turn signal INFINITI QX56 2011 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 117 of 5598

ADP-108

< DTC/CIRCUIT DIAGNOSIS >

RECLINING MOTOR

RECLINING MOTOR

Component Function CheckINFOID:0000000006248404

1.CHECK FUNCTION

1. Select “SEAT RECLINING” in “A ctive test” mode with CONSULT-III.

2. Check the reclining motor operation.

Is the operation of relevant parts normal?

YES >> INSPECTION END

NO >> Perform diagnosis procedure. Refer to ADP-108, "

DiagnosisProcedure".

Diagnosis ProcedureINFOID:0000000006248405

1.CHECK RECLINING MOTOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect reclining motor connector.

3. Turn ignition switch ON.

4. Perform “Active test” (“SEA T RECLINING”) with CONSULT-lll

5. Check voltage between reclining motor harness connector and ground.

Is the inspection result normal?

YES >> Replace reclining motor (built in seat back frame).

NO >> GO TO 2.

2.CHECK RECLINING MOTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit connector.

3. Check continuity between driver seat control unit harness connector and reclining motor harness connec-

tor.

4. Check continuity between driver seat control unit harness connector and ground.

Te s t i t e m D e s c r i p t i o n

SEAT RECLINING OFF

Seat recliningStop

FR Forward

RR Backward

(+) (-) Condition Voltage (V)

(Approx.)

Reclining motor

Connector Terminals

B454 35

Ground SEAT RECLINING OFF 0

FR (forward) 12

RR (backward) 0

39 OFF 0

FR (forward) 0

RR (backward) 12

Driver seat control unit Reclining motor

Continuity

Connector Terminal Connector Terminal

B451 35

B454 35

Existed

39 39

Revision: 2010 May2011 QX56

Page 119 of 5598

ADP-110

< DTC/CIRCUIT DIAGNOSIS >

LIFTING MOTOR (FRONT)

LIFTING MOTOR (FRONT)

Component Function CheckINFOID:0000000006248406

1.CHECK FUNCTION

1. Select “SEAT LIFTER FR” in “Active test” mode with CONSULT-III.

2. Check the lifting motor (front) operation.

Is the operation of relevant parts normal?

YES >> INSPECTION END

NO >> Perform diagnosis procedure. Refer to ADP-110, "

DiagnosisProcedure".

Diagnosis ProcedureINFOID:0000000006248407

1.CHECK LIFTING MOTOR (FRONT) INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect lifting motor (front) connector.

3. Turn ignition switch ON.

4. Perform “Active test” (“SEAT LIFTER FR”) with CONSULT-III.

5. Check voltage between lifting motor (front) harness connector and ground.

Is the inspection result normal?

YES >> Replace lifting motor (front) (built in seat cushion frame).

NO >> GO TO 2.

2.CHECK LIFTING MOTOR (FRONT) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit connector.

3. Check continuity between driver seat control uni t harness connector and lifting motor (front) harness con-

nector.

4. Check continuity between driver seat control unit harness connector and ground.

Te s t i t e m D e s c r i p t i o n

SEAT LIFTER FR OFF

Seat lifting (front)Stop

UP Upward

DWN Downward

(+) (-) Condition Voltage (V)

(Approx.)

Lifting motor (front)

Connector Terminals

B455 36

Ground SEAT LIFTER FR OFF 0

UP 0

DWN (down) 12

40 OFF 0

UP 12

DWN (down) 0

Driver seat control un

it Lifting motor (front)

Continuity

Connector Terminal Connector Terminal

B451 36

B455 36

Existed

40 40

Revision: 2010 May2011 QX56

Page 121 of 5598

ADP-112

< DTC/CIRCUIT DIAGNOSIS >

LIFTING MOTOR (REAR)

LIFTING MOTOR (REAR)

Component Function CheckINFOID:0000000006248408

1.CHECK FUNCTION

1. Select “SEAT LIFTER RR” in “A ctive test” mode with CONSULT-III.

2. Check the lifting motor (rear) operation.

Is the operation of relevant parts normal?

YES >> INSPECTION END

NO >> Perform diagnosis procedure. Refer to ADP-112, "

DiagnosisProcedure".

Diagnosis ProcedureINFOID:0000000006248409

1.CHECK LIFTING MOTOR (REAR) INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect lifting motor (rear) connector.

3. Turn ignition switch ON.

4. Perform “Active test” (“SEAT LIFTER RR”) with CONSULT-III

5. Check voltage between lifting motor (rear) harness connector and ground.

Is the inspection result normal?

