BATTERY INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1499 of 5598

DIAGNOSIS SYSTEM (BCM)DEF-7

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu nction (BCM - COMMON ITEM)INFOID:0000000006349773

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate each device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defo gger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 1518 of 5598

DEF-26

< DTC/CIRCUIT DIAGNOSIS >

REAR WINDOW DEFOGGER RELAY

REAR WINDOW DEFOGGER RELAY

DescriptionINFOID:0000000006299436

The rear window defogger is operated by turning the rear window defogger switch ON.

Component Function CheckINFOID:0000000006299437

1.CHECK FUNCTION

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. Check that the rear window heating wire is getting warmer.

Is the inspection result normal?

YES >> Rear window defogger relay function is OK.

NO >> Refer to DEF-26, "

Diagnosis Procedure"

Diagnosis ProcedureINFOID:0000000006299438

1.CHECK FUSE

1. Turn ignition switch OFF.

2. Check the 15A fuse (No. 41, 42 located in IPDM E/R).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

2.CHECK IPDM E/R OUTPUT SIGNAL

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. Check voltage between IPDM E/R harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace IPDM E/R. Refer to PCS-32, "

Removal and Installation".

(+)

(− ) CONSULT-III Active Test condition Voltage (V)

(Approx.)

IPDM E/R

Connector Terminal

E11 14 Ground REAR DEFOGGER ON Battery voltage

OFF 0

Revision: 2010 May2011 QX56

Page 1519 of 5598

REAR WINDOW DEFOGGERDEF-27

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

REAR WINDOW DEFOGGER

DescriptionINFOID:0000000006299439

Heats the heating wire with the power supply from the rear window defogger relay to prevent the rear window

from fogging up.

Component Function CheckINFOID:0000000006299440

1.CHECK FUNCTION

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. Check that the rear window heating wire is getting warmer.

Is the inspection result normal?

YES >> Rear window defogger relay function is OK.

NO >> Refer to DEF-26, "

Diagnosis Procedure"

Diagnosis ProcedureINFOID:0000000006299441

1.CHECK REAR WINDOW DEFOGG ER POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear window defogger connector.

3. Turn ignition switch ON.

4. Check voltage between rear window defogger harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK REAR WINDOW DE FOGGER GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between rear window defogger harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK FILAMENT

Refer to DEF-43, "

Inspection and Repair".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair filament.

4.CHECK REAR WINDOW DEFOGG ER POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and rear window defogger harness connector.

(+)

(− ) Condition Voltage (V)

(Approx.)

Rear window defogger

Connector Terminal

D103 1 Ground Rear window defogger switch ON Battery voltage

OFF 0

Rear window defogger GroundContinuity

Connector Terminal

D104 2 Existed

Revision: 2010 May2011 QX56

Page 1522 of 5598

DEF-30

< DTC/CIRCUIT DIAGNOSIS >

DRIVER SIDE DOOR MIRROR DEFOGGER

DRIVER SIDE DOOR MIRROR DEFOGGER

DescriptionINFOID:0000000006299445

Heats the heating wire with the power supply from the rear window defogger relay to prevent the door mirror

from fogging up.

Component Function CheckINFOID:0000000006299446

1.CHECK DRIVER SIDE DOOR MIRROR DEFOGGER

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. Check that the driver side door mirror glass is getting warmer.

Is the inspection result normal?

YES >> Driver side door mirror defogger is OK.

NO >> Refer to DEF-30, "

Diagnosis Procedure"

Diagnosis ProcedureINFOID:0000000006299447

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect door mirror (driver side) connector.

3. Turn ignition switch ON.

4. Check voltage between door mirror (driver side) harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace harness.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between door mirror (driver side) harness connector and ground.

Is the inspection result normal?

YES >> Replace door mirror glass (driver side).

NO >> Repair or replace harness.

(+)

(–) Condition Voltage (V)

(Approx.)

