ESP ISUZU KB P190 2007 Workshop Owners Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3273 of 6020

Engine Management – V6 – General Information Page 6C1-1–31

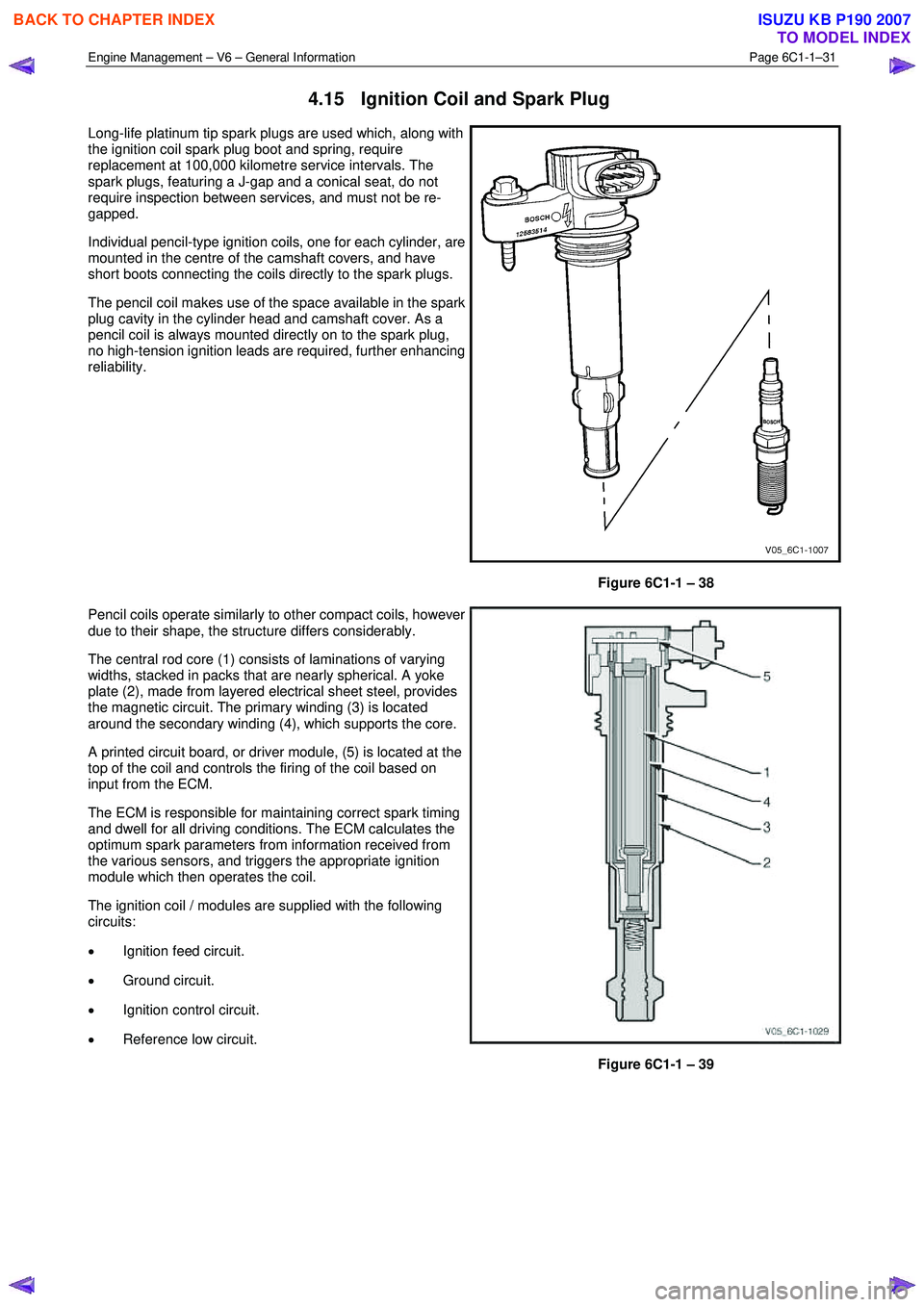

4.15 Ignition Coil and Spark Plug

Long-life platinum tip spark plugs are used which, along with

the ignition coil spark plug boot and spring, require

replacement at 100,000 kilometre service intervals. The

spark plugs, featuring a J-gap and a conical seat, do not

require inspection between services, and must not be re-

gapped.