YES >> Replace lifting motor (rear) (built in seat cushion frame).

NO >> GO TO 2.

2.CHECK LIFTING MOTOR (REAR) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit connector.

3. Check continuity between driver seat control uni t harness connector and lifting motor (rear) harness con-

nector.

4. Check continuity between driver seat control unit harness connector and ground.

Te s t i t e m D e s c r i p t i o n

SEAT LIFTER RR OFF

Seat lifting (rear)Stop

UP Upward

DWN Downward

(+) (-) Condition Voltage (V)

(Approx.)

Lifting motor (rear)

Connector Terminals

B456 41

Ground SEAT LIFTER RR OFF 0

UP 12

DWN (DOWN) 0

42 OFF 0

UP 0

DWN (DOWN) 12

Driver seat control unit Lifting motor (rear)

Continuity

Connector Terminal Connector Terminal

B451 41

B456 41

Existed

42 42

Revision: 2010 May2011 QX56

Page 123 of 5598

ADP-114

< DTC/CIRCUIT DIAGNOSIS >

TILT MOTOR

TILT MOTOR

Component Function CheckINFOID:0000000006248410

1.CHECK FUNCTION

1. Select “TILT MOTOR” in “Act ive test” mode with CONSULT-III.

2. Check the tilt motor operation.

Is the operation of relevant parts normal?

YES >> INSPECTION END

NO >> Perform diagnosis procedure. Refer to ADP-114, "

DiagnosisProcedure".

Diagnosis ProcedureINFOID:0000000006248411

1.CHECK TILT MOTOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect tilt motor connector.

3. Turn ignition switch ON.

4. Perform “Active test” (“TIL T MOTOR”) with CONSULT-III.

5. Check voltage between tilt motor harness connector and ground.

Is the inspection result normal?

YES >> Replace tilt motor (built in steering column assembly).

NO >> GO TO 2.

2.CHECK TILT MOTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit.

3. Check continuity between automatic drive positioner control unit harness connector and tilt motor harness

connector.

4. Check continuity between automatic drive positioner control unit harness connector and ground.

Te s t i t e m D e s c r i p t i o n

TILT MOTOR OFF

Steering tiltStop

UP Upward

DWN Downward

(+) (-) Condition Voltage (V)

(Approx.)

Tilt motor

Connector Terminals

M116 1

Ground TILT MOTOR OFF 0

UP 0

DWN (down) 12

2 OFF 0

UP 12

DWN (down) 0

Automatic drive positioner control unit Tilt motor

Continuity

Connector Terminal Connector Terminal

M104 28

M116 1

Existed

29 2

Revision: 2010 May2011 QX56

Page 125 of 5598

ADP-116

< DTC/CIRCUIT DIAGNOSIS >

TELESCOPIC MOTOR

TELESCOPIC MOTOR

Component Function CheckINFOID:0000000006248412

1.CHECK FUNCTION

1. Select “TELESCO MOTOR” in “Act ive test” mode with CONSULT-III.

2. Check the telescopic motor operation.

Is the operation of relevant parts normal?

YES >> INSPECTION END

NO >> Perform diagnosis procedure. Refer to ADP-116, "

DiagnosisProcedure".

Diagnosis ProcedureINFOID:0000000006248413

1.CHECK TELESCOPIC MOTOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect telescopic motor connector.

3. Turn ignition switch ON.

4. Perform “Active test” (“TELESCO MOTOR”) with CONSULT-lll

5. Check voltage between telescopic motor harness connector and ground.

Is the inspection result normal?

YES >> Replace telescopic motor (built in steering column assembly).

NO >> GO TO 2.

2.CHECK TELESCOPIC MOTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit.

3. Check continuity between automatic drive positi oner control unit harness connector and telescopic motor

harness connector.

4. Check continuity between automatic drive positioner control unit harness connector and ground.

Te s t i t e m D e s c r i p t i o n

TELESCO MOTOR OFF

Steering telescopicStop

FR Forward

RR Backward

(+) (-) Condition Voltage (V)

(Approx.)

Telescopic motor

Connector Terminals

M117 1

GroundTELESCOPIC MO-

TOR OFF 0

FR (forward) 0

RR (backward) 12

2 OFF 0

FR (forward) 12

RR (backward) 0

Automatic drive positioner control unit Telescopic motor

Continuity

Connector Terminal Connector Terminal

M75 26

M117 1

Existed

29 2

Revision: 2010 May2011 QX56

Page 127 of 5598

ADP-118

< DTC/CIRCUIT DIAGNOSIS >

DOOR MIRROR MOTOR

DOOR MIRROR MOTOR

Component Function CheckINFOID:0000000006248414

1.CHECK DOOR MIRROR MOTOR FUNCTION

Check the operation with “MIRROR MOTOR RH” and “MI RROR MOTOR LH” in “ACTIVE TEST” mode with

CONSULT-III

Refer to ADP-22, "

CONSULT-III Function".