Door mirror (driver side)

Connector Terminal

D3 7 Ground Rear window defogger

switchON Battery voltage

OFF 0

Door mirror (driver side)

GroundContinuity

Connector Terminal

D3 19 Existed

Revision: 2010 May2011 QX56

Page 1523 of 5598

PASSENGER SIDE DOOR MIRROR DEFOGGERDEF-31

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

PASSENGER SIDE DOOR MIRROR DEFOGGER

DescriptionINFOID:0000000006299448

Heats the heating wire with the power supply from t he rear window defogger relay to prevent the door mirror

from fogging up.

Component Function CheckINFOID:0000000006299449

1.CHECK PASSENGER SIDE DOOR MIRROR DEFOGGER

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. Check that the passenger side door mirror glass is getting warmer.

Is the inspection result normal?

YES >> Passenger side door mirror defogger is OK.

NO >> Refer to DEF-31, "

Diagnosis Procedure"

Diagnosis ProcedureINFOID:0000000006299450

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect door mirror (passenger side) connector.

3. Turn ignition switch ON.

4. Check voltage between door mirror (passenger side) harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace harness.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between door mirror (passenger side) harness connector and ground.

Is the inspection result normal?

YES >> Replace door mirror glass (passenger side).

NO >> Repair or replace harness.

(+)

(–) Condition Voltage (V)

(Approx.)

Door mirror (passenger side)

Connector Terminal

D23 7 Ground Rear window defogger

switchON Battery voltage

OFF 0

Door mirror (passenger side)

GroundContinuity

Connector Terminal

D23 19 Existed

Revision: 2010 May2011 QX56

Page 1524 of 5598

DEF-32

< DTC/CIRCUIT DIAGNOSIS >

WIPER DEICER RELAY

WIPER DEICER RELAY

Component Function CheckINFOID:0000000006299451

1.CHECK WIPER DEICER RELAY POWER SUPPLY CIRCUIT

1. Select Active Test (“REAR DEFOGGER”) mode of “BCM” using CONSULT-III.

2. Touch “ON”.

3. Check that the front window heating wire is getting warmer.

Is the inspection result normal?

YES >> Wiper deicer relay power supply circuit function is OK.

NO >> Refer to DEF-32, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006299452

1.CHECK WIPER DEICER CIRCUIT 1

1. Turn ignition switch ON.

2. Check voltage between wiper deicer relay harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK WIPER DEICER CIRCUIT 2

1. Turn ignition switch OFF.

2. Disconnect wiper deicer relay and IPDM E/R connector.

3. Check continuity between wiper deicer relay terminal connector and IPDM E/R harness connector.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair or replace harness.

3.CHECK WIPER DEICER CIRCUIT 3

Check voltage between wiper deicer relay harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK WIPER DEICER RELAY GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect wiper deicer relay connector.

3. Check continuity between wiper deicer relay terminal connector and ground.

(+)

(–) Condition Voltage (V)

(Approx.)

Wiper deicer relay

Connector Terminal

E23 1 Ground Rear window defogger switch: ON Battery voltage

Rear window defogger switch: OFF 0

Wiper deicer relay IPDM E/R

Continuity

Connector Terminal Connector Terminal

E23 1 E11 14 Existed

(+) (–)Voltage (V)

(Approx.)

Wiper deicer relay

Connector Terminal E23 3 Ground Battery voltage

Revision: 2010 May2011 QX56

Page 1526 of 5598

DEF-34

< DTC/CIRCUIT DIAGNOSIS >

WIPER DEICER

WIPER DEICER

Component Function CheckINFOID:0000000006299454

1.CHECK WIPER DEICER

1. Select Active Test (“REAR DEFOGGER”) mode of “BCM” using CONSULT-III.

2. Touch “ON”.

3. Check that the front window heating wire is getting warmer.

Is the inspection result normal?

YES >> Wiper deicer is OK.

NO >> Refer to DEF-34, "

Diagnosis Procedure"

Diagnosis ProcedureINFOID:0000000006299455

1.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 15 A fuse [No.75, located in fuse block (J/B)]

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between wiper deicer harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 4.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect wiper deicer connector.

3. Check continuity between wiper deicer harness connector and ground.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace harness between rear window defogger and ground.

4.CHECK WIPER DEICER CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect wiper deicer relay connector and wiper deicer connector.

