ESP ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4094 of 6020

ON-VEHICLE SERVICE (AW30–40LE) 7A3-9

Manual Shifting Test

NOTE: W ith this test, it can be determined whether the

trouble lies within the electrical circuit or is a mechanical

problem in the transmission.

1. Disconnect TCM connector

2. Inspect manual driving operation

Check that the relation of the position between

select lever and gear corresponds to the following

table.

If any abnormality is found in the above test, do

perform the stall, time lag or gear shift tests.

RTW 77ASH002901

3. Connect TCM connector

W ith the engine off, connect the TCM connector.

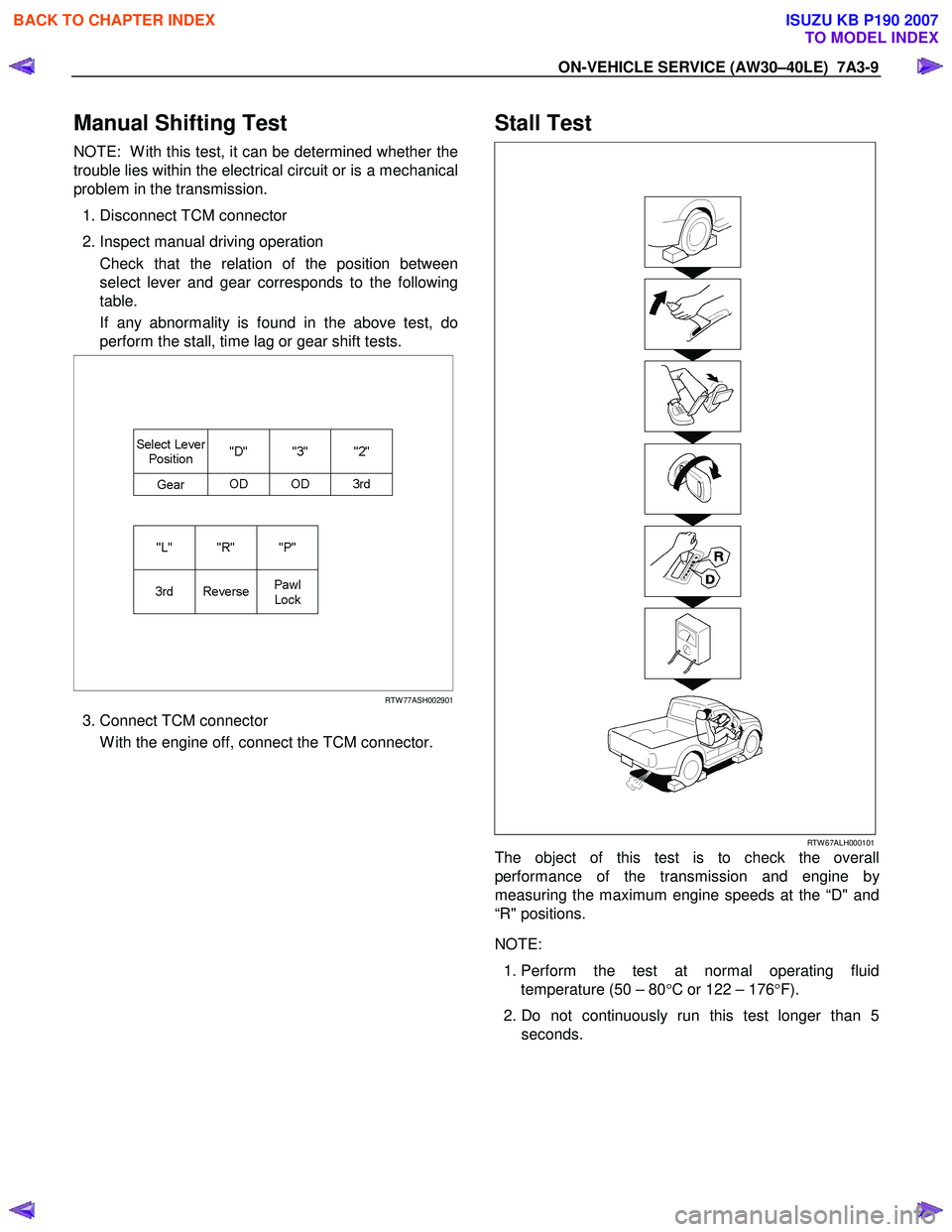

Stall Test

RTW 67ALH000101

The object of this test is to check the overall

performance of the transmission and engine b

y

measuring the maximum engine speeds at the “D" and

“R" positions.

NOTE:

1. Perform the test at normal operating fluid

temperature (50 – 80 °C or 122 – 176 °F).

