INFINITI QX56 2010 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 611 of 4210

![INFINITI QX56 2010 Factory Service Manual G SENSORBRC-119

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

G SENSOR

Removal and InstallationINFOID:0000000005148103

REMOVAL

1. Remove front center console. Refer to INFINITI QX56 2010 Factory Service Manual G SENSORBRC-119

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

G SENSOR

Removal and InstallationINFOID:0000000005148103

REMOVAL

1. Remove front center console. Refer to](/img/42/57032/w960_57032-610.png)

G SENSORBRC-119

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

G SENSOR

Removal and InstallationINFOID:0000000005148103

REMOVAL

1. Remove front center console. Refer to IP-20, "Removal and

Installation".

2. Remove yaw rate/side/decel G sensor attaching nuts. CAUTION:

• Do not use power tools to re move or install yaw rate/side/

decel G sensor.

• Do not drop or strike the yaw rate/side/decel G sensor.

3. Disconnect harness connector and remove the yaw rate/side/ decel G sensor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not drop or strike the yaw rate/side/decel G sensor.

• After installation, calibrate the yaw rate/side/decel G sensor. Refer to BRC-9, "

CALIBRATION OF

DECEL G SENSOR : Special Repair Requirement".

WFIA0202E

Revision: April 20092010 QX56

Page 612 of 4210

BRM-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

DE

F

G H

I

J

L

M

SECTION BRM

A

B

BRM

N

O P

CONTENTS

BODY REPAIR

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Handling Precaution For Plastics ..............................3