3. Check continuity between wiper deicer relay harness connector and wiper deicer harness connector.

(+)

(–) Condition Voltage (V)

(Approx.)

Wiper deicer

Connector Terminal

E40 1 Ground Rear window defogger switch: ON Battery voltage

Rear window defogger switch: OFF 0

Wiper deicer

GroundContinuity

Connector Terminal

E40 2 Existed

Revision: 2010 May2011 QX56

Page 1535 of 5598

FILAMENTDEF-43

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

REMOVAL AND INSTALLATION

FILAMENT

Inspection and RepairINFOID:0000000006299467

INSPECTION

1. When measuring voltage, wrap tin foil around the top of the neg- ative probe. Then press the foil against the wire with your finger.

2. Attach probe circuit tester (in Volt range) to middle portion of each filament.

3. If a filament is burned out, circuit tester registers 0 or battery voltage.

4. To locate burned out point, move probe to left and right along fil- ament. Test needle will swing abruptly when probe passes the

point.

REPAIR

REPAIR EQUIPMENT

Conductive silver composition (Dupont No. 4817 or equivalent)

SEL122R

SEL263

SEL265

Revision: 2010 May2011 QX56

Page 1537 of 5598

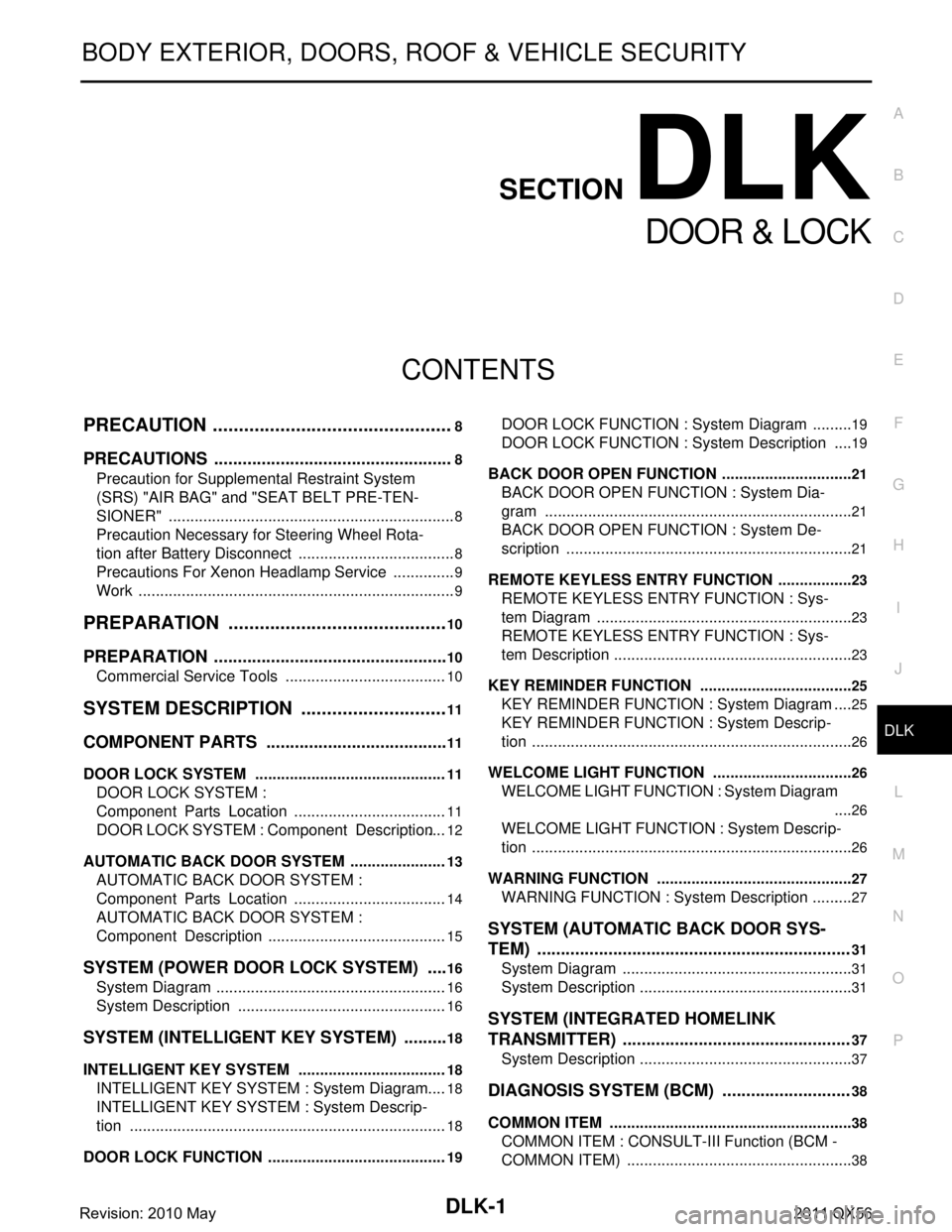

DLK-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G H

I

J

L

M

SECTION DLK

A

B

DLK

N

O P

CONTENTS

DOOR & LOCK

PRECAUTION ................ ...............................8

PRECAUTIONS .............................................. .....8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

8

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

8

Precautions For Xenon Headlamp Service ...............9

Work ..........................................................................9

PREPARATION ...........................................10

PREPARATION .............................................. ....10

Commercial Service Tools .................................. ....10

SYSTEM DESCRIPTION .............................11

COMPONENT PARTS ................................... ....11

DOOR LOCK SYSTEM .............................................11

DOOR LOCK SYSTEM :

Component Parts Location ................................ ....

11

DOOR LOCK SYSTEM : Component Description ....12

AUTOMATIC BACK DOOR SYSTEM .......................13

AUTOMATIC BACK DOOR SYSTEM :

Component Parts Location ................................ ....

14

AUTOMATIC BACK DOOR SYSTEM :

Component Description ..........................................

15

SYSTEM (POWER DOOR LOCK SYSTEM) .....16

System Diagram .................................................. ....16