Is the inspection result normal?

YES >> INSPECTION END

NO >> Refer to ADP-118, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006248415

1.CHECK DOOR MIRROR MOTOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect door mirror connector.

3. Turn ignition switch ON.

4. Check voltage between door mirror harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK DOOR MIRROR MOTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit connector.

3. Check continuity between automatic drive positi oner control unit harness connector and door mirror har-

ness connector.

[driver side]

[passenger side]

4. Check continuity between automatic drive positioner control unit harness connector and ground.

(+)

(-) Condition Voltage (V)

(Approx.)

Door mirror

Connector Terminals

D3 (Driver side)

D23 (Passenger side) 12

GroundDoor mirror remote

control switch UP 12

Other than the above 0

11 LEFT 12

Other than the above 0

10 DOWN / RIGHT 12

Other than the above 0

Automatic drive positioner contro

l unit Door mirror (driver side)

Continuity

Connector Terminal Connector Terminal

M75 12

D3 10

Existed

23 12

24 11

Automatic drive positioner control unit Door mirror (passenger side) Continuity

Connector Terminal Connector Terminal

M75 22

D23 10

Existed

10 12

11 11

Revision: 2010 May2011 QX56

Page 129 of 5598

ADP-120

< DTC/CIRCUIT DIAGNOSIS >

SEAT MEMORY INDICATOR

SEAT MEMORY INDICATOR

Component Function CheckINFOID:0000000006248417

1.CHECK FUNCTION

1. Select “MEMORY SW INDCTR” in “A ctive test” mode with CONSULT-III.

2. Check the memory indicator operation.

Is the operation of relevant parts normal?

YES >> INSPECTION END

NO >> Perform diagnosis procedure. Refer to ADP-120, "

DiagnosisProcedure".

Diagnosis ProcedureINFOID:0000000006248418

1.CHECK SEAT MEMORY SWITCH INDICATOR OPERATION

Check seat memory switch indicator operation.

Which is the malfunctioning indicator?

All indicators are NG>>GO TO 2.

An indicator is NG>>GO TO 4.

2.CHECK FUSE

1. Turn ignition switch OFF.

2. Check that the blown fuse after repairing the affected circuit if a fuse is blown.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

3.CHECK SEAT MEMORY SWITCH INDICATOR POWER SUPPLY

Check voltage between seat memory switch harness connector and ground.

Is the inspection result normal?

YES >> Replace seat memory switch.

NO >> Repair or replace harness or connector.

4.CHECK SEAT MEMORY SW ITCH INDICATOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect driver seat control uni t and seat memory switch connector.

3. Check continuity between driver seat control unit harness connector and seat memory switch harness

connector.

Te s t i t e m D e s c r i p t i o n

MEMORY SW INDCTR OFF

Memory switch indicatorOFF

ON-1 Indicator 1: ON

ON-2 Indicator 2: ON

Signal name Fuse No.

Battery power supply 10 (10 A)

(+) (-)Voltage (V)

(Approx.)

Seat memory switch

Connector Terminals D13 5 Ground Battery voltage

Revision: 2010 May2011 QX56

Page 162 of 5598

AV-14

< SYSTEM DESCRIPTION >

SYSTEM

MULTI AV SYSTEM : System Description

INFOID:0000000006216216

Multi AV system means that the following systems are integrated.

COMMUNICATION SIGNAL

AV control unit function by transmitting/receiving dat a one by one with each unit (slave unit) that configures

them completely as a master unit by connecting between units that configure MULTI AV system with two AV

communication lines (H, L).

Two AV communication lines (H, L) adopt a twisted pair line that is resistant to noise.

AV control unit is connected by CAN communication, and it receives data signal from ECM and combination

meter It computes and displays fuel economy information value with the obtained information. Transmitting/

receiving of data signal is performed by BCM. Also, it transmits the required signal of vehicle setting and

receives the response signal.

AV control unit is connected with front display unit and serial communication, and it transmits the required

signal of display and display control and receives the response signal from front display unit.

NAVIGATION SYSTEM FUNCTION

Description

The AV control unit controls navigation function whil e GPS tuner has built-in map data, GYRO (angle speed

sensor), on the HDD (Hard Disk Drive).