SERVICE INFORMATION ............................6

BODY REPAIR ...................................................6

Body Mounting ..................................................... .....6

Body Exterior Paint Color .........................................7

Body Component Parts ............................................8

Corrosion Protection ................................................13

Body Sealing ...........................................................16

Body Construction ...................................................20

Body Alignment .......................................................20

Handling Precaution for Plastics ..............................35

Precaution in Repairing High Strength Steel ...........38

Foam Repair ............................................................40

Replacement Operation ...........................................41

Revision: April 20092010 QX56

Page 613 of 4210

BRM-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005370276

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005370277

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 614 of 4210

PRECAUTIONSBRM-3

< PRECAUTION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

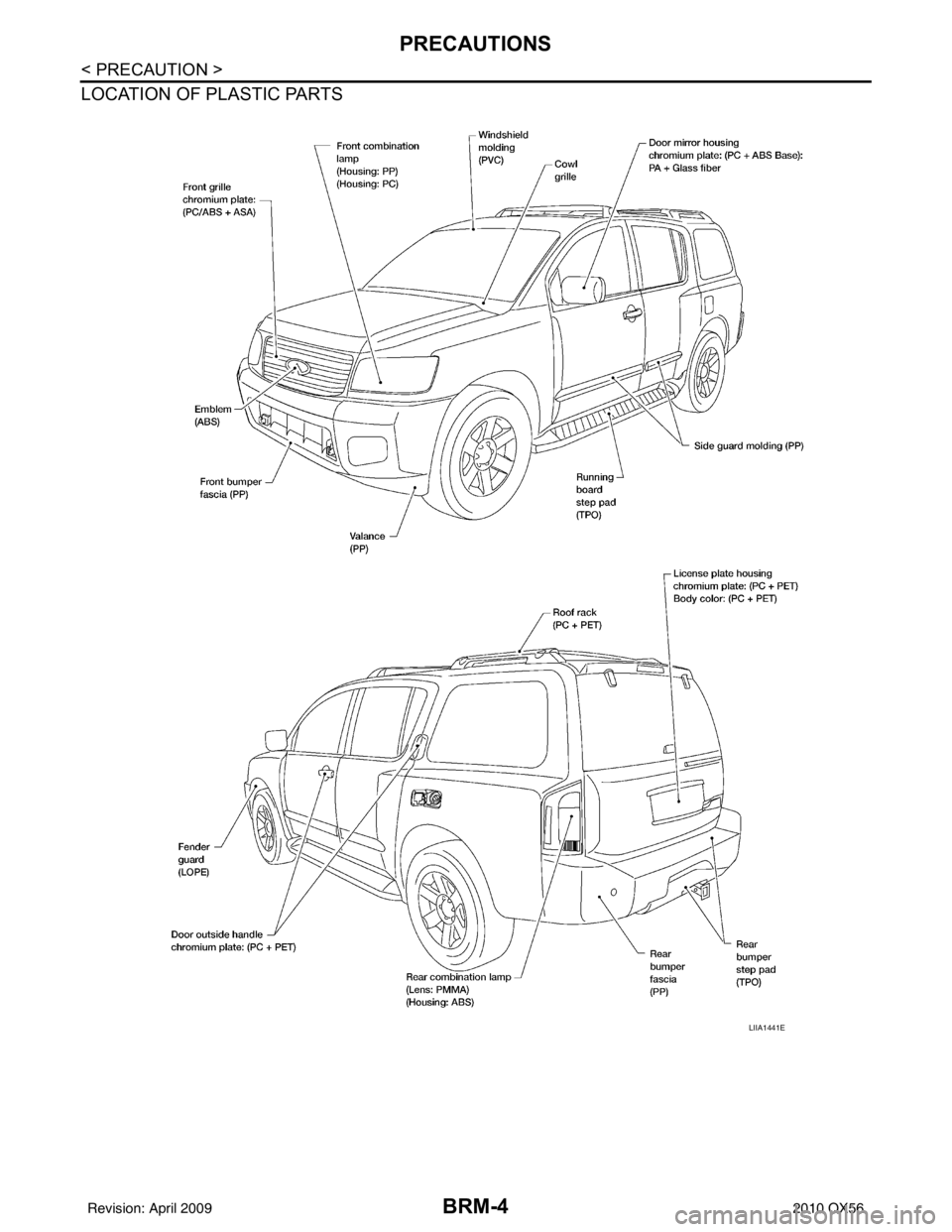

Handling Precaution For PlasticsINFOID:0000000005370283

PRECAUTIONS FOR PLASTICS

1. When repairing and painting a portion of the body adjacent to plastic parts, consider their characteristics (influence of hea t and sol-

vent) and remove them if necessary or take suitable measures to protect them.

2. Plastic parts should be repaired and painted using methods suiting the materials

, characteristics.

Abbre-

viation Material name Heat resisting

temperature

°C ( °F) Resistance to gasoline and

solvents Other cautions

PE Polyethylene 60 (140)Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly).

Flammable

ABS Acrylonitrile Butadiene Styrene 80 (176) Avoid gasoline and solvents. —

EPM/

EPDM Ethylene Propylene (Diene) co-

polymer

80 (176)Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly). Flammable

PS Polystyrene 80 (176) Avoid solvents. Flammable

PVC Poly Vinyl Chloride 80 (176)Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly). Poison gas is emitted

when burned.

TPO Thermoplastic Olefine 80 (176) Same as above. Flammable

AAS Acrylonitrile Acrylic Styrene 85 (185) Avoid gasoline and solvents. —

PMMA Poly Methyl Methacrylate 85 (185) Same as above. —

EVAC Ethylene Vinyl Acetate 90 (194) Avoid gasoline and solvents. —

PP Polypropylene 90 (194)Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly). Flammable, avoid bat-

tery acid.

PUR Polyurethane 90 (194) Avoid gasoline and solvents. —

UP Unsaturated Polyester 90 (194) Same as above. Flammable

ASA Acrylonitrile Styrene Acrylate 100 (212) Same as above. Flammable

PPE Poly Phenylene Ether 110 (230) Same as above. —

TPU Thermoplastic Urethane 110 (230) Same as above. —

PBT+

PC Poly Butylene Terephthalate +

Polycarbonate

120 (248) Same as above.

Flammable

PC Polycarbonate 120 (248) Same as above. —

POM Poly Oxymethylene 120 (248) Same as above. Avoid battery acid.