2. Do not continuously run this test longer than 5 seconds.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4171 of 6020

7A4–36 UNIT REPAIR (AW30–40LE)

Diaassembly, Inspection and

Reassembly of minor Components

NOTE: The instructions here are organized so that you

work on only one component group at a time.

This will help avoid confusion from similar-looking parts

of different subassemblies being on your workbench at

the same time.

The component groups are inspected and repaired from

the converter housing side.

As much as possible, complete the inspection, repair

and reassembly before proceeding to the next

component group. If a component group cannot be

reassembled because parts are being ordered, be sure

to keep all parts of that group in separate container

while proceeding with disassembly, inspection, repair

and reassembly of other component groups.

Recommended ATF type DEXRON III.

General Cleaning Notes:

1. All disassembled parts should be washed clean and any fluid passages and holes should be blown

through with compressed air.

2. When using compressed air to dry parts, always aim away from yourself to prevent accidentally spraying

automatic transmission fluid in your face.

3. The recommended automatic transmission fluid should be used for cleaning.

Parts Arrangement:

1. After cleaning, the parts should be arranged inproper order to allow performing inspection, repairs,

and reassembly with efficiency.

2. When disassembling a valve body, be sure to keep each valve together with the corresponding spring.

3. New brakes and clutches that are to be used for replacement must be soaked in transmission fluid

for at least thirty minutes before assembly.

General Assembly:

1. All oil seal rings, clutch discs, clutch plates, rotating parts, and sliding surfaces should be coated with

transmission fluid prior to reassembly.

2. All gaskets and rubber O-ring should be replaced.

3. Make sure that the ends of a snap ring are not aligned with one of the cutouts and are installed in

the groove correctly.

4. If a worn bushing is to be replaced, the subassembly containing that bushing must be

replaced.

5. Check thrust bearings and races for wear or damage. Replace if necessary.

6. Use petroleum jelly or vaseline to keep parts in place.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4253 of 6020

7A1-14 CONSTRUCTION AND FUNCTION

CONTROL VALVE

• Employing the direct electronic control (Direct Electronic Shift Control: DESC) for the clutch pressure has

simplified the oil pressure circuit, reduced the number of functional components and made the control

valve compact.

• The control valve body is divided into the upper body and the lower body. All solenoids, the oil pressure

switch and the ATF thermo sensor are installed to the lower body.

• Three-way valve type solenoids providing high responsibility are employed. Some of the solenoids are

switched between ON and OFF, and others repeat ON and OFF at 50Hz (duty cycle system).

Functionally, some supply output pressure when power is not supplied, and others drain the output

pressure.

• When the solenoid is driven based on the signal from the TCM, the oil pressure is changed.

