Fuel INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3448 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-28

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

Check CAN system type from the vehicle shape and equipment.

CAN COMMUNICATION SYSTEM : CA

N Communication Signal ChartINFOID:0000000006220533

Refer to LAN-17 INFINITI QX56 2011 Factory Service Manual

LAN-28

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

Check CAN system type from the vehicle shape and equipment.

CAN COMMUNICATION SYSTEM : CA

N Communication Signal ChartINFOID:0000000006220533

Refer to LAN-17](/img/42/57033/w960_57033-3447.png)

LAN-28

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

Check CAN system type from the vehicle shape and equipment.

CAN COMMUNICATION SYSTEM : CA

N Communication Signal ChartINFOID:0000000006220533

Refer to LAN-17, "How to Use CAN Communication Signal Chart" for how to use CAN communication signal

chart.

T: Transmit R: Receive

1. ICC sensor

A. With ICC system

JSMIA0342ZZ

Signal nameECM

4WD

ABS

TCM

A-BAG

AFSAV

BCM

CGW

HVAC

M&A

STRG

TPMS

IPDM-E ADP

PSB

E-SUS ICC

PWBD

A/C compressor request

signal TR

Accelerator pedal position

signal TRRR

R

ASCD OD cancel request

signal TR

ASCD operation signal T R

ASCD status signal T R

Closed throttle position sig-

nal TR

R

Cooling fan speed request

signal TR

Engine and A/T integrated

control signal TR

RT

Engine coolant temperature

signal TRR

Engine restart request sig-

nal TRR

TR

Engine speed signal T R R R R R R R

Engine status signal T R R R

Engine torque signal T R

Fuel consumption monitor

signal TRR

ICC brake switch signal T R

ICC prohibition signal T R

ICC steering switch signal T R

Malfunctioning indicator

lamp signal TR

N idle instruction signal TR

RT

Revision: 2010 May2011 QX56

Page 3451 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

SYSTEMLAN-31

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

Meter display signal

TR

RT

Oil pressure switch signal TR

RT

Position light request signal T R R

Rear fog light status signa INFINITI QX56 2011 Factory Service Manual

LAN

SYSTEMLAN-31

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

Meter display signal

TR

RT

Oil pressure switch signal TR

RT

Position light request signal T R R

Rear fog light status signa](/img/42/57033/w960_57033-3450.png)

LAN

SYSTEMLAN-31

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

Meter display signal

TR

RT

Oil pressure switch signal TR

RT

Position light request signal T R R

Rear fog light status signal T R

Rear window defogger con-

trol signal TR

RT

Sleep wake up signal T R R R R R R

Starter control relay signal T R

Starter relay status signal TRR

RT

Starting mode signal T R

Steering lock relay signal TRR

RT

Theft warning horn request

signal TR

Turn indicator signal R T R R

A/C display signal R T

A/C ON signal R T

Ambient temperature signal T R

Blower fan ON signal R T

Distance to empty signal R T

Fuel level low warning sig-

nal RT

Fuel level sensor signal R T

Manual mode shift down

signal RT

Manual mode shift up sig-

nal RT

Manual mode signal R T

Non-manual mode signal R T

Odometer signal R T

Parking brake switch signal R R T R R

Sleep-ready signal RT

RT

RT

Tow mode switch signal R T

Wake up signal RT

RT

Steering angle sensor mal-

function signal RR T R R

Steering angle sensor sig-

nal RR RR T R R

Steering angle speed signal R T R R Signal name

ECM

4WD

ABS

TCM

A-BAG AFS

AV

BCM

CGW

HVAC M&A

STRG

TPMS

IPDM-E

ADPPSB

E-SUS ICC

PWBD

Revision: 2010 May2011 QX56

Page 3671 of 5598

MA-1

MAINTENANCE

C

DE

F

G H

I

J

K L

M B

MA

SECTION MA

N

O A

CONTENTS

MAINTENANCE

PREPARATION .............