The AV control unit inputs operation signal with communication signal, through display (touch panel) and multifunction switch and steering switch.

Guide sound is output to front speaker through BOSE am p. from AV control unit when operating navigation

system.

A vehicle position is calculated with the GYRO (angl e speed sensor), vehicle sensor, signal from GPS satel-

lite and map data stored on HDD (Hard Disk Drive), and transmits the map image signal (RGB image, RGB

area, RGB image synchronizing) to the display.

Position Detection Principle

The navigation system periodically calculates the current vehicle

position according to the following three types of signals.

Travel distance of the vehicle as determined by the vehicle speed

sensor

Vehicle turning angle determined by the gyroscope (angular speed

sensor)

The travel direction of the v ehicle determined by the GPS antenna

(GPS information)

The current position of the vehicle is then identified by comparing the

calculated vehicle position with map data, which is stored in the HDD

(Hard Disk Drive) (map-matching), and indicated on the screen with

a current location mark. More accurate data is used by comparing

position detection results from GPS to the map-matching.

FUNCTION NAME

Navigation system function Audio function

DVD play function

Front auxiliary input function USB connection function

Mobile entertainment system Hands-free phone function Touch panel function

Around view monitor function

Camera assistance sonar system Vehicle information function

Auto Light adjustment system

JSNIA0177GB

Revision: 2010 May2011 QX56

Page 163 of 5598

AV

SYSTEMAV-15

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

The current position is calculated by detecting the travel distance

from the previous calculation point, and its direction change.

Travel distance The travel distance is generat ed from the vehicle speed sensor

input signal. The automatic distance correction function is adopted

for preventing a miss-detection of the travel distance because of

tire wear etc.

Travel direction The gyroscope (angular veloci ty sensor) and GPS antenna (GPS

information) generate the change of t he travel direction. Both have

advantages and disadvantages as per the following descriptions.

Input signals are prioritized in each situation. However, this order of priority may change in accordance with

more detailed travel conditions so that the tr avel direction is detected more accurately.

Map-matching

Map-matching repositions the vehicle on the road map when a new

location is judged to be more accurate. This is done by comparing

the current vehicle position (calculated by the normal position detec-

tion method) from the map data stored in the HDD (Hard Disk Drive).

There is a possibility that the vehicle position may not be corrected in the following case, and when vehicle is

driven over a certain distance or time in which GPS in formation is hard to receive. Correct manually the cur-

rent location mark on the screen.

In map-matching, several alternative routes are prepared and pri- oritized in addition to the road judged as currently driving on.

Therefore, due to errors in the distance and/or direction, an incor-

rect road may be prioritized, and the current location mark may be

repositioned to the incorrect road.

If two roads are running in parallel, they are of the same priority.

Therefore, the current location mark may appear on either of them

alternately, depending on maneuvering of the steering wheel and

configuration of the road, etc.

SEL684V

Type Advantage Disadvantage

Gyroscope (angular velocity

sensor) The turning angle is precisely detected.

Errors are accumulated when driving a long dis-

tance without stopping.

GPS antenna (GPS informa-

tion) The travel direction (North/South/East/West) is

detected. The travel direction is not precisely detected when

driving slowly.

SEL685V

SEL686V

Revision: 2010 May2011 QX56

Page 176 of 5598

AV-28

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

DescriptionINFOID:0000000006216218

The AV control unit diagnosis function starts up with multifunction switch operation and the AV control unit

performs a diagnosis for each unit in the system during the on board diagnosis.

Perform a CONSULT-III diagnosis if the on board diagnosis does not start, e.g., the screen does not display

anything, the multifunction switch does not function, etc.

On Board Diagn osis FunctionINFOID:0000000006216219

MULTIFUNCTION SWITCH AND PRESET SWITCH SELF-DIAGNOSIS FUNCTION

The ON/OFF operation (continuity) of each switch in the multifunction switch and preset switch can be

checked.