Figure 22. Construction of Valve Body

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4254 of 6020

CONSTRUCTION AND FUNCTION 7A1-15

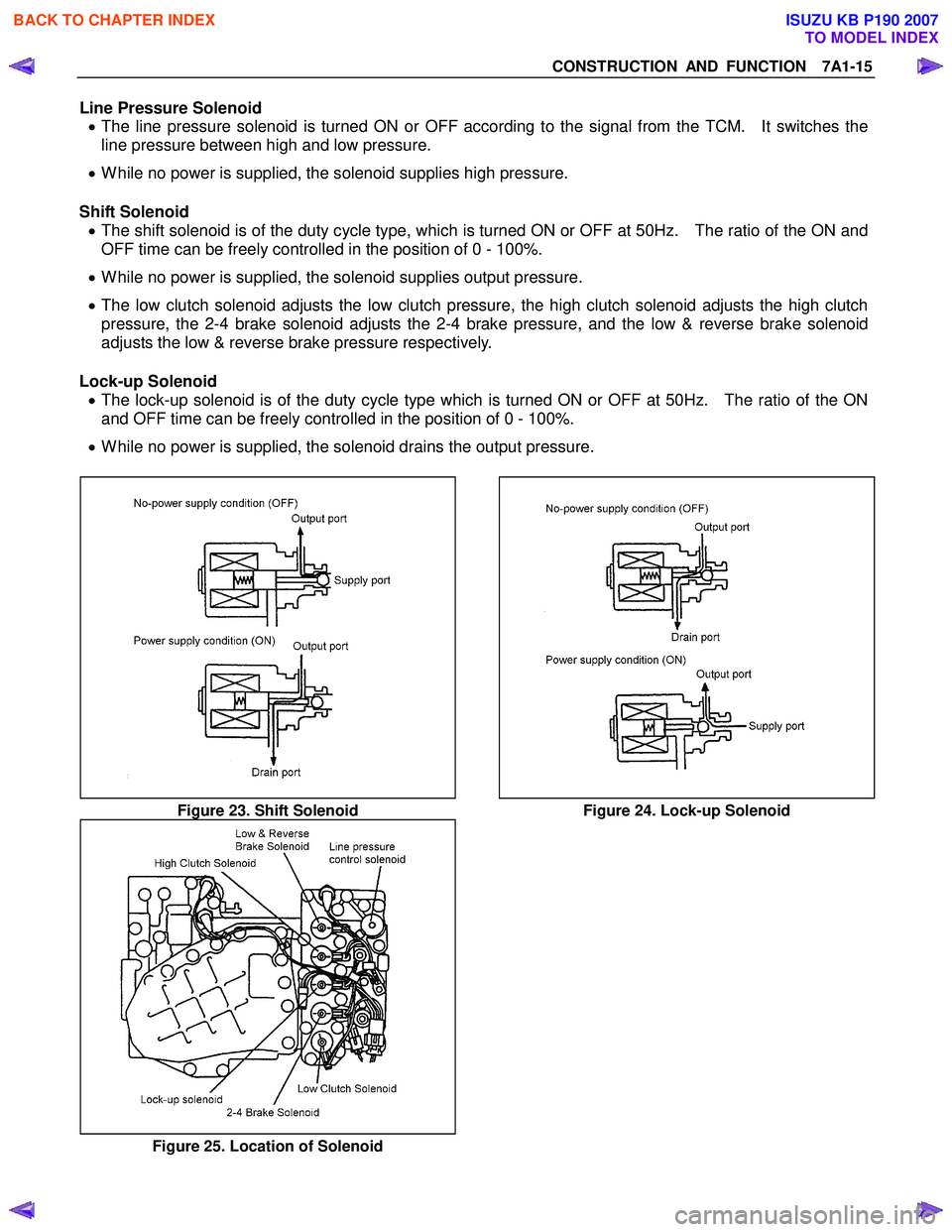

Line Pressure Solenoid • The line pressure solenoid is turned ON or OFF according to the signal from the TCM. It switches the

line pressure between high and low pressure.

• While no power is supplied, the solenoid supplies high pressure.

Shift Solenoid • The shift solenoid is of the duty cycle type, which is turned ON or OFF at 50Hz. The ratio of the ON and

OFF time can be freely controlled in the position of 0 - 100%.

• While no power is supplied, the solenoid supplies output pressure.

• The low clutch solenoid adjusts the low clutch pressure, the high clutch solenoid adjusts the high clutch

pressure, the 2-4 brake solenoid adjusts the 2-4 brake pressure, and the low & reverse brake solenoid

adjusts the low & reverse brake pressure respectively.

Lock-up Solenoid • The lock-up solenoid is of the duty cycle type which is turned ON or OFF at 50Hz. The ratio of the ON

and OFF time can be freely controlled in the position of 0 - 100%.

• While no power is supplied, the solenoid drains the output pressure.

Figure 23. Shift Solenoid Figure 24. Lock-up Solenoid

Figure 25. Location of Solenoid

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4255 of 6020

7A1-16 CONSTRUCTION AND FUNCTION

Control Valve Fail-safe Function • To prevent interlocking due to engagement of more than three clutches and brakes at the same time, the

2-4 brake fail-safe valve A and B, and the low & reverse brake fail-safe valve A and B are provided.

• When oil pressure is generated in the high clutch and the low clutch, the 2-4 brake solenoid is turned ON

to drain the oil pressure applied to the 2-4 brake.

• When oil pressure is generated in the high clutch or 2-4 brake, the low & reverse brake solenoid is turned

ON to drain the oil pressure applied to the low & reverse brake.