...............................3

PREPARATION .............................................. .....3

Special Service Tool ........................................... ......3

Commercial Service Tool ..........................................3

PERIODIC MAINTENANCE ..........................4

GENERAL MAINTENANCE ........................... .....4

Explanation of General Maintenance .................. ......4

PERIODIC MAINTENANCE ................................6

Introduction of Periodic Maintenance .................. ......6

Schedule 1 ................................................................6

Schedule 2 ................................................................8

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

10

Fluids and Lubricants .......................................... ....10

Engine Oil Recommendation ..................................10

Anti-Freeze Coolant Mixture Ratio ..........................11

ENGINE MAINTENANCE ...................................12

DRIVE BELTS ....................................................... ....12

DRIVE BELTS : Exploded View ..............................12

DRIVE BELTS : Checking .......................................12

DRIVE BELTS : Tension Adjustment .....................12

ENGINE COOLANT ............................................... ....12

ENGINE COOLANT : Inspection .............................12

ENGINE COOLANT : Draining ................................13

ENGINE COOLANT : Refilling ................................13

ENGINE COOLANT : Flushing ...............................15

RESERVOIR TANK CAP ..........................................15

RESERVOIR TANK CAP : Inspection ................. ....15

RADIATOR ............................................................ ....16

RADIATOR : Inspection ..........................................16

FUEL LINES .......................................................... ....16

FUEL LINES : Inspection ........................................17

AIR CLEANER FILTER ......................................... ....17

AIR CLEANER FILTER : Removal and Installation

....

17

ENGINE OIL ........................................................... ....17

ENGINE OIL : Draining ............................................17

ENGINE OIL : Refilling ............................................17

OIL FILTER ............................................................ ....18

OIL FILTER : Removal and Installation ...................18

SPARK PLUG ........................................................ ....18

SPARK PLUG : Removal and Installation ...............19

SPARK PLUG : Inspection ......................................19

EVAP VAPOR LINES ............................................ ....20

EVAP VAPOR LINES : Inspection ...........................20

CHASSIS MAINTENANCE ...............................21

EXHAUST SYSTEM . ..................................................21

EXHAUST SYSTEM : Inspec tion ............................21

A/T FLUID .............................................................. ....21

A/T FLUID : Inspection ............................................21

TRANSFER FLUID ................................................ ....21

TRANSFER FLUID : Inspection ..............................21

TRANSFER FLUID : Draining .................................21

TRANSFER FLUID : Refilling ..................................22

FRONT PROPELLER SHAFT: 2F P15 ................. ....22

FRONT PROPELLER SHAFT: 2F P15 : Inspec-

tion ...........................................................................

22

REAR PROPELLER SHAFT: 2F P26 .................... ....23

REAR PROPELLER SHAFT: 2F P26 : Inspection ....23

REAR PROPELLER SHAFT: 2S1410 ................... ....23

REAR PROPELLER SHAFT: 2S1410 : Inspection ....23

FRONT DIFFERENTIAL GEAR OIL: R180A ........ ....24

FRONT DIFFERENTIAL GEAR OIL: R180A : In-

spection ...................................................................

24

Revision: 2010 May2011 QX56

Page 3675 of 5598

GENERAL MAINTENANCEMA-5

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should

be checked periodically (e.g. each time you check the engine oil or refuel).

Seats Check seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restrains move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seatbacks. —

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage. MA-34

Accelerator pedal

Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to

keep the floor mats away from the pedal. BR-7

BR-15

Parking brake

Check that the lever or pedal has the proper travel and make sure that the ve-

hicle is held securely on a fairly steep hill when only the parking brake is ap-

plied. PB-3

Automatic transmis-

sion “Park” mecha-

nismCheck that the lock release button on the selector lever operates properly and

smoothly. On a fairly steep hill check that the vehicle is held securely with the

selector lever in the P (Park) position without applying any brakes.

