boot INFINITI QX56 2011 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4992 of 5598

PREPARATIONST-5

< PREPARATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000006225574

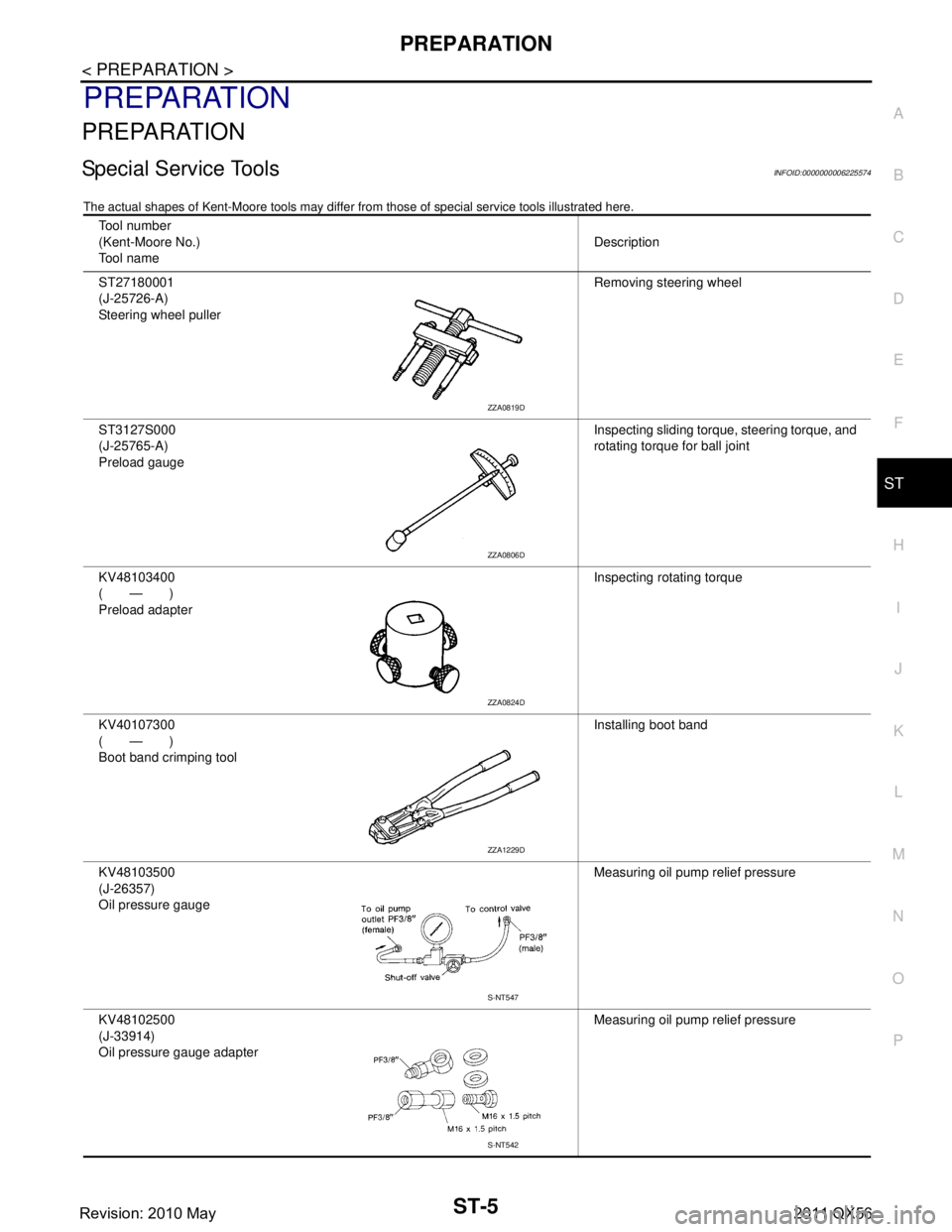

The actual shapes of Kent-Moore t ools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name Description

ST27180001

(J-25726-A)

Steering wheel puller Removing steering wheel

ST3127S000

(J-25765-A)

Preload gauge Inspecting sliding torque, steering torque, and

rotating torque for ball joint

KV48103400

(—)

Preload adapter Inspecting rotating torque

KV40107300

(—)

Boot band crimping tool Installing boot band

KV48103500

(J-26357)

Oil pressure gauge Measuring oil pump relief pressure

KV48102500

(J-33914)

