light INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2514 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-490

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

ASCD BRAKE SWITCH

ASCD BRAKE SWITCH

Component Function CheckINFOID:0000000006217989

1.CHECK ASCD BRAKE SWITCH FUNCTION

WITH CONSULT-III

1. Turn ignition swit INFINITI QX56 2011 Factory Service Manual

EC-490

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

ASCD BRAKE SWITCH

ASCD BRAKE SWITCH

Component Function CheckINFOID:0000000006217989

1.CHECK ASCD BRAKE SWITCH FUNCTION

WITH CONSULT-III

1. Turn ignition swit](/img/42/57033/w960_57033-2513.png)

EC-490

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

ASCD BRAKE SWITCH

ASCD BRAKE SWITCH

Component Function CheckINFOID:0000000006217989

1.CHECK ASCD BRAKE SWITCH FUNCTION

WITH CONSULT-III

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DAT A MONITOR” mode with CONSULT-III.

3. Check “BRAKE SW1” indication under the following conditions.

WITHOUT CONSULT-III

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector terminals as per the following.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-490, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006217990

1.CHECK ASCD BRAKE SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ASCD brake switch harness connector.

3. Turn ignition switch ON.

4. Check the voltage between ASCD brake switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.DETECT MALFUNCTIONING PART

Check the following.

10 A fuse (No. 3)

Harness for open or short between ASCD brake switch and fuse

Loose or poor connection for each connector and harness

>> Repair open circuit or short to ground in harness or connectors.

3.CHECK ASCD BRAKE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between ASCD brake s witch harness connector and ECM harness connector.

Monitor item Condition Indication

BRAKE SW1

(ASCD brake switch) Brake pedalSlightly depressed OFF

Fully released ON

ECM Condition Voltage (V)

Connector +–

Te r m i n a l Te r m i n a l

E80 147

(ASCD brake switch signal) 175 Brake pedalSlightly depressed Approx. 0

Fully released Battery voltage

ASCD brake switch

Ground Voltage

Connector Terminal

E109 1 Ground Battery voltage

Revision: 2010 May2011 QX56

Page 2515 of 5598

![INFINITI QX56 2011 Factory Service Manual

ASCD BRAKE SWITCHEC-491

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO INFINITI QX56 2011 Factory Service Manual

ASCD BRAKE SWITCHEC-491

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO](/img/42/57033/w960_57033-2514.png)

ASCD BRAKE SWITCHEC-491

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

Harness for open or short between ECM and ASCD brake switch

Loose or poor connection for each connector and harness

>> Repair open circuit, short to ground or short to power in harness or connectors.

5.CHECK ASCD BRAKE SWITCH

Refer to EC-491, "

Component Inspection (ASCD Brake Switch)".

Is the inspection result normal?

YES >> GO TO 6.

NO >> Replace ASCD brake switch. Refer to BR-20, "

Removal and Installation".

6.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component Inspection (ASCD Brake Switch)INFOID:0000000006217991

1.CHECK ASCD BRAKE SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect ASCD brake switch harness connector.

3. Check the continuity between ASCD brake swit ch terminals under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK ASCD BRAKE SWITCH-II

1. Adjust ASCD brake switch installation. Refer to BR-21, "

Inspection and Adjustment".

2. Check the continuity between ASCD brake swit ch terminals under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace ASCD brake switch. Refer to BR-20, "

Removal and Installation".

ASCD brake switch ECM

Continuity

Connector Terminal Connector Terminal

E109 2 E80 147 Existed

Terminals Condition Continuity

1 and 2 Brake pedal Fully released Existed

Slightly depressed Not existed

Terminals Condition Continuity

1 and 2 Brake pedal Fully released Existed

Slightly depressed Not existed

Revision: 2010 May2011 QX56

Page 2517 of 5598

![INFINITI QX56 2011 Factory Service Manual

ELECTRICAL LOAD SIGNALEC-493

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000006217994

The electrical load signal (Rear window defog INFINITI QX56 2011 Factory Service Manual

ELECTRICAL LOAD SIGNALEC-493

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000006217994

The electrical load signal (Rear window defog](/img/42/57033/w960_57033-2516.png)

ELECTRICAL LOAD SIGNALEC-493

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000006217994

The electrical load signal (Rear window defogger switch

signal, headlamp switch signal, heater fan switch sig-

nal, etc.) is transferred via the CAN communication line.