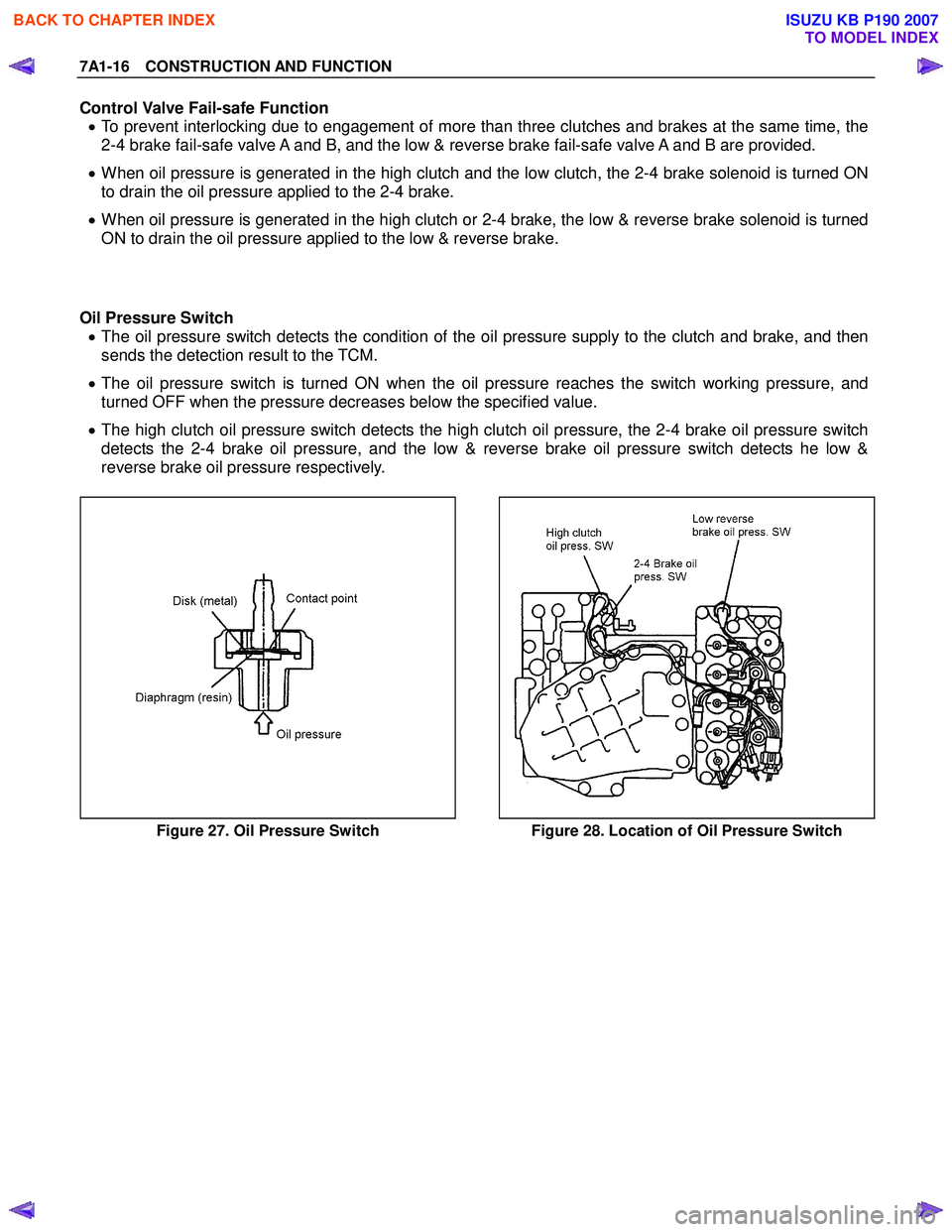

Oil Pressure Switch • The oil pressure switch detects the condition of the oil pressure supply to the clutch and brake, and then

sends the detection result to the TCM.

• The oil pressure switch is turned ON when the oil pressure reaches the switch working pressure, and

turned OFF when the pressure decreases below the specified value.

• The high clutch oil pressure switch detects the high clutch oil pressure, the 2-4 brake oil pressure switch

detects the 2-4 brake oil pressure, and the low & reverse brake oil pressure switch detects he low &

reverse brake oil pressure respectively.

Figure 27. Oil Pressure Switch Figure 28. Location of Oil Pressure Switch

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4270 of 6020

CONSTRUCTION AND FUNCTION 7A1-31

As a result, the lock-up piston is fitted slowly to the converter cover under pressure securing smooth lock-

up engagement.

Figure 51. Lock-up Control

DIRECT ELECTRIC SHIFT CONTROL (DESC)

Feature

• Based on each switch signal (low & reverse brake pressure, 2-4 brake pressure & high clutch pressure)

and each sensor signal (turbine sensor, speed sensor, engine speed signal & APP position signal), the

duty cycle type solenoid adjusts the clutch pressure to match the engine load and vehicle travel

conditions. Controlling the engagement and disengagement of the clutch and brake pressure is directly

and accurately controlled via TCM, which is different to the previous accumulator type.

Operation

• Instead of the previous system (on/off type of shift solenoid and shift valve), the combination of the duty

cycle type solenoid and the amplifier (Amp) valve are used to adjust the clutch pressure to match the

engine load and vehicle travel conditions, based on the signal from the TCM. Also, the pressure switch

provided in the oil passage of the control valve transmits the oil pressure condition (at that time) to TCM,

enabling the engagement and disengagement control of the clutch and brake to be directly and finely

carried out.

