wheel torque ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4471 of 6020

ON-VEHICLE SERVICE (JR405E) 7A3-17

Remove or Disconnect

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Drain the fluid.

Refer to “ATF CHANGE” in this section.

4. Remove the 19 bolts and oil pan.

5. Inspect the bottom of the oil pan and strainer netting for foreign material (clutch facing and metal

shavings).

If there is an excessive accumulation of foreign material, the oil strainer must be replaced.

Further inspection is required to determine the source of the foreign material.

6. Remove the harness assembly (including the oil temperature sensor).

7. Remove the 11 bolts and the solenoid fixing plate.

8. Remove the 6 solenoids and 3 oil pressure switches.

Inspect

Oil pressure switch

Apply compressed air (390 kPa/4.0 kgf/cm2/57 psi) to

the oil pressure switch to check the oil pressure switch

continuity between the connector and screw.

Replace the oil pressure switch if the result of inspection

is abnormal.

Oil temperature sensor (harness assembly)

Check the oil temperature sensor resistance between

harness terminals 7 and 6 (ground).

Oil temperature sensor resistance:

2,400~2,600 ohms (20 °

°°

°

C)

244L300011

Solenoid

Measure the resistance of each solenoid.

Resistance:

Brown connector – 3.0~3.4 ohms (20 °

°°

°

C)

Gray connector – 12.0~13.2 ohms (20 °

°°

°

C)

White connector – 12.2~13.4 ohms (20 °

°°

°

C)

Replace the solenoid if the result of inspection is

abnormal.

Install or connect

1. Install the O-rings to each of the solenoids.

2. Install the 6 solenoids and 3 oil pressure switches.

Line pressure solenoid bolt torque:

8 N·m (0.8 kgf·m/69 lb·in)

Oil pressure switch bolt torque:

4 N·m (0.4 kgf·m/35 lb·in)

3. Install the solenoid fixing plate together with the harness brackets.

Number Length (Color)

Solenoid fixing plate bolt

(A)

(B)

4

7

16 mm (0.63 in) (Gold)

45 mm (1.77 in) (Silver)

Bolt torque : 8 N·m (0.8 kgf·m/69 lb·in)

4. Install the harness assembly.

5. If removed, install the oil strainer.

Number Length (Color)

Oil strainer bolt

(C)

(D)

9

4

13 mm (0.51 in) (Silver)

45 mm (1.77 in) (Silver)

Bolt torque : 8 N·m (0.8 kgf·m/69 lb·in)

6. Install the new gasket and oil pan.

Bolt torque : 8 N·m (0.8 kgf·m/69 lb·in)

7. Fill the fluid.

Refer to “ATF CHANGE” in this section.

8. Connect the negative battery cable.

9. Remove the wheel blocks.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4473 of 6020

ON-VEHICLE SERVICE (JR405E) 7A3-19

Install or Connect

1. Align the manual valve and the manual plate of the

transmission case.

43ASSY119

2. Install the control valve assembly and tighten the 12 fixing bolts to the specified torque.

Number of bolts Length Color

10 (A) 40 mm (1.57 in) Gold

2 (B) 30 mm (1.18 in) Gold

Bolt torque : 8 N·m (0.8 kgf·m/69 lb·in)

3. Connect the 2 harness connectors.

4. If removed, install the oil strainer.

Refer to “Solenoids, Oil Pressure Switch and Oil Temperature Sensor” previously in this section.

5. Install the new gasket and oil pan.

Bolt torque : 8 N·m (0.8 kgf·m/69 lb·in)

6. Fill with the fluid.

Refer to “ATF CHANGE” in this section.

7. Connect the negative battery cable.

8. Remove the wheel blocks.

FLUSHING THE TRANSMISSION FLUID COOLER AND LINE

The fluid cooler and lines may be flushed under the

following condition. This will help prevent more trouble

after the transmission is repaired.

1. W hen an abnormal amount of debris is found.

2. W hen an abnormal wear or chips on gears and shafts is found while overhauling.

3. W hen there is abnormal clutch facing wear and oil contamination found.

Procedures

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Raise the vehicle and support it with suitable safet

y

stands.

4. Disconnect the fluid cooler lines at the transmission case and fluid cooler.

5. Flush and back-flush the fluid cooler and lines using solvent and compressed air.

Note:

DO NOT exceed (200 kPa/2.0 kgf/cm

2/28 psi) air

pressure, or damage may result to oil cooler.

6. Remove all remaining solvent from the system with

compressed air.

7. Flush the cooling system again with Automatic Transmission Fluid (ATF).

After the final flush, connect all lines.

Cooler line joint connector torque :

44 N·m (4.5 kgf·m/33 lb·ft)

8. Replenish the ATF.

9. Start the engine to test the system for the free flow o

f

fluid. If the flow is restricted, the cooler assembly o

r

lines must be replaced.

Repeated cleaning and flushing may not remove all the debris from the fluid cooler circuit.

Move the select lever through the various ranges and return to neutral.

Check for fluid level.

If the fluid level is below the specified range, ATF must be added.

