check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3990 of 6020

7A2-24 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

TRANSMISSION DATA

Scan Tool Parameter Units Displayed Typical Data Value at Engine Idle

Operating Conditions: Engine idling/ Engine coolant temperature is between 75 to 85 °C(167 to 185 °F)/

Accelerator pedal is constant/ Neutral or Park/ Accessories OFF/ Vehicle located at sea level

Engine Coolant temperature °C/ °F 75 to 85°C (167 to 185 °F)

Engine Speed RPM 700

Vehicle Speed Km/h / MPH 0

Ignition Voltage V 13.6

Accelerator Pedal Position Signal % 0

Throttle Position % 0

Accelerator Pedal Position Signal

During Cruise Control % 0

Cruise Control

Inactive / Active Inactive

Cruise Control OD Cancel Request ON / OFF OFF

Engine W arm Up Cycle Achieved FALSE / TRUE FALSE

Transmission Shift in Progress Inactive / Active Inactive

Garage Shift Control Inactive / Active Inactive

MIL Request Command ON / OFF OFF

Transmission Check Light ON / OFF OFF

Transmission Oil Temperature Lamp ON / OFF OFF

Power Drive Lamp ON / OFF OFF

3rd Start Lamp ON / OFF OFF

Transmission Fluid Temperature

°C/ °F 70 to 80°C (158 to 176 °F)

AT Input Speed RPM 625

AT Output Speed RPM 0

Transmission Range Park / Reverse /

Neutral / Drive 4 / Drive 3 / Drive 2 / Drive 1 Park

TR Switch P

ON / OFF ON

TR Switch R ON / OFF OFF

TR Switch N ON / OFF OFF

TR Switch D ON / OFF OFF

TR Switch 3 ON / OFF OFF

TR Switch 2 ON / OFF OFF

TR Switch L ON / OFF OFF

Diagnostic Switch Open / Close Open

Brake Pedal Switch ON / OFF OFF

Power Drive Switch ON / OFF OFF

3rd Start Switch ON / OFF OFF

4 W heel Drive Low ON / OFF OFF

Shift Solenoid 1 Command ON / OFF ON

Shift Solenoid 2 Command ON / OFF OFF

TCC Solenoid Engaged / Disengaged Disengaged

Downhill Mode Inactive / Active Inactive

Active Shift Mode Normal Mode /

Power Mode /

3rd Gear Start /

Transfer 4L MODE Hot 1 / Hot 2 /

UPHILL MODE 1 /

UPHILL MODE 2 / Cruise MODE /

W arm Up MODE Normal Mode

Estimated Gear Ratio

:1 7.97 : 1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3996 of 6020

7A2-30 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

Service Programming System (SPS)

The procedure to program the control unit by using the

Service Programming System (SPS) software

contained in TIS2000 is explained below.

NOTE: • Should Tech2 display “SPS Procedure was not

successful”, engine will not start, but no DTCs are

present, low battery voltage or poor electrical

connections should be the primary suspects.

Perform the SPS procedure again after rectifying

the fault/s.

IMPORTANT:

Perform the following checks before attempting to

program the control unit:

•

••

•

The Tech2 PCMCIA card is programmed with

the latest software release.

•

••

•

The latest release of TIS2000 is loaded on the

PC.

•

••

•

The vehicle battery is fully charged.

•

••

•

The control unit to be programmed is

connected to the vehicle.

1. Preparations of TIS 2000

1. Connect Tech 2 to P/C.

2. Check to see if Hardware Key is plugged into Port.

3. Activate TIS 2000 by P/C.

4. On the activating screen of TIS2000, choose

“Service Programming System”.

5. On the screen of “Diagnostic Tester and

Processing Program Selection”, choose the one

that will comply with the following.

• Diagnostic tester in use

• New programming by the existing module or ne

w

programming by the replaced/new module.

• Fixing position of the control unit.