PA Polyamide 140 (284) Same as above. Avoid immersing in wa-

ter.

PBT Poly Butylene Terephthalate 140 (284) Same as above. —

PAR Polyarylate 180 (356) Same as above. —

PET Polyester 180 (356) Same as above. —

PEI Polyetherimide 200 (392) Same as above. —

Revision: April 20092010 QX56

Page 615 of 4210

BRM-4

< PRECAUTION >

PRECAUTIONS

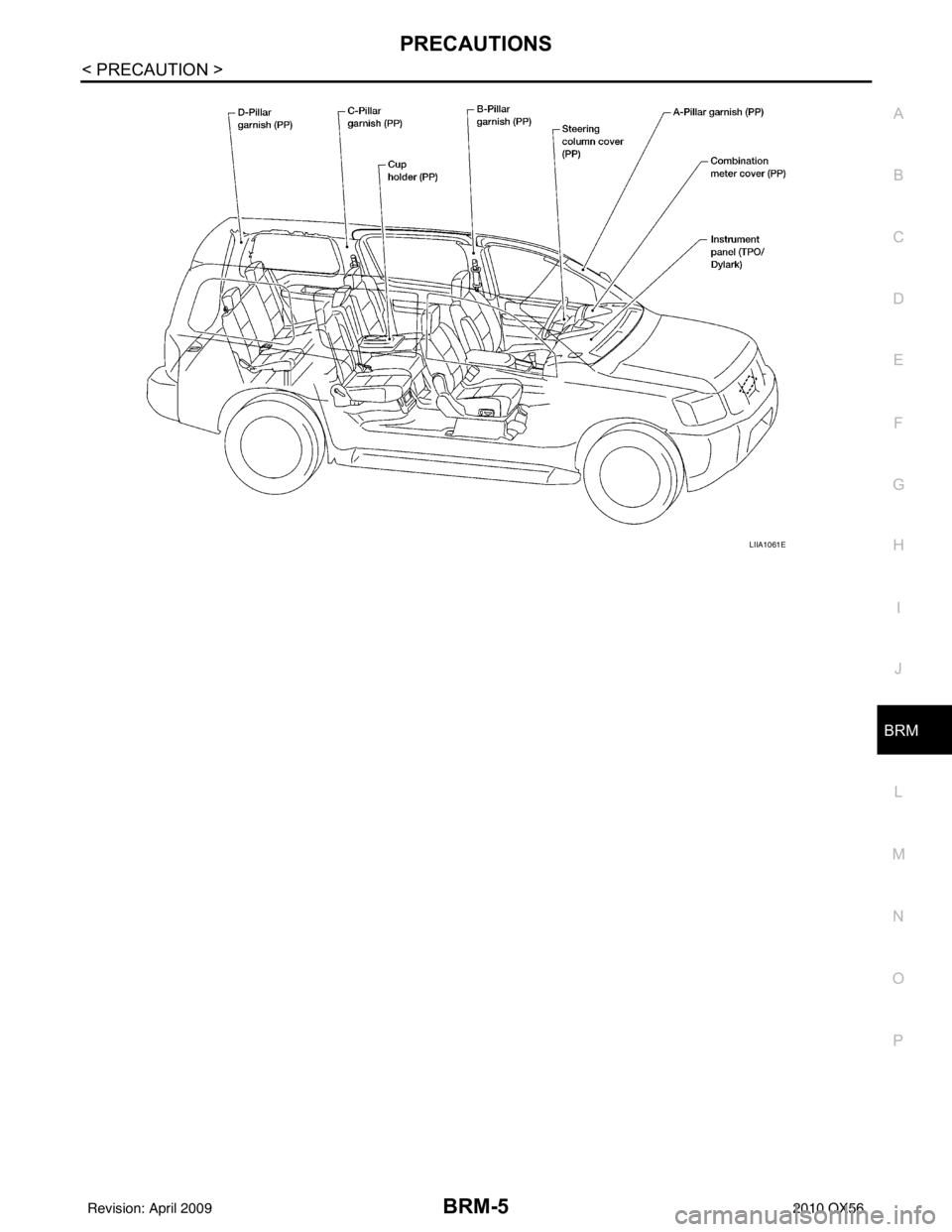

LOCATION OF PLASTIC PARTS

LIIA1441E

Revision: April 20092010 QX56