10. Connect the negative battery cable.

11. Remove the safety stands.

12. Remove the wheel blocks.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4476 of 6020

7A3-22 ON-VEHICLE SERVICE (JR405E)

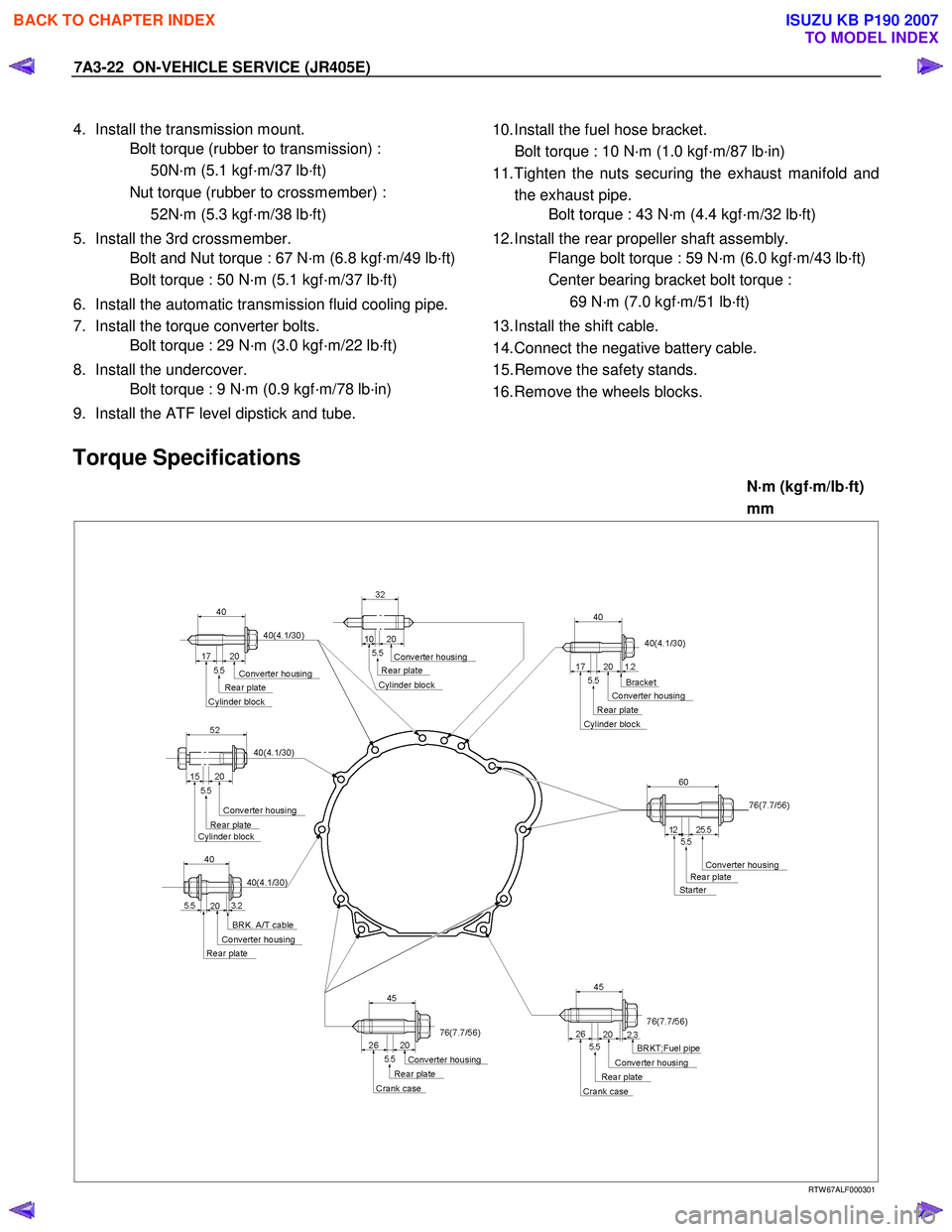

4. Install the transmission mount.

Bolt torque (rubber to transmission) :

50N·m (5.1 kgf·m/37 lb·ft)

Nut torque (rubber to crossmember) :

52N·m (5.3 kgf·m/38 lb·ft)

5. Install the 3rd crossmember.

Bolt and Nut torque : 67 N·m (6.8 kgf·m/49 lb·ft)

Bolt torque : 50 N·m (5.1 kgf·m/37 lb·ft)

6. Install the automatic transmission fluid cooling pipe.

7. Install the torque converter bolts.

Bolt torque : 29 N·m (3.0 kgf·m/22 lb·ft)

8. Install the undercover.

Bolt torque : 9 N·m (0.9 kgf·m/78 lb·in)

9. Install the ATF level dipstick and tube.

10. Install the fuel hose bracket.

Bolt torque : 10 N·m (1.0 kgf·m/87 lb·in)

11. Tighten the nuts securing the exhaust manifold and the exhaust pipe.

Bolt torque : 43 N·m (4.4 kgf·m/32 lb·ft)

12. Install the rear propeller shaft assembly.

Flange bolt torque : 59 N·m (6.0 kgf·m/43 lb·ft)

Center bearing bracket bolt torque :