6. Upon completion of the selection, push the button

of “Continue”.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3997 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-31

2.Demand of Data

1. Connect Tech 2 to the vehicle. W hen activated b

y

turning on the power of Tech 2, push the "Enter"

switch.

2. Turn on the ignition switch (without starting the

engine)

3. In the main menu of Diagnostic Tester, push "F1:

Service Programming System (SPS)".

4. Push “F0: Request Info” of Tech 2.

5. W here vehicle data has been already saved in

Tech 2, the existing data come on display. In this

instance, as Tech 2 starts asking whether to keep

the data or to continue obtaining a new data from

the control unit, choose either of them.

6. If you select “continue”, you have to select “Model

Year”, “Vehicle Type”, “Controller Type (Engine)”.

7.

After that. then push button and turn Ignition switch

tuned on, off, on following Tech 2 display. Tech 2

will read information from controller after this

procedure.

8. During obtaining information, Tech 2 is receiving

information from the control unit chosen. In

replacing the control unit, please be sure to

undertake “Obtaining Information” from the ne

w

unit. W ith VIN not being programmed into the new

control unit at the time of shipment, "obtaining

information" is not complete (because the vehicle

model, engine model and model year are specified

from VIN). For the procedure get additional

information on vehicles, instruction will be provided

in dialog form, when TIS2000 is in operation.

9. Following instructions by Tech 2, push the “Exit”

switch of Tech 2, turn off the ignition of the vehicle

and turn off the power of Tech 2, thereby removing

from the vehicle.

3.Data Exchange

1. Connect Tech 2 to P/C, turn on the power and

click the “Next” button of P/C.

2. Check VIN of the vehicle and choose “Next”.

3. W hen a lack of data is asked from among the

following menu, enter accordingly.

Select following Menu

• Model Year

• Model

• Engine type

• Transmission type

• Destination code (vehicles for general export)*1

• Immobiliser

* 1: How to read the destination code

"Destination code can be read from ID Plate affixed on

vehicles, while on VIN plate the destination code is

described at the right-hand edge of Body Type line. In

Fig.-3, the destination code can be read as “EK4”

(Europe).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3998 of 6020

7A2-32 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

4. After choosing the data, click the “Next” button.

5. W hen all the necessary information is entered, the

“details” of software within the database that match

the entered data will appear for confirmation. Click

the “Program” switch and then download the ne

w

software onto Tech 2.

6. “Data Transfer” comes on display. The progress o

f

downloading will be displayed on the screen in the

form of bar graph.

7. Upon finishing the data transfer, turn off the powe

r

of Tech-2, removing from P/C.

4. Programming of TCM 1. Check to see if batteries are fully charged.

2. Connect Tech 2 to Vehicle Diagnostic Connectors.

3. Turn on the power of Tech 2 and the title screen

comes on display.

4. Turn on the ignition (without allowing the engine to

start)

5. On the title screen of Tech 2, push the "Enter"

button.

6. Choose “F: Service Programming System” on the

main screen and then choose “F1: Programming”.

7. W hile data is being transferred, “Downloading” will

be displayed on the Tech 2 screen.

8. Upon finishing the data transfer, Tech 2 will displa

y

“Reprogramming Successful”. Push the “Exit”

button to bring program to completion.

9. Following “Procedure 2: Demand of Data”, try ove

r

again "Information Obtaining" and check to confirm

if the data has been correctly re-loaded.

10. Upon finishing confirmation, turn off the ignition o

f

the vehicle and then turn off the power of Tech 2,

removing from the vehicle.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4005 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-39

Diagnostic Trouble Code (DTC) Type

Definitions

Emission Related DTC

Action Taken When the DTC Sets - Type A

• The Engine Control Module (ECM) illuminates the

malfunction indicator lamp (MIL) when the

diagnostic runs and fails.

• The ECM records the operating conditions at the

time the diagnostic fails. The ECM stores this

information in the Freeze Frame/ Failure Records.

Action Taken When the DTC Sets - Type B

• The ECM illuminates the MIL on the second

consecutive driving cycle when the diagnostic runs

and fails.