Page 616 of 4210

PRECAUTIONSBRM-5

< PRECAUTION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

LIIA1061E

Revision: April 20092010 QX56

Page 617 of 4210

BRM-6

< SERVICE INFORMATION >

BODY REPAIR

SERVICE INFORMATION

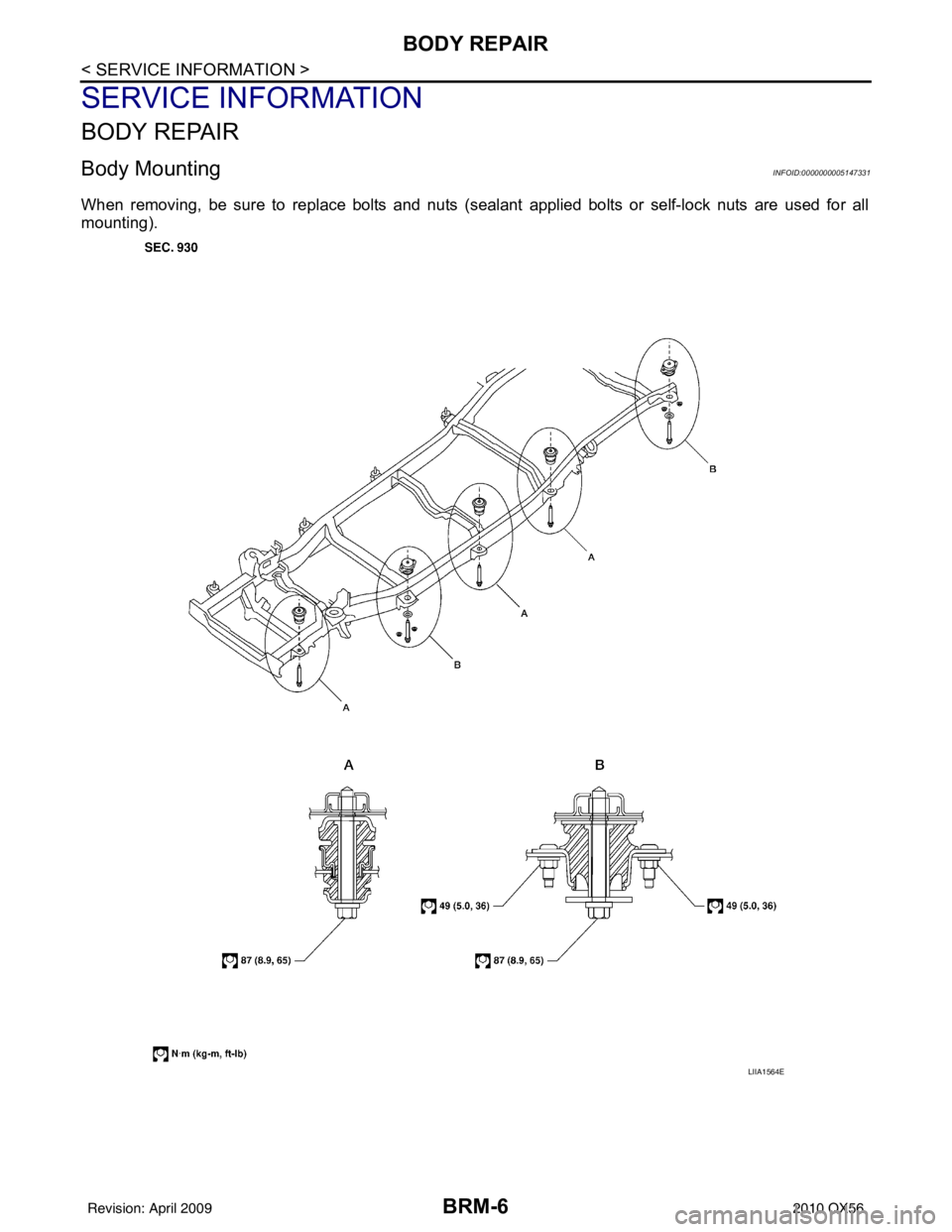

BODY REPAIR

Body MountingINFOID:0000000005147331

When removing, be sure to replace bolts and nuts (sealant applied bolts or self-lock nuts are used for all

mounting).