Individual pencil-type ignition coils, one for each cylinder, are

mounted in the centre of the camshaft covers, and have

short boots connecting the coils directly to the spark plugs.

The pencil coil makes use of the space available in the spark

plug cavity in the cylinder head and camshaft cover. As a

pencil coil is always mounted directly on to the spark plug,

no high-tension ignition leads are required, further enhancing

reliability.

Figure 6C1-1 – 38

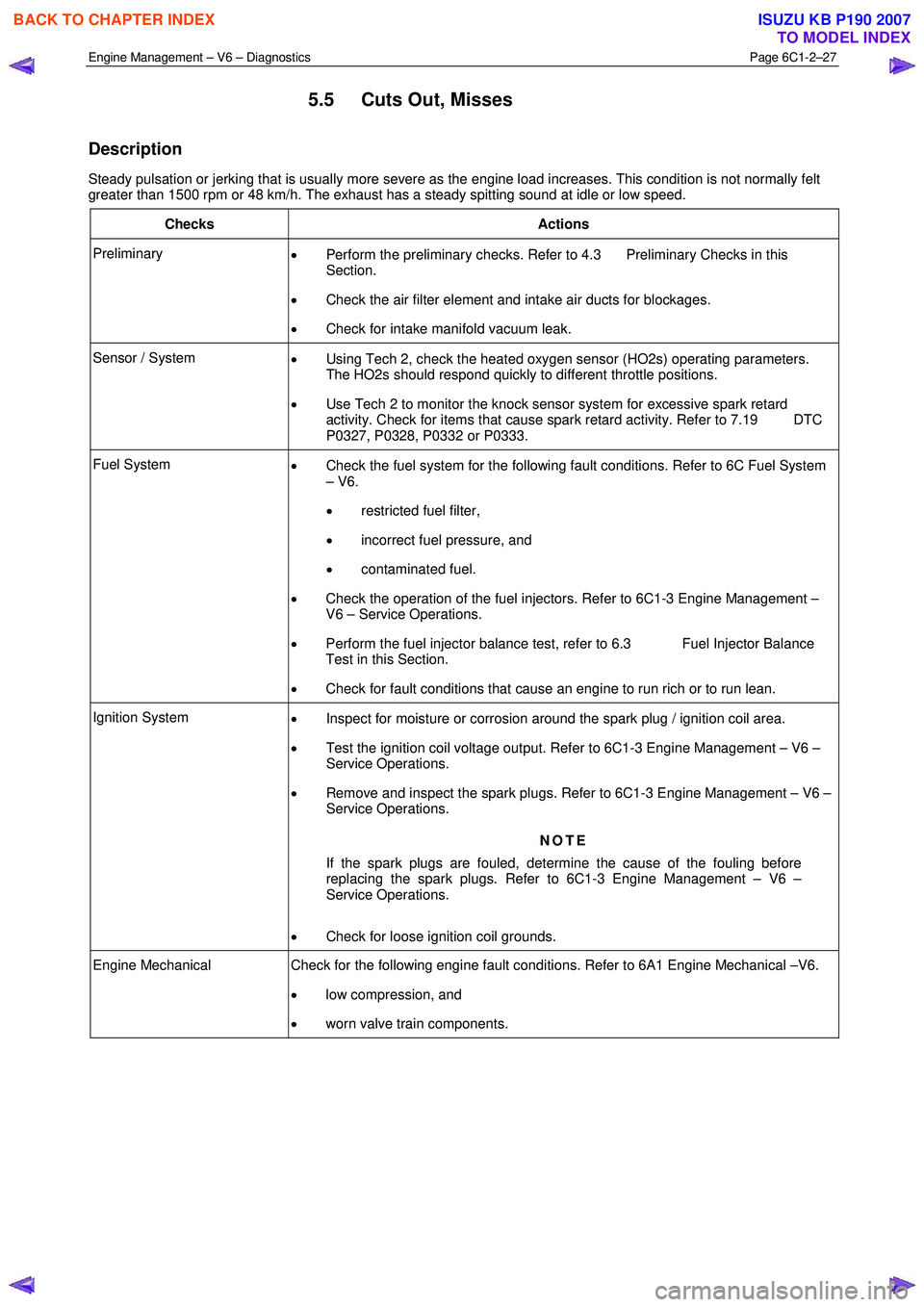

Pencil coils operate similarly to other compact coils, however

due to their shape, the structure differs considerably.

The central rod core (1) consists of laminations of varying

widths, stacked in packs that are nearly spherical. A yoke

plate (2), made from layered electrical sheet steel, provides

the magnetic circuit. The primary winding (3) is located

around the secondary winding (4), which supports the core.

A printed circuit board, or driver module, (5) is located at the

top of the coil and controls the firing of the coil based on

input from the ECM.

The ECM is responsible for maintaining correct spark timing

and dwell for all driving conditions. The ECM calculates the

optimum spark parameters from information received from

the various sensors, and triggers the appropriate ignition

module which then operates the coil.

The ignition coil / modules are supplied with the following

circuits:

• Ignition feed circuit.

• Ground circuit.

• Ignition control circuit.

• Reference low circuit.

Figure 6C1-1 – 39

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3274 of 6020

Engine Management – V6 – General Information Page 6C1-1–32

4.16 Intake Air Temperature Sensor

The intake air temperature (IAT) sensor is a thermistor,

which is a resistor that changes it’s resistance value based

on temperature.

The IAT sensor is part of the air mass sensor and is not a

serviceable item. The sensor is a negative temperature

coefficient (NTC) type, intake air temperature produces a

high sensor resistance while high engine coolant

temperature causes low sensor resistance.

Legend

A Temperature

B Resistance