Oil pressure gauge adapter Measuring oil pump relief pressure

ZZA0819D

ZZA0806D

ZZA0824D

ZZA1229D

S-NT547

S-NT542

Revision: 2010 May2011 QX56

Page 5017 of 5598

ST-30

< PERIODIC MAINTENANCE >

POWER STEERING FLUID

PERIODIC MAINTENANCE

POWER STEERING FLUID

InspectionINFOID:0000000006225597

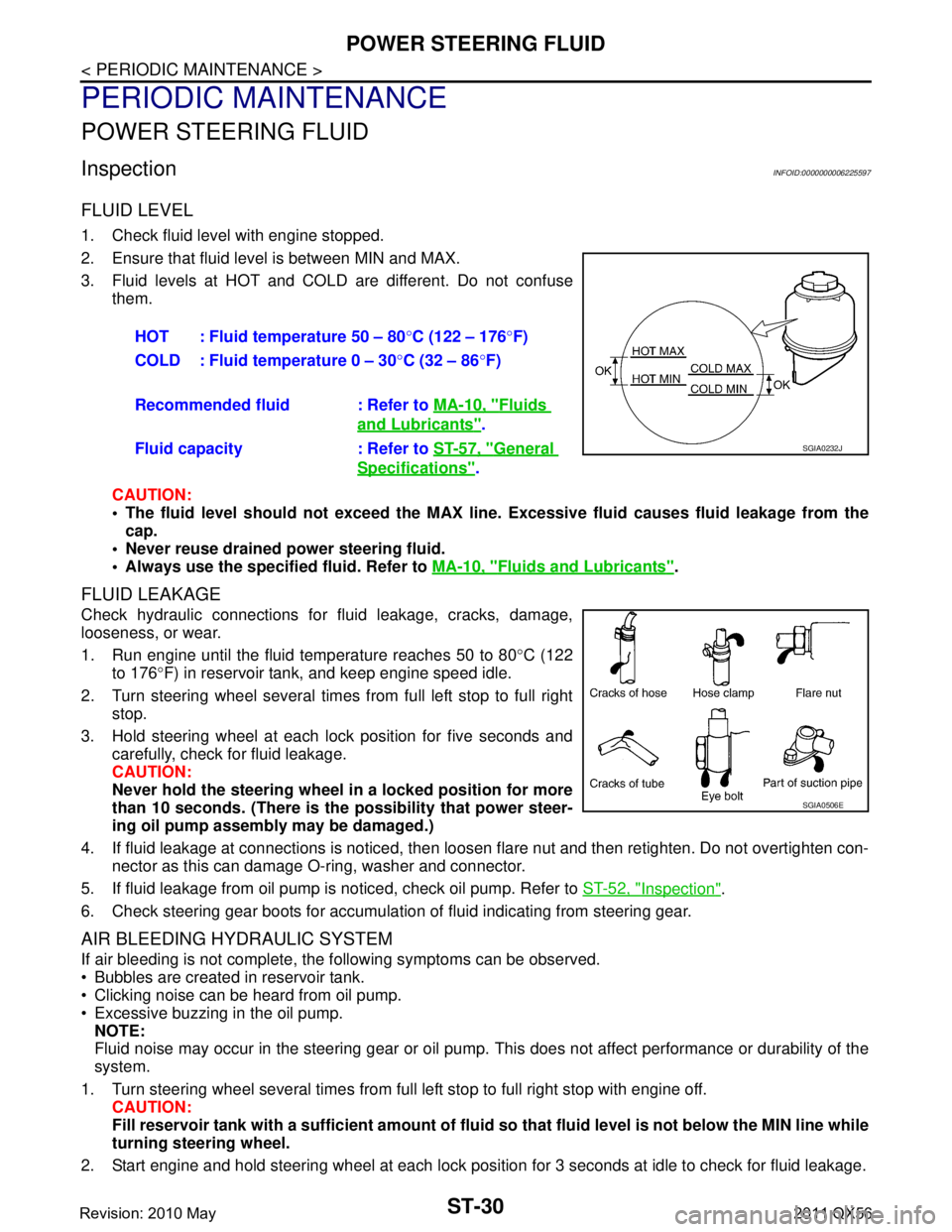

FLUID LEVEL

1. Check fluid level with engine stopped.

2. Ensure that fluid level is between MIN and MAX.

3. Fluid levels at HOT and COLD are different. Do not confuse

them.