69 N·m (7.0 kgf·m/51 lb·ft)

13. Install the shift cable.

14. Connect the negative battery cable.

15. Remove the safety stands.

16. Remove the wheels blocks.

Torque Specifications

N ⋅

⋅⋅

⋅

m (kgf ⋅

⋅⋅

⋅

m/lb ⋅

⋅⋅

⋅

ft)

mm

RTW 67ALF000301

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4802 of 6020

7C-24 CLUTCH

015RW 053

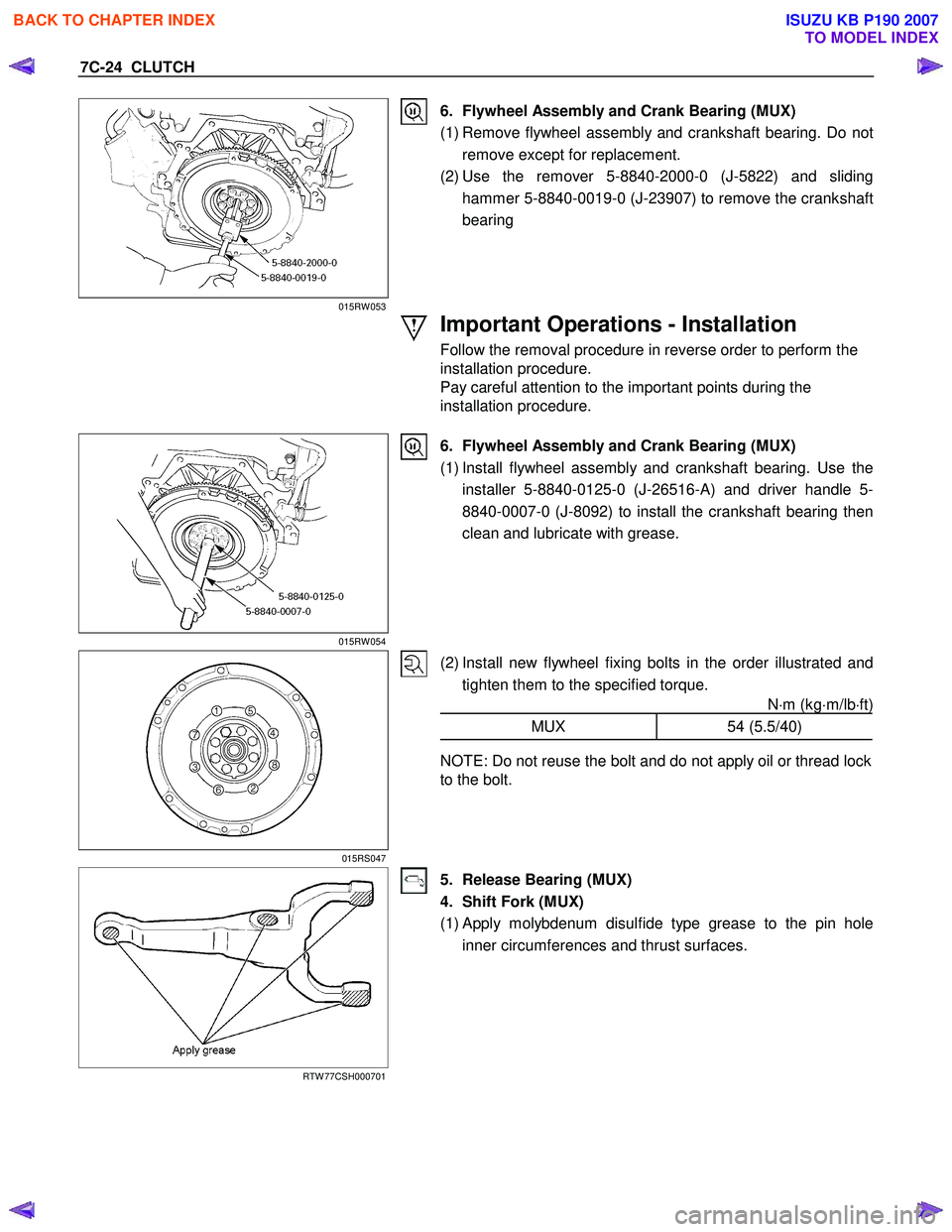

6. Flywheel Assembly and Crank Bearing (MUX)

(1) Remove flywheel assembly and crankshaft bearing. Do not remove except for replacement.

(2) Use the remover 5-8840-2000-0 (J-5822) and sliding hammer 5-8840-0019-0 (J-23907) to remove the crankshaft

bearing

Important Operations - Installation

Follow the removal procedure in reverse order to perform the

installation procedure.

Pay careful attention to the important points during the

installation procedure.

015RW 054

6. Flywheel Assembly and Crank Bearing (MUX)

(1) Install flywheel assembly and crankshaft bearing. Use the installer 5-8840-0125-0 (J-26516-A) and driver handle 5-

8840-0007-0 (J-8092) to install the crankshaft bearing then

clean and lubricate with grease.

015RS047

(2) Install new flywheel fixing bolts in the order illustrated and tighten them to the specified torque. N⋅m (kg ⋅m/lb ⋅ft)

MUX 54 (5.5/40)

NOTE: Do not reuse the bolt and do not apply oil or thread lock

to the bolt.