• When the gear is shifted from the 2nd to 3rd, 3rd to 4th (O/D), 4th (O/D) to 3rd and 3rd to 2nd, the clutch

pressures on the engagement side and disengagement side are simultaneously controlled.

As a result, engine racing or clutch drag is prevented which enables a smooth and quick shift response.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4395 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-111

D2: Gearshift Frequently

Diagnosis Hints• When inspecting faulty gear shifting, it is important to distinguish between

the fault of the electric system and transmission main unit.

• Fault of electric system. - Monitor the output signal (each solenoid driving signal) using a scan tool. If a trouble signal is sent to the solenoid synchronously with the faulty

gear shifting, the fault is originated in the electric system.

- Monitor the input signal (signal from each sensor) using a scan tool and find an input signal which has an output signal (each solenoid driving

signal) subjected to a fault.

- Fault of the electric system may be derived from temperature or vibration. For instance, although the engine is normal while it is cold, fault may

occur when the engine is warmed up or the vehicle is running.

• Fault of mechanical system. - If the gear is incorrectly shifted, irrespective of the operating signal (On/ Off) of each solenoid, the fault is originated from the transmission main

unit.

- If the clutch slips, or the transmission fluid smells burnt or is contaminated or black, or the stall speed increases. Gear ratio error DTC might be set.

Transmission Range Switch & Selector

Lever Cable Checks Inspect the transmission range switch and selector lever cable for misadjusting

or disordering. Refer to On-Vehicle Service section.

Transmission Fluid Checks Inspect the transmission fluid for the following conditions. If the transmission fluid

is extremely blacked, contaminated or smells burnt, slipping of clutch is

suspected.

• Low quantity

• Contamination

•Smell

Line Pressure Checks Inspect the line pressure in forward ranges for a possible dropped pressure.

Refer to Line Pressure Test in Test Instruction section.

Stall Speed Checks Inspect the stall speed in forward ranges. Refer to Stall Test in Test Instruction

section.

Control Valve Body Checks Inspect the valve body for the following conditions.

• Faulty operation

• Sticking spool valve

• Sticking shift solenoid valve. Perform function check. Refer to On-Vehicle Service section.

• Faulty operation of transmission fluid pressure switch. Perform function check. Refer to On-Vehicle Service section.

• Clogged hydraulic circuit

Checks

Action

Checks Action

Definition:

Shift down or engine overrun occurs above than kick-down area.

Diagnosis Hints The same causes as in category No. “C1 - C8: Engine Race Up (Slipping)” are