• The ECM records the operating conditions at the

time the diagnostic fails, the ECM stores this

information in the Failure Records. If the

diagnostic reports a failure on the second

consecutive driving cycle, the ECM records the

operating conditions at the time of failure and

stores this information in the Freeze Frame and

updates the Failure Records.

Conditions for Clearing the MIL/ DTC - Type A o

r

Type B • The ECM turns OFF the MIL after 3 consecutive

driving cycles when the diagnostic runs and does

not fail. (Euro 4 Specification)

• The ECM turns OFF the MIL after 1 driving cycle

when the diagnostic runs and does not fail.

(Except Euro 4 Specification)

•

A current DTC clears when the diagnostic runs

and passes after 1 driving cycle.

• A history DTC clears after 40 consecutive warm-

up cycles, if no failures are reported.

• Use a scan tool to clear the MIL and the DTC.

Non-Emissions Related DTCs

Action Taken When the DTC Sets - Type C or Type

D

• The TCM illuminates the Check Trans lamp when

the diagnostic runs and fails.

• The TCM records the operating conditions at the

time the diagnostic fails. The TCM stores this

information in the Failure Records.

• The TCM illuminates the Check Trans on the

second consecutive driving cycle when the

diagnostic runs and fails.

• The TCM records the operating conditions at the

time the diagnostic fails, the TCM stores this

information in the Failure Records. If the

diagnostic reports a failure on the second

consecutive driving cycle, the TCM records the

operating conditions at the time of failure and

stores this information in the Freeze Frame and

updates the Failure Records.

Conditions for Clearing the Check Trans Lamp/ DTC

- Type C or Type D

• The TCM turns OFF the Check Trans lamp after 1

driving cycle when the diagnostic runs and does

not fail.

•

A current DTC clears when the diagnostic runs

and passes after 3 driving cycle.

• A history DTC clears after 40 consecutive warm-

up cycles, if no failures are reported.

• Use a scan tool to clear the Check Trans lamp and

the DTC.

Action Taken When the DTC Sets - Type E or Type F • The TCM will not illuminate the Check Trans lamp.

• The TCM records the operating conditions at the

time the diagnostic fails. The TCM stores this

information in the Failure Records.

Conditions for Clearing the DTC - Type E or Type F •

A current DTC clears when the diagnostic runs

and passes after 1 driving cycle.

• A history DTC clears after 40 consecutive warm-

up cycles, if no failures are reported.

• Use a scan tool to clear the DTC.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4007 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-41

• All of the following conditions are met.