RTW 77CSH000701

5. Release Bearing (MUX)

4. Shift Fork (MUX)

(1)

Apply molybdenum disulfide type grease to the pin hole

inner circumferences and thrust surfaces.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4803 of 6020

CLUTCH 7C-25

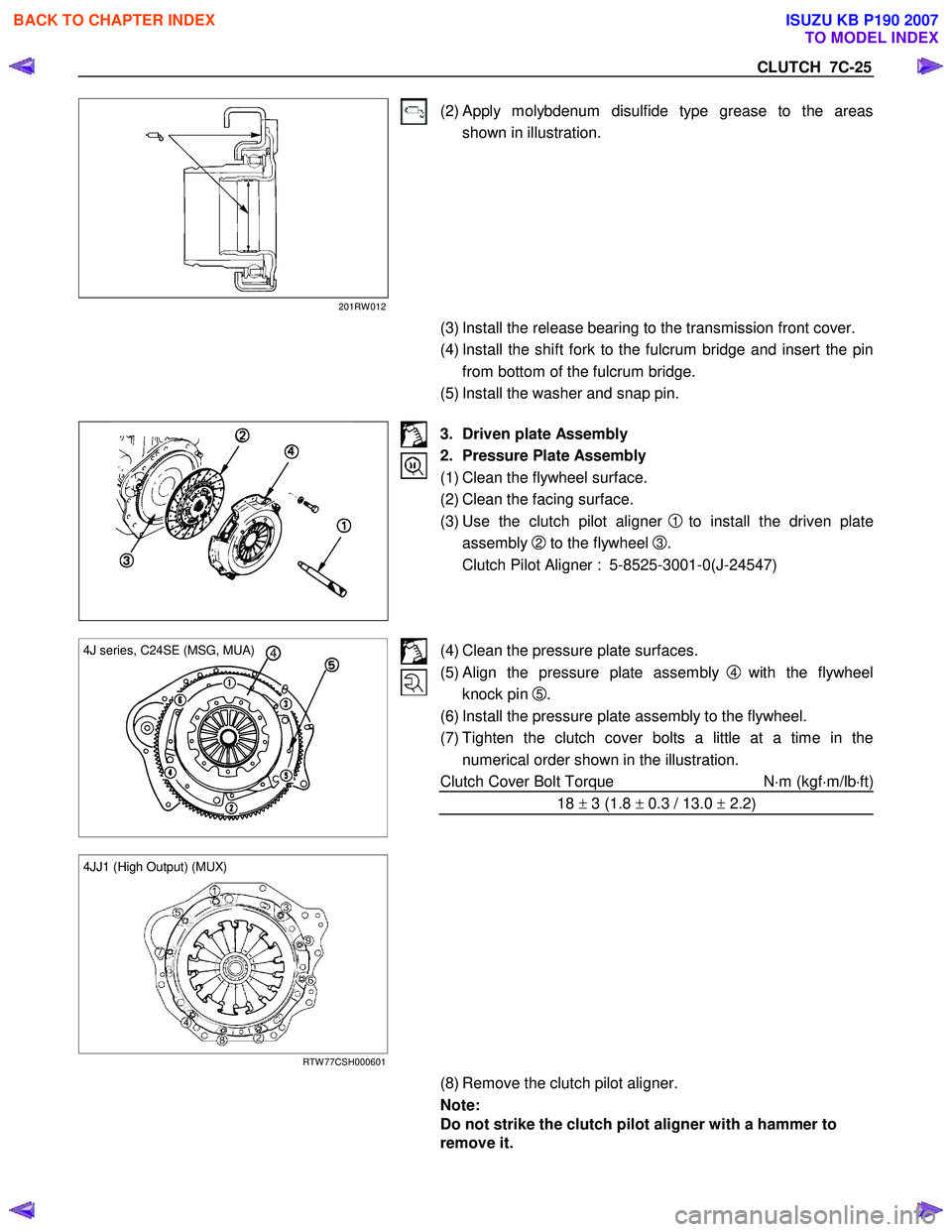

201RW 012

(2) Apply molybdenum disulfide type grease to the areas shown in illustration.

(3) Install the release bearing to the transmission front cover.

(4) Install the shift fork to the fulcrum bridge and insert the pin from bottom of the fulcrum bridge.

(5) Install the washer and snap pin.

3. Driven plate Assembly

2. Pressure Plate Assembly

(1) Clean the flywheel surface.

(2) Clean the facing surface.

(3) Use the clutch pilot aligner

1 to install the driven plate

assembly

2 to the flywheel 3.

Clutch Pilot Aligner : 5-8525-3001-0(J-24547)

4 4J series, C24SE (MSG, MUA)

(4) Clean the pressure plate surfaces.

(5) Align the pressure plate assembly

4 with the flywheel

knock pin

5.

(6) Install the pressure plate assembly to the flywheel.

(7) Tighten the clutch cover bolts a little at a time in the numerical order shown in the illustration.

Clutch Cover Bolt Torque N⋅m (kgf ⋅m/lb ⋅ft)

18 ± 3 (1.8 ± 0.3 / 13.0 ± 2.2)

4JJ1 (High Output) (MUX)

RTW 77CSH000601

(8) Remove the clutch pilot aligner.