suspected.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4432 of 6020

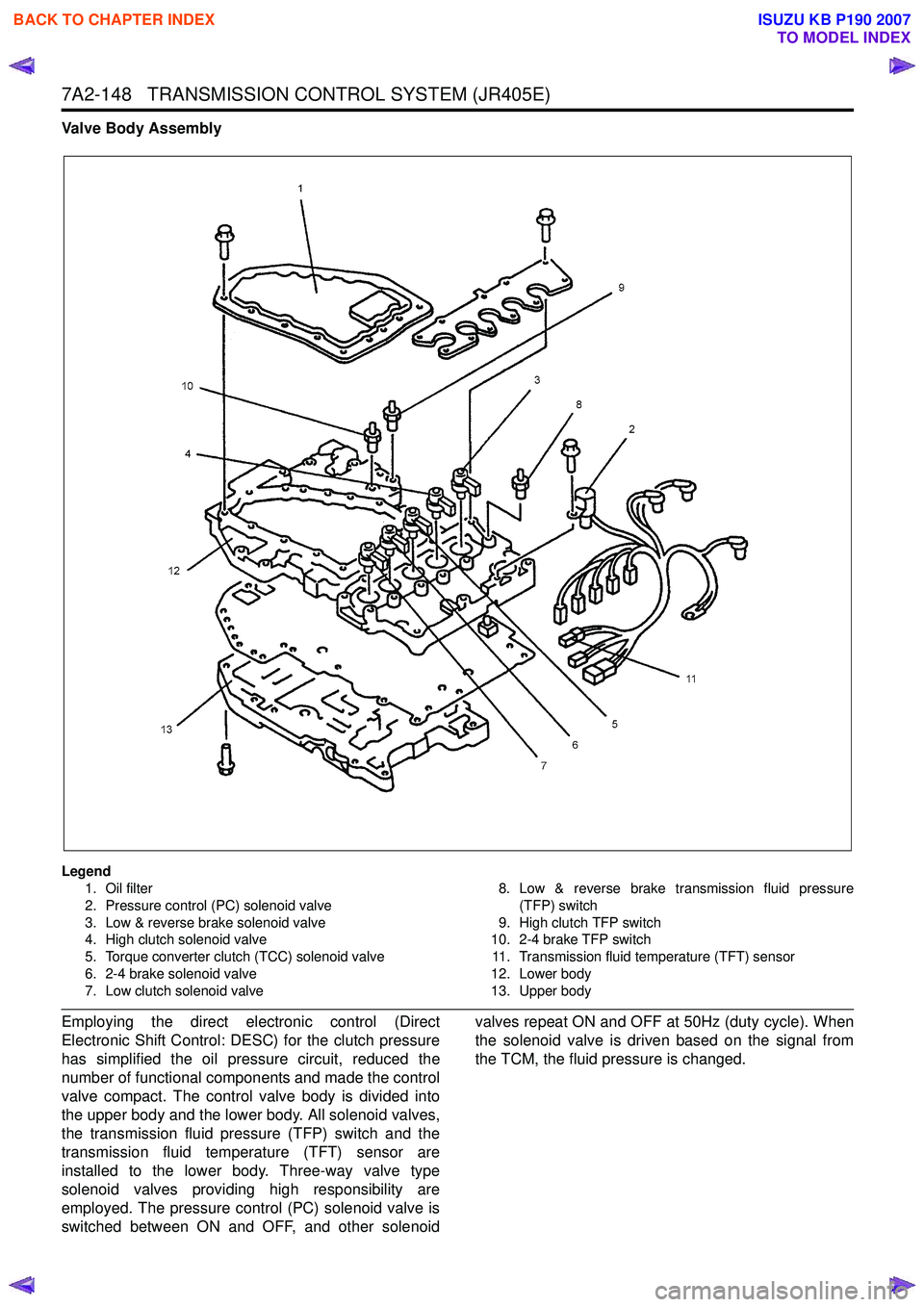

7A2-148 TRANSMISSION CONTROL SYSTEM (JR405E)

Valve Body Assembly

Legend1. Oil filter

2. Pressure control (PC) solenoid valve

3. Low & reverse brake solenoid valve

4. High clutch solenoid valve

5. Torque converter clutch (TCC) solenoid valve

6. 2-4 brake solenoid valve

7. Low clutch solenoid valve 8. Low & reverse brake transmission fluid pressure

(TFP) switch

9. High clutch TFP switch

10. 2-4 brake TFP switch

11. Transmission fluid temperature (TFT) sensor

12. Lower body

13. Upper body

Employing the direct electronic control (Direct

Electronic Shift Control: DESC) for the clutch pressure

has simplified the oil pressure circuit, reduced the

number of functional components and made the control

valve compact. The control valve body is divided into

the upper body and the lower body. All solenoid valves,

the transmission fluid pressure (TFP) switch and the

transmission fluid temperature (TFT) sensor are

installed to the lower body. Three-way valve type

solenoid valves providing high responsibility are

employed. The pressure control (PC) solenoid valve is

switched between ON and OFF, and other solenoid valves repeat ON and OFF at 50Hz (duty cycle). When

the solenoid valve is driven based on the signal from

the TCM, the fluid pressure is changed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4433 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-149