- Device Control is not operating

- Disable Normal Communication Service is receiving enable

- DTC Clear is not operating

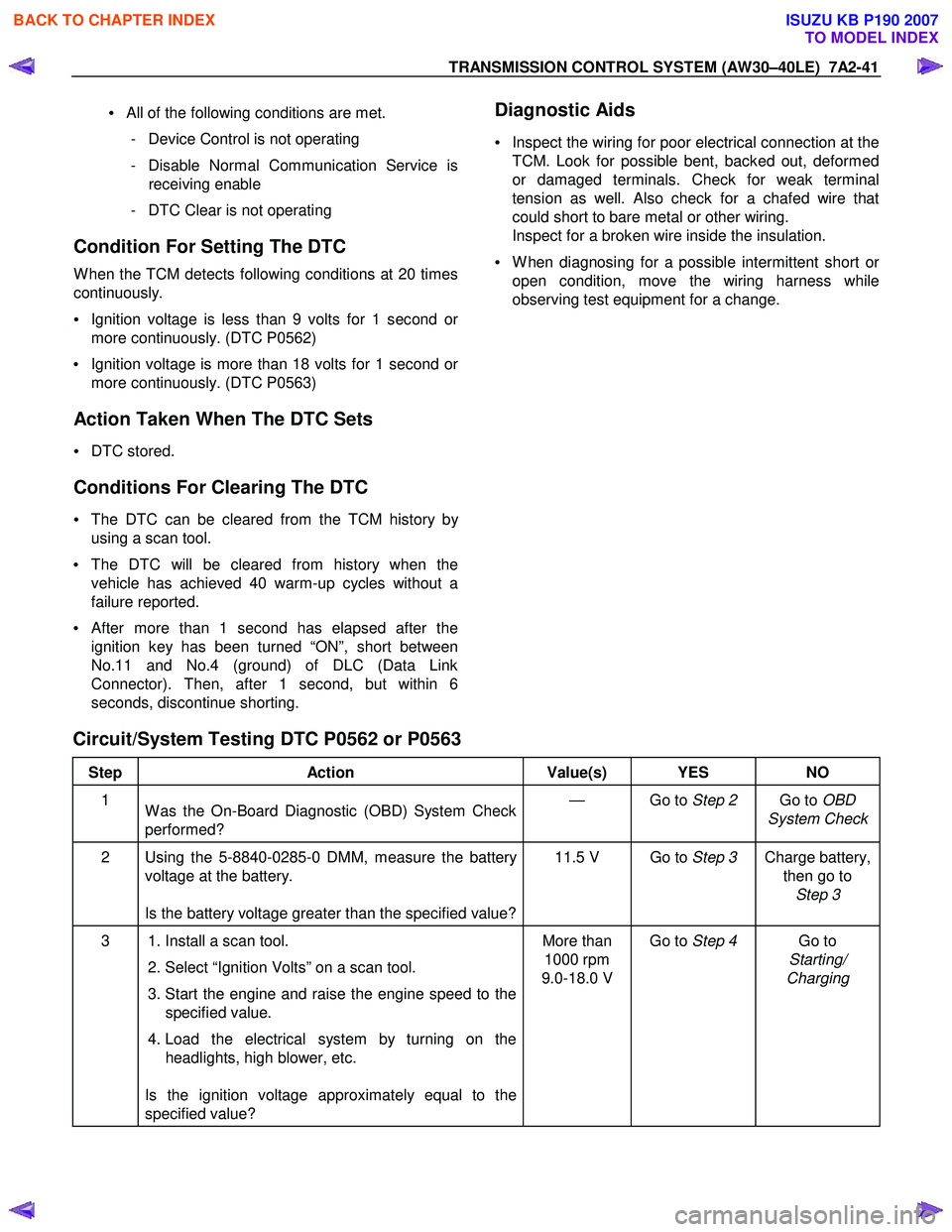

Condition For Setting The DTC

W hen the TCM detects following conditions at 20 times

continuously.

• Ignition voltage is less than 9 volts for 1 second o

r

more continuously. (DTC P0562)

• Ignition voltage is more than 18 volts for 1 second o

r

more continuously. (DTC P0563)

Action Taken When The DTC Sets

• DTC stored.

Conditions For Clearing The DTC

• The DTC can be cleared from the TCM history by

using a scan tool.

• The DTC will be cleared from history when the

vehicle has achieved 40 warm-up cycles without a

failure reported.

•

After more than 1 second has elapsed after the

ignition key has been turned “ON”, short between

No.11 and No.4 (ground) of DLC (Data Link

Connector). Then, after 1 second, but within 6

seconds, discontinue shorting.

Diagnostic Aids

•

Inspect the wiring for poor electrical connection at the

TCM. Look for possible bent, backed out, deformed

or damaged terminals. Check for weak terminal

tension as well. Also check for a chafed wire that

could short to bare metal or other wiring.

Inspect for a broken wire inside the insulation.

• W hen diagnosing for a possible intermittent short o

r

open condition, move the wiring harness while

observing test equipment for a change.

Circuit/System Testing DTC P0562 or P0563

Step Action Value(s) YES NO

1

W as the On-Board Diagnostic (OBD) System Check

performed? — Go to

Step 2 Go to OBD

System Check

2 Using the 5-8840-0285-0 DMM, measure the battery voltage at the battery.

Is the battery voltage greater than the specified value? 11.5 V Go to

Step 3 Charge battery,

then go to Step 3

3 1. Install a scan tool.