Note:

Do not strike the clutch pilot aligner with a hammer to

remove it.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4871 of 6020

TRANSFER CASE 7D-41

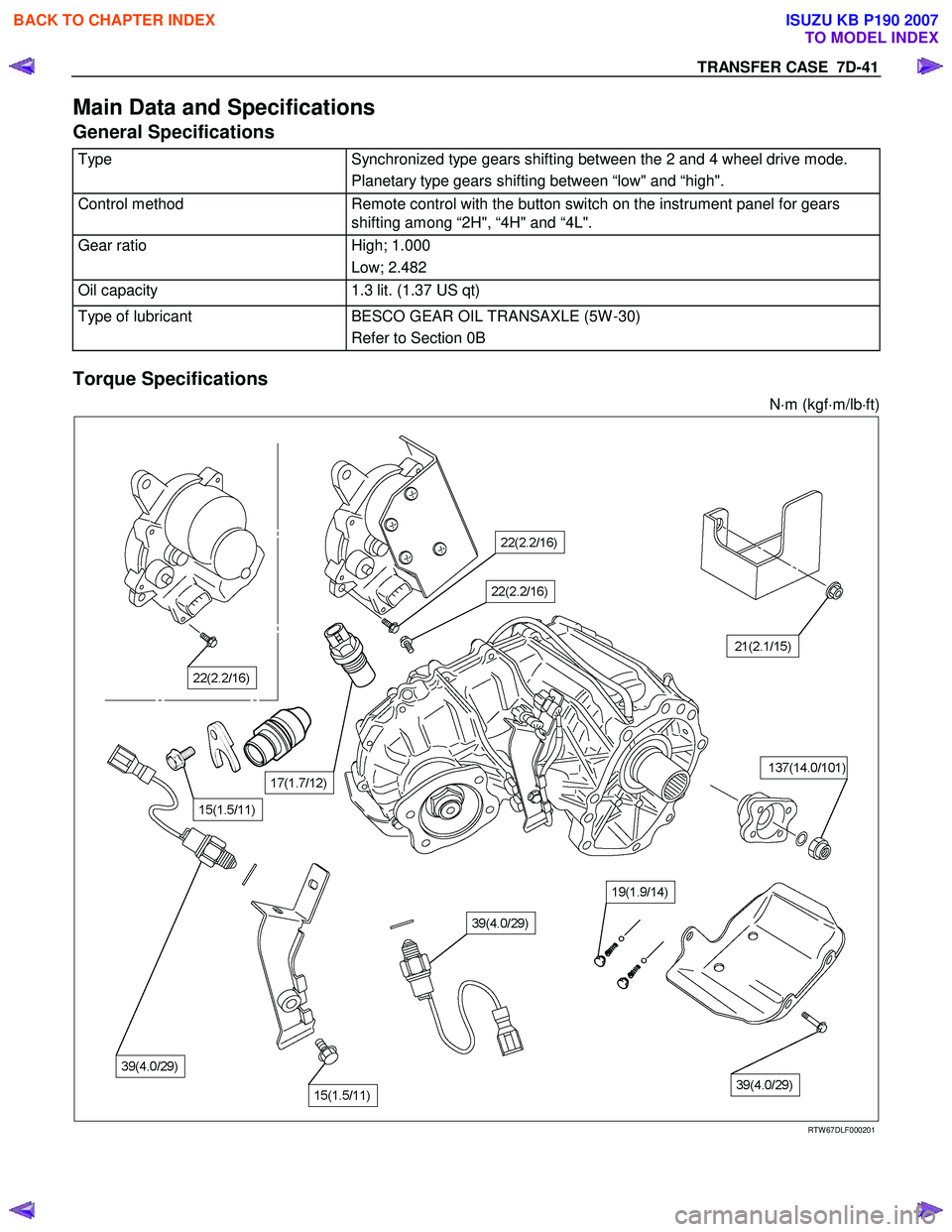

Main Data and Specifications

General Specifications

Type Synchronized type gears shifting between the 2 and 4 wheel drive mode.

Planetary type gears shifting between “low" and “high".

Control method Remote control with the button switch on the instrument panel for gears

shifting among “2H", “4H" and “4L".

Gear ratio High; 1.000

Low; 2.482

Oil capacity 1.3 lit. (1.37 US qt)

Type of lubricant BESCO GEAR OIL TRANSAXLE (5W -30)

Refer to Section 0B

Torque Specifications

N⋅m (kgf ⋅m/lb ⋅ft)

RTW 67DLF000201

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4920 of 6020

7D1-46 TRANSFER CONTROL SYSTEM

Diagnosis

Before determining a trouble (Non-trouble mode)

1. When shifting from 2H to 4H:

1-1-1 When the flashing frequency of the 4WD indicator is changed from 2Hz to 4Hz (Shift on the fly) If the load is too large to shift the gears synchronously, the operation is repeated up to 3 times. If the shifting

is not effected after being repeated 3 times, the indicator frequency is changed from 2Hz to 4Hz. At the same

time, the actuator condition is changed to 2H, indicator flashes at 4Hz for 10 seconds, and then goes out.

Cause of excessive synchronous shifting load

• Extremely low temperature (the oil viscosity of the front differential increases requiring a large load for

synchronization).