LIIA1564E

Revision: April 20092010 QX56

Page 618 of 4210

BODY REPAIRBRM-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

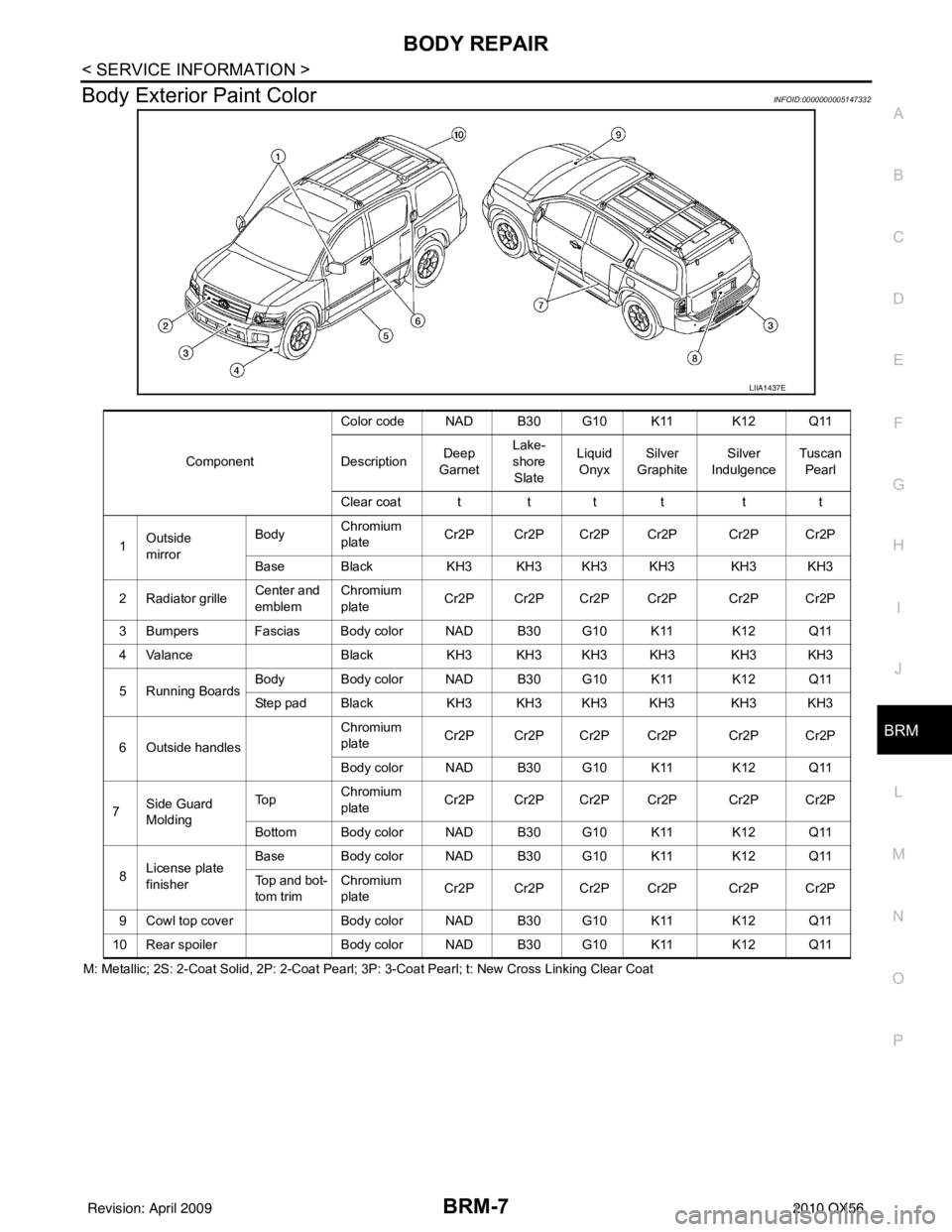

Body Exterior Paint ColorINFOID:0000000005147332

M: Metallic; 2S: 2-Coat Solid, 2P: 2-Coat Pearl; 3P: 3-Coat Pearl; t: New Cross Linking Clear Coat