The ECM provides a 5 V reference signal to the IAT and

monitors the return signal which enables it to calculate the

intake air temperature.

The ECM uses this signal to make corrections to the

operating parameters of the system based on changes in air

intake temperature.

Figure 6C1-1 – 40

4.17 Knock Sensor

The knock sensor (KS) signal is used by the ECM to provide

optimum ignition timing while minimising engine knock or

detonation.

The ECM monitors the voltage of the left-hand (Bank 2)

sensor during the 45 degrees after cylinder 2, 4, or 6 has

fired and the voltage of the right-hand (Bank 1) sensor

during the 45 degrees after cylinder 1, 3, or 5 has fired.

If knock occurs in any of the cylinders, the ignition will be

retarded by three degrees for that particular cylinder. If the

knocking then stops, the ignition will be restored to what it

was before in steps of 0.75 degrees.

Should knocking continue in the same cylinder despite of

the ignition being retarded, the ECM will retard the ignition

an additional step of three degrees, and so on, up to a

maximum of 12.75 degrees. The ignition will also be

retarded at high ambient temperatures to counteract

knocking tendencies provoked by high intake air

temperatures.

Should either Bank 1 or Bank 2 sensor fail to work, or

should an open circuit occur, the ignition timing will then be

set at a default strategy that will retard the ignition much

more than normal.

Figure 6C1-1 – 41

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3305 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–27

5.5 Cuts Out, Misses

Description

Steady pulsation or jerking that is usually more severe as the engine load increases. This condition is not normally felt

greater than 1500 rpm or 48 km/h. The exhaust has a steady spitting sound at idle or low speed.

Checks Actions

Preliminary • Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

• Check the air filter element and intake air ducts for blockages.

• Check for intake manifold vacuum leak.

Sensor / System

• Using Tech 2, check the heated oxygen sensor (HO2s) operating parameters.

The HO2s should respond quickly to different throttle positions.