CAUTION:

The fluid level should not exceed the MAX line. Excessive flui d causes fluid leakage from the

cap.

Never reuse drained power steering fluid.

Always use the specified fluid. Refer to MA-10, "

Fluids and Lubricants".

FLUID LEAKAGE

Check hydraulic connections for fluid leakage, cracks, damage,

looseness, or wear.

1. Run engine until the fluid temperature reaches 50 to 80 °C (122

to 176 °F) in reservoir tank, and keep engine speed idle.

2. Turn steering wheel several times from full left stop to full right stop.

3. Hold steering wheel at each lock position for five seconds and carefully, check for fluid leakage.

CAUTION:

Never hold the steering wheel in a locked position for more

than 10 seconds. (There is the possibility that power steer-

ing oil pump assembly may be damaged.)

4. If fluid leakage at connections is noticed, then loos en flare nut and then retighten. Do not overtighten con-

nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer to ST-52, "

Inspection".

6. Check steering gear boots for accumulation of fluid indicating from steering gear.

AIR BLEEDING HYDRAULIC SYSTEM

If air bleeding is not complete, the following symptoms can be observed.

Bubbles are created in reservoir tank.

Clicking noise can be heard from oil pump.

Excessive buzzing in the oil pump. NOTE:

Fluid noise may occur in the steering gear or oil pump. This does not affect performance or durability of the

system.

1. Turn steering wheel several times from full left stop to full right stop with engine off. CAUTION:

Fill reservoir tank with a sufficien t amount of fluid so that fluid level is not below the MIN line while

turning steering wheel.

2. Start engine and hold steering wheel at each lock position for 3 seconds at idle to check for fluid leakage.

HOT : Fluid temperature 50 – 80

°C (122 – 176 °F)

COLD : Fluid temperature 0 – 30 °C (32 – 86 °F)

Recommended fluid : Refer to MA-10, "

Fluids

and Lubricants".

Fluid capacity : Refer to ST-57, "

General

Specifications".

SGIA0232J

SGIA0506E

Revision: 2010 May2011 QX56

Page 5026 of 5598

STEERING SHAFTST-39

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

- Align rear cover cap projection (A) with the marking position of gear housing assembly (B).

- Install slit part of lower joint (C) aligning with the rear cover cap projection (A). Make sure that the slit part of lower joint (C) is

aligned with rear cover cap projection (A) and the marking position

of gear housing assembly (B).

When installing lower joint (1) to steering shaft (2), check the fixing length (A).

Perform inspection after installation. Refer to ST-39, "

Inspection".

InspectionINFOID:0000000006225606

INSPECTION AFTER REMOVAL

Lower Joint

Check dust boot clamp (looseness and disconnection) and dust boot (scratches, cracks, and holes).

Replace the lower joint, as necessary.

Check each part of lower joint for damage and other malfunctions. Replace if there is a malfunction.

Steering Shaft

Check steering shaft and hole cover seal for scratches, cracks, and holes. Replace the stee\

ring shaft or hole

cover seal, as necessary.

Check the sliding range of the steering shaft.

CAUTION:

Check the sliding range (A) (b etween the extended position

and the contracted position) of the steering shaft.

Check the length (L) (extended posit ion) of the steering shaft.

: Bolt

JPGIA0038ZZ

A : 15.3 mm (0.602 in)

JPGIA0068ZZ

A : Refer to ST-58, "Steering Shaft Sliding Range".

JPGIA0070ZZ

L : Refer to ST-58, "Steering Shaft Sliding Range".

JPGIA0069ZZ

Revision: 2010 May2011 QX56

Page 5027 of 5598

ST-40

< REMOVAL AND INSTALLATION >

STEERING SHAFT

Rotate the steering shaft to check runout of the steering shaft atthe runout measuring point ( ) by using dial indicator and V-block.

Check each part of steering shaft for damage and other malfunc- tions. Replace if there is a malfunction.

INSPECTION AFTER INSTALLATION

Check dust boot bellows (deformation, such as dent s). Manually rework the bellows, as necessary.

Check if steering wheel turns smoothly when it is tur ned several times fully to the end of the left and right.

Check the steering wheel play, neutral position steeri ng wheel, steering wheel turning force, and front wheel

turning angle. Refer to ST-32, "

Inspection".

Adjust neutral position of steering angle sensor. Refer to BRC-64, "

Work Procedure".