2. Select “Ignition Volts” on a scan tool.

3. Start the engine and raise the engine speed to the specified value.

4. Load the electrical system by turning on the headlights, high blower, etc.

Is the ignition voltage approximately equal to the

specified value? More than

1000 rpm

9.0-18.0 V Go to

Step 4 Go to

Starting/

Charging

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4008 of 6020

7A2-42 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

Step Action Value(s) YES NO

4 1. Turn “OFF” the ignition. 2. Disconnect the TCM connector at the TCM.

3. Using the 5-8840-0285-0 DMM, measure the battery voltage between the TCM connector

terminal C94 (Pin No.24)

Is it approximately equal to battery voltage? — Check for

excessive

current with

ignition “OFF”

engine “OFF”. Go to

Step 5

5 1. Check for faulty connections at the TCM harness

terminals.

2. Repair as necessary.

W as a repair necessary? — Go to

Step 8 Go to Step 6

6 1. Check for an open battery feed circuit to the TCM.

2. Repair as necessary.

W as a repair necessary? — Go to

Step 8 Go to Step 7

7 Replace the TCM.

Important: The replacement TCM must be

programmed. (Refer to SPS for procedure.)

W as the action complete? — Go to

Step 8 —

8 1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with a scan tool.

3. Turn “OFF” the ignition.

4. Start the engine.

5. Operate the vehicle within the Conditions For Running the DTC. You may also operate the

vehicle within the conditions that you observed

from the Freeze Frame/ Failure Records.

Did the DTC fail this ignition? — Go to

Step 2 Go to Step 9

9 Observe the stored information, Capture Info with a

scan tool.

Are there any DTCs that you have not diagnosed? — Go

to

Diagnostic

Trouble Code (DTC) List Verify repair

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4010 of 6020

7A2-44 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

Circuit/System Testing DTC P0602

Step Action Value(s) YES NO

1

W as the “On-Board Diagnostic (OBD) System Check”

performed? — Go to

Step 2 Go to OBD

System Check

2 1. Install a scan tool.

2. Turn “ON” the ignition.

3. Check the Vehicle Identification Number (VIN) by the scan tool.

Is VIN on the scan tool same as VIN of vehicles? — Go to

Step 4 Go to Step 3

3 W rite a VIN by a scan tool. (Refer to SPS for

procedure.)

Is the action complete? — Go to

Step 4 —

4 Clear the DTC P0602 with a scan tool.

Is the action complete? — Go to

Step 5 —

5 Perform the SPS and perform security lock. (Refer to

SPS for procedure)

Is the action complete? — Go to

Step 6 —

6 Recheck the DTC with a scan tool.

1. Turn “OFF” the ignition.

2. W ait a few seconds.

3. Turn “ON” the ignition.

Does a scan tool indicate DTC P0602? — Go to

Step 7 Go to Step 8

7 Replace the TCM.

Important: The replacement TCM must be

programmed. (Refer to SPS for procedure.)

W as the action complete? — Go to

Step 8 —

8 1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with a scan tool.

3. Turn “OFF” the ignition.

4. Start the engine.

5. Operate the vehicle within the Conditions For Running the DTC. You may also operate the

vehicle within the conditions that you observed

from the Freeze Frame/ Failure Records.

Did the DTC fail this ignition? — Go to

Step 2 Go to Step 9

9 Observe the stored information, Capture Info with a

scan tool.

Are there any DTCs that you have not diagnosed? — Go

to

Diagnostic

Trouble Code (DTC) List Verify repair

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4012 of 6020

7A2-46 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

(2) Not emergency mode.

(3) All of the following conditions are met. • Device Control is not operating.

• Disable Normal Communication service is

receiving enable.

• DTC Clear is not operating.