LIIA1437E

Component Color code NAD B30 G10 K11 K12 Q11

Description

Deep

Garnet Lake-

shore

Slate Liquid

Onyx Silver

Graphite Silver

Indulgence Tuscan

Pearl

Clear coat t t t t tt

1 Outside

mirror Body

Chromium

plate Cr2P Cr2P Cr2P Cr2P Cr2P Cr2P

Base Black KH3 KH3 KH3 KH3 KH3 KH3

2 Radiator grille Center and

emblemChromium

plate

Cr2P Cr2P Cr2P Cr2P Cr2P Cr2P

3 Bumpers Fascias Body color NAD B30 G10 K11 K12 Q11

4 Valance BlackKH3 KH3 KH3 KH3 KH3 KH3

5 Running Boards Body Body color NAD B30 G10 K11 K12 Q11

Step pad Black

KH3 KH3 KH3 KH3 KH3 KH3

6 Outside handles Chromium

plate

Cr2P Cr2P Cr2P Cr2P Cr2P Cr2P

B o d y c o l o r N A D B 3 0 G 1 0 K 11 K 1 2 Q 11

7 Side Guard

Molding To p

Chromium

plate Cr2P Cr2P Cr2P Cr2P Cr2P Cr2P

Bottom Body color NAD B30 G10 K11 K12 Q11

8 License plate

finisher Base Body color NAD B30 G10 K11 K12 Q11

Top and bot-

tom trim

Chromium

plate

Cr2P Cr2P Cr2P Cr2P Cr2P Cr2P

9 Cowl top cover Body color NAD B30 G10 K11 K12 Q11

10 Rear spoiler Body color NAD B30 G10 K11 K12 Q11

Revision: April 20092010 QX56

Page 619 of 4210

BRM-8

< SERVICE INFORMATION >

BODY REPAIR

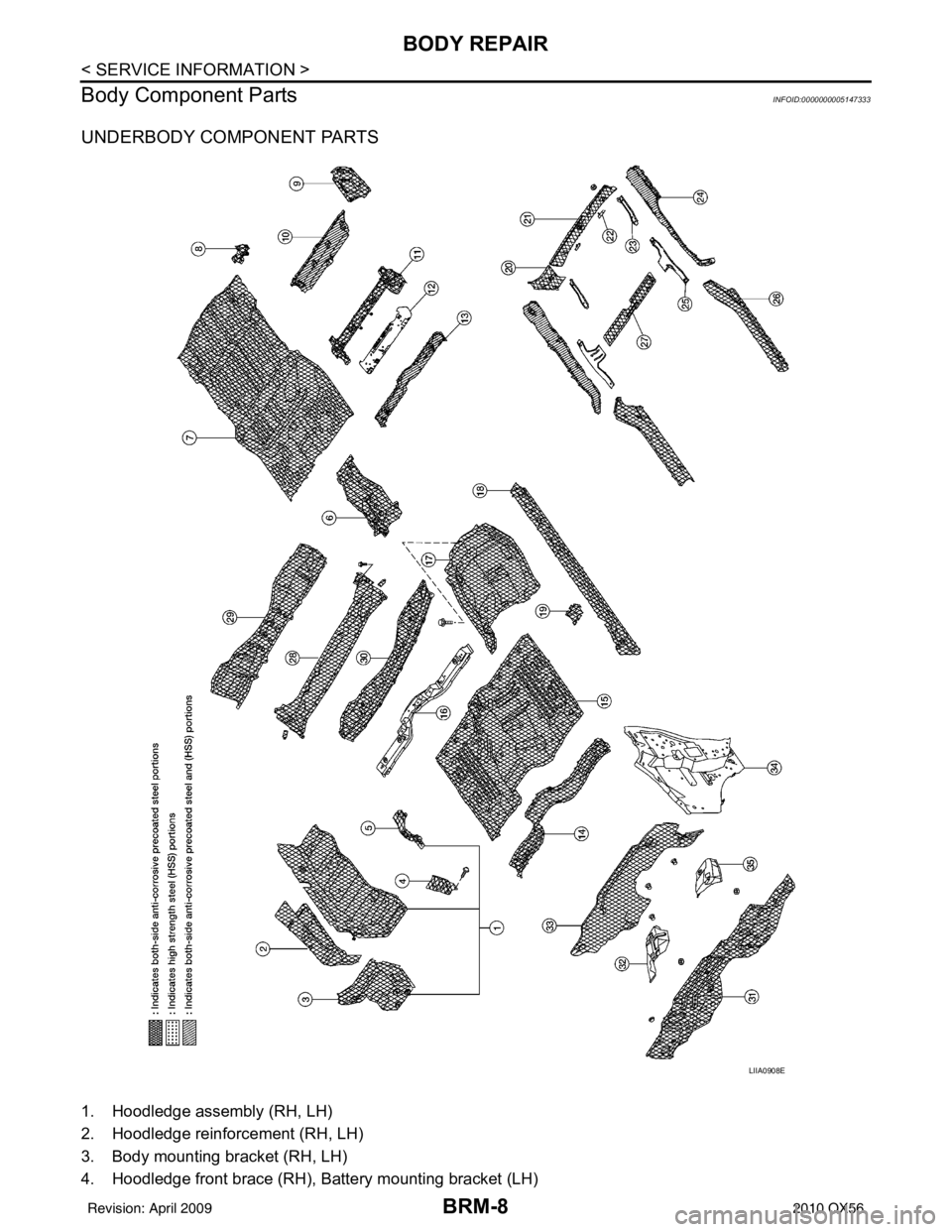

Body Component Parts

INFOID:0000000005147333