Runout : Refer to

ST-58, "

Steering Shaft Sliding

Range".

A : 120 mm (4.72 in)

B : 240 mm (9.45 in)

JPGIA0075ZZ

Revision: 2010 May2011 QX56

Page 5028 of 5598

STEERING GEAR AND LINKAGEST-41

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

STEERING GEAR AND LINKAGE

Exploded ViewINFOID:0000000006225607

REMOVAL

DISASSEMBLY

Engine speed sensitive type

1. Steering gear assembly 2. Cotter pin

Refer to GI-4, "

Components" for symbols in the figure.

JPGIA0072GB

JPGIA0095GB

1. Outer socket 2. Boot clamp 3. Boot

4. Inner socket 5. Boot clamp 6. Gear housing assembly

7. Adjusting screw 8. Adjusting screw lock nut 9. Spring

Revision: 2010 May2011 QX56

Page 5029 of 5598

ST-42

< REMOVAL AND INSTALLATION >

STEERING GEAR AND LINKAGE

Vehicle speed sensitive type

Removal and InstallationINFOID:0000000006225608

REMOVAL

1. Set vehicle to the straight-ahead position.

2. Remove tires.

3. Remove front final drive assembly. Refer to DLN-162, "

Removal and Installation".

10. Retainer 11. O-ring 12. Low pressure piping

13. Gear-sub assembly 14. Rear cover cap 15. Cylinder tubes

: Apply power steering fluid.

: Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to GI-22, "

Recommended Chemical Products

and Sealants".

: A p p l y G e n u i n e L i q u i d G a s k e t , T h r e e B o n d 1111 B o r e q u i v a l e n t . : Apply multi-purpose grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPGIA0073GB

1. Outer socket 2. Boot clamp 3. Boot

4. Inner socket 5. Boot clamp 6. Gear housing assembly

7. Adjusting screw 8. Adjusting screw lock nut 9. Spring

10. Retainer 11. O-ring 12. Low pressure piping

13. Power steering solenoid valve 14. Gear-sub assembly 15. Rear cover cap

16. Cylinder tubes

: Apply power steering fluid.

: Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to GI-22, "

Recommended Chemical Products

and Sealants".

: A p p l y G e n u i n e L i q u i d G a s k e t , T h r e e B o n d 1111 B o r e q u i v a l e n t . : Apply multi-purpose grease.

Refer to GI-4, "

Components" for symbols not described on the above.

Revision: 2010 May2011 QX56

Page 5030 of 5598

STEERING GEAR AND LINKAGEST-43

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

4. Remove cotter pin (1), and then loosen the nut.

5. Remove steering outer socket (2) from steering knuckle (3) so as not to damage ball joint boot (4) using suitable ball joint

remover (commercial service tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover from suddenly coming

off.

6. Remove high pressure piping and low pressure piping of hydraulic piping, and then drain power steering fluid.

7. Remove power steering solenoid valve harness connector.

8. Remove lower joint fixing bolt (steering gear side).

9. Separate the lower joint from the steering gear assembly. Refer to ST-37, "

Exploded View".

CAUTION:

When removing lower joint, n ever insert a tool, such as a screw driver, into the yoke groove to

pull out the lower joint. In case of the violation of the above, replace lower joint with a new one.

Spiral cable may be cut if steering wheel tu rns while separating steering column assembly and

steering gear assembly. Be sure to secure st eering wheel using string to avoid turning.

10. Remove steering gear assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steer-

ing gear assembly. Be sure to secure steer ing wheel using string to avoid turning.

When installing lower joint to steering gear assembly, follow the procedure listed below.

- Set rack of steering gear in the neutral position.

NOTE:

To get the neutral position of rack, turn gear-sub a ssembly and measure the distance of inner socket, and

then measure the intermediat e position of the distance.

- Align rear cover cap projection (A) with the marking position of gear housing assembly (B).

- Install slit part of lower joint (C) aligning with the rear cover cap projection (A). Make sure that the slit part of lower joint (C) is

aligned with rear cover cap projection (A) and the marking position

of gear housing assembly (B).

Never reuse cotter pin and steering gear mounting nut.

Perform inspection after installation. Refer to ST-46, "

Inspection".

Disassembly and AssemblyINFOID:0000000006225609

DISASSEMBLY

CAUTION:

Disassemble and assemble steering gear assembly by fixing the mounting area with a vise using

copper plates.