• Use Tech 2 to monitor the knock sensor system for excessive spark retard

activity. Check for items that cause spark retard activity. Refer to 7.19 DTC

P0327, P0328, P0332 or P0333.

Fuel System • Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6.

• restricted fuel filter,

• incorrect fuel pressure, and

• contaminated fuel.

• Check the operation of the fuel injectors. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

• Perform the fuel injector balance test, refer to 6.3 Fuel Injector Balance

Test in this Section.

• Check for fault conditions that cause an engine to run rich or to run lean.

Ignition System

• Inspect for moisture or corrosion around the spark plug / ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Check for loose ignition coil grounds.

Engine Mechanical Check for the following engine fault conditions. Refer to 6A1 Engine Mechanical –V6.

• low compression, and

• worn valve train components.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3308 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–30

Checks Actions

Ignition System

• Inspect for moisture or corrosion around the spark plug / ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Check for loose ignition coil ground circuit.

Engine Mechanical

• Check for excessive oil in combustion chamber. Refer to 6A1 Engine Mechanical

– V6.

• Check for the following engine fault conditions. Refer to 6A1 Engine Mechanical –

V6.

• low compression, and

• worn valve train components.

When all diagnosis and repairs are completed, check the system for correct operation.

5.9 Hesitation, Sag and Stumble

Description

Momentary lack of response or hesitation as the accelerator is depressed. This condition is usually more severe when

first trying to make the vehicle move from a standing start but can occur at any vehicle speed.

Checks Actions

Preliminary • Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

• Check the air filter element and intake air ducts for blockages.

Sensor / System

• Using Tech 2, check the heated oxygen sensor (HO2s) operating parameters.

The HO2s should respond quickly to different throttle positions.

• Inspect the accelerator pedal position (APP) sensor harness connector for correct

connection. Poor connection of this connector will not set a DTC.

Fuel System • Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6.

• restricted fuel filter,

• incorrect fuel pressure, and

• contaminated fuel.

• Check the operation of the fuel injectors. Refer to 6C Fuel System – V6.

• Perform the fuel injector balance test, refer to 6.3 Fuel Injector Balance

Test in this Section.

• Check for fault conditions that cause an engine to run rich or to run lean.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3311 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–33

Checks Actions

Sensor / System

• Check the air intake system and crankcase for air leaks.

• Check the PCV System for correct operation. Refer to 6A1 Engine Mechanical –

V6.

• Check for the correct calibration of the speedometer. Refer to 8A Electrical-Body.

• Use Tech 2 to monitor the knock sensor system for excessive spark retard

activity. Check for items that cause spark retard activity.

• Using Tech 2, check the heated oxygen sensor (HO2s) operating parameters.

The HO2s should respond quickly to different throttle positions.

Fuel System • Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6.

− restricted fuel filter,

− incorrect fuel pressure, and

− contaminated fuel.

• Check the operation of the fuel injectors. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

• Perform the fuel injector balance test, refer to 6.3 Fuel Injector Balance

Test in this Section.

• Check the items that cause an engine to run rich.

• Check for foreign material accumulation in the throttle bore, carbon build-up on

the throttle valve or on the throttle shaft.

• Check the throttle body for tampering.

Ignition System

• Inspect for moisture or corrosion around the spark plug / ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Check for loose ignition coil ground circuit.

Engine Cooling System

• Check the engine thermostat for proper operation and correct heat range. Refer to

6B1 Engine Cooling – V6.

Engine Mechanical Check for the following engine fault conditions. Refer to 6A1 Engine Mechanical – V6.

• low compression, and

• worn valve train components.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3312 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–34

Checks Actions

Additional Checks

• Check the exhaust system for possible restrictions. Refer to 6F Exhaust System –

V6.

• Electromagnetic interference (EMI) on the crankshaft position (CKP) sensor can

cause an engine misfire condition.

Using Tech 2, monitor the engine speed parameter. A sudden increase in the engine speed parameters without moving the throttle position indicates that an

Electromagnetic Interference fault may be present.

W iring harness routing which may be positioned very close to a high voltage or high current device such as the following may induce EMI:

• secondary ignition components, and

• motors and generators.