—

Item

Reference page

Item Reference page

Windshield washer

fluid Check that there is adequate fluid in the tank. —

Engine coolant level Check the coolant level when the engine is cold. MA-12

Radiator and hosesCheck the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the hoses have no cracks, deformation, de-

terioration or loose connections. MA-16

Brake fluid levels

Make sure that the brake fluid level is between the “MAX” and “MIN” lines on the

reservoir(s). MA-28

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN”

lines. Vehicles operated in high temperatures or under severe conditions re-

quire frequent checks of the battery fluid level. PG-159

Engine drive belts

Make sure that no belt is frayed, worn, cracked or oily. MA-12

Engine oil levelCheck the level on the oil level gauge after parking the vehicle on a level spot

and turning off the engine. LU-7

Power steering fluid

level and linesCheck the level on the dipstick with the engine off. Check the lines for improper

attachment, leaks, cracks, etc.

MA-32

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate

the trouble and correct it. MA-21

Underbody

The underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around

the exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately. —

Revision: 2010 May2011 QX56

Page 3676 of 5598

MA-6

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

Introduction of Periodic MaintenanceINFOID:0000000006287729

Two different maintenance schedules are provided, and should be used, depending upon the conditions in

which the vehicle is mainly operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage/time intervals.

Schedule 1INFOID:0000000006287730

EMISSION CONTROL SYSTEM

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary. [ ]: At the mileage intervals only

Schedule 1Follow Periodic Maintenance Schedule 1 if the driving habits frequently include

one or more of the following driving conditions:

Repeated short trips of less than 5 miles (8 km).

Repeated short trips of less than 10 miles (16 km) with outside temperatures

remaining below freezing.

Operating in hot weather in stop-and-go “rush hour” traffic.

Extensive idling and/or low speed driving for long distances, such as police, taxi

or door-to-door delivery use.

Driving in dusty conditions.

Driving on rough, muddy, or salt spread roads.

Towing a trailer, using a camper or a car-top carrier. Emission Control Sys-

tem Maintenance

MA-6Chassis and Body

Maintenance

Schedule 2 Follow Periodic Maintenance Schedule 2 if none of driving conditions shown in

Schedule 1 apply to the driving habits. Emission Control Sys-

tem Maintenance

MA-8

Chassis and Body

Maintenance

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles,

kilometers or months, which-

ever comes first. Miles x 1,000

(km x 1,000) Months 3.75

(6)3 7.50

(12) 6 11 . 2 5

(18) 9 15

(24) 12 18.75

(30)15 22.5

(36) 18 26.25

(42)21 30

(48) 24

Drive belts NOTE (1) MA-12

Air cleaner filter NOTE (2) [R]MA-17

EVAP vapor linesI*MA-20

Fuel lines I*MA-17

Fuel filter NOTE (3) —

Engine coolant* NOTE (4) MA-13

Engine oil R R R R R R R RMA-17

Engine oil filter (Use genuine

NISSAN engine oil filter or

equivalent.)R R RRRRR R

MA-18

Spark plugs (Iridium-tipped

type)Replace every 105,000 miles (168,000 km).

MA-19

Intake & exhaust valve clear-

ance*NOTE (5)

EM-12

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles,

kilometers or months, which-

ever comes first. Miles x 1,000

(km x 1,000) Months 33.75

(54)27 37.5

(60) 30 41.25

(66)33 45

(72) 36 48.75

(78)39 52.5

(84) 42 56.25

(90)45 60

(96) 48

Drive belts NOTE (1) I* MA-12

Air cleaner filter NOTE (2) [R]MA-17

EVAP vapor linesI*MA-20

Fuel lines I*MA-17

Revision: 2010 May2011 QX56

Page 3677 of 5598

PERIODIC MAINTENANCEMA-7

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts i

f found

damaged or if the auto belt tensioner reading reaches the maximum limit.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, refer to FL section.