UNDERBODY COMPONENT PARTS

1. Hoodledge assembly (RH, LH)

2. Hoodledge reinforcement (RH, LH)

3. Body mounting bracket (RH, LH)

4. Hoodledge front brace (RH), Battery mounting bracket (LH)

LIIA0908E

Revision: April 20092010 QX56

Page 620 of 4210

BODY REPAIRBRM-9

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

5. Harness connector bracket

6. Rear floor reinforcement

7. Rear floor

8. Rear floor reinforcement

9. Rear floor side (RH, LH)

10. Crossmember

11. Second seat rear crossmember

12. Second seat front crossmember

13. Rear front seat crossmember

14. Second Body crossmember

15. Front floor

16. Front seat front crossmember

17. Front floor reinforcement

18. Outer sill (RH, LH)

19. Second crossmember extension

20. Rear crossmember end

21. Rear lower crossmember end

22. Rear crossmember end (RH, LH)

23. Rear side member rear reinforcement (RH, LH)

24. Rear side member (RH, LH)

25. Rear side member reinforcement (RH, LH)

26. Inner sill extension (RH, LH)

27. Rear crossmember

28. Upper dash top

29. Upper dash bottom

30. Cowl top

31. Lower dash

32. Lower dash insulator (RH)

33. Lower dash reinforcement

34. Side dash (RH, LH)

35. Lower dash insulator

Revision: April 20092010 QX56