• Check the torque converter clutch (TCC) operation. A TCC that applies too soon

can cause engine detonation, which will trigger spark retard activity. Refer to 7C2

Automatic Transmission – 4L60E – Electrical Diagnosis.

• Test for other TCM related faults that may cause the transmission to operate in

the default mode. Refer to 7C2 Automatic Transmission – 4L60E – Electrical

Diagnosis.

• Check for transmission mechanical faults such as slipping clutch. Refer to 7C3

Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis.

• Check the brake system including the parking brake for sticking or incorrect

operation.

When all diagnosis and repairs are completed, check the system for correct operation.

5.12 Rough, Unstable, Incorrect Idle or

Stalling

Description

Engine idle speed fluctuates causing the engine to run unevenly. If the engine idle speed drops too low, the engine may

stall.

Checks Actions

Preliminary • Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

• Check the air filter element and intake air ducts for blockages.

Sensor / System

• Check the throttle actuator control (TAC) system. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

• Check the air intake system and crankcase for air leaks. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

• Check the PCV System for correct operation. Refer to 6A1 Engine Mechanical –

V6.

• Use Tech 2 to monitor the knock sensor system for excessive spark retard

activity. Check for items that cause spark retard activity.

• Using Tech 2, check the heated oxygen sensor (HO2s) operating parameters.

The HO2s sensor should respond quickly to different throttle positions.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3313 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–35

Checks Actions

Fuel System

• Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6.

− restricted fuel filter,

− incorrect fuel pressure, and

− contaminated fuel.

• Check the operation of the fuel injectors. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

• Perform the fuel injector balance test, refer to 6.3 Fuel Injector Balance

Test in this Section.

• Check the items that cause an engine to run rich.

Ignition System

• Inspect for moisture or corrosion around the spark plug and ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management –V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Check for loose ignition coil grounds.

Engine Mechanical

• Parasitic load on the engine such as the following:

• automatic transmission fault condition, or

• a belt driven accessory fault condition.

• Check for the following engine fault conditions. Refer to 6A1 Engine Mechanical –

V6.

• low compression, or

• worn valve train components.

When all diagnosis and repairs are completed, check the system for correct operation.

5.13 Surges / Chuggles

Description

W ith the accelerator pedal in a steady position, the vehicle speeds up and slows down or the engine power fluctuates.

Checks Actions

Preliminary Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this Section.

Sensor / System

• Using Tech 2, check the heated oxygen sensor (HO2s) operating parameters.

The HO2s should respond quickly to different throttle positions.

• Test the resistance of the crankshaft position (CKP) sensor. The CKP sensor

resistance must be 700 – 1,200 Ω at all temperatures.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3329 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–51

DTC Description Diagnostic Table

P0058 O2 Sensor Heater Circuit High Voltage (Bank 2, Sensor 2) 7.3 DTC P0030, P0031, P0032, P0036,

P0037, P0038, P0050, P0051, P0052,

P0056, P0057 or P0058

P0059 O2 Sensor Heater Resistance Range / Performance (Bank 2, Sensor 1) 7.5 DTC P0053 or P0059

P0101 Mass Air Flow Sensor Circuit Range / Performance 7.6 DTC P0101, P0102 or P0103

P0102 Mass Air Flow Sensor Voltage Low

7.6 DTC P0101, P0102 or P0103

P0103 Mass Air Flow Sensor Voltage High 7.6 DTC P0101, P0102 or P0103

P0112 Intake Air Temperature Sensor Circuit Low Voltage 7.7 DTC P0112 or P0113

P0113 Intake Air Temperature Sensor Circuit High Voltage 7.7 DTC P0112 or P0113

P0116 Engine Coolant Temperature Sensor Circuit Range /

Performance 7.8 DTC P0116, P0117, P0118, P0125 or

P1258

P0117 Engine Coolant Temperature Sensor Circuit Low Voltage 7.8 DTC P0116, P0117, P0118, P0125 or P1258