• High speed (since the difference of relative revolutions of gears to be shifted synchronously is too large,

required work load per unit time becomes larger).

Step 1-1-1:

Stop the vehicle or decrease the speed and operate as required again.

1-1-2 When the flashing frequency of the 4WD indicator is changed from 2Hz to 4Hz (Rigid and free wheel

Hub) / Block out of meshing spline in transfer case.

Step 1-1-2:

Run the vehicle forward and backward several meters and operate as required again.

1-2 When the flashing of 4WD indicator at 2Hz continues more than 11.5 seconds (repetition of 3 times of

above No.1 is counted) (Shift on the fly)

If there is difference of revolutions and phases between the front wheel and the axle, connecting the front

wheel and axle is difficult.

Until shifting in the transfer and connection of the front wheel and axle are completed

∗, the indicator flashes at

a frequency of 2Hz. In the above case, the indicator continues flashing at a frequency of 2Hz until the

connection of the front axle is completed. (If the shifting in the transfer is not completed, the flashing

frequency is changed to 4Hz (above No.1).)

By correcting the difference of relative revolutions and deviation of phases, the shifting can be completed.

Step 1-2:

While the vehicle is running, check it is safe around the vehicle and then accelerate or decelerate the

vehicle while going straight.

When the vehicle is at a stop, run the vehicle forward and backward several meters.

2. When shifting from 4H to 2H

2-1 When 4WD indicator continues flashing at 2Hz

W hen shifting from 4H to 2H, the 4W D indicator continues flashing at 2Hz until separation in the transfer and

the separation of the front wheel axle are completed∗. W hen torsional torque is accumulated in the drive

system, separation in the transfer and separation of the front axle∗ is difficult. In such a case, they can be

separated by removing the torsional torque of the drive system.

Step 2-1:

While the vehicle is running, check it is safe around the vehicle and then accelerate or decelerate the

vehicle while going straight.

When the vehicle is in stop, run the vehicle several meters forward and backward.

∗: Shift on the fly only.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5639 of 6020

9A-4 SUPPLEMENTAL RESTRAINT SYSTEM

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING A SERVICE ON, OR NEAR, THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING A SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE

TO FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNECESSARY SRS

SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU/GM will call out those fasteners that require

a replacement after removal. ISUZU/GM will also

call out the fasteners that require thread lockers o

r

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (paints,

greases, or other corrosion inhibitors) on threaded

fasteners or fastener joint interfaces. Generally,

such coatings adversely affect the fastener torque

and the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

General Description

CAUTION: When fasteners are removed, always

reinstall them at the same location from which

they were removed. If a fastener needs to be

replaced, use the correct part number fastener fo

r

that application. If the correct part numbe

r

fastener is not available, a fastener of equal size

and strength (or stronger) may be used.

Fasteners that are not reused, and those requiring

thread locking compound will be called out. The

correct torque value must be used when installing

fasteners that require it. If the above conditions

are not followed, parts or system damage could

result.

Restraint Devices

RTW 79ASH000801

Legend

(1) Deployed Air Bag

(2) Knee Bolster

(3) Seat Belt

The Supplemental Restraint System (SRS) helps

supplement the protection offered by the driver and

front passenger seat belts by deploying an air bag

from the center of the steering wheel and from the

front of the passenger side of the instrument panel.