Component Function CheckINFOID:0000000006217995

1.CHECK REAR WINDOW DEF OGGER SWITCH FUNCTION

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-III.

3. Select “LOAD SIGNAL” and check indication under the following conditions.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Go to EC-493, "

Diagnosis Procedure".

2.CHECK LIGHTING SWITCH FUNCTION

Check “LOAD SIGNAL” indication under the following conditions.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Go to EC-493, "

Diagnosis Procedure".

3.CHECK HEATER FAN CONTROL SWITCH FUNCTION

Select “HEATER FAN SW” and check indication under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-493, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006217996

1.INSPECTION START

Confirm the malfunctioning circuit (rear window defogger, headlamp or heater fan). Refer to EC-493, "

Compo-

nent Function Check".

Which circuit is related to the incident?

Rear window defogger>>GO TO 2.

Headlamp>>GO TO 3.

Heater fan>>GO TO 4.

2.CHECK REAR WINDOW DEFOGGER SYSTEM

Refer to DEF-24, "

Work Flow".

Monitor item Condition Indication

LOAD SIGNAL Rear window defogger switch ON ON

OFF OFF

Monitor item Condition Indication

LOAD SIGNAL Lighting switch ON at 2nd position ON

OFF OFF

Monitor item Condition Indication

HEATER FAN SW Heater fan control switch ON ON

OFF OFF

Revision: 2010 May2011 QX56

Page 2527 of 5598

![INFINITI QX56 2011 Factory Service Manual

ICC BRAKE SWITCHEC-503

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ICC BRAKE SWITCH

Component Function CheckINFOID:0000000006218008

1.CHECK ICC BRAKE SWITCH FUNCTION

WITH CONS INFINITI QX56 2011 Factory Service Manual

ICC BRAKE SWITCHEC-503

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ICC BRAKE SWITCH

Component Function CheckINFOID:0000000006218008

1.CHECK ICC BRAKE SWITCH FUNCTION

WITH CONS](/img/42/57033/w960_57033-2526.png)

ICC BRAKE SWITCHEC-503

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ICC BRAKE SWITCH

Component Function CheckINFOID:0000000006218008

1.CHECK ICC BRAKE SWITCH FUNCTION

WITH CONSULT-III

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DATA MONITOR” mode with CONSULT-III.

3. Check “BRAKE SW1” indication under the following conditions.

WITHOUT CONSULT-III

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector terminals as per the following.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-503, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006218009

1.CHECK DTC WITH ADAS CONTROL UNIT

Refer to DAS-21, "

CONSULT-III Function (ICC/ADAS)" and DAS-38, "DTC Index".

Are any DTCs detected?

YES >> Perform the Diagnosis Procedur e corresponding to the detected DTC.

NO >> GO TO 2.

2.CHECK OVERALL FUNCTION

WITH CONSULT-III

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DATA MONITOR” mode with CONSULT-III.

3. Check “BRAKE SW1” indication under the following conditions.

WITHOUT CONSULT-III

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector terminals under the following conditions.

Monitor item Condition Indication

BRAKE SW1

(ICC brake switch) Brake pedalSlightly depressed OFF

Fully released ON

ECM

Condition Voltage

Connector +–

Terminal Terminal

E80 147

(ICC brake switch signal) 175 Brake pedalSlightly depressed Approx. 0 V

Fully released Battery voltage

Monitor item Condition Indication

BRAKE SW1

(ICC brake switch) Brake pedalSlightly depressed OFF

Fully released ON

Revision: 2010 May2011 QX56

Page 2528 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-504

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

ICC BRAKE SWITCH

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 3.

3.CHECK ICC BRAKE SWITCH POWER SUPPLY CIRCUIT-I

1. Turn ignition switch INFINITI QX56 2011 Factory Service Manual

EC-504

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

ICC BRAKE SWITCH

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 3.

3.CHECK ICC BRAKE SWITCH POWER SUPPLY CIRCUIT-I

1. Turn ignition switch](/img/42/57033/w960_57033-2527.png)

EC-504

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

ICC BRAKE SWITCH

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 3.

3.CHECK ICC BRAKE SWITCH POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF.

2. Disconnect ICC brake switch harness connector.

3. Turn ignition switch ON.

4. Check the voltage between ICC brake switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 7.

NO >> GO TO 4.

4.CHECK ICC BRAKE SWITCH POWER SUPPLY CIRCUIT-II

Check the voltage between ICC brake switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 6.