P0118 Engine Coolant Temperature Sensor Circuit High Voltage 7.8 DTC P0116, P0117, P0118, P0125 or P1258

P0121 Throttle Position Sensor 1 Circuit Range / Performance 7.9 DTC P0121, P0122, P0123, P0221, P0222,or P0223

P0122 Throttle Position Sensor 1 Circuit Low Voltage 7.9 DTC P0121, P0122, P0123, P0221,

P0222,or P0223

P0123 Throttle Position Sensor 1 Circuit High Voltage 7.9 DTC P0121, P0122, P0123, P0221,

P0222,or P0223

P0125 Insufficient Engine Coolant Temperature For Closed Loop Fuel Control 7.8 DTC P0116, P0117, P0118, P0125 or

P1258

P0130 O2 Sensor Circuit Malfunction (Bank 1, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0131 O2 Sensor Circuit Low Voltage (Bank 1, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0132 O2 Sensor Circuit High Voltage (Bank 1 Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0133 O2 Sensor Circuit Slow Response (Bank 1 Sensor 1) 7.11 DTC P0133 or P0153

P0135 O2 Sensor Heater Circuit Range / Performance (Bank 1, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0137 O2 Sensor Circuit Low Voltage (Bank 1, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3330 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–52

DTC Description Diagnostic Table

P0138 O2 Sensor Circuit High Voltage (Bank 1, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0139 O2 Sensor Slow Response (Bank1 Sensor 2) 7.12 DTC P0139 or P0159

P0140 O2 Sensor Circuit No Activity Detected (Bank 1

Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0141 O2 Sensor Heater Circuit Range / Performance (Bank 1, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0150 O2 Sensor Circuit Malfunction (Bank 2, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0151 O2 Sensor Circuit Low Voltage (Bank 2, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0152 O2 Sensor Circuit High Voltage (Bank 2, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0153 O2 Sensor Circuit Slow Response (Bank 2 Sensor 1) 7.11 DTC P0133 or P0153

P0155 O2 Sensor Heater Circuit Range / Performance (Bank 2, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0157 O2 Sensor Circuit Low Voltage (Bank 2, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0158 O2 Sensor Circuit High Voltage (Bank 2, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0159 O2 Sensor Slow Response (Bank1 Sensor 2) 7.12 DTC P0139 or P0159

P0160 O2 Sensor Circuit No Activity Detected (Bank 2, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0161 O2 Sensor Heater Circuit Range / Performance (Bank 2, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3365 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–87

Step Action Yes No

4 1 Disconnect the appropriate HO2S wiring connector.

2 Switch on the ignition with the engine not running.

3 Using a digital multimeter, measure the voltage between the HO2S reference signal circuit and low reference circuit.

Does the multimeter display 350 – 550 mV? Go to Step 7 Go to Step 5

5 1 Test the reference signal circuit of the HO2S for a high

resistance, open circuit, short to ground or short to voltage fault

condition. Refer to 8A Electrical - Body and Chassis for

information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 10 Go to Step 6

6 1 Test the low reference circuit of the HO2S for a high resistance,

open circuit, short to ground or short to voltage fault condition.

Refer to 8A Electrical - Body and Chassis for information on

electrical fault diagnosis.

W as any fault found and rectified? Go to Step 10 Go to Step 9

7 1 Test or inspect for the following conditions that may cause the

HO2S to detect an incorrect air / fuel mixture:

− lean or rich fuel injector fuel delivery,

− restricted air intake system,

− contaminated fuel,

− low fuel line pressure,

− exhaust leak near the HO2S, and

− leak in the crankcase or vacuum line.

W as any fault found and rectified? Go to Step 10 Go to Step 8

8 1 Replace the appropriate HO2S. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

W as the repair completed? Go to Step 10 —

9 1 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 10 —

10 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any HO2S reference circuit DTC fail this ignition cycle? Go to Step 2 Go to Step 11

11 1 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.11 DTC P0133 or P0153

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P0133 – HO2S Circuit Slow Response – Bank 1 Sensor 1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007