System Description .................................................16

SYSTEM (INTELLIGENT KEY SYSTEM) ..........18

INTELLIGENT KEY SYSTEM ...................................18

INTELLIGENT KEY SYSTEM : System Diagram ....18

INTELLIGENT KEY SYSTEM : System Descrip-

tion ..........................................................................

18

DOOR LOCK FUNCTION ...................................... ....19

DOOR LOCK FUNCTION : System Diagram ..........19

DOOR LOCK FUNCTION : System Description .....19

BACK DOOR OPEN FUNCTION ........................... ....21

BACK DOOR OPEN FUNCTION : System Dia-

gram ........................................................................

21

BACK DOOR OPEN FUNCTION : System De-

scription ...................................................................

21

REMOTE KEYLESS ENTRY FUNCTION ..................23

REMOTE KEYLESS ENTRY FUNCTION : Sys-

tem Diagram ........................................................ ....

23

REMOTE KEYLESS ENTRY FUNCTION : Sys-

tem Description ........................................................

23

KEY REMINDER FUNCTION ................................ ....25

KEY REMINDER FUNCTION : System Diagram ....25

KEY REMINDER FUNCTION : System Descrip-

tion ...........................................................................

26

WELCOME LIGHT FUNCTION ............................. ....26

WELCOME LIGHT FUNCTION : System Diagram

....

26

WELCOME LIGHT FUNCTION : System Descrip-

tion ...........................................................................

26

WARNING FUNCTION .......................................... ....27

WARNING FUNCTION : System Description ..........27

SYSTEM (AUTOMATIC BACK DOOR SYS-

TEM) ..................................................................

31

System Diagram .................................................. ....31

System Description ..................................................31

SYSTEM (INTEGRATED HOMELINK

TRANSMITTER) ................................................

37

System Description .............................................. ....37

DIAGNOSIS SYSTEM (BCM) ...........................38

COMMON ITEM ..................................................... ....38

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

38

Revision: 2010 May2011 QX56

Page 1538 of 5598

DLK-2

DOOR LOCK .............................................................39

DOOR LOCK : CONSULT-III Function (BCM -

DOOR LOCK) .........................................................