(4) First replacement interval is 105,000 miles (168,000 km) or 84 months. After first replacement, replace every 75,000 miles (120,000

km) or 60 months. Use only Genu ine NISSAN Long Life Antifreeze/Coo lant (blue) or equivalent with proper mixture ratio of 50% anti-

freeze and 50% demineralized or distilled water. Mixing any other type of coolant or the use of non-distilled water will reduce the life

expectancy of the factory-fill coolant.

(5) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by INFINITI for reliable vehicle operation. The owner need not perfo rm

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

CHASSIS AND BODY

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary.

Fuel filter NOTE (3) —

Engine coolant* NOTE (4) MA-13

Engine oil R R R R R R R RMA-17

Engine oil filter (Use genuine

NISSAN engine oil filter or

equivalent.)R R RRRRRR

MA-18

Spark plugs (Iridium-tipped

type)Replace every 105,000 miles (168,000 km).

MA-19

Intake & exhaust valve clear-

ance*NOTE (5)

EM-12

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles,

kilometers or months, which-

ever comes first. Miles x 1,000

(km x 1,000)

Months 33.75

(54)

27 37.5

(60)

30 41.25

(66)

33 45

(72)

36 48.75

(78)

39 52.5

(84)

42 56.25

(90)

45 60

(96)

48

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section -

Page or - Con- tent Title

Perform at number of miles,

kilometers or months,

whichever comes first. Miles x 1,000

(km x 1,000)

Months 3.75

(6)

3 7.50

(12)

6 11 . 2 5

(18)

9 15

(24)

12 18.75

(30)

15 22.5

(36)

18 26.25

(42)

21 30

(48)

24

Brake lines & cables I I MA-28

Brake fluid R RMA-28

Brake pads & rotors I I I IMA-30

BR-16

BR-18

BR-16

BR-18

Transfer fluid & differential

gear oil

NOTE (1) I I MA-21MA-24

MA-25

Automatic transmission flu-

id

NOTE (2)

—

Steering gear & linkage,

axle & suspension parts IIII

MA-31

MA-32

Tire rotation NOTE (3) MA-4WT-63

Drive shaft boots and pro-

peller shaft (4WD models) IIII MA-33MA-22

MA-23

MA-23

Revision: 2010 May2011 QX56

Page 3678 of 5598

MA-8

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) fluid /oil at every

30,000 miles (48,000 km) or 24 months.

(2) Automatic transmission fluid is maintenance-free.

(3) Refer to “Tire rotation” unde r the “General maintenance” heading earlier in this section.

Schedule 2INFOID:0000000006287731

EMISSION CONTROL SYSTEM

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary. [ ]: At the mileage intervals only

Exhaust system I I I I MA-21

In-cabin microfilter R RVTL-17

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or - Con- tent Title

Perform at number of miles,

kilometers or months,

whichever comes first. Miles x 1,000

(km x 1,000)

Months 3.75

(6)

3 7.50

(12)

6 11 . 2 5

(18)

9 15

(24)

12 18.75

(30)

15 22.5

(36)

18 26.25

(42)

21 30

(48)

24

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section - Page

or - Content Title

Perform at number of miles,

kilometers or months,

whichever comes first. Miles x 1,000

(km x 1,000) Months 33.75

(54)27 37.5

(60) 30 41.25

(66)33 45

(72) 36 48.75

(78)39 52.5

(84) 42 56.25

(90)45 60

(96) 48

Brake lines & cables I I MA-28

Brake fluid R RMA-28

Brake pads & rotors I I I IMA-30

BR-16

BR-18

BR-16

BR-18

Transfer fluid & differential

gear oil

NOTE (1) I I MA-21MA-24

MA-25

Automatic transmission flu-

id

NOTE (2)