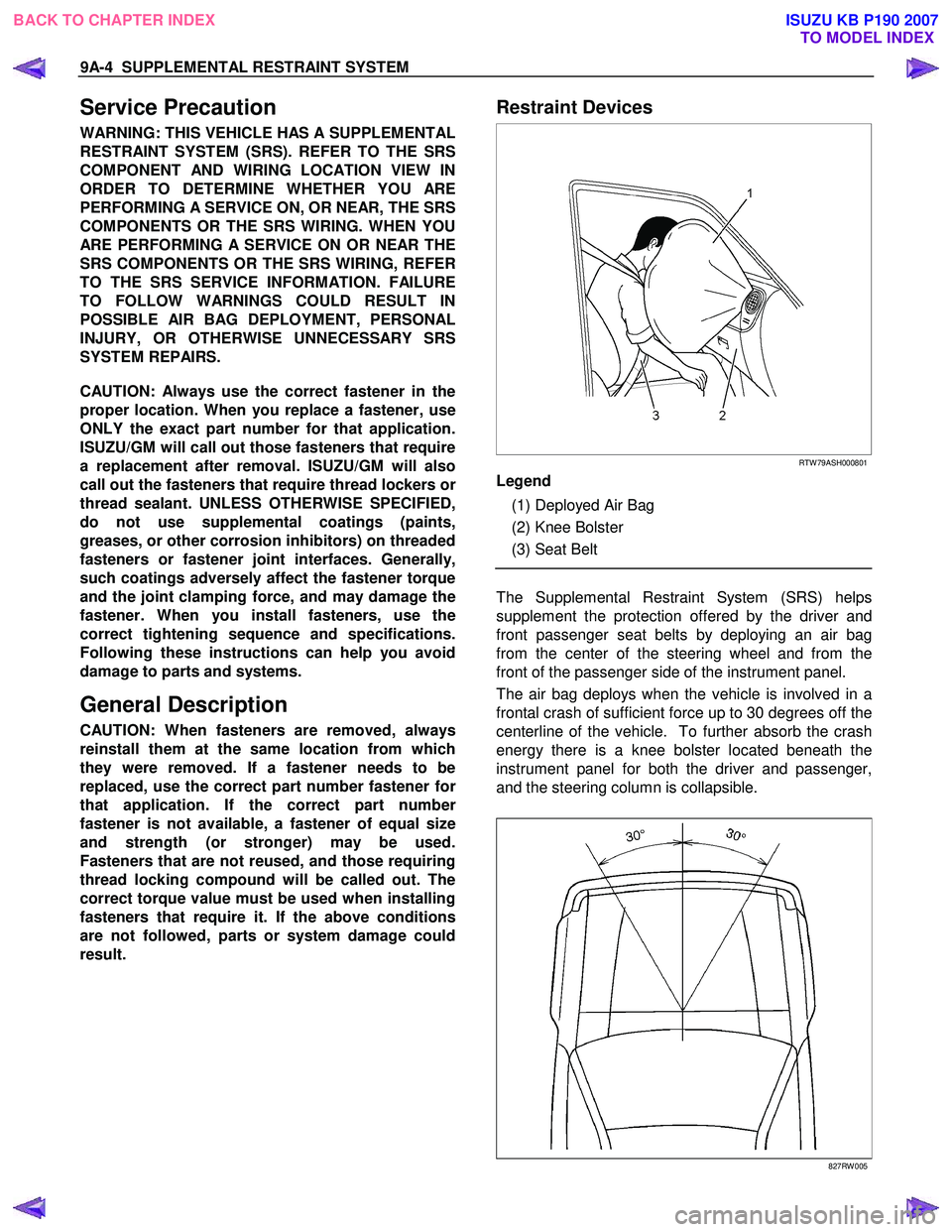

The air bag deploys when the vehicle is involved in a

frontal crash of sufficient force up to 30 degrees off the

centerline of the vehicle. To further absorb the crash

energy there is a knee bolster located beneath the

instrument panel for both the driver and passenger,

and the steering column is collapsible.

827RW 005

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5667 of 6020

9A-32 SUPPLEMENTAL RESTRAINT SYSTEM

Service Precautions for SRS

Component Service

CAUTION: When fasteners are removed, always

reinstall them at the same location from which

they were removed. If a fastener needs to be

replaced, use the correct part number fastener fo

r

that application. If the correct part number

fastener is not available, a fastener of equal size

and strength (or stronger) may be used. Fasteners

that are not reused, and those requiring a thread

locking compound will be called out. The correct

torque value must be used when installing

fasteners that require it. If the above conditions

are not followed, parts or system damage could

result.

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND SRS COMPONENTS OR SRS WIRING,

FOLLOW THE PROCEDURES LISTED BELOW TO

TEMPORARILY DISABLE THE SRS. FAILURE TO

FOLLOW PROCEDURES COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY OR OTHERWISE UNNEEDED SRS

REPAIRS.

The SRS control unit in the Driver–Passenger SRS

can maintain sufficient voltage to cause a deployment

for up to 15 seconds after the ignition switch is turned

“OFF,” the battery is disconnected, or the fuse

powering the SRS control unit is removed.

Many of the service procedures require removal of the

“SRS” fuse, and disconnection of the air bag assembl

y

from the deployment loop to avoid an accidental

deployment. If the air bag assembly is disconnected

from the deployment loop as noted in the “Disabling

the SRS” procedure that follows, service can begin

immediately without waiting for the 15 second time

period to expire.

Disabling The SRS

Removal

Turn the ignition switch to “OFF” and turn the steering

wheel so that the vehicle's wheels are pointing straight

ahead.

1. Remove the SRS fuse “SRS” from the left dash side lower fuse block or disconnect the battery.

2. Disconnect the yellow connector at the base o

f

steering column.

3. Remove the glove box assembly; Refer to “Passenger air bag assembly replacement” in this

section.

4. Disconnect the passenger air bag assembly yello

w

connector behind the glove box assembly.

CAUTION: With the “SRS” fuse removed and the

ignition switch to “ON,” the “SRS” warning lamp

will be “ON.” This is normal operation and does

not indicate an SRS malfunction.

Enabling The SRS

Installation

Turn the ignition switch to “LOCK” and remove the

key.

1. Connect the yellow connector passenger air bag assembly.

2. Install the glove box assembly. Refer to “Passenger Air Bag Assembly Replacement” in

this section.

3. Connect the yellow connector at the base of the steering column.

4. Install the “AIR BAG” fuse “SRS” to the left dash side lower fuse block or connect the battery.

Turn the ignition switch to “ON” and verify that the

“SRS” warning lamp flashes seven times and then

turns to “LOCK”. If it does not operate as described,

perform the “SRS Diagnostic System Check” in this

section.

Handling / Installation / Diagnosis

1. Air bag assembly should not be subjected to

temperatures above 65 °C (150 °F).

2.

Air bag assembly, and SRS control unit should not

be used if they have been dropped from a height

of 100 centimeters (3.28 feet) or more.