Clean steering gear assembly with kerosene before disassembling. Be careful to avoid splashing or

applying any kerosene over connector of discharge port or return port.

1. Remove cylinder tubes from gear housing assembly.

2. Remove rear cover cap from gear-sub assembly.

PGIA0063E

: Bolt

JPGIA0038ZZ

Revision: 2010 May2011 QX56

Page 5031 of 5598

ST-44

< REMOVAL AND INSTALLATION >

STEERING GEAR AND LINKAGE

3. Measure adjusting screw height (H), and loosen adjusting screwlock nut (1) and adjusting screw (2).

CAUTION:

Never loosen adjusting screw 2 turns or more.

Replace steering gear assembly if adjusting screw is

loosened 2 turns or more and it is removed.

4. Remove gear-sub assembly from gear housing assembly.

5. Remove O-ring from gear housing assembly.

6. Loosen outer socket lock nut, and remove outer socket.

7. Remove boot clamps, and then remove boot from inner socket. CAUTION:

Never damage inner socket and gear housing assembly when removing boot. Inner socket and

gear housing assembly must be replaced if inne r socket and gear housing assembly are damaged

because it may cause foreign material interfusion.

8. Remove inner socket from gear housing assembly.

ASSEMBLY

1. Apply recommended fluid to O-ring, and then install O-ring to gear housing assembly. CAUTION:

Never reuse O-ring.

2. Install gear-sub assembly to gear housing assembly. CAUTION:

In order to protect oil seal from any da mage, insert gear-sub assembly straightly.

3. Install inner socket to gear housing assembly with the following procedure.

a. Apply thread locking sealant into the thread of inner socket. Use Genuine High Strength Thread Locking Sealant or equivalent. Refer to GI-22, "

Recommended

Chemical Products and Sealants".

4. Screw inner socket into rack part and tighten at the specified torque.

5. Decide on the neutral position of the rack stroke (L).

6. Install rear cover cap to gear sub-assembly. CAUTION:

Make sure that the projection of rear cover cap is aligned

with the marking position of gear housing assembly.

7. Install adjusting screw with the following procedure.

a. Apply recommended sealant into the thread of adjusting screw (2) (2 turns thread), and then screw in the adjusting screw until it

reaches height (H) from gear housing assembly (3) measured

before disassembling.

Use Genuine Liquid Gasket Gasket, Three Bond 1111B or

equivalent.

b. Tighten the adjusting screw lock nut (1) to the specified torque.

8. Move rack assembly 10 strokes throughout the full stroke so that the parts can fit with each other.

9. Adjust pinion rotating torque with the following procedure.

3 : Gear housing assembly

JPGIA0065ZZ

L : Refer to ST-58, "Rack Stroke".

SGIA0877E

JPGIA0065ZZ

Revision: 2010 May2011 QX56

Page 5033 of 5598

ST-46

< REMOVAL AND INSTALLATION >

STEERING GEAR AND LINKAGE

10. Install large end of boot to gear housing assembly.CAUTION:

Never reuse boot.

11. Install small end of boot to inner socket boot mounting groove.

12. Install boot clamp to boot small end.

13. Install boot clamp to the large side using the boot band crimping tool (A) [SST: KV40107300 ( — )].

CAUTION:

Never reuse boot clamp.

14. Install cylinder tubes to gear housing assembly.

15. Adjust inner socket to standard length (L), and then tighten lock nut to the specified torque. Check length again after tightening

lock nut.

CAUTION:

Adjust toe-in after this proced ure. The length achieved after

toe-in adjustment is not necessary the above value.

InspectionINFOID:0000000006225610

INSPECTION AFTER DISASSEMBLY

Boot

Check boot for cracks, and replace it if a malfunction is detected.

Rack Assembly

Check rack for damage or wear, and replace it if a malfunction is detected.

Gear-Sub Assembly

Check gear-sub assembly for damage or wear, and replace it if a malfunction is detected.

Rotate gear-sub assembly and check for torque variation or rattle, and replace it if a malfunction is detected.

Gear Housing Assembly

Check gear housing assembly for damage and scratches (inner wall), and replace it if a malfunction is

detected.

Outer Socket and Inner Socket

Check the following items and replace the component if it does not meet the standard.

BALL JOINT SWINGING TORQUE

SGIA1325E

PDIA1187J

L : Refer to ST-58, "Inner Socket Length".

SGIA0167E

Revision: 2010 May2011 QX56