NO >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

Fuse block (J/B) connector E103

10 A fuse (No. 3)

Harness for open or short between ICC brake switch and fuse

>> Repair open circuit or short to ground in harness or connectors.

6.CHECK ICC BRAKE SWITCH

Refer to EC-445, "

Component Inspection (ICC Brake Switch)".

Is the inspection result normal?

YES >> GO TO 9.

NO >> Replace ICC brake switch. Refer to BR-20, "

Removal and Installation".

7.CHECK ICC BRAKE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between ICC brake s witch harness connector and ECM harness connector.

ECM

Condition Voltage (V)

Connector +–

Te r m i n a l Te r m i n a l

E80 147

(ICC brake switch signal) 175 Brake pedalSlightly depressed Approx. 0

Fully released Battery voltage

ICC brake switch

Ground Voltage

Connector Terminal

E68 2 Ground Battery voltage

ICC brake switch Ground Voltage

Connector Terminal

E68 1 Ground Battery voltage

Revision: 2010 May2011 QX56

Page 2529 of 5598

![INFINITI QX56 2011 Factory Service Manual

ICC BRAKE SWITCHEC-505

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 9 INFINITI QX56 2011 Factory Service Manual

ICC BRAKE SWITCHEC-505

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 9](/img/42/57033/w960_57033-2528.png)

ICC BRAKE SWITCHEC-505

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 9.

NO >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the following.

Harness for open or short between ICC brake switch and ECM

Loose or poor connection for each connector and harness

>> Repair open circuit, short to ground or short to power in harness or connectors.

9.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component Inspection (ICC Brake Switch)INFOID:0000000006218010

1.CHECK ICC BRAKE SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect ICC brake switch harness connector.

3. Check the continuity between ICC brake switch terminals under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK ICC BRAKE SWITCH-II

1. Adjust ICC brake switch installation. Refer to BR-21, "

Inspection and Adjustment".

2. Check the continuity between ICC brake switch terminals under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace ICC brake switch. Refer to BR-20, "

Removal and Installation".

ICC brake switch ECM

Continuity

Connector Terminal Connector Terminal

E68 2 E80 147 Existed

Terminals Condition Continuity

1 and 2 Brake pedal Fully released Existed

Slightly depressed Not existed

Terminals Condition Continuity

1 and 2 Brake pedal Fully released Existed

Slightly depressed Not existed

Revision: 2010 May2011 QX56

Page 2555 of 5598

![INFINITI QX56 2011 Factory Service Manual

IGNITION TIMINGEC-531

< PERIODIC MAINTENANCE > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

IGNITION TIMING

InspectionINFOID:0000000006218031

1.CHECK IGNITION TIMING

1. Attach timing light to loop wire a INFINITI QX56 2011 Factory Service Manual

IGNITION TIMINGEC-531

< PERIODIC MAINTENANCE > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

IGNITION TIMING

InspectionINFOID:0000000006218031

1.CHECK IGNITION TIMING

1. Attach timing light to loop wire a](/img/42/57033/w960_57033-2554.png)

IGNITION TIMINGEC-531

< PERIODIC MAINTENANCE > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

IGNITION TIMING

InspectionINFOID:0000000006218031

1.CHECK IGNITION TIMING

1. Attach timing light to loop wire as shown.

2. Check ignition timing.

>> INSPECTION END

1. Loop wire

A. Timing light B. Timing indicator

JSBIA0492ZZ

Revision: 2010 May2011 QX56

Page 2562 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-538

< SERVICE DATA AND SPECIFICATIONS (SDS) [VK56VD]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:000000000621 INFINITI QX56 2011 Factory Service Manual

EC-538

< SERVICE DATA AND SPECIFICATIONS (SDS) [VK56VD]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:000000000621](/img/42/57033/w960_57033-2561.png)

EC-538

< SERVICE DATA AND SPECIFICATIONS (SDS) [VK56VD]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:0000000006218038

*: Under the following conditions

A/C switch: OFF

Electric load: OFF (Lights, heater fan & rear window defogger)

Steering wheel: Kept in straight-ahead position

Ignition TimingINFOID:0000000006218039

*: Under the following conditions

A/C switch: OFF

Electric load: OFF (Lights, heater fan & rear window defogger)