39

INTELLIGENT KEY ................................................ ...40

INTELLIGENT KEY : CONSULT-III Function

(BCM - INTELLIGENT KEY) ...................................

41

TRUNK ................................................................... ...44

TRUNK : CONSULT-III Function (BCM - TRUNK) ...44

DIAGNOSIS SYSTEM (AUTOMATIC BACK

DOOR CONTROL UNIT) ...................................

45

CONSULT-III Function (AUTOMATIC BACK

DOOR CONTROL UNIT) ..................................... ...

45

ECU DIAGNOSIS INFORMATION ..............46

BCM ................................................................ ...46

List of ECU Reference ......................................... ...46

AUTOMATIC BACK DOOR CONTROL MOD-

ULE ....................................................................

47

Reference Value .................................................. ...47

Fail Safe .................................................................49

DTC Inspection Priority Chart ..............................49

DTC Index ..............................................................50

WIRING DIAGRAM .....................................51

DOOR & LOCK SYSTEM ............................... ...51

Wiring Diagram - DOOR & LOCK SYSTEM - ...... ...51

AUTOMATIC BACK DOOR SYSTEM ...............66

Wiring Diagram - AUTOMATIC BACK DOOR

SYSTEM - ............................................ ...................

66

INTEGRATED HOMELINK TRANSMITTER

SYSTEM ............ .............................................. ...

75

Wiring Diagram - INTEGRATED HOMELINK

TRANSMITTER SYSTEM - ....................................

75

BASIC INSPECTION ...... .............................77

DIAGNOSIS AND REPAIR WORK FLOW ..... ...77

Work Flow ............................................................ ...77

INSPECTION AND ADJUSTMENT ...................80

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL ............................... ...

80

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Description ....

80

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Work Proce-

dure ........................................................................

80

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (BCM) ......................................... ...

80

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (BCM) : Description ....................

80

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (BCM) : Work Procedure .......... ...

80

ADDITIONAL SERVICE WHEN REPLACING (AU-

TOMATIC BACK DOOR CONTROL MODULE) .......

80

ADDITIONAL SERVICE WHEN REPLACING

(AUTOMATIC BACK DOOR CONTROL MOD-

ULE) : Description ................................................ ...

80

ADDITIONAL SERVICE WHEN REPLACING

(AUTOMATIC BACK DOOR CONTROL MOD-

ULE) : Work Procedure ........................................ ...

80

DTC/CIRCUIT DIAGNOSIS ........................82

U1000 CAN COMM CIRCUIT ......................... ...82

Description ........................................................... ...82

DTC Logic ...............................................................82

Diagnosis Procedure ...............................................82

U1010 CONTROL UNIT (CAN) .........................83

DTC Logic ............................................................ ...83

Diagnosis Procedure ...............................................83

B2401 IGNITION POWER SUPPLY CIRCUIT ...84

DTC Logic ............................................................ ...84

Diagnosis Procedure ...............................................84

B2403 ENCODER ..............................................85

DTC Logic ............................................................ ...85

Diagnosis Procedure ...............................................85

B2409 HALF LATCH SWITCH ..........................86

DTC Logic ............................................................ ...86

Diagnosis Procedure ...............................................86

Component Inspection ............................................87

B2416 TOUCH SENSOR RH ............................88

DTC Logic ............................................................ ...88

Diagnosis Procedure ...............................................88

Component Inspection ............................................89

B2417 TOUCH SENSOR LH .............................90

DTC Logic ............................................................ ...90

Diagnosis Procedure ...............................................90

Component Inspection ............................................91

B2419 OPEN SWITCH ......................................92

DTC Logic ............................................................ ...92

Diagnosis Procedure ...............................................92

Component Inspection ............................................93

B2420 CLOSE SWITCH ....................................95

DTC Logic ............................................................ ...95

Diagnosis Procedure ...............................................95

Component Inspection ............................................96

B2421 CLUTCH OPERATION TIME .................97

DTC Logic ............................................................ ...97

Diagnosis Procedure ...............................................97

B2422 BACK DOOR STATE .............................98

DTC Logic ............................................................ ...98

Revision: 2010 May2011 QX56