—

Steering gear & linkage,

axle & suspension parts IIII

MA-31

MA-32

Tire rotation NOTE (3) MA-4WT-63

Drive shaft boots and pro-

peller shaft (4WD models)IIII MA-33MA-22

MA-23

MA-23

Exhaust system I I I I

MA-21

In-cabin microfilter R RVTL-17

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference Sec-

tion - Page or -

Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000)

Months 7.5

(12)

6 15

(24)

12 22.5

(36)

18 30

(48)

24 37.5

(60)

30 45

(72)

36 52.5

(84)

42 60

(96)

48

Drive belts NOTE (1) I* MA-12

Air cleaner filter [R] [R]MA-17

EVAP vapor lines I* I*MA-20

Fuel lines I* I*MA-17

Fuel filter NOTE (2) —

Engine coolant* NOTE (3) MA-13

Revision: 2010 May2011 QX56

Page 3680 of 5598

MA-10

< PERIODIC MAINTENANCE >

RECOMMENDED FLUIDS AND LUBRICANTS

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and LubricantsINFOID:0000000006220904

*1: For further details, see “Engine Oil Recommendation”.

*2: Using automatic transmission fluid other than Genuine NISSAN Matic S ATF will cause deterioration in driveability and autom atic

transmission durability, and may damage the automatic transmission, which is not covered by the INFINITI new vehicle limited wa rranty.

*3: DEXRON™ VI type ATF may also be used.

*4: Available in mainland U.S.A. through an INFINITI dealer.

*5: Using transfer fluid other t han Genuine NISSAN Transfer Fluid will damage the transfer , which is not covered by the INFINITI new

vehicle limited warranty. See an INFINITI retailer for recommended transfer fluid.

*6: For hot climates, Viscosity SAE 90 is suitable for ambient temperatures above 0 °C (32 °F)

*7: See an INFINITI dealer for service for synthetic oil.

*8: Using Hydraulic Suspen sion fluid other than Genuine NISSAN Hydraulic Susp ension fluid will damage the Hydraulic Suspension,

which is not covered by the INFINITI new vehicle limited warranty. See an INFINITI retailer for recommended hydraulic suspensio n fluid.

*9: The fluid capacity is the reference value.

Engine Oil RecommendationINFOID:0000000006287732

NISSAN recommends the use of an energy conservi ng oil in order to improve fuel economy.

Select only engine oils that meet the American Petroleum Institute (API) certification and International Lubri-

cant Standardization and Approval Committee (ILSAC) ce rtification and SAE viscosity standard. These oils

have the API certification mark on t he front of the container. Oils which do not have the specified quality label

should not be used as they could cause engine damage.

Capacity (Approximate) Recommended Fluids/Lubricants

US measure Imp measure Liter

Engine oil

Drain and refill With oil filter change 6-7/8 qt 5-3/4 qt 6.5

Engine oil with API Certification Mark

*1

Viscosity SAE 5W-30

Without oil filter change 6-4/8 qt 5-1/2 qt 6.2

Dry engine (engine overhaul) 8 qt 6-3/4 qt 7.6

Cooling system With reservoir tank 15

-6/8 qt 13-1/8 qt 14.9

Genuine NISSAN Long Life Antifreeze/

Coolant (blue) or equivalent

Reservoir tank 1 qt 7/8 qt 1.0

Automatic transmission fluid 10-5/8 qt

*98-3/4 qt*910.0*9Genuine NISSAN Matic S ATF *2

Power steering fluid 1-1/8 qt 7/8 qt 1.0

Genuine NISSAN PSF or equivalent*3

Brake fluid — — —Genuine NISSAN Super Heavy Duty

Brake Fluid*4 or equivalent DOT 3 (US FM-

VSS No. 116)