Steering wheel: Kept in straight-ahead position

Calculated Load ValueINFOID:0000000006218040

Mass Air Flow SensorINFOID:0000000006218041

*: Engine is warmed up to normal operating temperature and running under no load.Condition Specification

No load* (in P or N position) 600 ± 50 rpm

Condition Specification

No load* (in P or N position) 12 ± 2 °BTDC

Condition Specification (U sing CONSULT-III or GST)

At idle 5 – 35%

At 2,500 rpm 5 – 35%

Supply voltageBattery voltage (11 – 14 V)

Output voltage at idle 0.9 – 1.1 V*

Mass air flow (Using CONSULT-III or GST) 1.0 – 5.0 g/s at idle*

7.0 – 20.0 g/s at 2,500 rpm*

Revision: 2010 May2011 QX56

Page 2567 of 5598

PRECAUTIONSEM-5

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Avoid damaging sliding or mating surfaces. Completely re

move foreign materials such as cloth lint or dust.

Before assembly, oil sliding surfaces well.

Release air within route when refilling after draining engine coolant.

After repairing, start engine and increase engine speed to check engine coolant, fuel, engine oil, and

exhaust gases for leakage.

Parts Requiring Angle TighteningINFOID:0000000006289515

Use angle wrench [SST: KV10112100 (BT8653-A)] for the final tightening of the following engine parts:

- Cylinder head bolts

- Main bearing cap bolts

- Main bearing cap sub bolts

- Connecting rod cap bolts

- Crankshaft pulley bolt (No angle wrench is required as the bolt flange is provided with notches for angletightening)

Ensure thread and seat surfaces are clean and coated with engine oil.