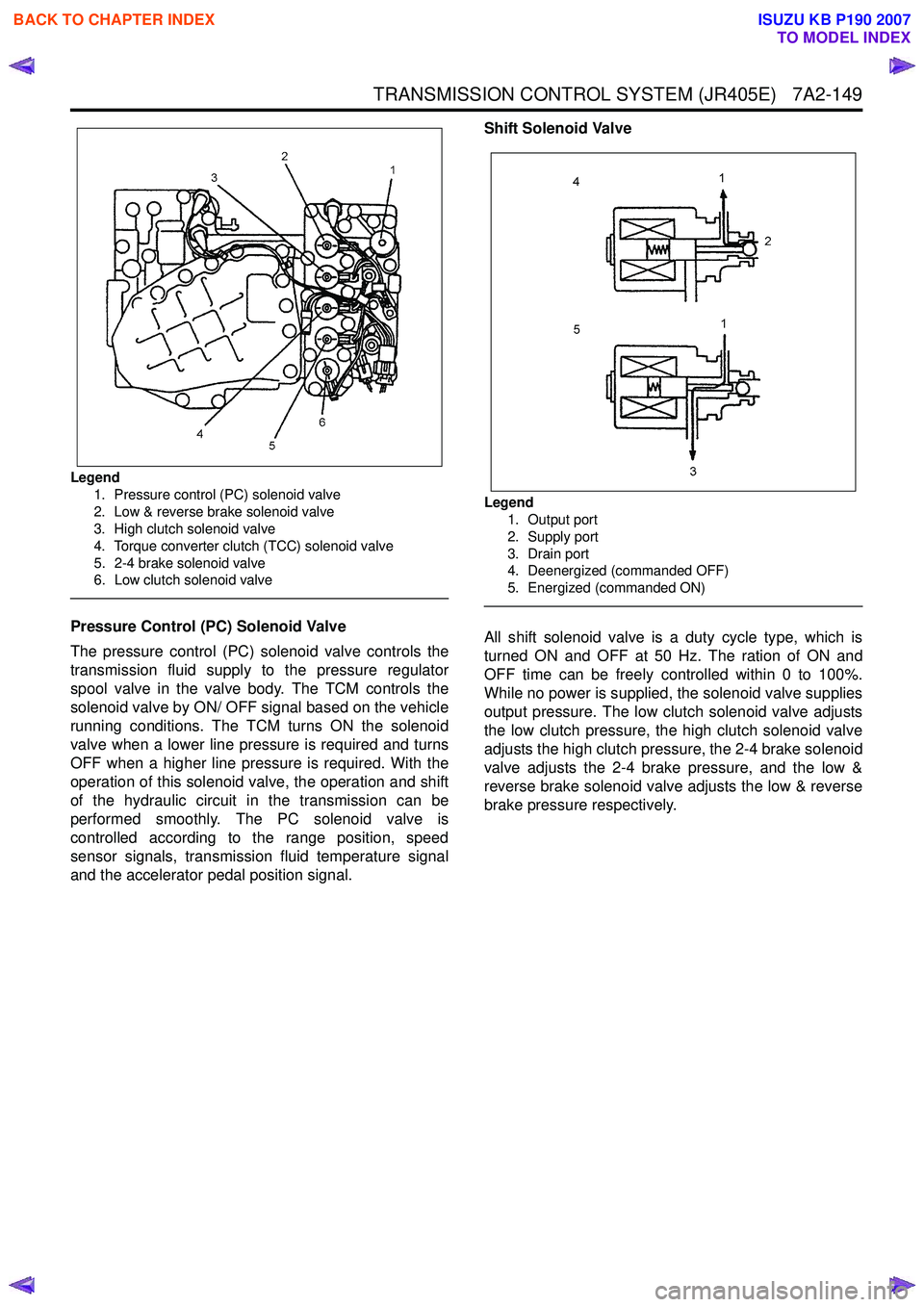

Legend1. Pressure control (PC) solenoid valve

2. Low & reverse brake solenoid valve

3. High clutch solenoid valve

4. Torque converter clutch (TCC) solenoid valve

5. 2-4 brake solenoid valve

6. Low clutch solenoid valve

Pressure Control (PC) Solenoid Valve

The pressure control (PC) solenoid valve controls the

transmission fluid supply to the pressure regulator

spool valve in the valve body. The TCM controls the

solenoid valve by ON/ OFF signal based on the vehicle

running conditions. The TCM turns ON the solenoid

valve when a lower line pressure is required and turns

OFF when a higher line pressure is required. With the

operation of this solenoid valve, the operation and shift

of the hydraulic circuit in the transmission can be

performed smoothly. The PC solenoid valve is

controlled according to the range position, speed

sensor signals, transmission fluid temperature signal

and the accelerator pedal position signal. Shift Solenoid Valve

Legend

1. Output port

2. Supply port

3. Drain port

4. Deenergized (commanded OFF)

5. Energized (commanded ON)

All shift solenoid valve is a duty cycle type, which is

turned ON and OFF at 50 Hz. The ration of ON and

OFF time can be freely controlled within 0 to 100%.

While no power is supplied, the solenoid valve supplies

output pressure. The low clutch solenoid valve adjusts

the low clutch pressure, the high clutch solenoid valve

adjusts the high clutch pressure, the 2-4 brake solenoid

valve adjusts the 2-4 brake pressure, and the low &

reverse brake solenoid valve adjusts the low & reverse

brake pressure respectively.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4434 of 6020