Condition For Setting The DTC

DTC P0707

All of the following conditions are met for 30 seconds or

more continuously.

• All of the switches are “OFF”.

• Output revolution is more than 30 km/h (19 mph).

• Output revolution sensor is not detecting failure o

r

not deciding failure.

• The engine revolution is more than 1500 rpm.

DTC P0708

The following condition is met at 10 seconds

continuously.

• 2 switches or more are “ON” at the same time.

Action Taken When The DTC Sets

• No 3rd start mode.

• No slope control.

• No coast control.

• No output revolution sensor failure detection.

• No input revolution sensor failure detection.

• Keep oil temperature sensor OPEN failure detection accumulated timer.

• No T/F HI-Low SW failure detection.

• No shift solenoid functional failure detection.

• No L-up solenoid functional failure detection.

• No engine torque reduction at stall.

• Regard as D position. (DTC P0707)

• There is a priority in order of D, 3, 2, L, R, N, and P.

(DTC P0708)

• Check Trans “ON”.

• DTC stored.

• MIL request “ON”. (EURO 4 only)

Conditions For Clearing The DTC

•

The DTC can be cleared from the TCM history by

using a scan tool.

• The DTC will be cleared from history when the vehicle has achieved 40 warm-up cycles without a

failure reported.

•

After more than 1 second has elapsed after the

ignition key has been turned “ON”, short between

No.11 and No.4 (ground) of DLC (Data Link

Connector). Then, after 1 second, but within 6

seconds, discontinue shorting.

Diagnostic Aids

• Inspect the wiring for poor electrical connection at the

TCM. Look for possible bent, backed out, deformed

or damaged terminals. Check for weak terminal

tension as well. Also check for a chafed wire that

could short to bare metal or other wiring.

Inspect for a broken wire inside the insulation.

• W hen diagnosing for a possible intermittent short o

r

open condition, move the wiring harness while

observing test equipment for a change.

• Check neutral start switch for proper mounting and adjustment. (Refer to section 7A4 Components (1)

neutral start switch)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4013 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-47

Circuit/System Testing DTC P0707 or P0708

Step Action Value(s) YES NO

1

W as the On-Board Diagnostics (OBD) System check

performed? — Go to

Step 2 Go to OBD

System Check

2 1. Install a scan tool.

2. Turn “ON” the ignition, with the engine “OFF”.

3. Select each lever position: D, 3, 2, L, N, R and P.

Does each selected transmission position match the

“Transmission Range” display on a scan tool? — Refer to

Diagnostic Aids Go to

Step 3

3 Measure the voltage shifting the select lever every position, between TCM connector terminals and

ground which performed selecting to every position.

1. Turn “OFF” the ignition.

2. Disconnect the TCM connector.

3. Turn “ON” the ignition.

4. Connect the 5-8840-0285-0 DMM to the TCM

connector terminal and ground.

Is the displayed voltage at every position normal? 7~16V Go to

Step 8 Go to Step 4

4 Measure the voltage between terminals the neutral

start switch and ground.

1. Turn “OFF” the ignition.

2. Disconnect the inhibitor switch harness connector.

3. Turn “ON” the ignition.

4. Connect the 5-8840-0285-0 DMM to the each

terminal of the neutral start switch harness

connector E51-3 and ground.

If a problem was found, repair as necessary.

W as the problem found? 7~16V Go to

Step 9 Go to Step 5

5 Measure the resistance shifting the select lever to

every position, between terminal neutral start switch

connector E51-3 and E51 other terminal.

1. Turn “OFF” the ignition.

2. Disconnect the neutral start switch connector.

3. Connect the DMM to the each terminal of the neutral start switch connector E51-3 and E51-5

or E51-2 or E51-6, E51-8or E51-7or E51-9 or

E51-10.

If a problem was found repair as necessary.

W as the problem found? Less than

1

Ω

Go to Step 6 Go to Step 7

6 Replace the neutral start switch.

Is the action complete? — Go to

Step 9 —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007