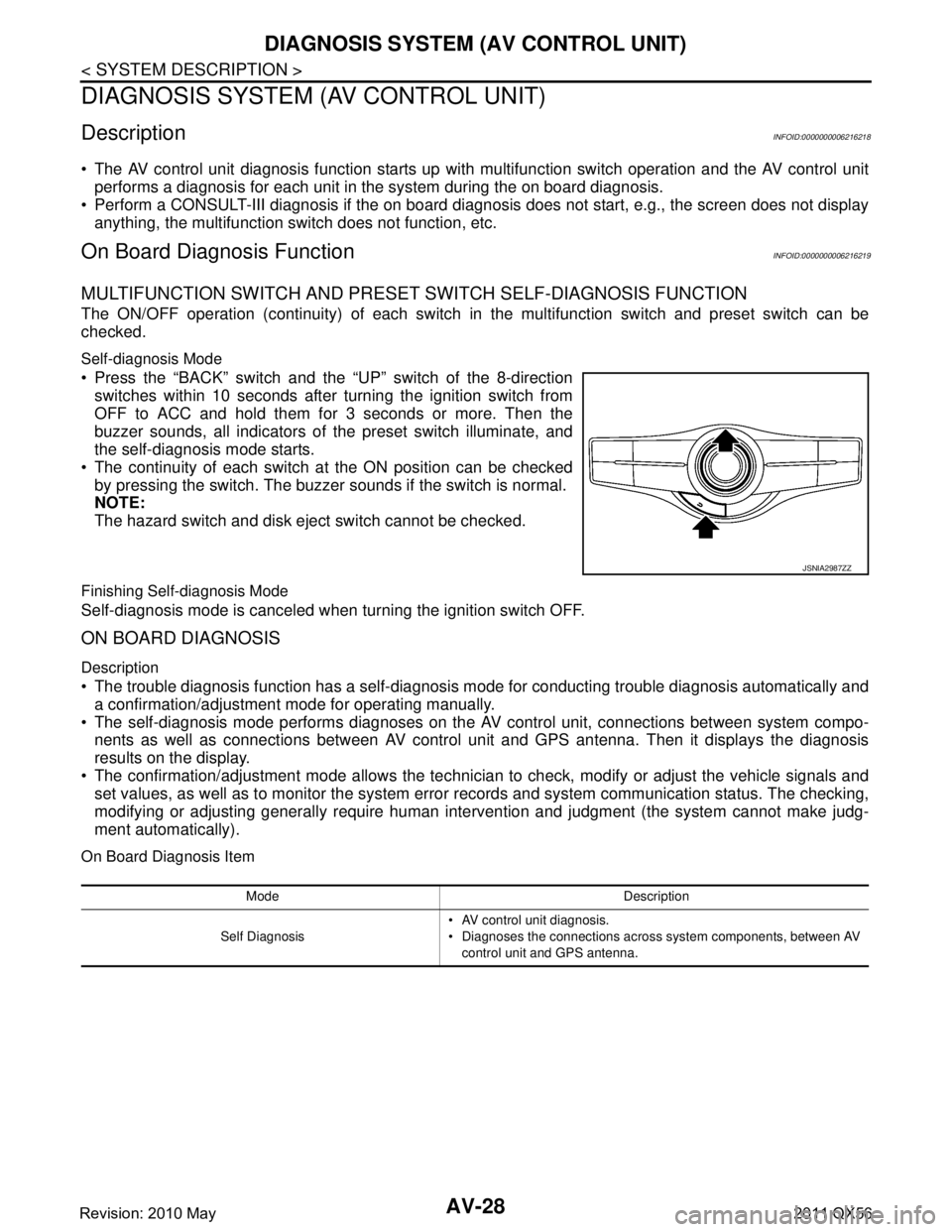

Self-diagnosis Mode

Press the “BACK” switch and the “UP” switch of the 8-direction switches within 10 seconds after turning the ignition switch from

OFF to ACC and hold them for 3 seconds or more. Then the

buzzer sounds, all indicators of the preset switch illuminate, and

the self-diagnosis mode starts.

The continuity of each switch at the ON position can be checked

by pressing the switch. The buzzer sounds if the switch is normal.

NOTE:

The hazard switch and disk eject switch cannot be checked.

Finishing Self-diagnosis Mode

Self-diagnosis mode is canceled when turning the ignition switch OFF.

ON BOARD DIAGNOSIS

Description

The trouble diagnosis function has a self-diagnosis mode for conducting trouble diagnosis automatically and

a confirmation/adjustment mode for operating manually.

The self-diagnosis mode performs diagnoses on the AV control unit, connections between system compo-

nents as well as connections between AV contro l unit and GPS antenna. Then it displays the diagnosis

results on the display.

The confirmation/adjustment mode allows the technician to check, modify or adjust the vehicle signals and

set values, as well as to monitor the system erro r records and system communication status. The checking,

modifying or adjusting generally require human inte rvention and judgment (the system cannot make judg-

ment automatically).

On Board Diagnosis Item

JSNIA2987ZZ

Mode Description

Self Diagnosis AV control unit diagnosis.

Diagnoses the connections across system components, between AV

control unit and GPS antenna.

Revision: 2010 May2011 QX56