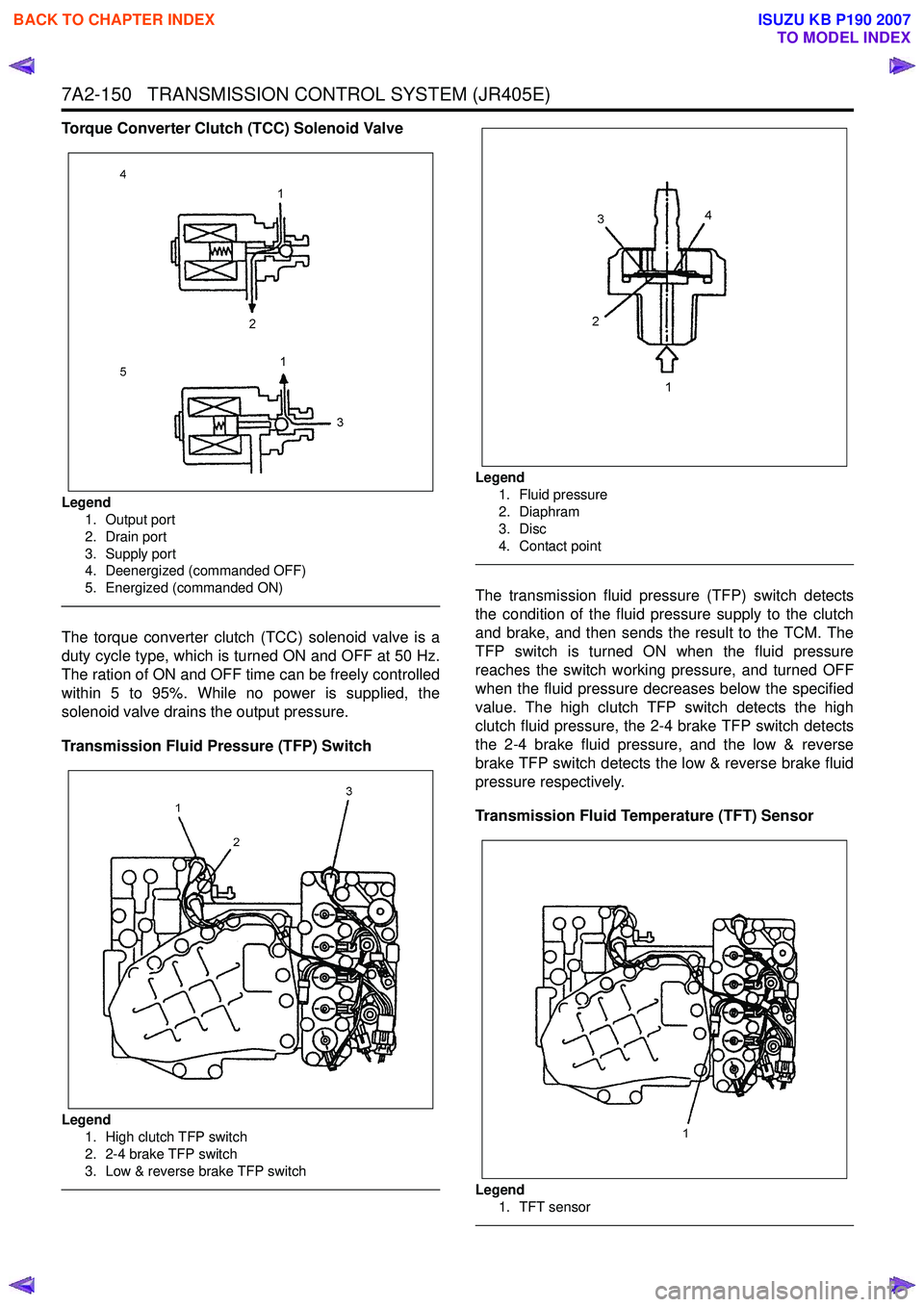

7A2-150 TRANSMISSION CONTROL SYSTEM (JR405E)

Torque Converter Clutch (TCC) Solenoid Valve

Legend1. Output port

2. Drain port

3. Supply port

4. Deenergized (commanded OFF)

5. Energized (commanded ON)

The torque converter clutch (TCC) solenoid valve is a

duty cycle type, which is turned ON and OFF at 50 Hz.

The ration of ON and OFF time can be freely controlled

within 5 to 95%. While no power is supplied, the

solenoid valve drains the output pressure.

Transmission Fluid Pressure (TFP) Switch

Legend 1. High clutch TFP switch

2. 2-4 brake TFP switch

3. Low & reverse brake TFP switch

Legend

1. Fluid pressure

2. Diaphram

3. Disc

4. Contact point

The transmission fluid pressure (TFP) switch detects

the condition of the fluid pressure supply to the clutch

and brake, and then sends the result to the TCM. The

TFP switch is turned ON when the fluid pressure

reaches the switch working pressure, and turned OFF

when the fluid pressure decreases below the specified

value. The high clutch TFP switch detects the high

clutch fluid pressure, the 2-4 brake TFP switch detects

the 2-4 brake fluid pressure, and the low & reverse

brake TFP switch detects the low & reverse brake fluid

pressure respectively.

Transmission Fluid Temperature (TFT) Sensor

Legend

1. TFT sensor

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007