Precaution for Liquid GasketINFOID:0000000006289516

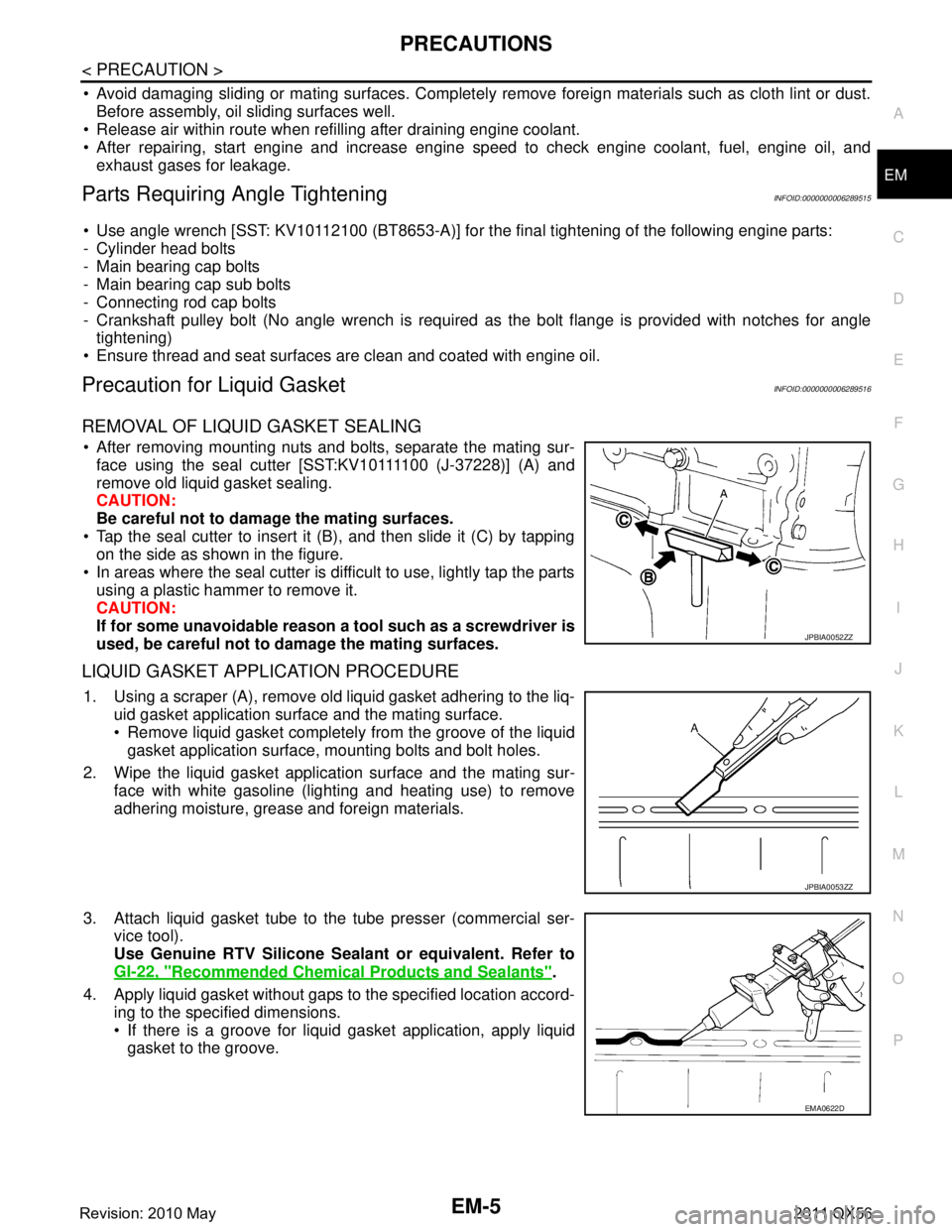

REMOVAL OF LIQUID GASKET SEALING

After removing mounting nuts and bolts, separate the mating sur- face using the seal cutter [SST:KV10111100 (J-37228)] (A) and

remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

Tap the seal cutter to insert it (B), and then slide it (C) by tapping on the side as shown in the figure.

In areas where the seal cutter is difficult to use, lightly tap the parts using a plastic hammer to remove it.

CAUTION:

If for some unavoidable reason a tool such as a screwdriver is

used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper (A), remove old liquid gasket adhering to the liq- uid gasket application surface and the mating surface.

Remove liquid gasket completely from the groove of the liquidgasket application surface, mounting bolts and bolt holes.

2. Wipe the liquid gasket application surface and the mating sur- face with white gasoline (lighting and heating use) to remove

adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to the tube presser (commercial ser- vice tool).

Use Genuine RTV Silicone Seal ant or equivalent. Refer to

GI-22, "

Recommended Chemical Products and Sealants".

4. Apply liquid gasket without gaps to the specified location accord- ing to the specified dimensions.

If there is a groove for liquid gasket application, apply liquidgasket to the groove.

JPBIA0052ZZ

JPBIA0053ZZ

EMA0622D

Revision: 2010 May2011 QX56

Page 2608 of 5598

EM-46

< REMOVAL AND INSTALLATION >

HIGH PRESSURE FUEL PUMP AND FUEL HOSE

Check that rotation stopper (A) of fuel feed hose contact highpressure fuel pump.

6. Tighten mounting bolts that are temporarily tightened in step 3.

7. Connect harness connector to high pressure fuel pump.

8. Install fuel pump connector protector.

9. Connect harness connector to low fuel pressure sensor.

10. Note the following, and connect quick connector to install fuel feed hose.

a. Check the connection for foreign material and damage.

b. Align center to insert quick connector straightly into fuel tube. NOTE:

The figure shows engine side as an example.

Insert fuel tube into quick connector until the top spool on fueltube is inserted completely and the second level spool is posi-

tioned slightly below quick connector bottom end.

CAUTION:

Hold “A” position in the figure when inserting fuel tube

into quick connector.

Carefully align center to avoid inclined insertion to pre-

vent damage to O-ring inside quick connector.

Insert until you hear a “c lick” sound and actually feel

the engagement.

To avoid misidentification of engagement with a similar sound , be sure to perform the next

step.

c. Before clamping fuel feed hose with hose clamps, pull quick connector hard by hand holding “A” position.

Check it is completely engaged (connected) so that it does not come out from fuel feed tube.

d. Install quick connector cap to quick connector connection. Install so that the arrow mark on the side faces up.

CAUTION:

Check that quick connector and fuel tube are securely fitinto quick connector cap installation groove.

If quick connector cap canno t be installed smoothly,

quick connector may have not been installed correctly.

Check connection again.

11. Install in the reverse order of removal.

InspectionINFOID:0000000006289555

INSPECTION AFTER INSTALLATION

Check for Fuel Leakage

1. Turn ignition switch “ON” (with the engine stopped). With fuel pressure applied to fuel piping, check that

there is no fuel leakage at connection points.

NOTE:

Use mirrors for checking at points out of clear sight.

2. Start the engine. With engine speed increased, check again that there is no fuel leakage at connection

points.

JSBIA0364ZZ

KBIA0272E

PBIC2348E

Revision: 2010 May2011 QX56