1. Perform

EC-18, "Accelerator Pedal Released Position Learning" .

2. Perform EC-18, "

Throttle Valve Closed Position Learning" .

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic PREP ARATION (previously mentioned) are in good order.

5. Select “IDLE AIR VOL LEA RN” in “WORK SUPPORT” mode.

6. Touch “START” and wait 20 seconds.

7. Make sure that “CMPLT” is displayed on CONSULT-III screen. If “CMPLT” is not displayed, Idle Air Vol-

ume Learning will not be carried out successfully. In this case, find the cause of the incident by referring to

the DIAGNOSTIC PROCEDURE below.

8. Rev up the engine two or three times and make sure that idle speed and ignition timing are within the specifications.

Without CONSULT-III

NOTE:

•It is better to count the time accurately with a clock.

• It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform EC-18, "

Accelerator Pedal Released Position Learning" .

2. Perform EC-18, "

Throttle Valve Closed Position Learning" .

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic PREP ARATION (previously mentioned) are in good order.

5. Turn ignition switch OFF and wait at least 10 seconds.

6. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

7. Repeat the following procedure quick ly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

8. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 20 seconds until the MIL stops blinking and turned ON.

9. Fully release the accelerator pedal within 3 seconds after the MIL turned ON.

10. Start engine and let it idle.

11. Wait 20 seconds.

12. Rev up the engine two or three times and make sure that idle speed and ignition timing are within the specifications.

ITEM SPECIFICATION

Idle speed 650 ± 50 rpm (in P or N position)

Ignition timing 15 ± 5° BTDC (in P or N position)

SEC897C

Revision: April 20092010 QX56

Page 1375 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-22

< FUNCTION DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM

Engine Control Comp onent Parts Location

INFOID:0000000005149063

1. ECM 2. Battery current sensor 3. Power steering pressure sensor

4. Igniti INFINITI QX56 2010 Factory Service Manual EC-22

< FUNCTION DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM

Engine Control Comp onent Parts Location

INFOID:0000000005149063

1. ECM 2. Battery current sensor 3. Power steering pressure sensor

4. Igniti](/img/42/57032/w960_57032-1374.png)

EC-22

< FUNCTION DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM

Engine Control Comp onent Parts Location

INFOID:0000000005149063

1. ECM 2. Battery current sensor 3. Power steering pressure sensor

4. Ignition coil (with power transistor) and spark plug (bank 2) 5. Refrigerant pressure sensor 6. Intake valve timing control position

sensor (bank 2)

7. Intake valve timing control solenoid valve (bank 2) 8. Engine coolant temperature sensor 9. Electric throttle control actuator

10. Intake valve timing control position sensor (bank 1) 11. Intake valve timing control solenoid

valve (bank 1) 12. Cooling fan motor

13. Camshaft position sensor (PHASE) 14. I gnition coil (with power transistor)

and spark plug (bank 1) 15. Mass air flow sensor (with intake air

temperature sensor)

16. A/F sensor 1 (bank 1) 17. EVAP service port 18. Fuel injector (bank 1)

19. Knock sensor (bank 1) 20. EVAP canister purge volume control

solenoid valve 21. Knock sensor (bank 2)

22. Fuel injector (bank 2) 23. A/F sensor 1 (bank 2) 24. IPDM E/R

BBIA0743E

Revision: April 20092010 QX56