Transfer fluid 3-1/8 pt 2-5/8 pt 1.5 Genuine NISSAN Transfer Fluid for

ATX90A transfer*

5

Differential gear oilFront 1-5/8 pt 1-3/8 pt 0.75

Genuine NISSAN Differential Oil Hypoid

Super GL-5 80W-90 or API GL-5, Viscosity

SAE 80W-90*

6

Rear 3/3/4 pt 3-1/8 pt 1.75Genuine NISSAN Differential Oil Synthetic

75W-90 or API GL-5 synthetic gear oil, Vis-

cosity SAE 75W-90*7

Suspension fluid — — —

Genuine NISSAN Hydraulic Suspension

Fluid*8

Multi-purpose grease — — — NLGI No. 2 (Lithium soap base)

Revision: 2010 May2011 QX56

Page 3686 of 5598

MA-16

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

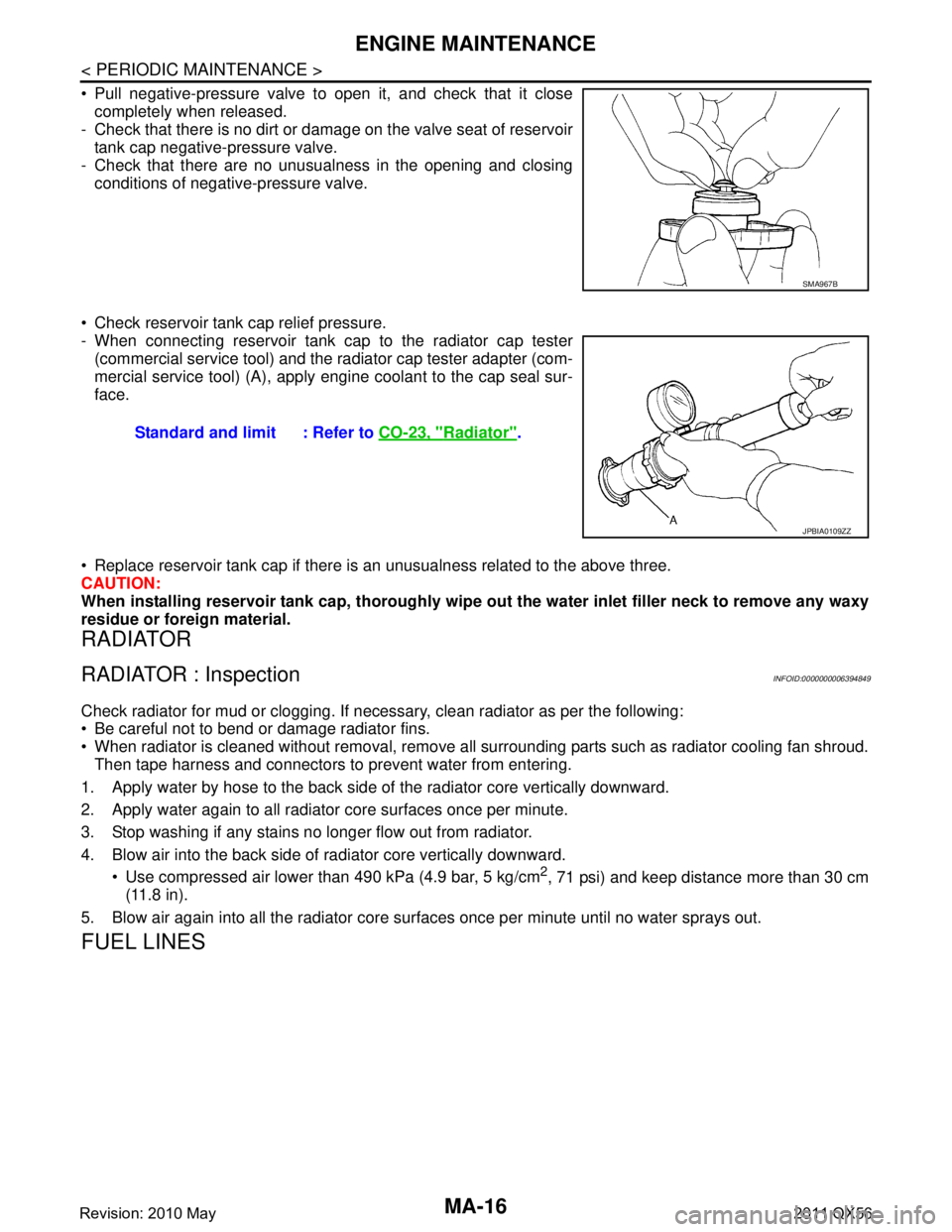

Pull negative-pressure valve to open it, and check that it closecompletely when released.

- Check that there is no dirt or damage on the valve seat of reservoir

tank cap negative-pressure valve.

- Check that there are no unusualness in the opening and closing conditions of negative-pressure valve.

Check reservoir tank cap relief pressure.

- When connecting reservoir tank cap to the radiator cap tester (commercial service tool) and the radiator cap tester adapter (com-

mercial service tool) (A), apply engine coolant to the cap seal sur-

face.

Replace reservoir tank cap if there is an unusualness related to the above three.

CAUTION:

When installing reservoir tank cap, thoroughly wipe out the water inlet filler neck to remove any waxy

residue or foreign material.

RADIATOR

RADIATOR : InspectionINFOID:0000000006394849

Check radiator for mud or clogging. If nec essary, clean radiator as per the following:

Be careful not to bend or damage radiator fins.

When radiator is cleaned without removal, remove all surrounding parts such as radiator cooling fan shroud. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surfaces once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward. Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2, 71 psi) and keep distance more than 30 cm

(11.8 in).

5. Blow air again into all the radiator core su rfaces once per minute until no water sprays out.

FUEL LINES

SMA967B