3. W hen a SRS control unit is replaced, it must be oriented with the arrow on the SRS control unit

pointing toward the front of the vehicle. It is ver

y

important for the SRS control unit to be located flat

on the mounting surface, parallel to the vehicle

datum line. It is important that the SRS control unit

mounting surface is free of any dirt or other foreign

material.

4. Do not apply power to the SRS unless all components are connected or a diagnostic chart

requests it, as this will set a diagnostic trouble

code.

5. The “SRS Diagnostic System Check” must be the starting point of any SRS diagnostics. The “SRS

Diagnostic System Check” will verify proper “SRS”

warning lamp operation and will lead you to the

correct chart to diagnose any SRS malfunctions.

Bypassing these procedures may result in

extended diagnostic time, incorrect diagnosis, and

incorrect parts replacements.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5792 of 6020

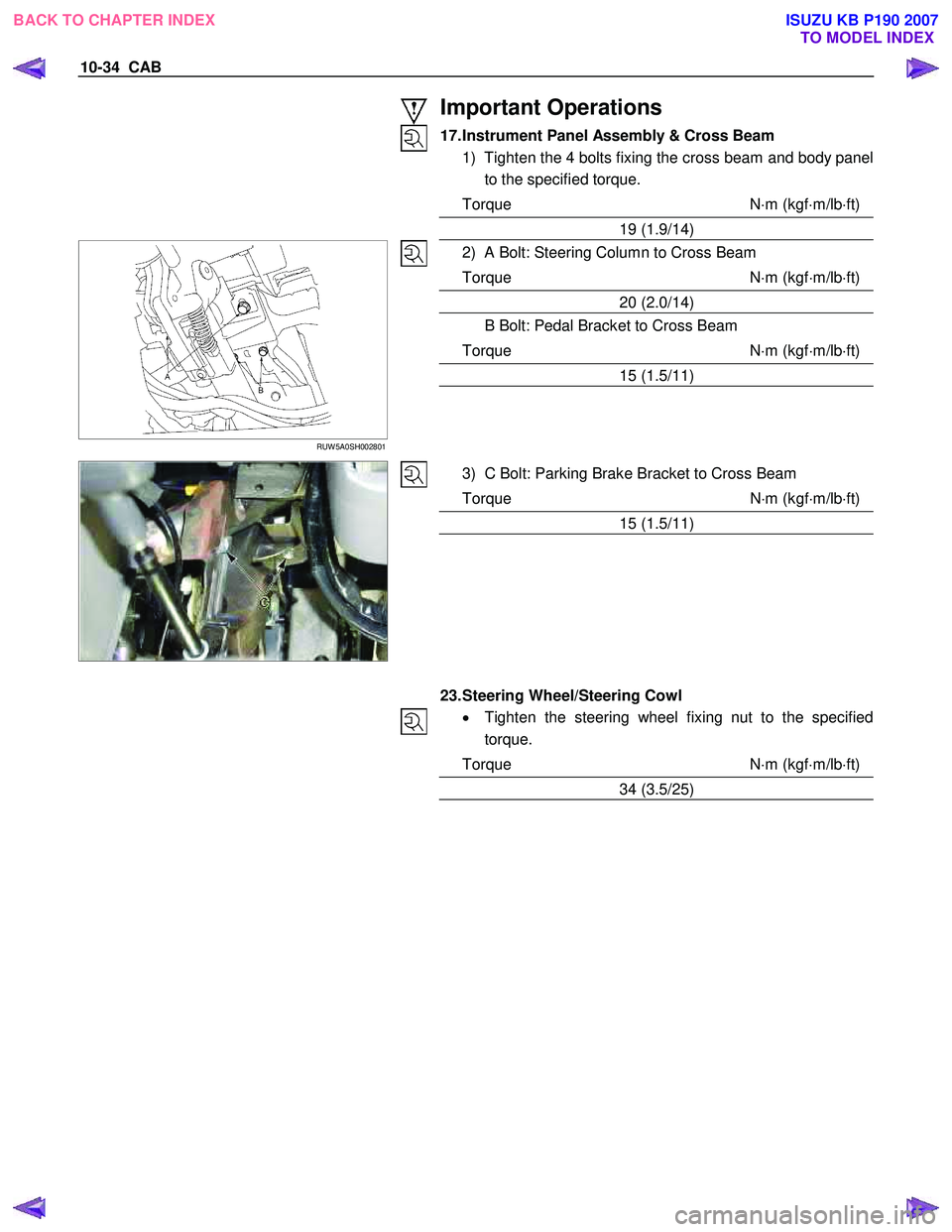

10-34 CAB

Important Operations

17. Instrument Panel Assembly & Cross Beam 1) Tighten the 4 bolts fixing the cross beam and body panel to the specified torque.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

19 (1.9/14)

RUW 5A0SH002801

2) A Bolt: Steering Column to Cross Beam

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

20 (2.0/14)

B Bolt: Pedal Bracket to Cross Beam

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

15 (1.5/11)

3) C Bolt: Parking Brake Bracket to Cross Beam

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

15 (1.5/11)

23. Steering Wheel/Steering Cowl • Tighten the steering wheel fixing nut to the specified

torque.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

34 (3.5/25)

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007