Standard and limit : Refer to CO-23, "Radiator".

JPBIA0109ZZ

Revision: 2010 May2011 QX56

Page 3687 of 5598

ENGINE MAINTENANCEMA-17

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

FUEL LINES : InspectionINFOID:0000000006394850

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leakage, cracks, damage, loose connections, chafing or

deterioration.

If necessary, repair or replace damaged parts.

AIR CLEANER FILTER

AIR CLEANER FILTER : Removal and InstallationINFOID:0000000006394838

REMOVAL

NOTE:

The viscous paper type filter does not need cleaning between replacement intervals.

Replace the air filter as necessary for periodic maintenance. Refer to MA-6, "

Introduction of Periodic Mainte-

nance".

1. Unhook clips, and lift air cleaner case (upper).

2. Remove air cleaner filter from air cleaner case.

INSTALLATION

Install is the reverse order of removal.

ENGINE OIL

ENGINE OIL : DrainingINFOID:0000000006394841

WARNING:

Be careful not to burn yourself, as th e engine and engine oil may be hot.

Prolonged and repeated contact with used engine oil may cau se skin cancer; try to avoid direct skin

contact with used oil. If skin contact is made, w ash thoroughly with soap or hand cleaner as soon as

possible.

1. Warm up the engine, and check for any oil leaks.

2. Stop the engine and wait for at least 10 minutes.

3. Remove drain plug and oil filler cap to drain the old oil.

ENGINE OIL : RefillingINFOID:0000000006394842

1. Install drain plug with new washer. CAUTION:

Be sure to clean drain plug and install with new washer.

2. Refill with new engine oil. Engine oil specificat ion and viscosity:

Refer to MA-10, "

Fluids and Lubricants".

CAUTION:

The refill capacity depends on the engine oi l temperature and drain time. Use these specifica-

tions for reference only.

Always use oil level gauge to determine the proper amount of engine oil in engine.

A : Engine

B : Fuel line

C : Fuel tank

JPBIA0129ZZ

Tightening torque : Refer to EM-54, "Exploded View".

Engine oil capacity : Refer to LU-17, "

Periodical Maintenance Specification".

Revision: 2010 May2011 QX56